Fully drawn polyester fiber and methods for preparing the same

A polyester fiber, full-drawing technology, which is applied in the field of full-drawing polyester fiber and its preparation, can solve the problems of low boiling water shrinkage and can not be satisfied, and achieves low boiling water shrinkage, production process control, and excellent fiber performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

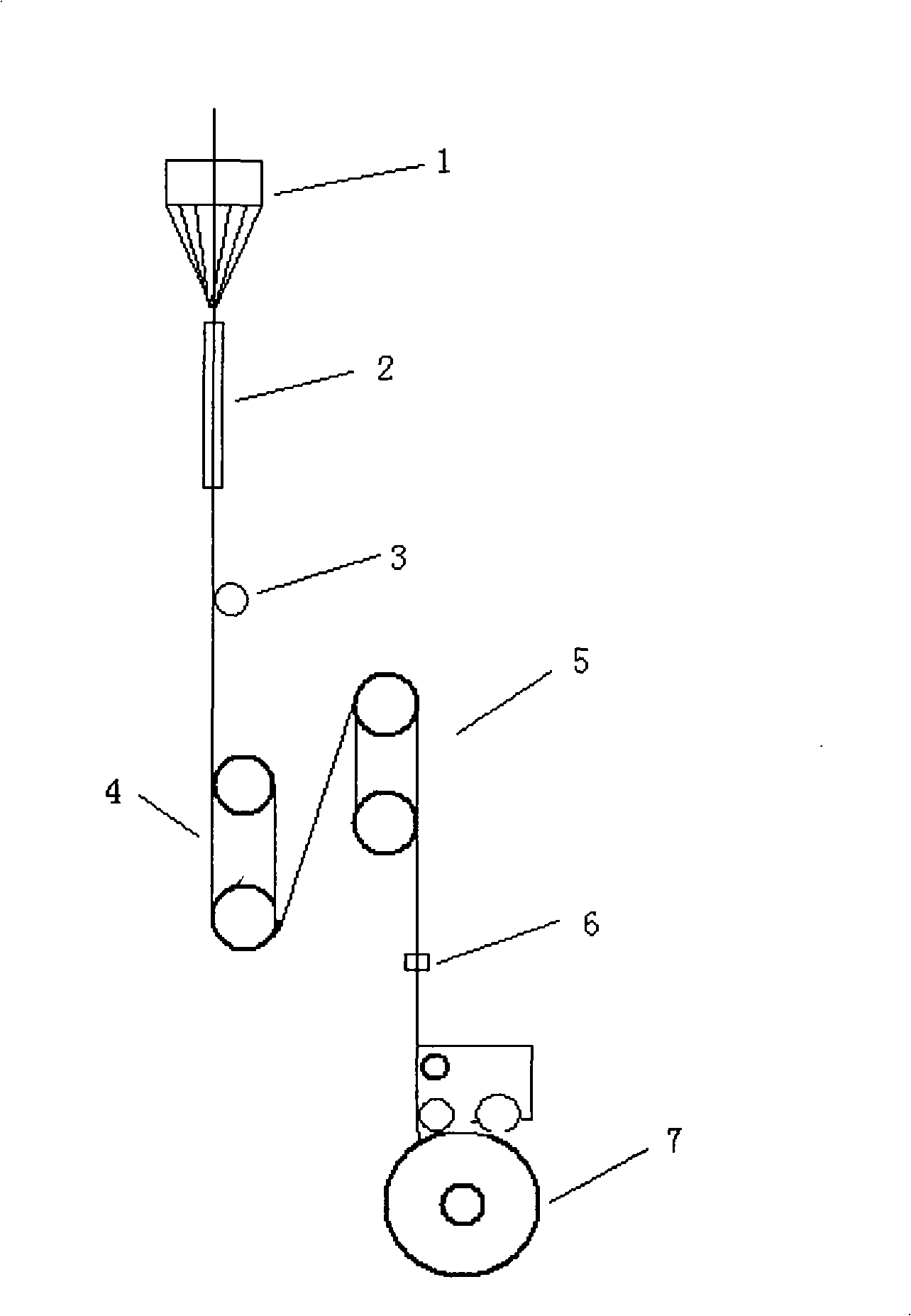

Method used

Image

Examples

Embodiment 1

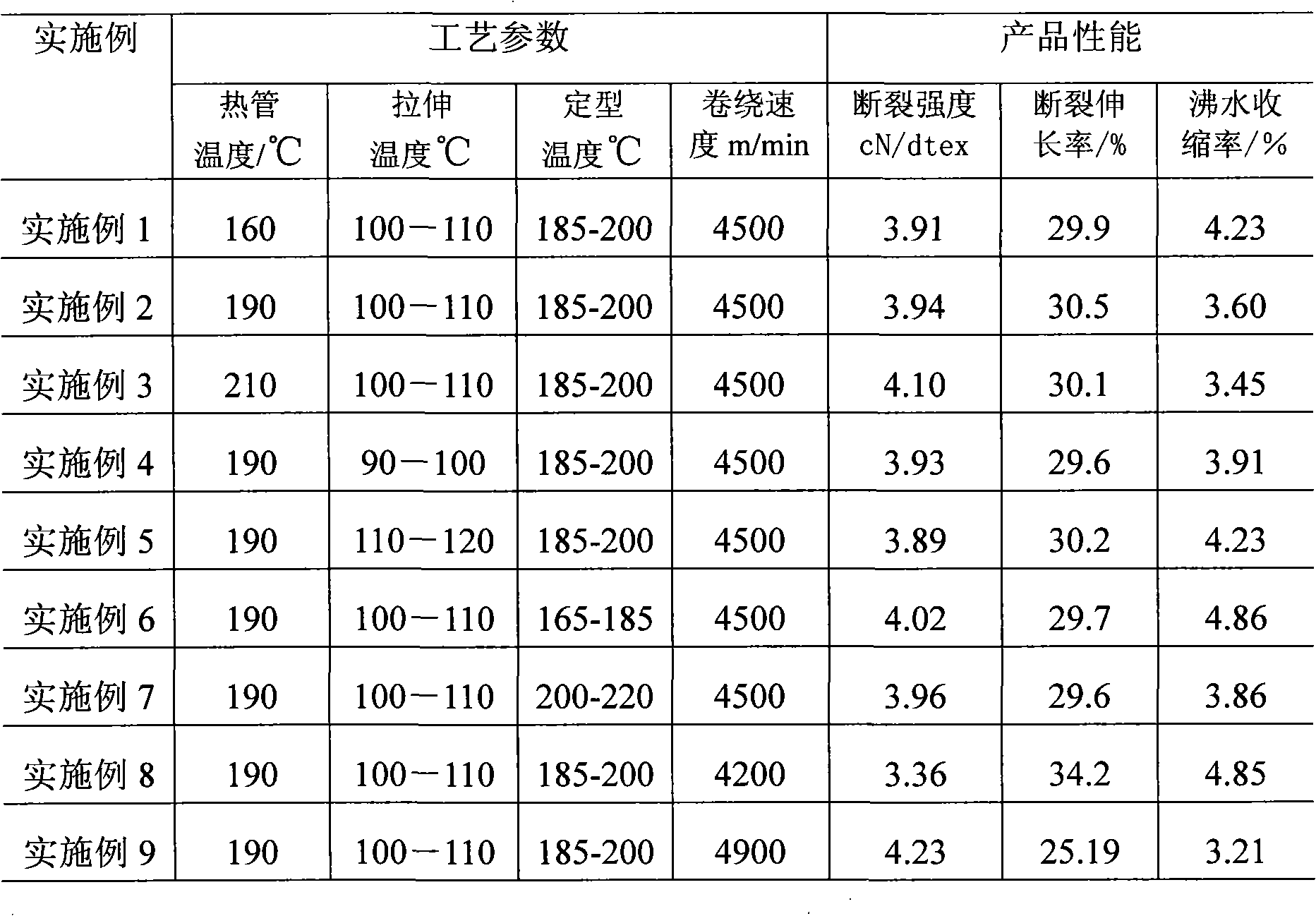

[0018] Fully drawn polyester FDY is made of conventional polyester. The conventional polyester melt is sprayed out through the spinning assembly, and after cooling, the primary fiber is directly added to the heat pipe to complete the induced crystallization of the primary fiber, and then the orientation crystallization of the fiber is further improved by two sets of hot rollers, so that the crystallization area in the fiber macromolecular structure and When the amorphous zone is controlled, the finished fully drawn polyester FDY can be obtained. In this example, the spinning temperature is 285-300°C, the side blowing wind speed is 0.35-0.5 m / s, the heat pipe temperature is 160°C, the stretching temperature is 100-110°C, the setting temperature is 185-200°C, and the winding speed is 4500°C. m / min, the main index of fully drawn polyester FDY is shown in the attached table.

Embodiment 2

[0020] The spinning temperature is 285-300°C, the side blowing wind speed is 0.35-0.5 m / s, the heat pipe temperature is 190°C, the stretching temperature is 100-110°C, the setting temperature is 185-200°C, and the winding speed is 4500 m / s points, and the rest are the same as in Example 1 above. The main indicators of fully drawn polyester FDY are shown in the attached table.

Embodiment 3-9

[0021] Examples 3-9 are shown in the following table.

[0022]

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com