Spinning process and die head of chinlon 66 monofilament of high-strength and high-precision industry

A spinning process and high-precision technology, which is applied in the spinning process and die head field of high-strength and high-precision industrial nylon 66 monofilament, can solve the problems of high shrinkage in boiling water, increased cost, low yield, etc. Good roundness, improved production efficiency, and low boiling water shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: a kind of spinning process of nylon 66 monofilament for high-strength and high-precision industry, comprises the following steps:

[0031] (1) Drying Remove moisture from the raw material nylon 66 particles, dry at 85°C for 6 hours, and make the moisture requirement reach 600ppm;

[0032] (2) Heating and melting The dried nylon 66 particles enter the screw extruder for heating and melting, and the heating temperature is 295°C; at the same time, the extrusion pressure of the extruder is controlled at 87kg / cm2;

[0033] (3) Metering The melt extruded by the extruder enters the metering pump, and the output volume is measured by adjusting the speed of the metering pump according to the diameter of the finished product;

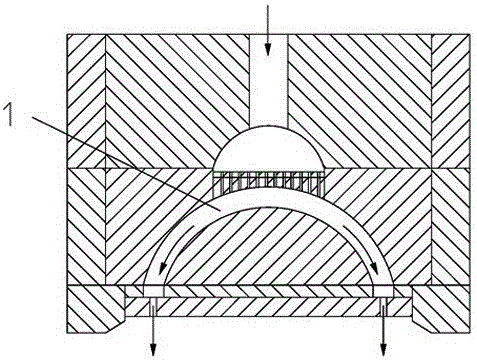

[0034] (4) Spinning heated molten melt is extruded by the metering pump and added to the die, passes through the distribution plate and the filter layer, enters the diversion cavity of the deflector, and spins through the spinneret, and the i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com