Low-shrink polyester fully drawn yarn FDY and production method thereof

A technology of polyester polyester and fully drawn yarn, which is applied in the direction of stretch spinning, single-component polyester artificial filament, single-component copolyester artificial filament, etc., which can solve the problem that cannot meet the needs of carpet or industrial use , Unstable fabric size, high boiling water shrinkage and other problems, to achieve the effect of solving the problem of oil fume in production, good low carbon and environmental protection, and low boiling water shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

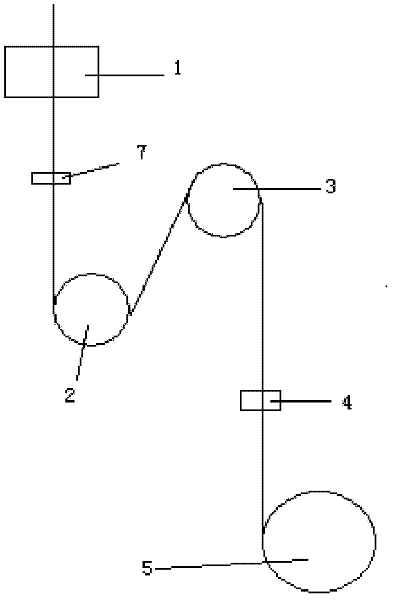

[0030] Such as figure 2 As shown, the polyester melt is sprayed from the spinneret hole of the spinneret (1), and after cooling into fibers, the oil tanker (7) used for oiling before stretching and setting is used for pre-oiling, and the oiling rate is controlled at 0.18%. , after the high-temperature high-stretching and high-temperature heat-setting processing of the first hot roller (2) and the second hot roller (3), oil the nozzle (6) to 0.7%, and then wind it at the winder (5) around the shape. One heat roll (2) and two heat roll (3) surfaces and the yarn guide used therefor carry out the surface coating retreatment of nano-scale nickel-cadmium chromium alloy with low friction coefficient, requiring friction coefficient 0.08, spinning speed 4500m / min, one The stretching temperature of the hot roll is 100°C, the setting temperature of the second hot roll is 180°C, the draw ratio is 3.3, the oil nozzle is installed 12cm before the network nozzle (4), and the boiling water ...

Embodiment 2

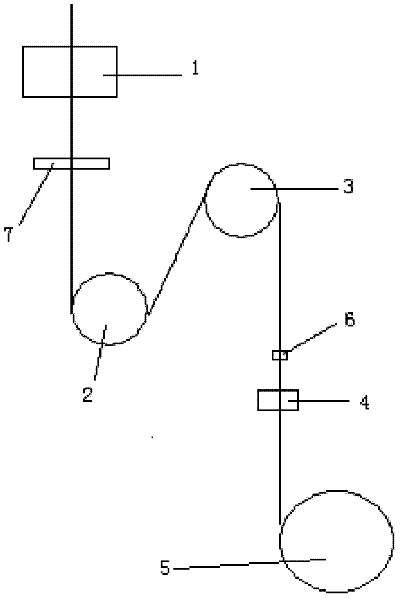

[0032] Such as image 3 As shown, the polyester melt is sprayed from the spinneret hole of the spinneret (1), and after cooling into fibers, the oil tanker (7) used for oiling before stretching and setting is used for pre-oiling, and the oiling rate is controlled at 0.06%. , after the high-temperature, high-stretching and high-temperature heat-setting processing of the first hot roller (2) and the second hot roller (3), oil the oil to 0.8% at the oil nozzle (6), and then at the winding machine (5) Roll forming. One heat roll (2) and two heat rolls (3) surfaces and the yarn guide used therefor carry out the surface coating retreatment of nano-scale nickel-cadmium chromium alloy with low friction coefficient, spinning speed 4400m / min, one heat roll stretching temperature 150°C, the setting temperature of the second hot roller is 200°C, the draw ratio is 3.5, the nozzle is installed at 20cm behind the network nozzle (4), and the 150D / 96F low-shrinkage polyester polyester with a ...

Embodiment 3

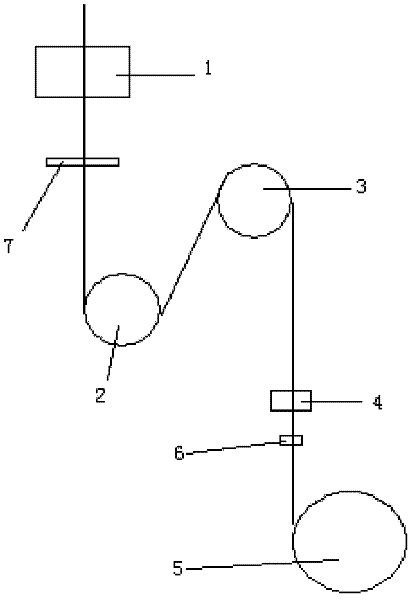

[0034] Such as Figure 4As shown, the polyester melt is sprayed from the spinneret hole of the spinneret (1), and after being cooled into fibers, it is processed by a hot roller (2) and a second hot roller (3) at high temperature and high stretching and high temperature heat setting. Finally, use the oil nozzle to oil at the oil nozzle (6), and then wind and shape it at the winder (5) place. The oiling rate is controlled at 1.0%, the surface of a hot roll and the yarn guide used are not re-treated with a surface coating of nano-scale nickel-cadmium-chromium alloy with a low friction coefficient, the spinning speed is 4200m / min, and the stretching temperature of a hot roll is 150 ℃, the setting temperature of the second hot roller is 230 ℃, the draw ratio is 3.8, the oiling rate is controlled at 0.9%, the oil nozzle is installed at 18cm before the network nozzle (4), and the boiling water shrinkage rate is 2.5%, and the dry heat shrinkage rate is 8.5%. 800D / 192F low shrinkage ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com