Technique for preparing bright polyester filament yarn with high extension

A production technology, a technology of light polyester, which is applied in the production field of differentiated polyester filaments, can solve the problems of no polyester brocade, and the maximum elongation at break of polyester filaments does not exceed 35%, and achieves low boiling water shrinkage and product. The effect of high added value and high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

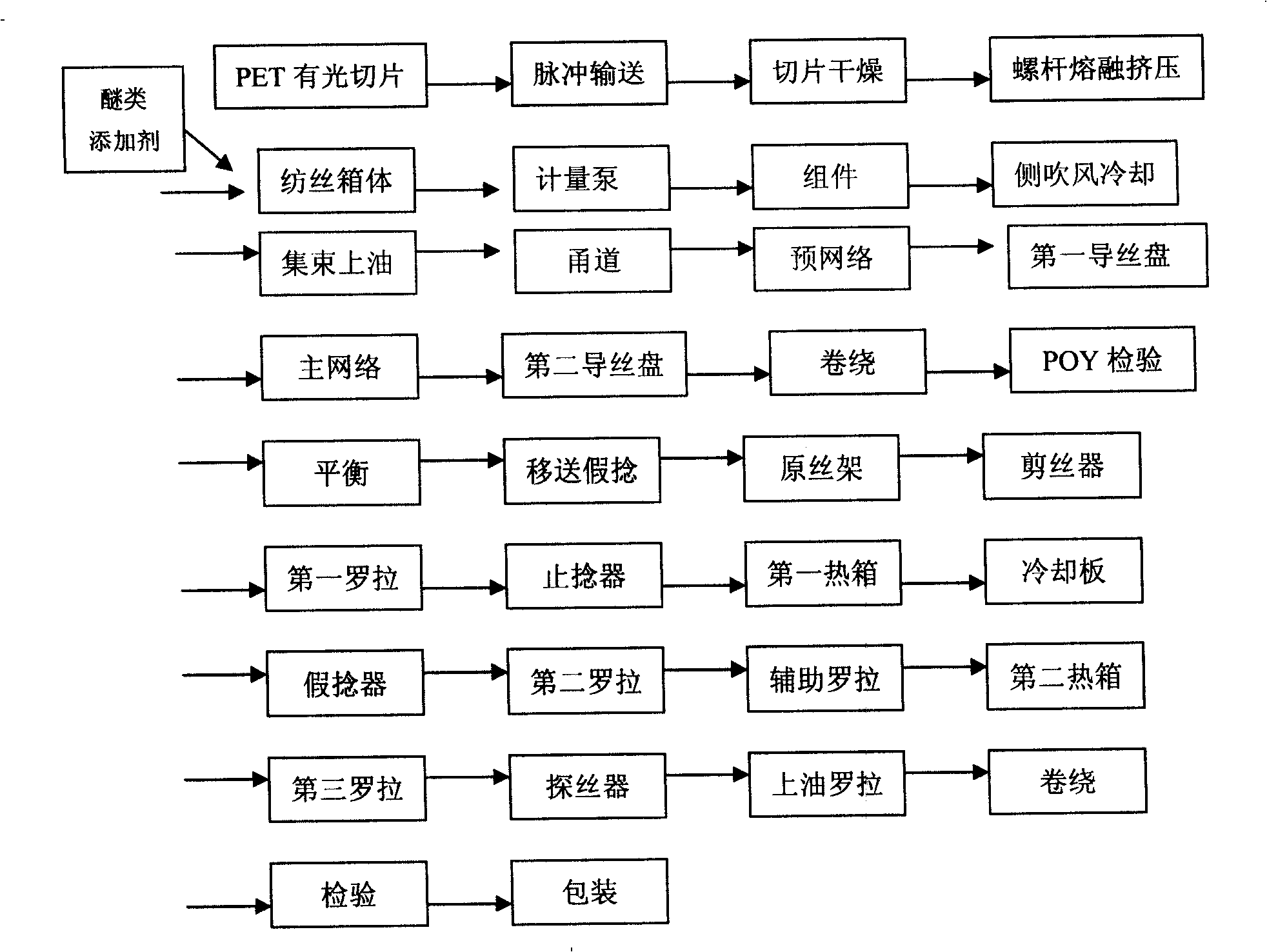

Image

Examples

Embodiment Construction

[0016] The spinning melt containing the special ether additives is spun into POY filaments with a specification of 125dtex / 24f according to the common chip spinning production method, and the control concentration of the ether additives is 0.80%. Production is carried out on the FK6M-1000 type texturing machine of Barmag Corporation in Germany by the process parameters described in Table 1.

[0017] Table 1: Specific process parameter table of spinning and texturing after the present embodiment

[0018] project

unit

production conditions

speed

M / MIN

580

DR

1.700

[0019] D / Y

1.650

0. F X

%

/

O.F 2

%

4.60

0.F 3

%

6.50

H1

℃

180

H2

℃

140

Tension 1

16.0

Tension 2

15.0

Tg

7.0

Interlace

bar

1.40

disc

pu

1-7-1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com