A guide rail for magnetic levitation and its preparation method

A magnetic levitation and guide rail technology, applied in the field of rail transit, can solve the problems of difficulty in train braking, loss of anti-corrosion effect, and easy damage to guide rail coating, so as to shorten the construction period, increase the anti-corrosion ability, and improve the construction environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with drawings and embodiments.

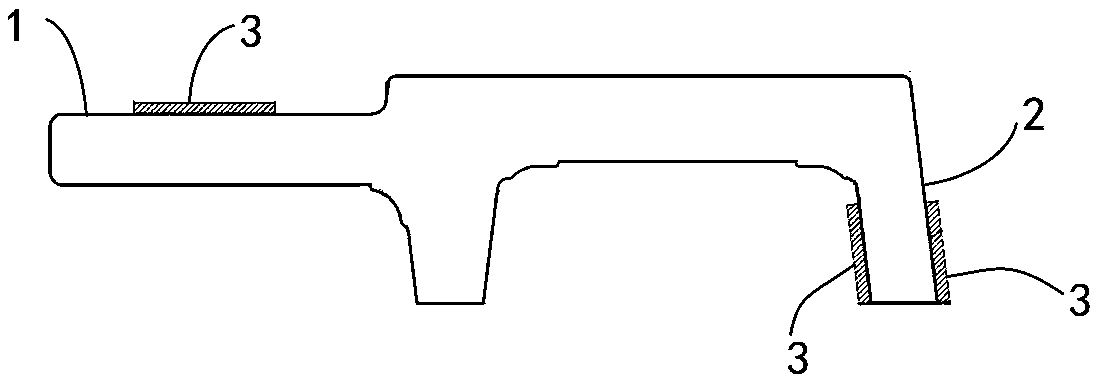

[0045] The schematic cross-sectional view of the guide rail of the present invention is as figure 1 As shown in the figure, the unfilled structure surrounded by the black solid line is the main body of the guide rail, 1 indicates the skid surface of the guide rail main body, 2 indicates the braking surface of the guide rail main body, both inside and outside belong to the braking surface, and 3 indicates the overlay layer.

[0046] The preparation method of this rail is as follows:

[0047] (1) Use acetone to clean the residual oil on the welding surface of the F-shaped steel guide rail and the stainless steel protective material, and perform sandblasting and roughening treatment. The abrasive is SiC to remove the attachment, rust and oxide layer on the surface.

[0048] Use jet-suction sandblasting equipment to pre-treat the surface of the substrate by sandblasting. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com