Method for producing ultra-low-shrinkage composite crystal fibrilia and apparatus thereof

A production method and technology of hemp fiber, applied in the production method and device field of ultra-low shrinkage composite crystal hemp fiber, can solve many quality problems, do not have high-temperature heating and shaping and oiling, and the hand feeling cannot meet customer requirements, etc. problem, to achieve the effect of high oil content and low boiling water shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

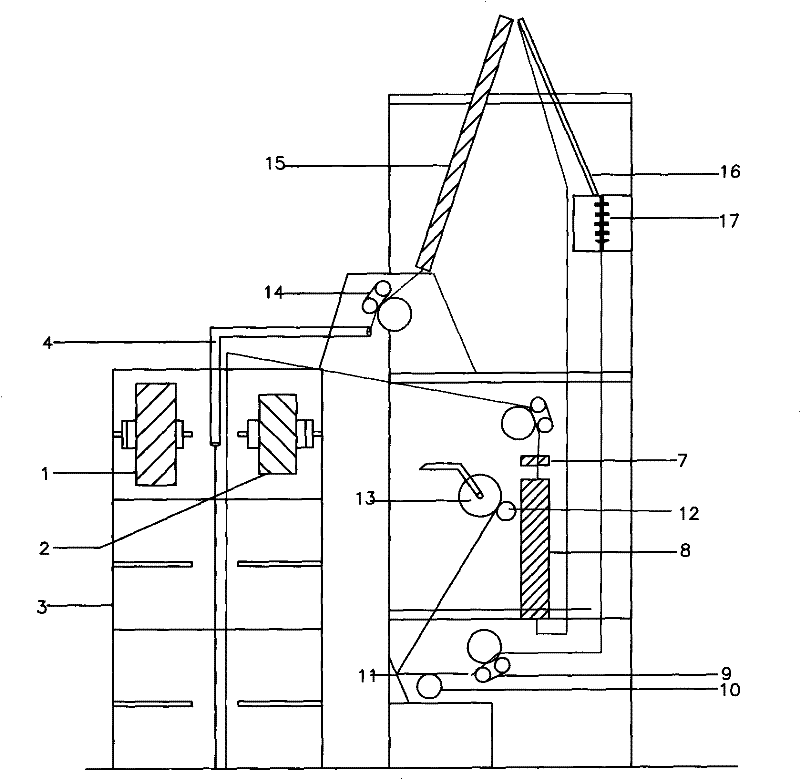

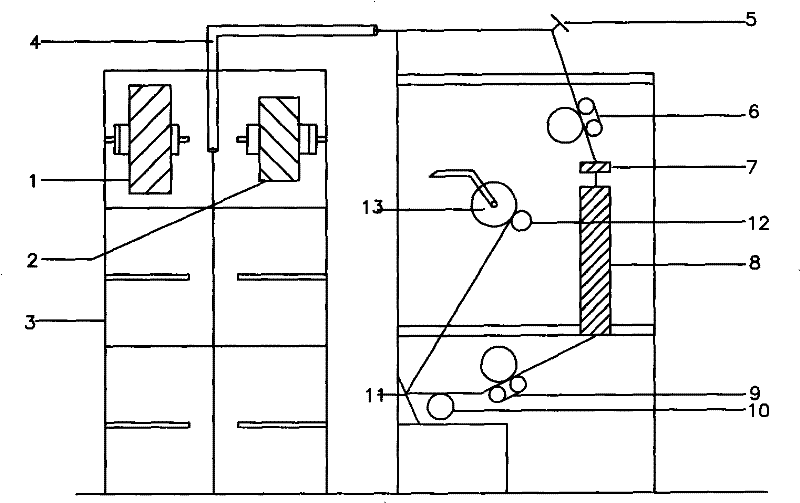

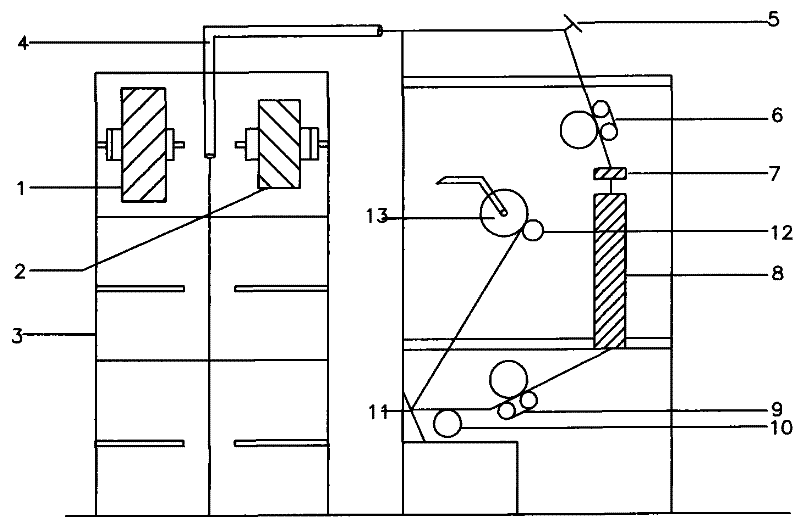

[0028] The production method of the ultra-low-shrinkage composite crystal hemp fiber provided in this embodiment includes adopting semi-dull FDY precursors and semi-dull POY precursors as main raw materials, and introducing two different precursors into the tow traction tube simultaneously , so that the tow directly enters the yarn feeding roller through the yarn guide, that is, the second roller, and performs compressed air network under the second roller, and then enters the lower hot box for high-temperature shaping, and the shaped composite tow passes through the silk outlet roller, that is, the third roller. The roller is sent out, and after being fully oiled on the tanker, it is guided to the friction roller of the spindle position by the wire guide for winding and forming.

[0029] Such as figure 2 As shown, the production device of the ultra-low shrinkage composite crystal hemp fiber provided by the present embodiment includes a raw silk frame 3, a traction pipe 4, a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com