Machining polishing device

A machining and clamping technology, applied in grinding drives, metal processing equipment, grinding machines, etc., can solve problems such as grinding of different shafts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

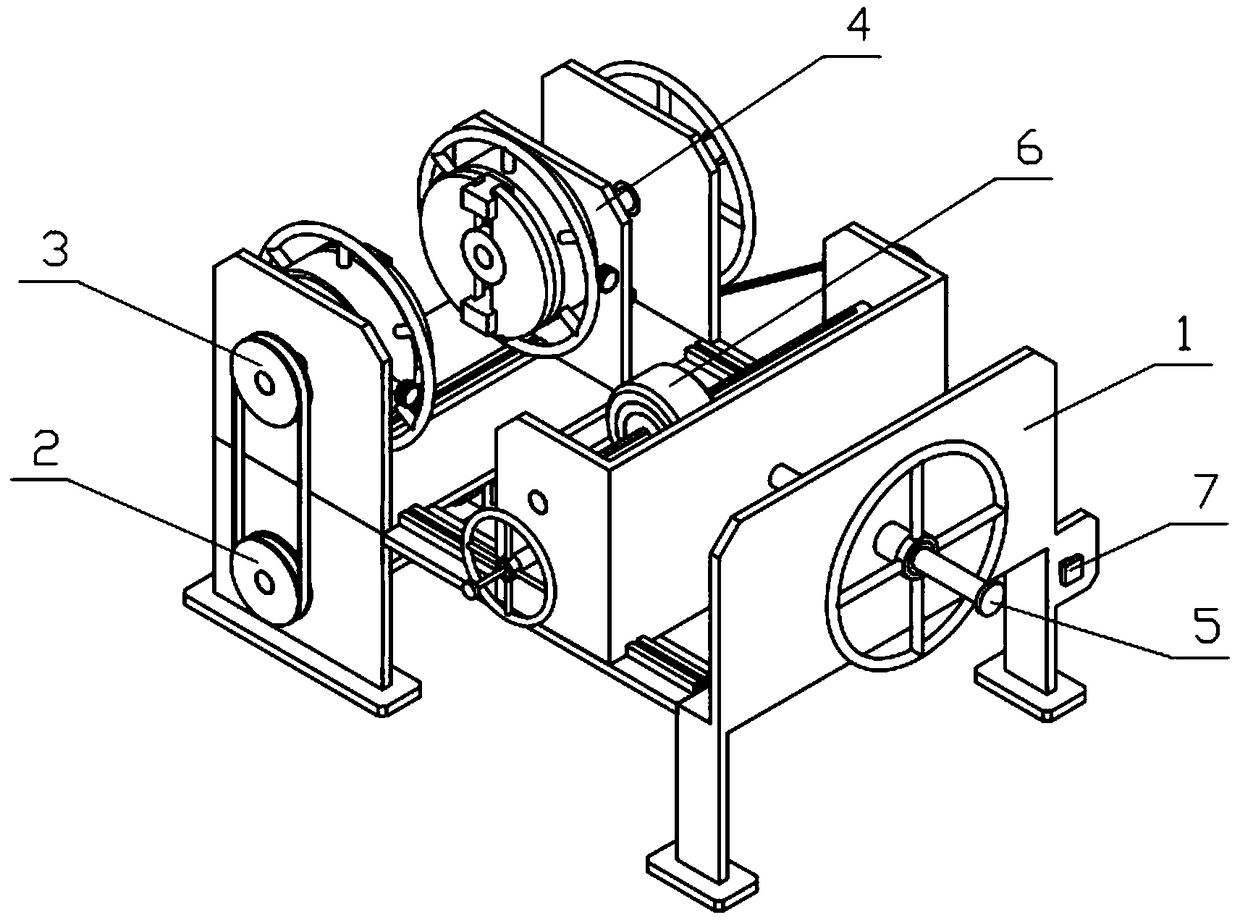

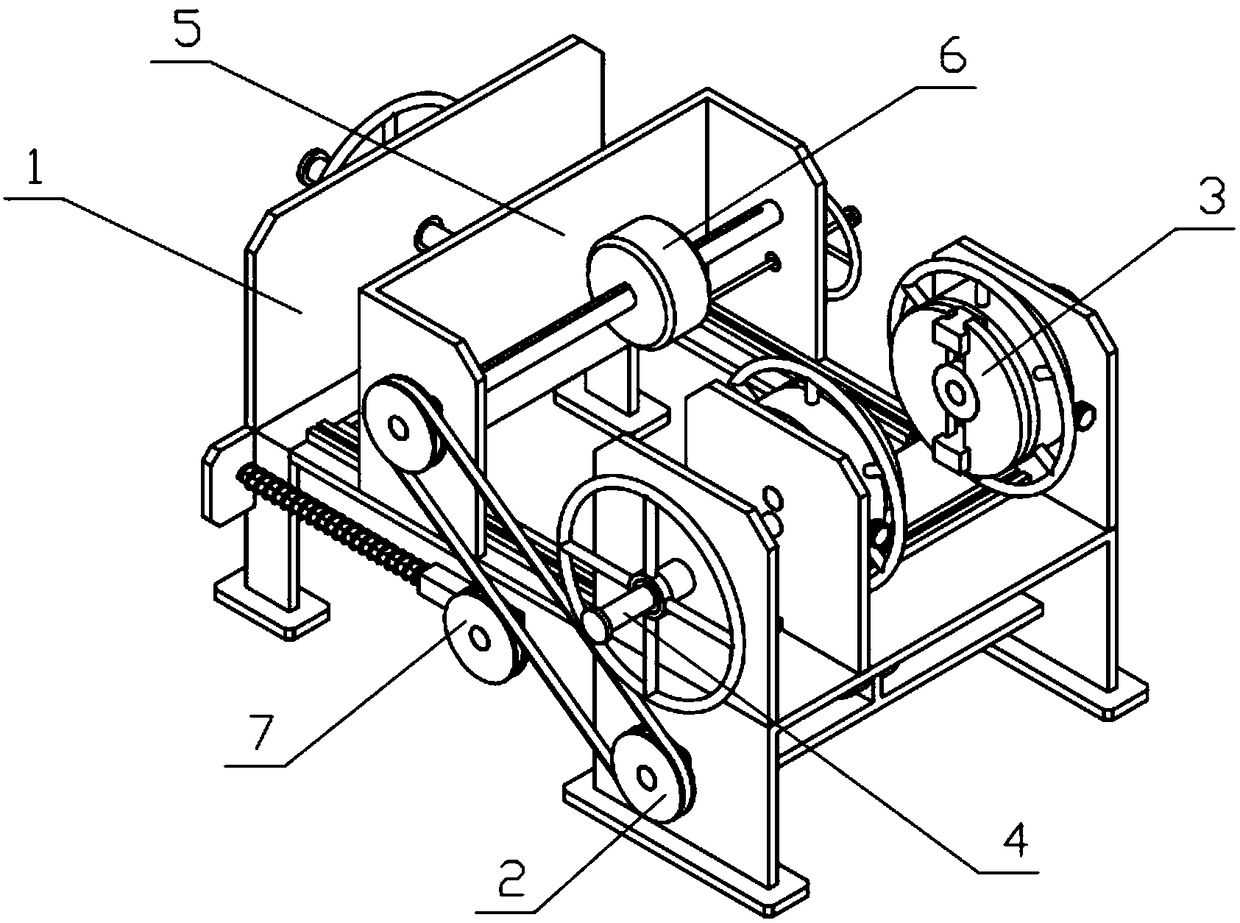

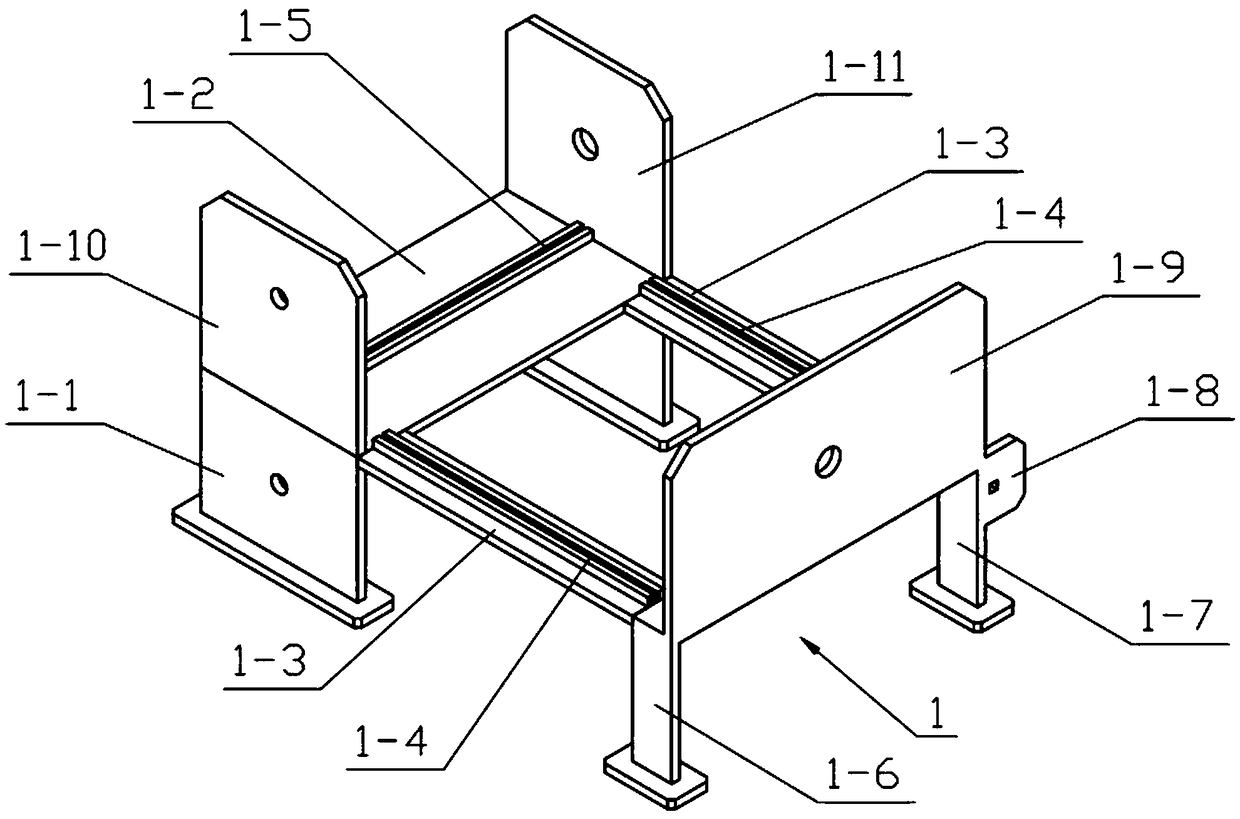

[0034] Combine below Figure 1-14Description of this embodiment, a mechanical processing and grinding device, including a complete machine support 1, a power mechanism 2, a clamping mechanism 3, a stretching mechanism 4, a pushing mechanism 5, and an adjustment mechanism 6, which can be used for different diameters by the clamping mechanism 3 One end of the shaft is clamped, and the other end of the shaft with different diameters is clamped and stretched by the stretching mechanism 4, so as to reduce the influence of extrusion and clamping on the long axis due to the processing of the long axis, and driven by the power mechanism 2 The clamping mechanism 3 and the adjusting mechanism 6 rotate, and the pushing mechanism 5 drives the adjusting mechanism 6 to move to adjust the relative distance between the clamping mechanism 3 and the adjusting mechanism 6, so that the adjusting mechanism 6 can grind shafts of different diameters, push The grinding disc 6-4 provided on the adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com