Fine denier high intensity low shrinkage polyester filament yarn processing method

A polyester filament and processing method technology, applied in filament/thread forming, single-component polyester artificial filament, textiles and papermaking, etc., can solve the problems of long drawing process and inconvenient operation, and achieve short process flow , low equipment requirements and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

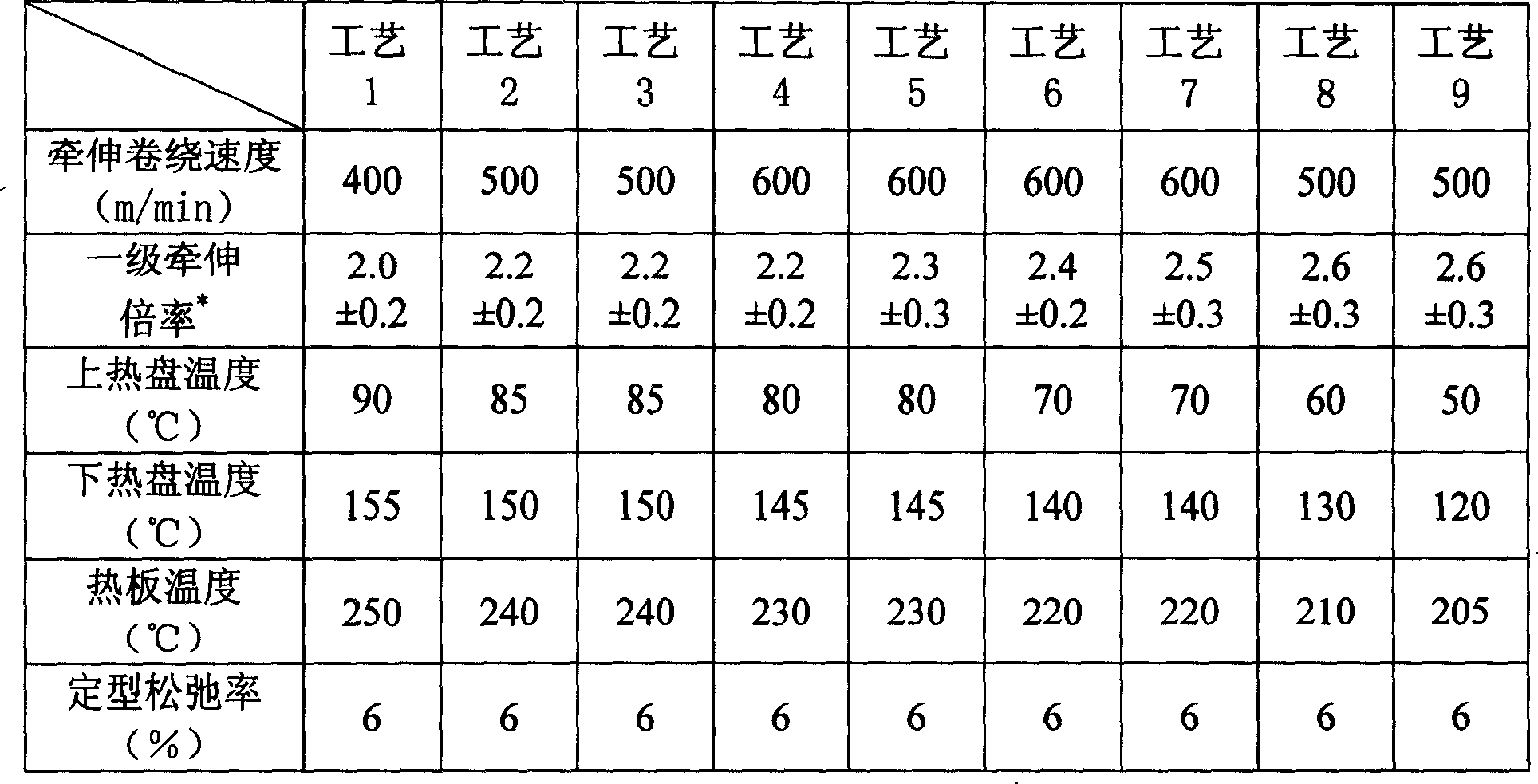

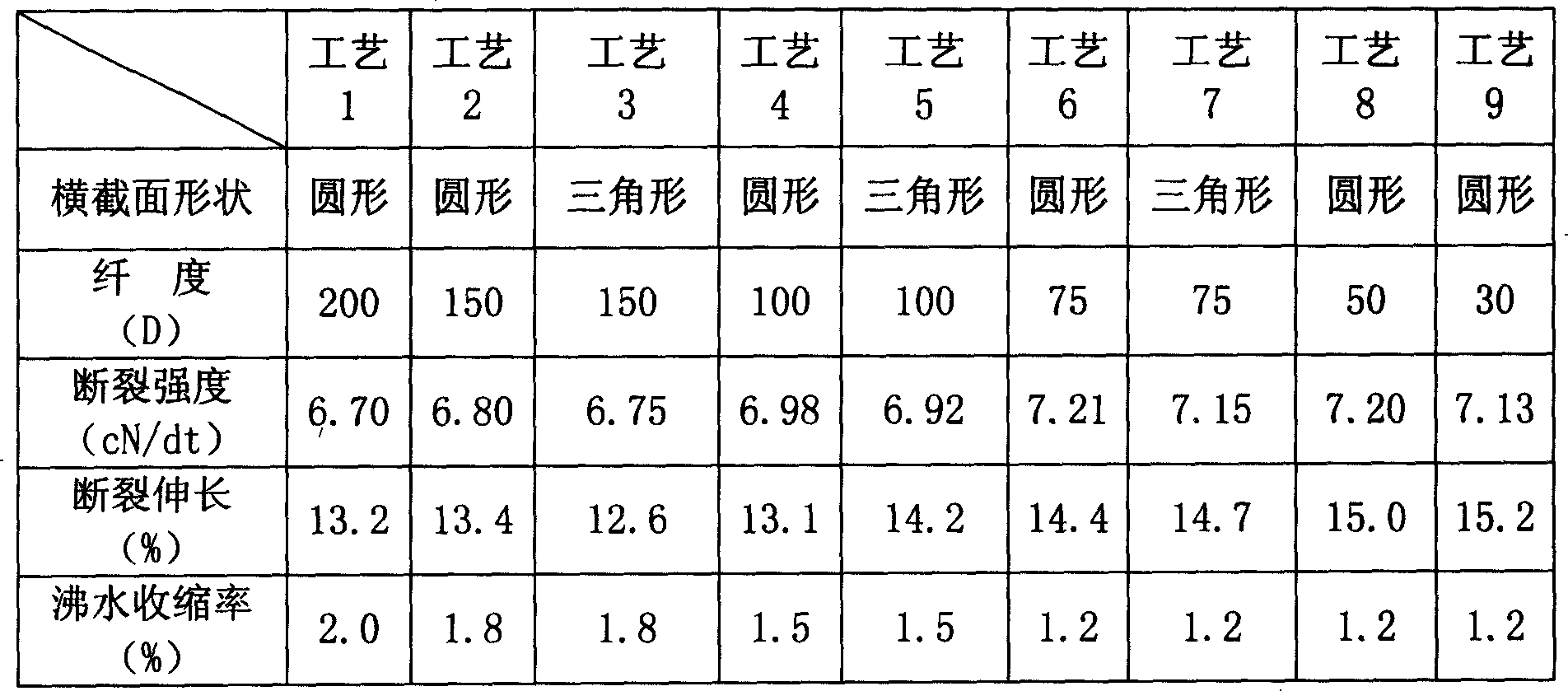

Embodiment 1

[0015] The conventional POY polyester pre-oriented yarn obtained by spinning at a spinning speed of 2500-3300m / min, with a specification of 520dt / (48-72)f, and a circular cross-section, is drawn in parallel on the FTF1001 double-heated disc. On the stretching and winding machine, it is processed through the processes of "pre-drawing roller → upper hot plate → lower hot plate → hot plate → cold plate → winding". , the package is well formed, and the physical indicators of the obtained DT wire are shown in Table 2.

Embodiment 2

[0017] The conventional POY polyester pre-oriented yarn obtained by spinning at a spinning speed of 2500-3300m / min, with a specification of 390dt / (36-48)f, and a circular cross-section, is drawn in parallel on the FTF1001 double-heated disc. On the stretching and winding machine, it is processed through the processes of "pre-drawing roller → upper hot plate → lower hot plate → hot plate → cold plate → winding". , the package is well formed, and the physical indicators of the obtained DT wire are shown in Table 2.

Embodiment 3

[0019] The conventional POY polyester pre-oriented yarn obtained by spinning at a spinning speed of 2500-3300m / min, with a specification of 390dt / (36-48)f, and a triangular cross-section, is drawn in parallel with FTF1001 double-heated discs On the winding machine, it is processed through the processes of "pre-drawing roller→upper hot plate→lower hot plate→hot plate→cold plate→winding". The process conditions of the main process are shown in "Process 3" in Table 1. The package is well formed, and the physical indicators of the obtained DT yarn are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com