12ends spinning polyamide-6 fine denier low shrink industrial yarn production technology

A production process and low-shrinkage technology, which is applied to complete sets of equipment for the production of artificial threads, stretch spinning, filament/thread forming, etc. The effect of low boiling water shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1.1 Raw material and oil agent

[0020] The raw material is nylon 6 chips produced by Jiangsu Haiyang Chemical Fiber Co., Ltd., with a viscosity of 2.8, a monomer mass fraction of ≤1.5%, and a moisture content of ≤0.04%;

[0021] The oil is Japanese bamboo oil.

[0022] 1.2 Main equipment

[0023] The spinning equipment is the nylon high-speed spinning equipment of Dalian Synthetic Fiber Research Institute, 2 spinning positions / screw, 12 heads / spinning position, component position cup type, 4 pairs of hot rollers, fully automatic winding head.

[0024] Tensile testing machine, constant temperature water bath.

[0025] 1.3 Process flow

[0026] 1) The nylon 6 dry chip raw material is introduced into the screw extruder through the silo and melted, so that the raw material is molten, becomes a spinning melt, and enters the melt pipeline;

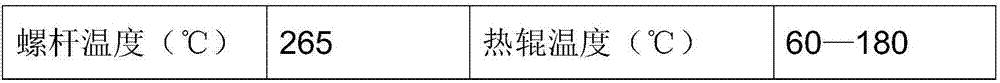

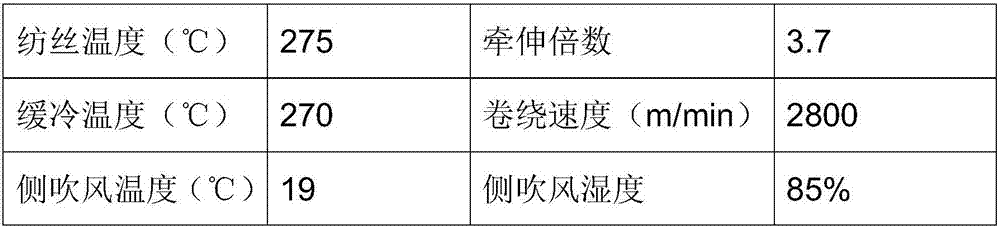

[0027] (2) Spinning: the above-mentioned spinning melt is input into the spinning box, and the speed of the metering pump is contro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com