Single stage drawing method for terylene continuous yarn filament in use for meshbelt, and preparation

A technology of polyester filament and drawing method, applied in the field of polyester filament, can solve the problems of easy fading, affect the appearance, and stiff point yarn, and achieve the effect of good luster and softness, easy production management, and small shrinkage in boiling water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

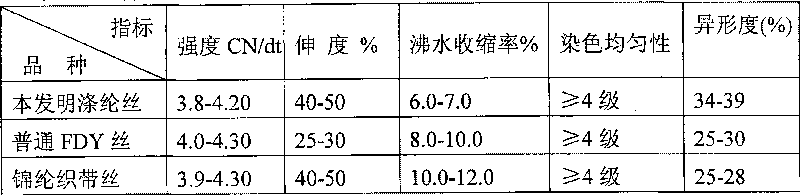

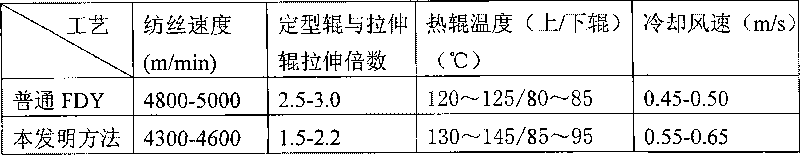

[0014] Embodiment: the present invention one-step stretching method prepares the specification to be 76dt / 36f polyester long filament, adopts the spinneret of trilobal shape hole, and spinneret stretching ratio is 150 times, spinning speed 4500m / min, drawing roll speed 2300m / min, setting roller speed 4550m / min (stretching ratio 1.98), stretching roller temperature 88°C, setting roller temperature 130°C, cooling wind speed (wind temperature 23°C) 0.6m / s, melt freezing point position moves up 8cm. The cross-section of the obtained filament is trilobal, the degree of irregularity is 35%, the strength is 3.9CN / dt, the elongation is 44%, the shrinkage in boiling water is 6.7%, and the dyeing uniformity is ≥ 4 grades.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Irregularity | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

| Irregularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com