Method for producing polyester ITY (Interlaced Texture Yarn) through flat drafting

A production method, the technology of flat drawing, applied in the direction of textiles, papermaking, yarn, etc., can solve the problems of unevenness, jumpy drafting, etc., and achieve the effect of improving product grade, reducing boiling water shrinkage, and good dyeing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

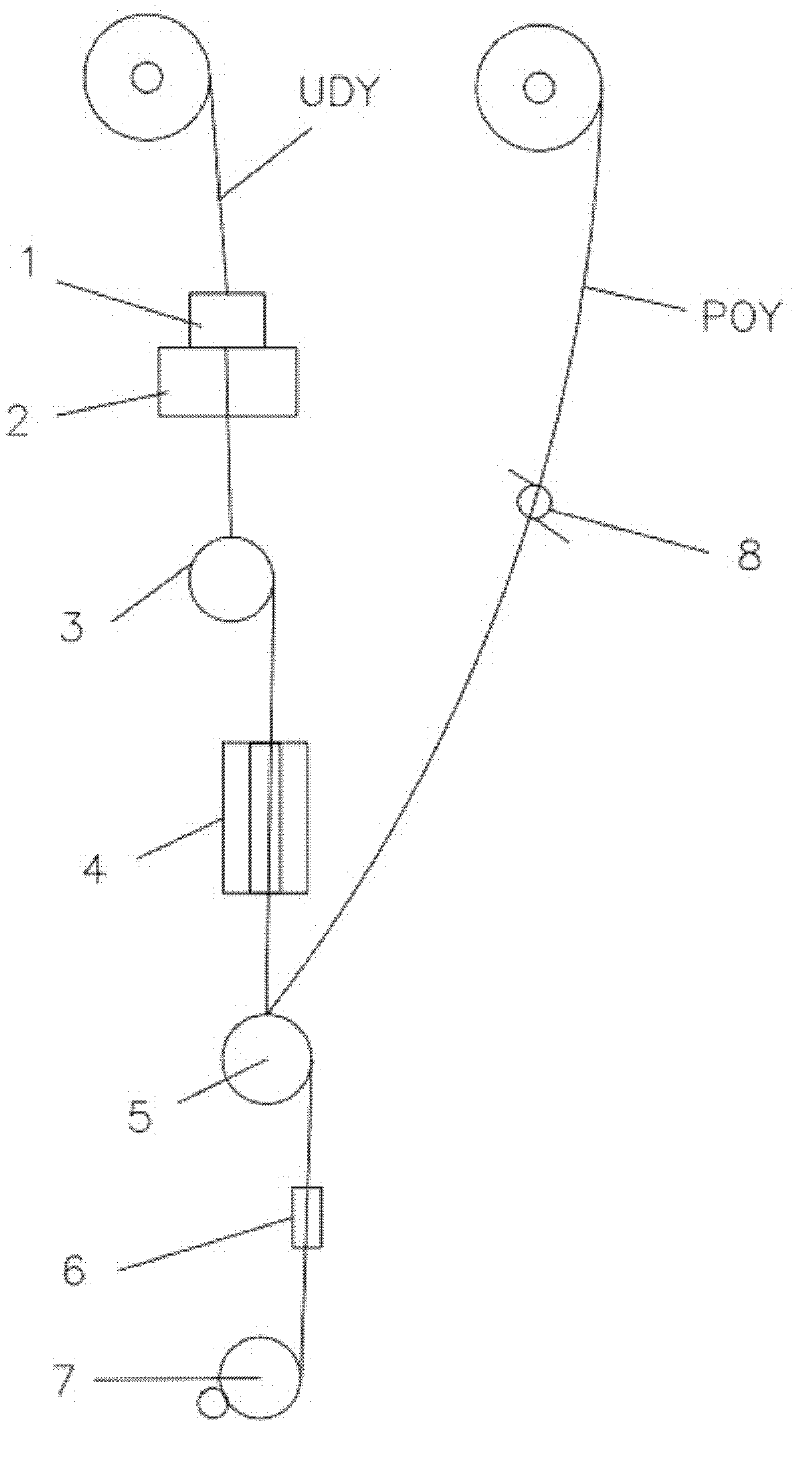

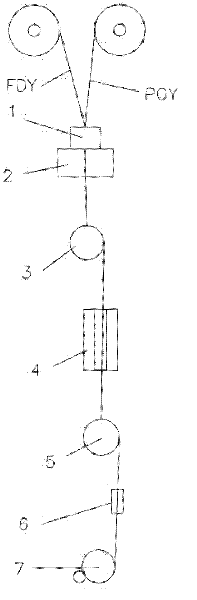

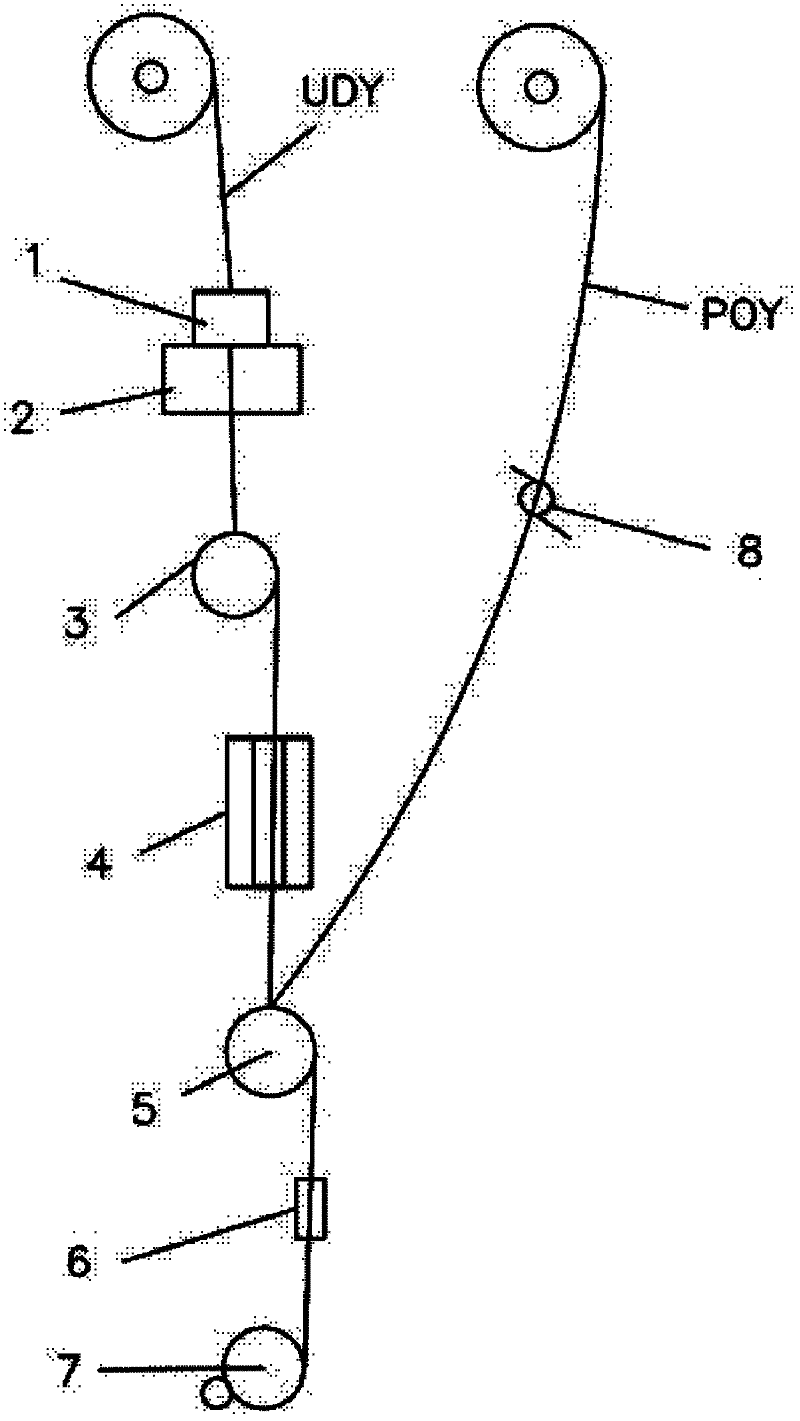

[0027] Such as figure 1 As shown, the production method of polyester flat-drawn ITY yarn described in this embodiment uses a drafting machine to carry out fiber blending and compounding of FDY and POY. The drafting disc, the hot plate, the second drafting disc, the network device and the winding roller, the wire feeding pressure roller is pressed on the wire feeding tension control roller, and it is characterized in that: the FDY is a finished product FDY obtained by a one-step method; The above FDY specifications are: 60dtex / 24F;

[0028] Breaking strength: ≥4.00CN / dtex;

[0029] Elongation at break: 35±3%;

[0030] Boiling water shrinkage: ≤7.0%;

[0031] Oil content: 0.80±0.10%;

[0032] The POY specifications mentioned are: 90dtex / 48F;

[0033] Breaking strength: ≥2.50CN / dtex;

[0034] Elongation at break: 125±5%;

[0035] Boiling water shrinkage: 60.0±5.0%;

[0036] The FDY and POY pass through the wire feeding pressure roller and the wire feeding tension control ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com