Colored special-shaped super fine denier polyester monofilaments and production method thereof

A technology of ultra-fine denier polyester and a production method, applied in the field of polyester monofilament, can solve problems such as poor dyeing and no fiber preparation involved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] A colored special-shaped ultrafine denier polyester monofilament, the mass percentage of its raw material is:

[0064]

[0065] The preparation method of described antiaging capsule, its concrete steps are:

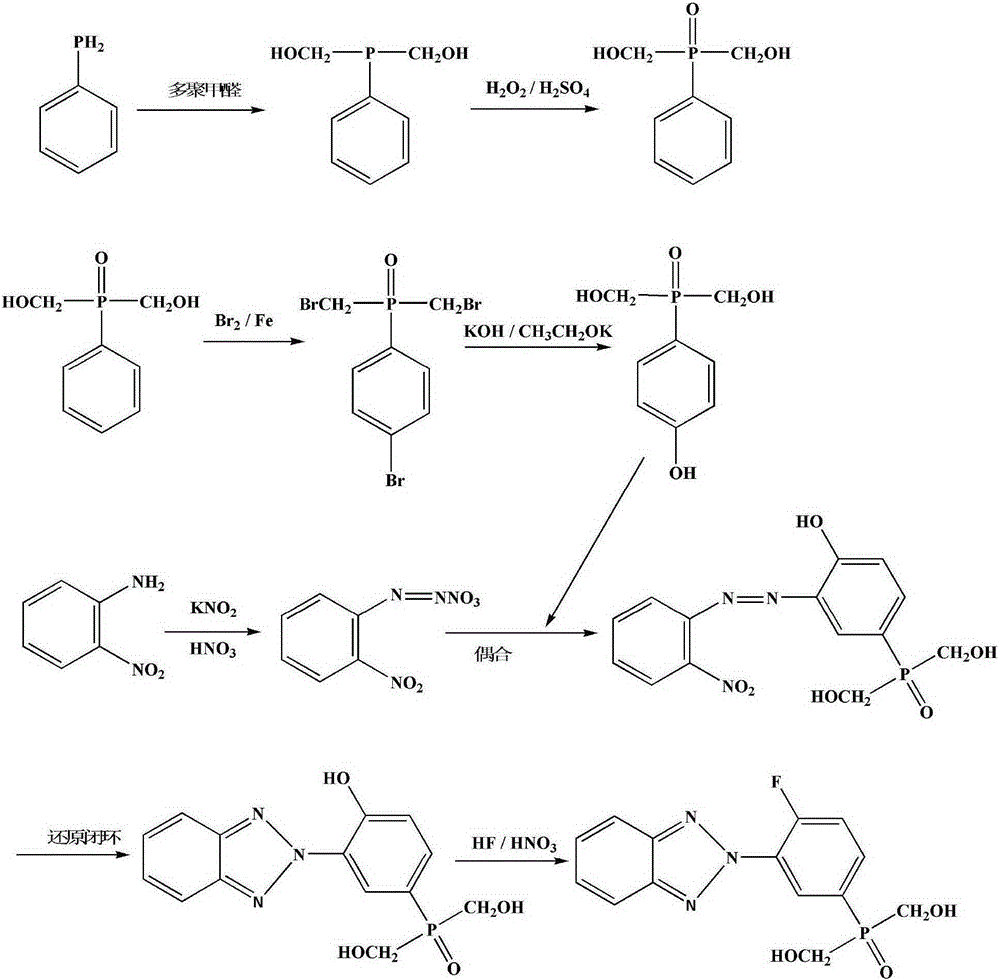

[0066] (a) preparation of p-dihydroxy p-phenol phosphine

[0067] Using phenylphosphine and paraformaldehyde as raw materials, using a mixed solution of water and isopropanol as a solvent, an affinity addition reaction occurs under the action of a catalyst, the reaction temperature is controlled at 35-50°C, and the reaction time is 3-4 hours; preparation Dihydroxymethylphenylphosphine is obtained, and then at 85-95°C, a mixed solution of hydrogen peroxide and concentrated sulfuric acid is added as a strong oxidant, and the oxidation is performed for 45-60 minutes to prepare dimethylolphenylphosphine oxide. Add p-dihydroxyphenylphosphine, bromine water and iron powder into the reaction vessel, heat to 65-75°C and react for 0.5-1.75 hours, then filter to obtain a...

Embodiment 2

[0115] A colored special-shaped ultrafine denier polyester monofilament, the mass percentage of its raw material is:

[0116]

[0117] A kind of production method of colored special-shaped superfine denier polyester monofilament is the same as embodiment 1.

Embodiment 3

[0119] A colored special-shaped ultrafine denier polyester monofilament, the mass percentage of its raw material is:

[0120]

[0121] A kind of production method of colored special-shaped superfine denier polyester monofilament is the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com