Patents

Literature

35results about How to "High dye utilization rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Milk protein fiber or its filament or its blended yarn dyeing method and coloured woven fabric producing method

ActiveCN1865574ASolve the problem of not being able to dyeHigh dye utilization rateHeating/cooling textile fabricsWoven fabricsAlcoholPolyvinyl acetate

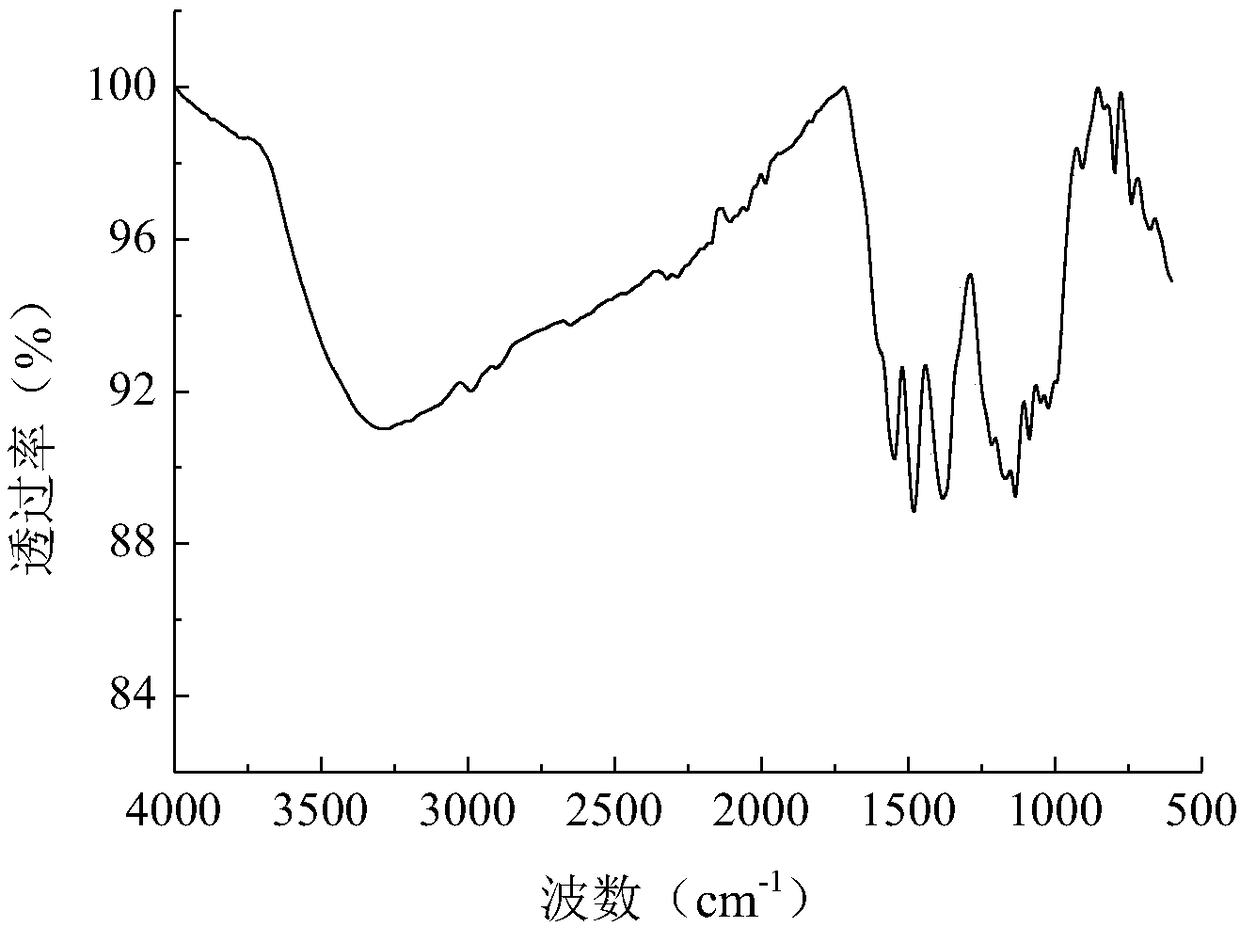

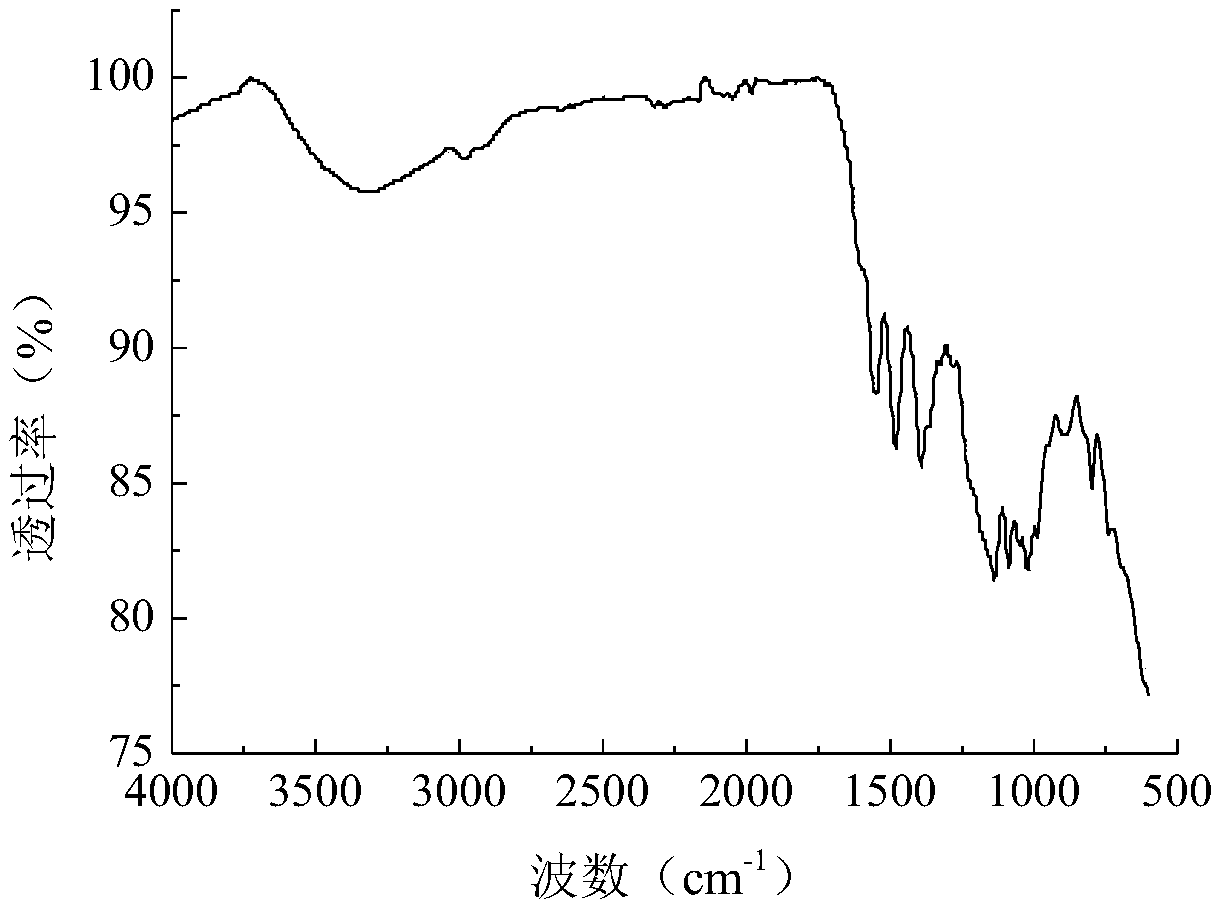

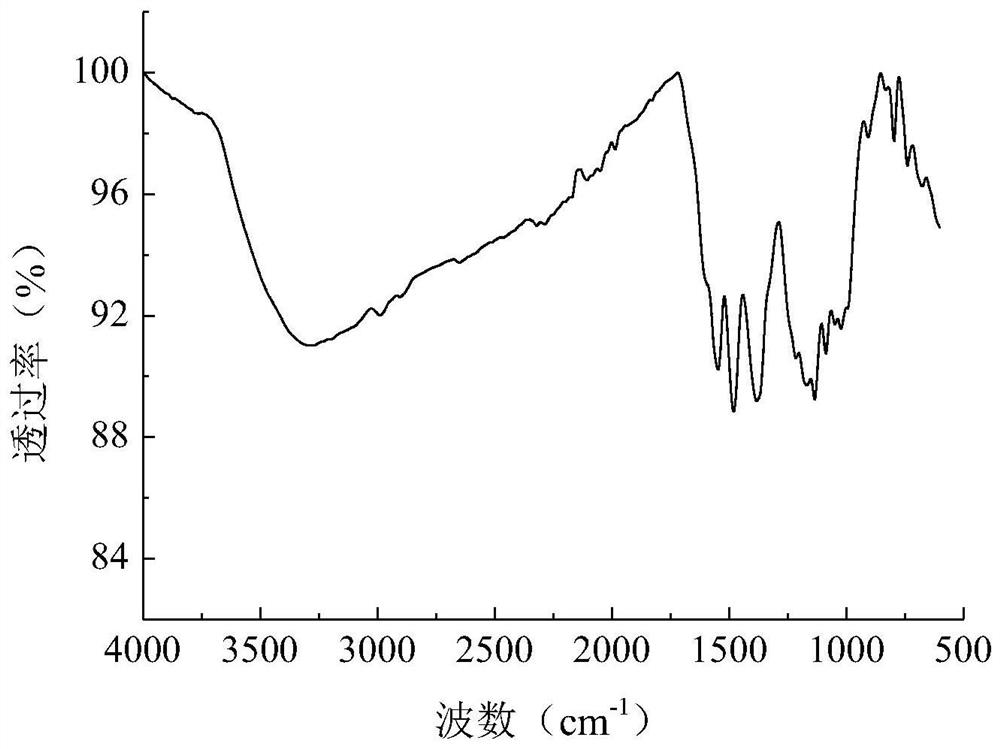

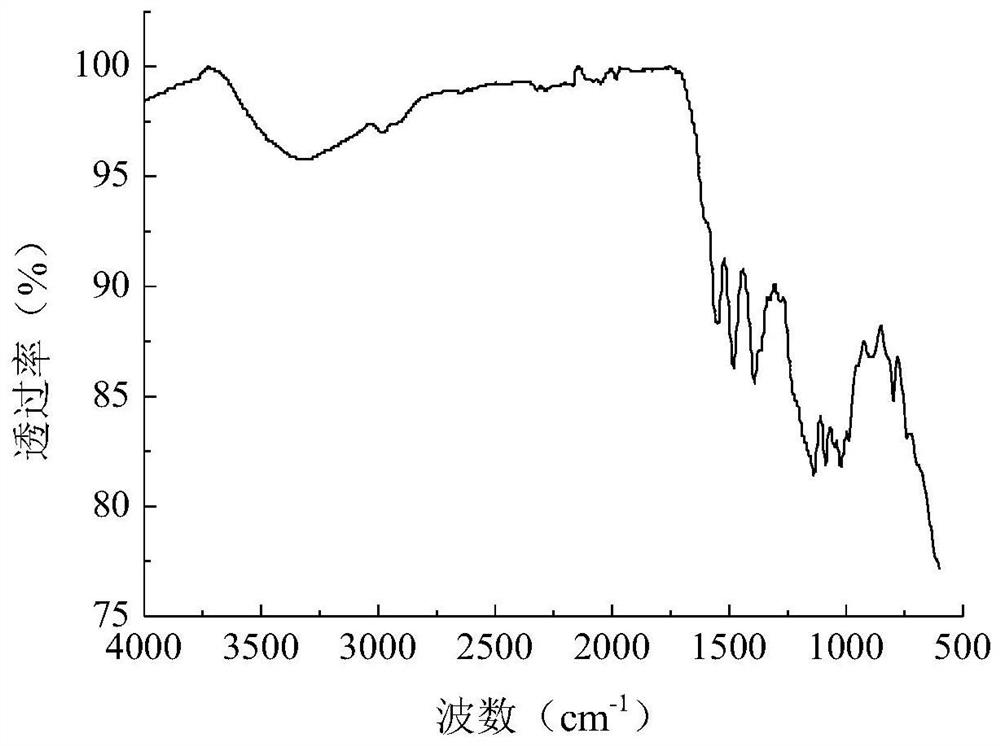

The invention discloses a manufacturing method of milk protein fiber or filament or blended yarn dyeing and yarn-colored product, which is characterized by the following: changing coiling density of yarn; controlling heating temperature; adopting segmented contraction in the cylinder yarn dyeing course; adding self-producing milk protein fiber dyeing specific adjuvant; utilizing polyacrylonitile or polyvinyl acetate alcohol as carrier realize active dyeing technology of milk protein fiber; solving the difficulties of flower color, weak color and bad fastening degree problem to produce excellent washing shrinkage and stable size yarn-dyed product through weaving, shrinking and softening and final disposal.

Owner:SHANGHAI TIQIAO TEXTILE & YARN DYEING

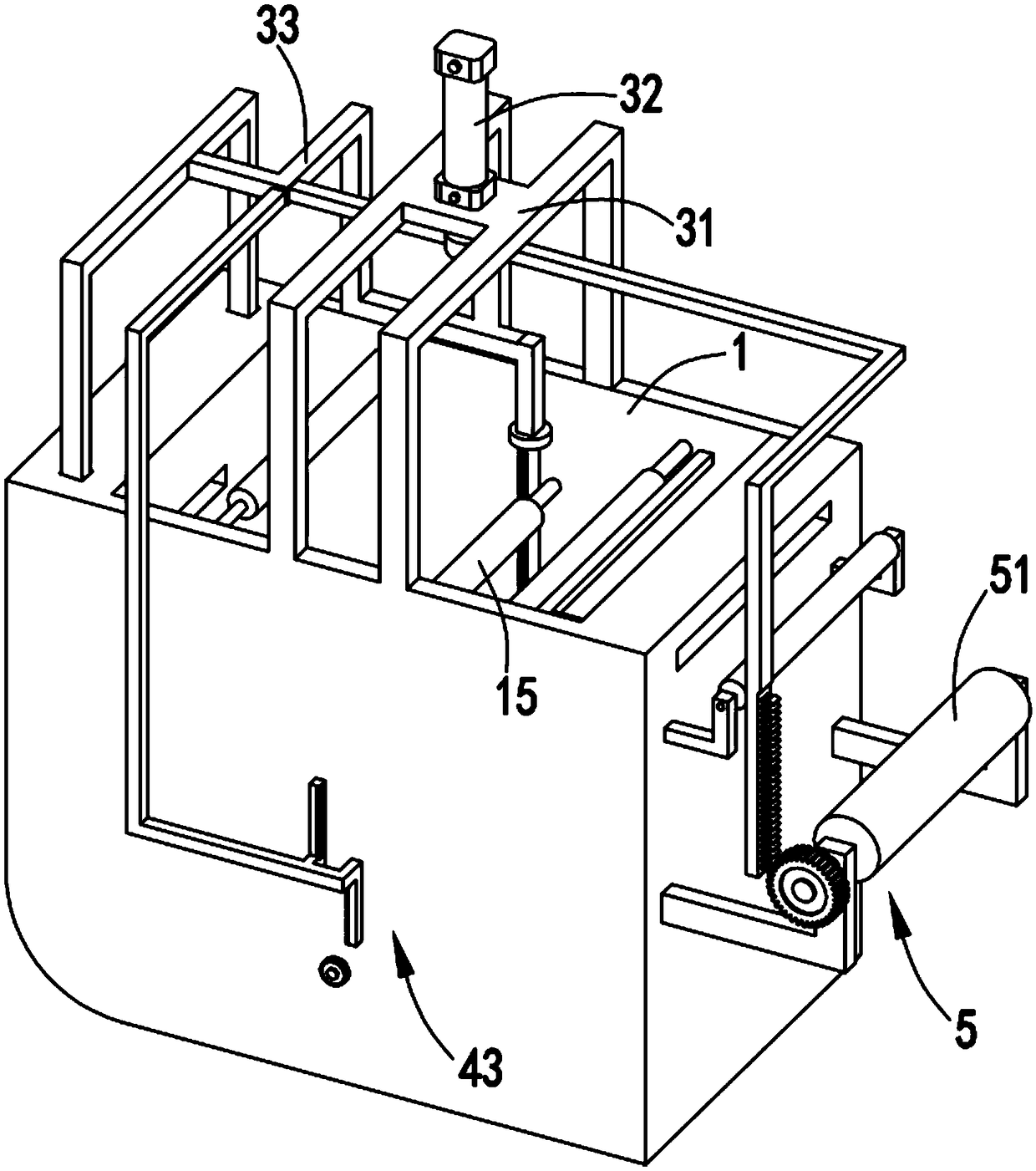

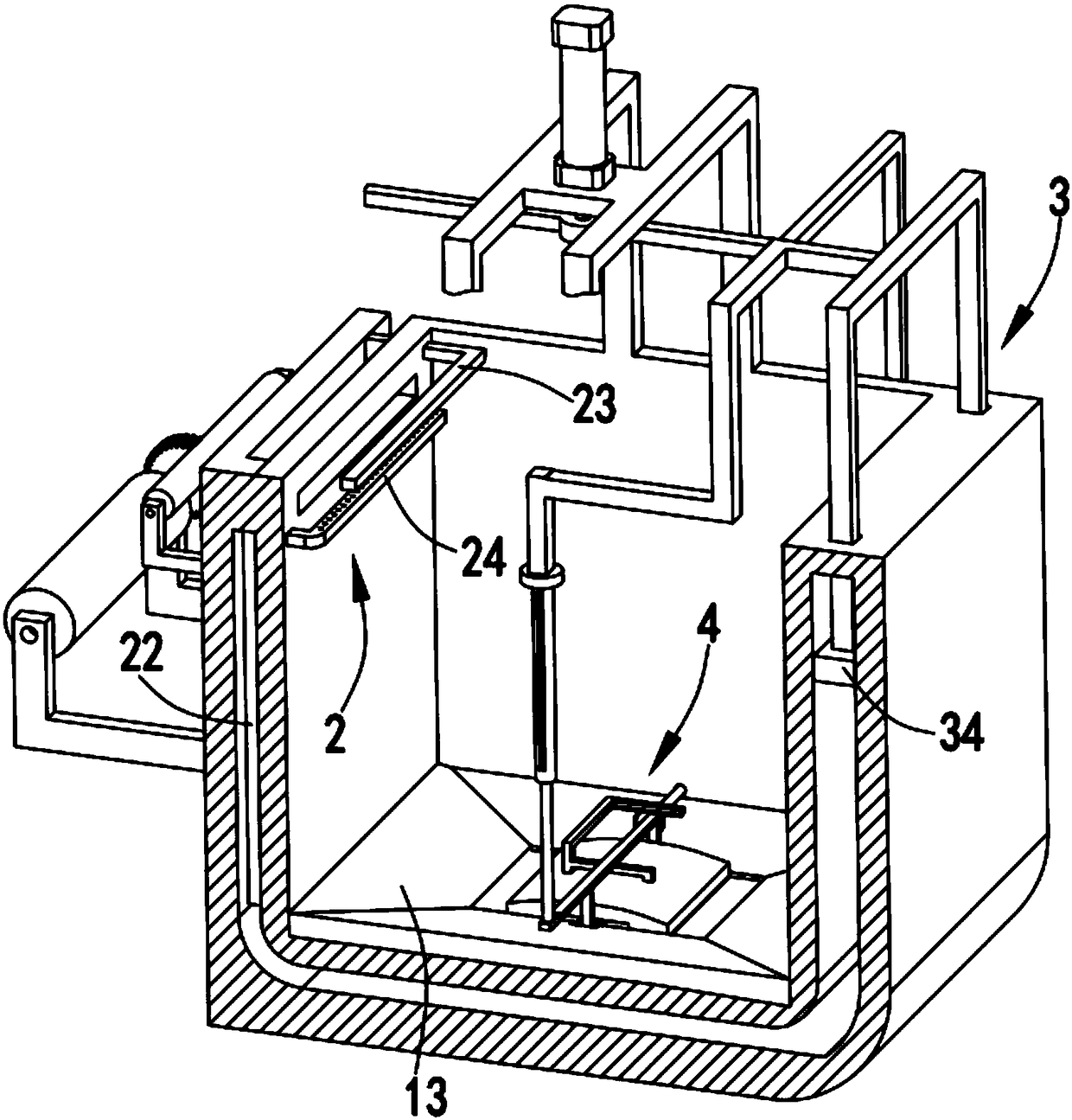

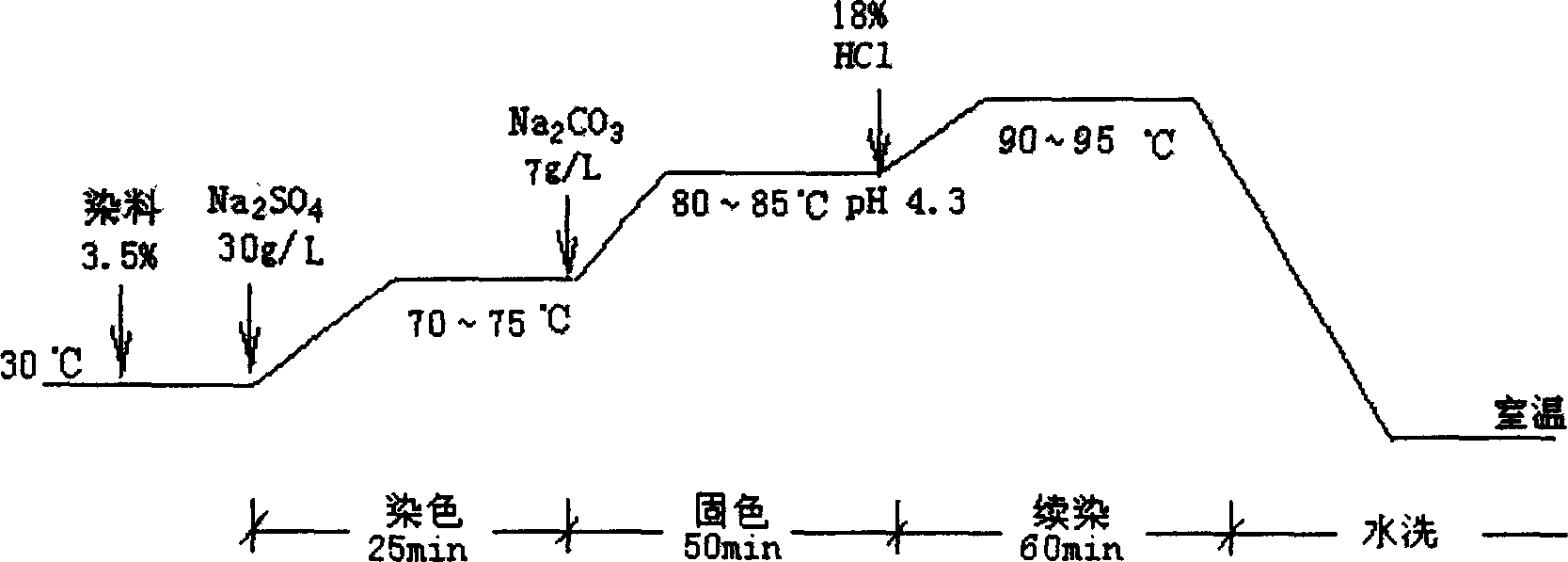

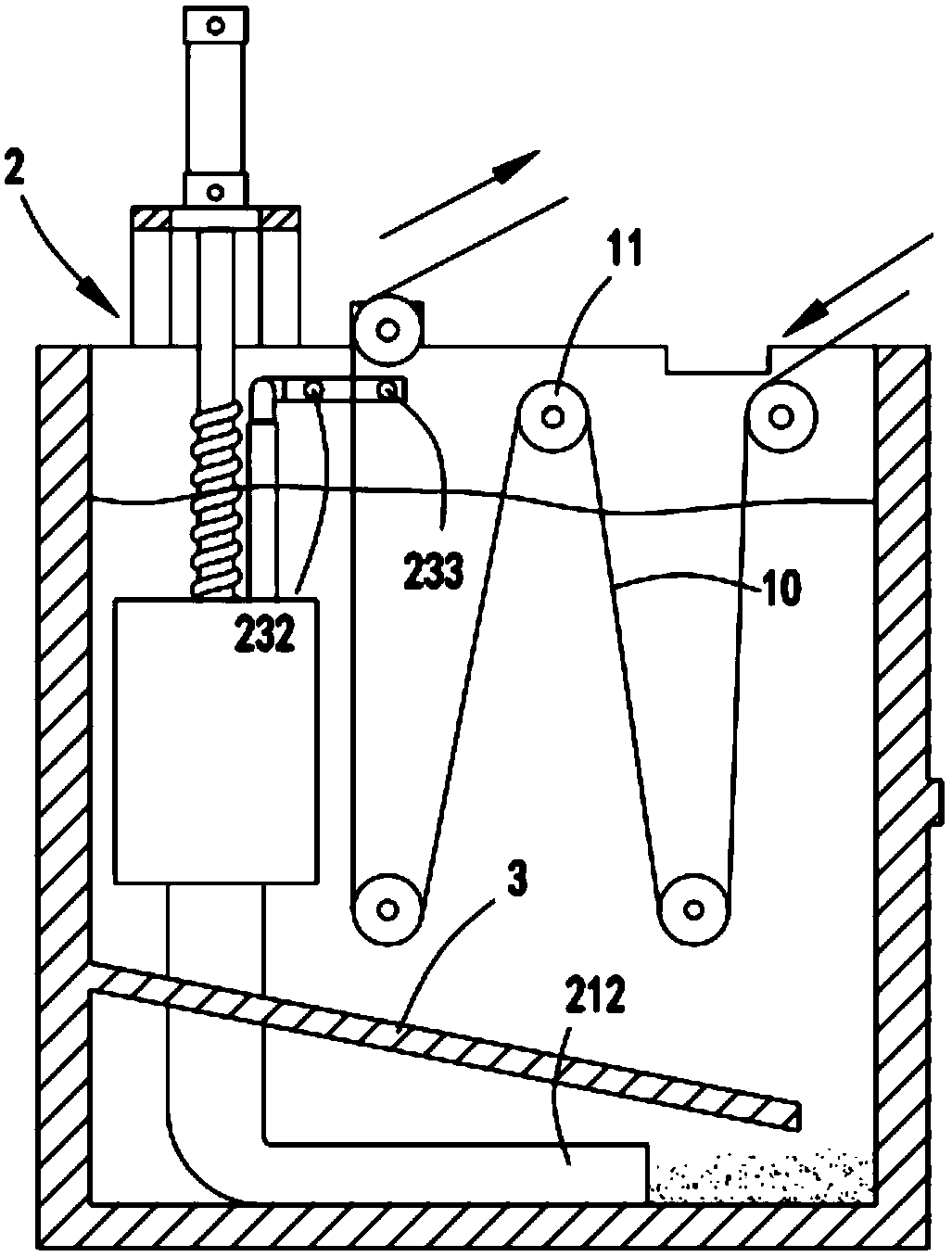

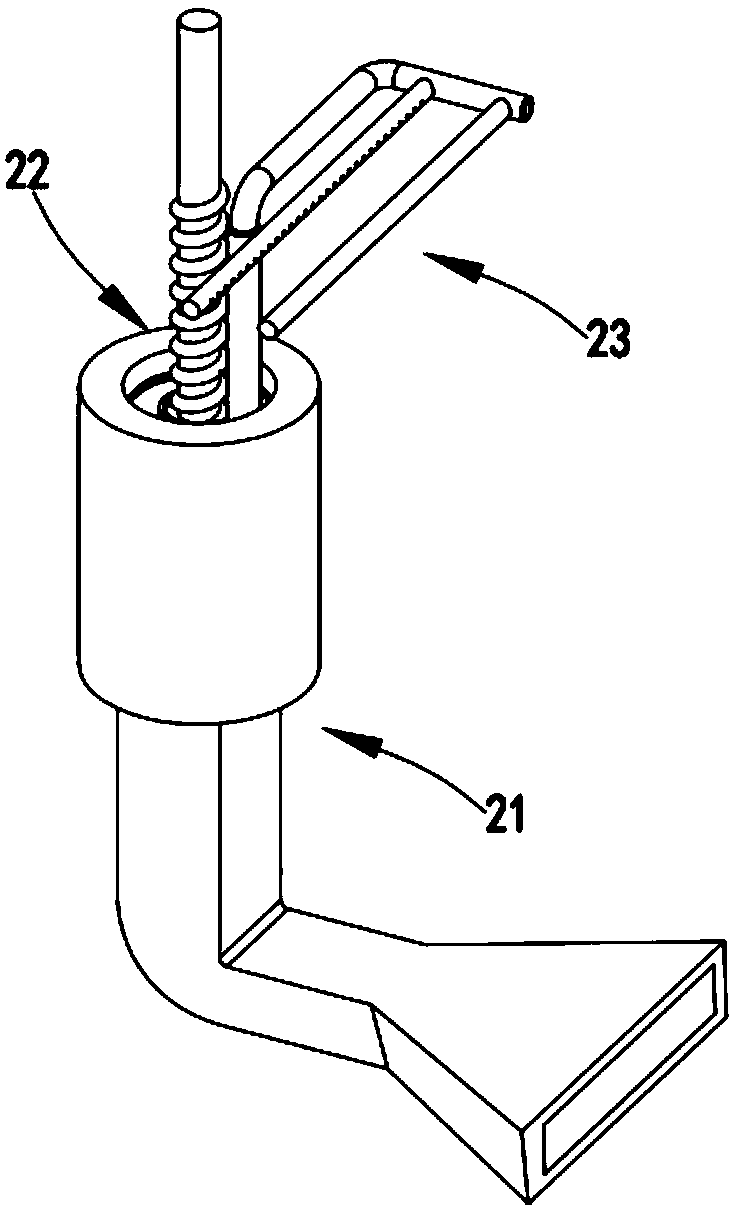

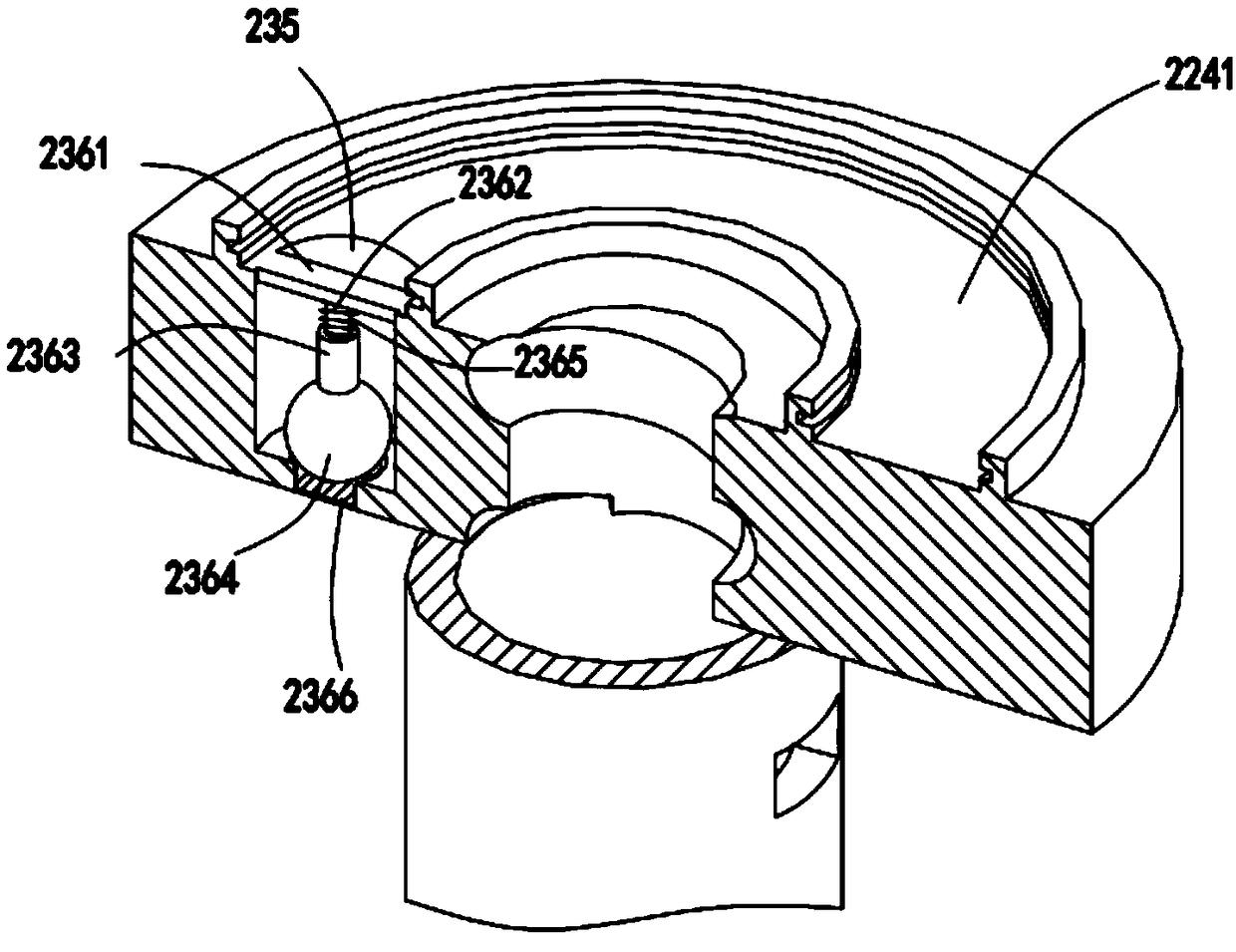

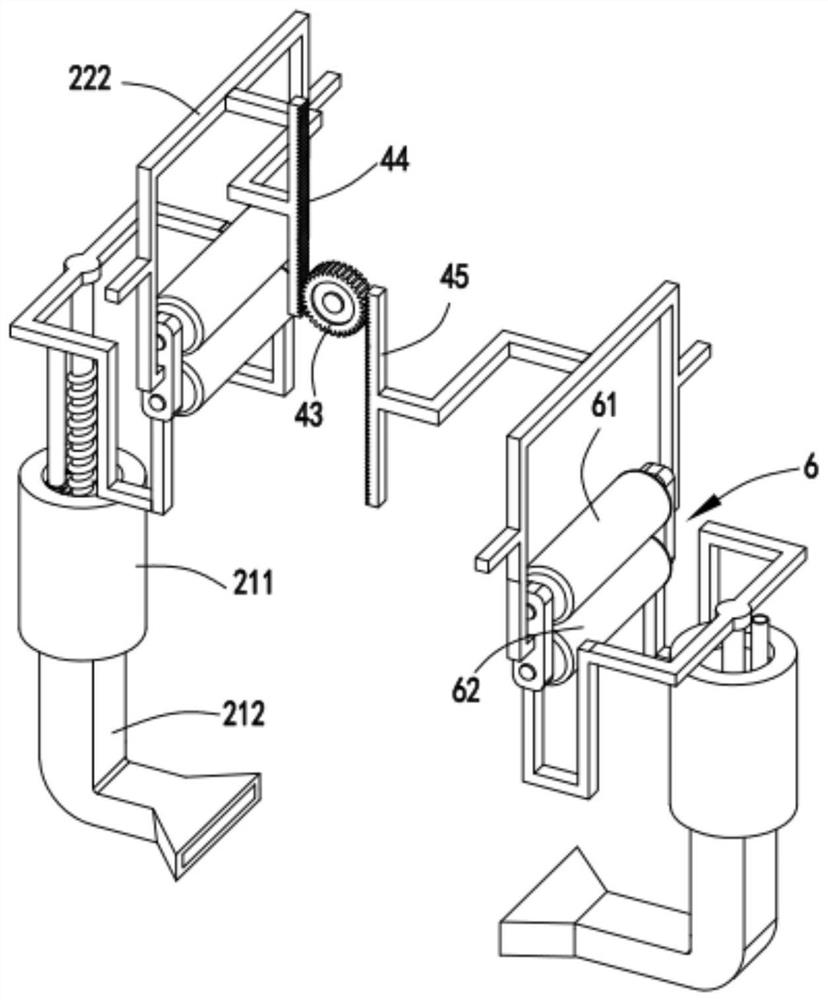

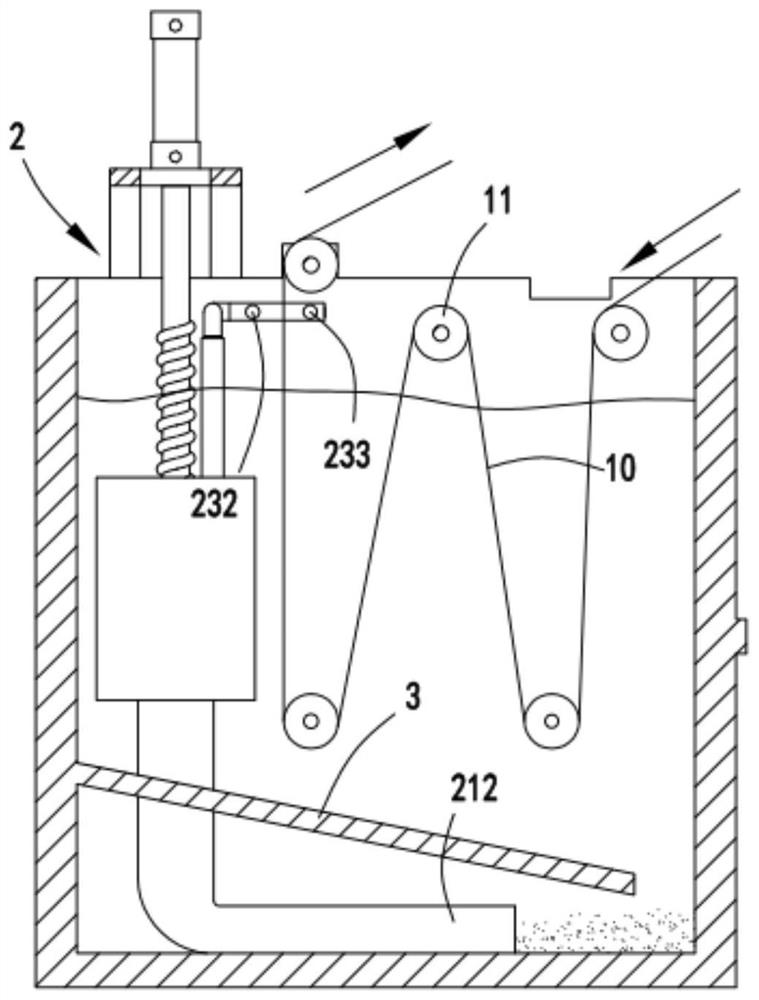

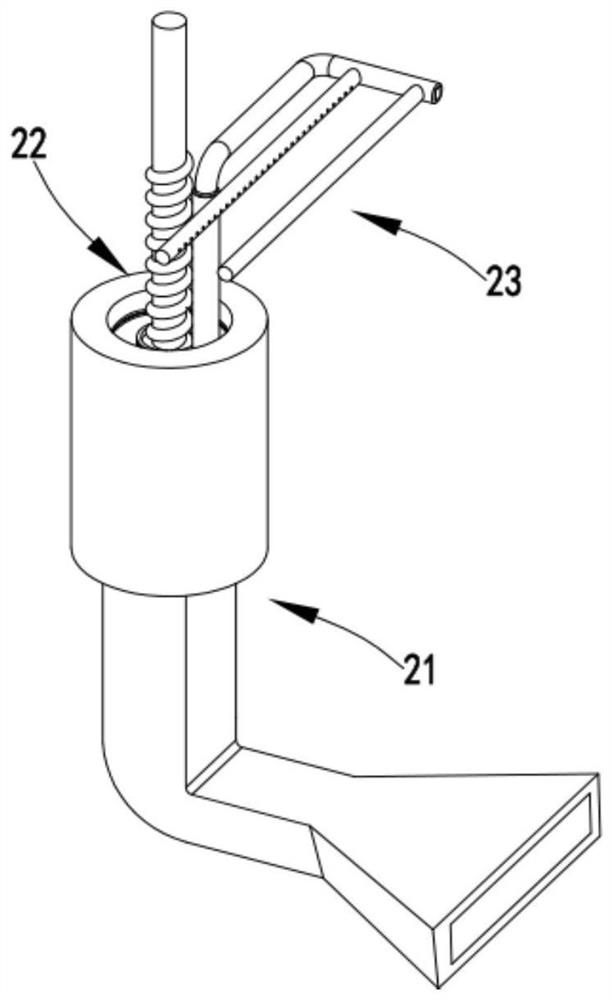

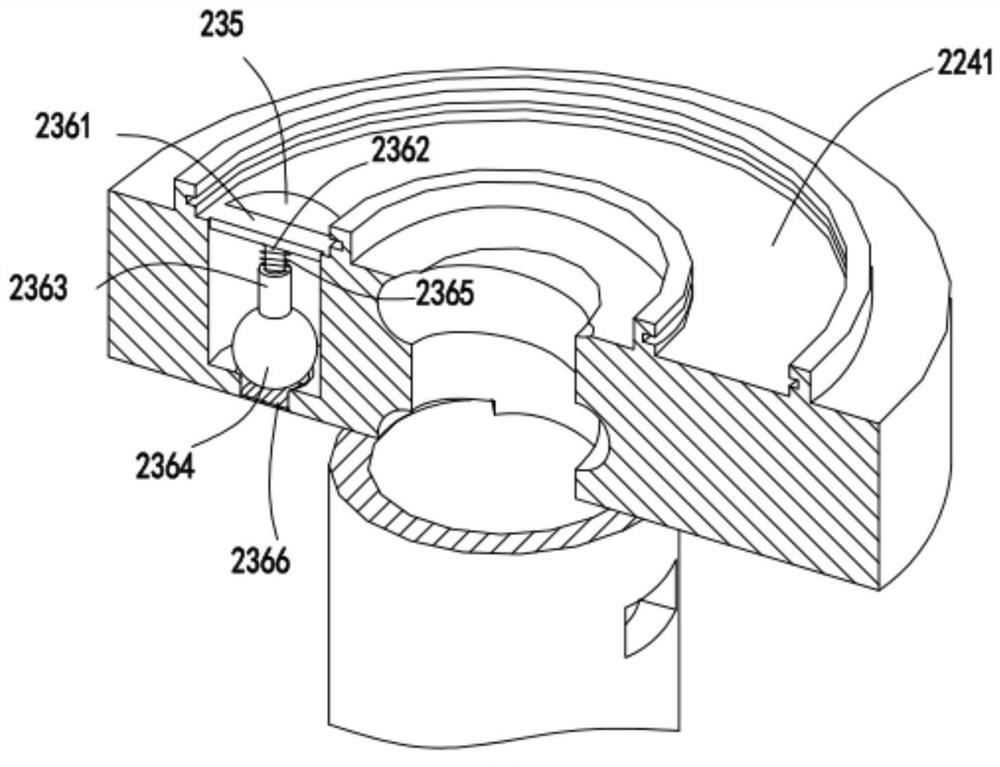

High-quality printing and dyeing device for textile fabric

InactiveCN108866865AImprove color uniformityImprove uniformityTextile treatment machine arrangementsTextile treatment by spraying/projectingEngineeringImpurity

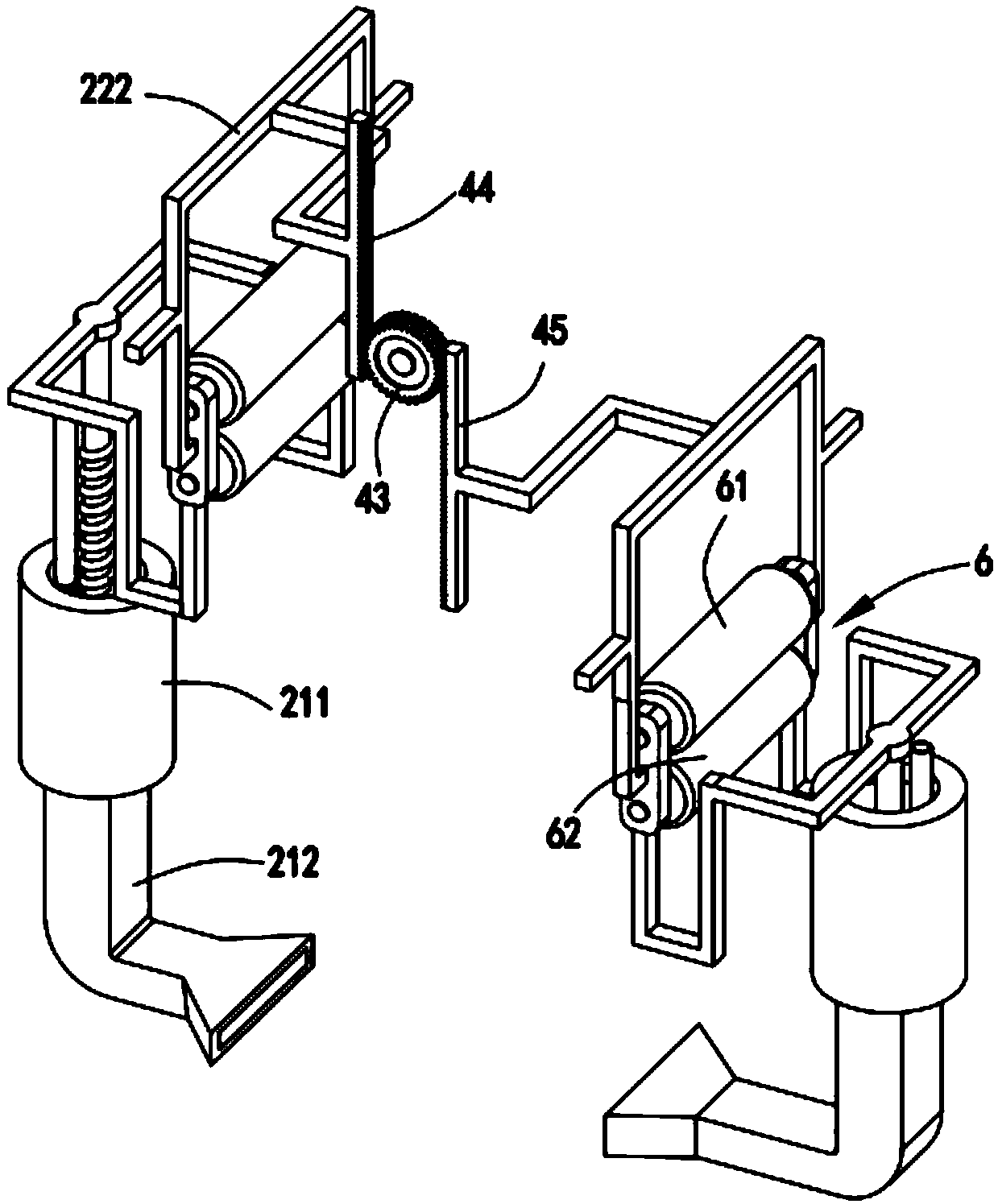

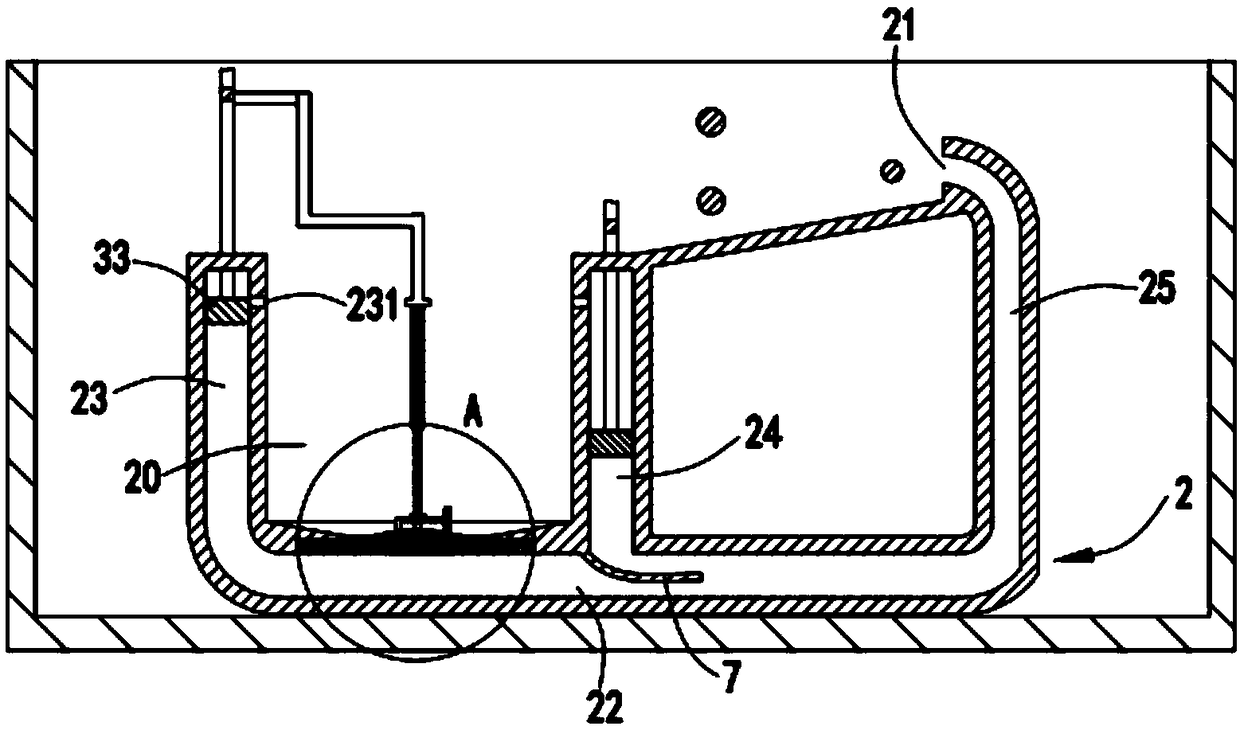

The invention relates to a high-quality printing and dyeing device for textile fabric. The device comprises a dyestuff box, the left side of the dyestuff box is provided with an extrusion cavity, thebottom side of the dyestuff box is provided with a flow guide channel communicated with the extrusion cavity, and the right side of the dyestuff box is provided with a spray-painting mechanism communicated with the flow guide channel; the extrusion cavity is provided with an extrusion mechanism, which is used for extruding dye liquor in the extrusion cavity to enable the dye liquor to be sprayed out through the spray-painting mechanism; a grinding mechanism is arranged at a position which is close to a bottom side in the dyestuff box, and comprises a lower grinding component as well as an upper grinding component and a driving component which are arranged above the lower grinding component, the extrusion mechanism downwards drives the upper grinding component to move downwards to the lowergrinding component, the driving component drives the upper grinding component to move left and right to grind coarse particle dyestuff on the lower grinding component; the right side of the dyestuffbox is further provided with a fabric rolling mechanism, and the extrusion mechanism drives the fabric rolling mechanism to roll the fabric; the high-quality printing and dyeing device is used for solving the problems that in the dyeing process, the dyestuff chroma homogeneity is poor, the dyestuff use ratio is not high, the dyeing effect is not good and impurities are easily adhered to the fabricsurface.

Owner:CHANGXING DEHONG MACHINERY CO LTD

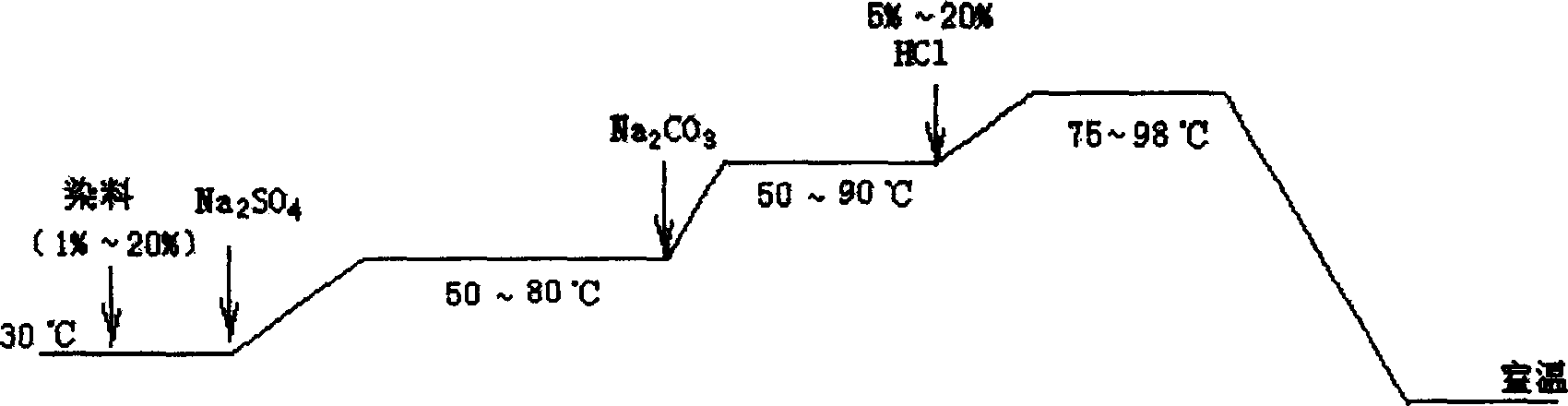

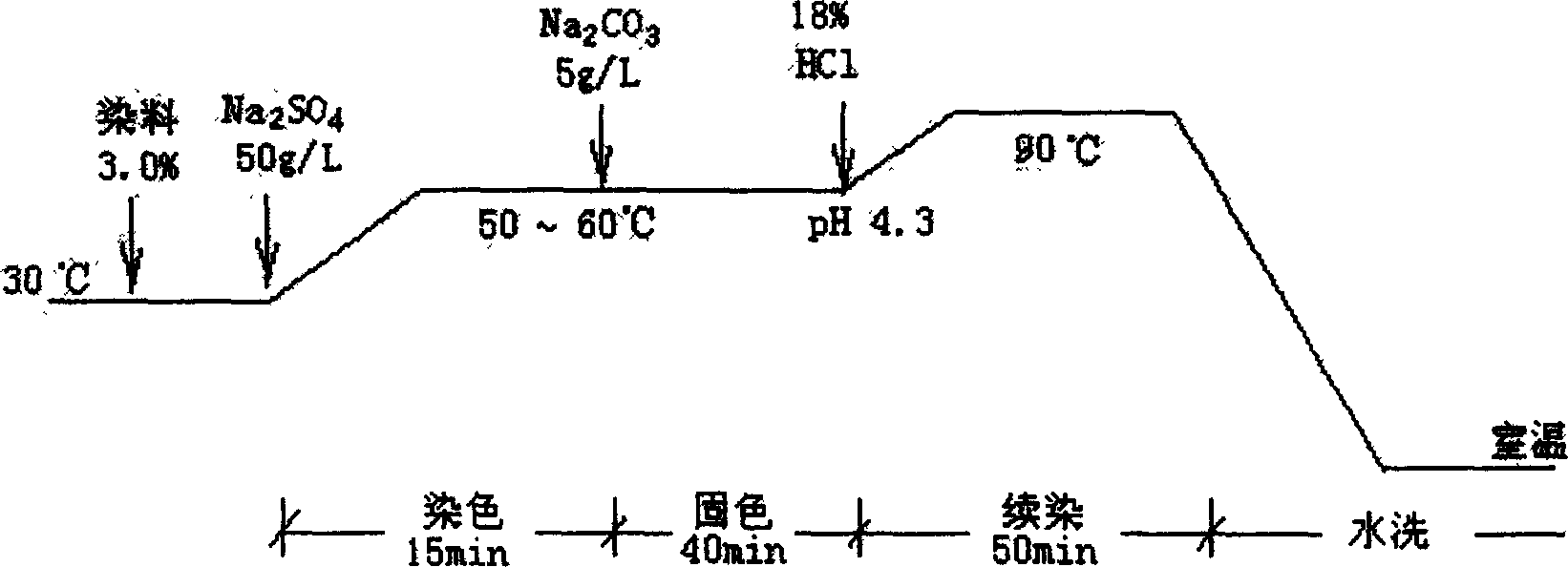

Active, dyestuff modified bath dyeing technology

The present invention relates to a modification bath dyeing technique by using active dyes. Said technique can dye fibre, yarn and fabrics, and includes the following processes: under the alkaline condition utilizing active dyes to dye, fix colour and regulate pH value, and under the acidic condition utilizing acidic dyes to dye, heat-up continuously dye and water-wash, etc. The adoption of said method is applicable to new fibre variety, for example, soybean protein / PVA polyblend fibre can be one-bath dyed by using said method.

Owner:DONGHUA UNIV

Production process for cellulose fiber interwoven or cellulose fiber blended fabric

InactiveCN106835441ANot easy to fade and white hairNot easy to get white hairDrafting machinesDyeing processSizingDyeing

The invention provides a production process for cellulose fiber interwoven or cellulose fiber blended fabric. The production process includes the steps of selection of raw materials, spinning, sizing, weaving, dyeing, final treatment and the like; A100-type cellulose fiber is selected as the raw materials, fibrillation is assured not to occur to the cellulose fiber, the obtained fabric is ensured not to fade easily and generate white hairs easily, yarn hairness can be effectively controlled by adopting a Siro spinning yarn mode, the hairness 3mm above the surface of the yarn can be reduced by 80% as compared with a traditional ring spinning method, a sizing agent without PVA (polyvinyl acetate) is used for sizing, possibility that the cellulose fiber interwoven or cellulose fiber blended yarn is split by swelling friction under the damp condition can be reduced, weaving difficulties brought by the cellulose fiber interwoven or cellulose fiber blended yarn and other hairness can be further avoided, friction of the yarn and a machine during dyeing can be reduced by controlling warp and weft-density difference of gray fabric, and fibrillation risk of the cellulose fiber in production is reduced.

Owner:LILANG CHINA

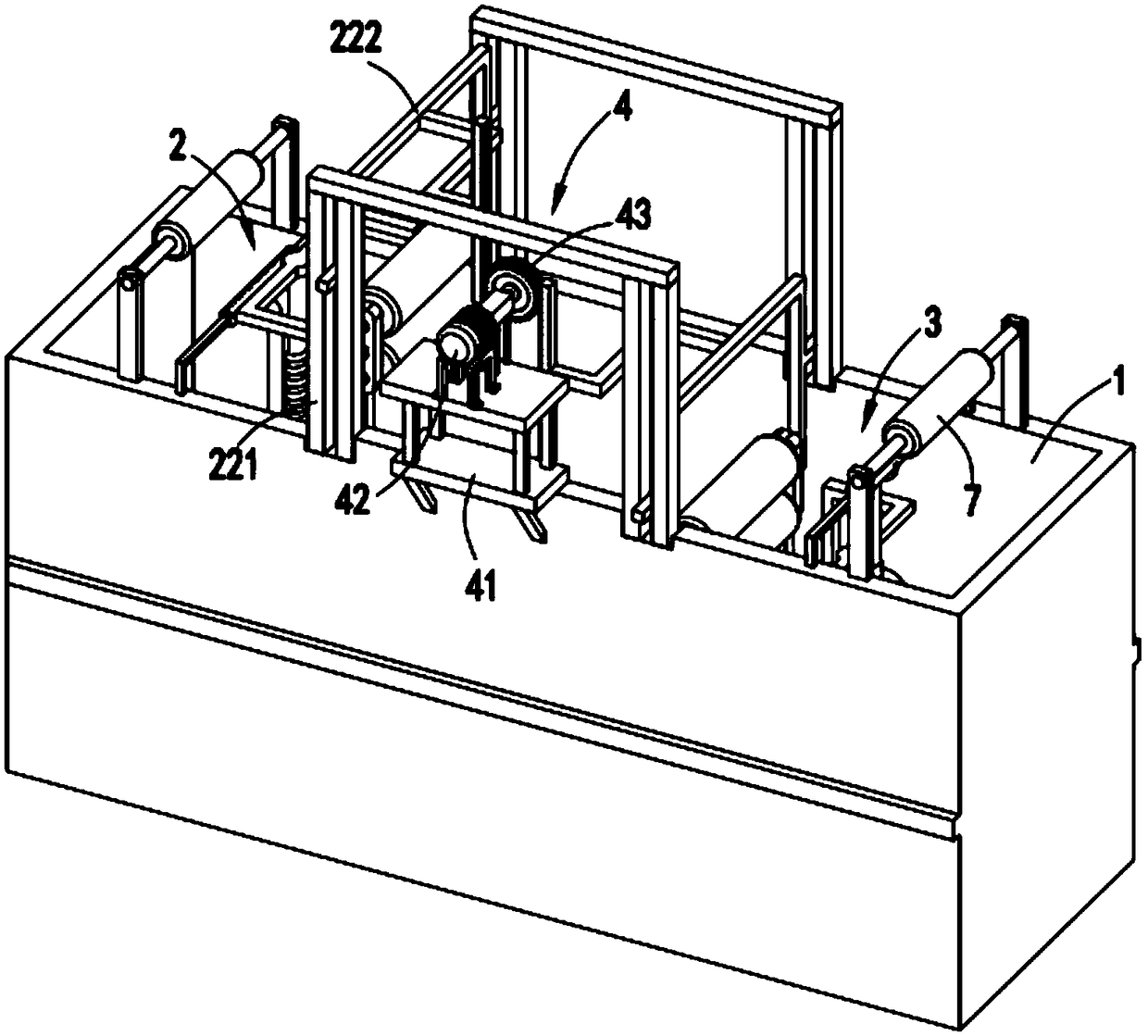

High-efficiency textile fabric printing and dyeing treatment system and process

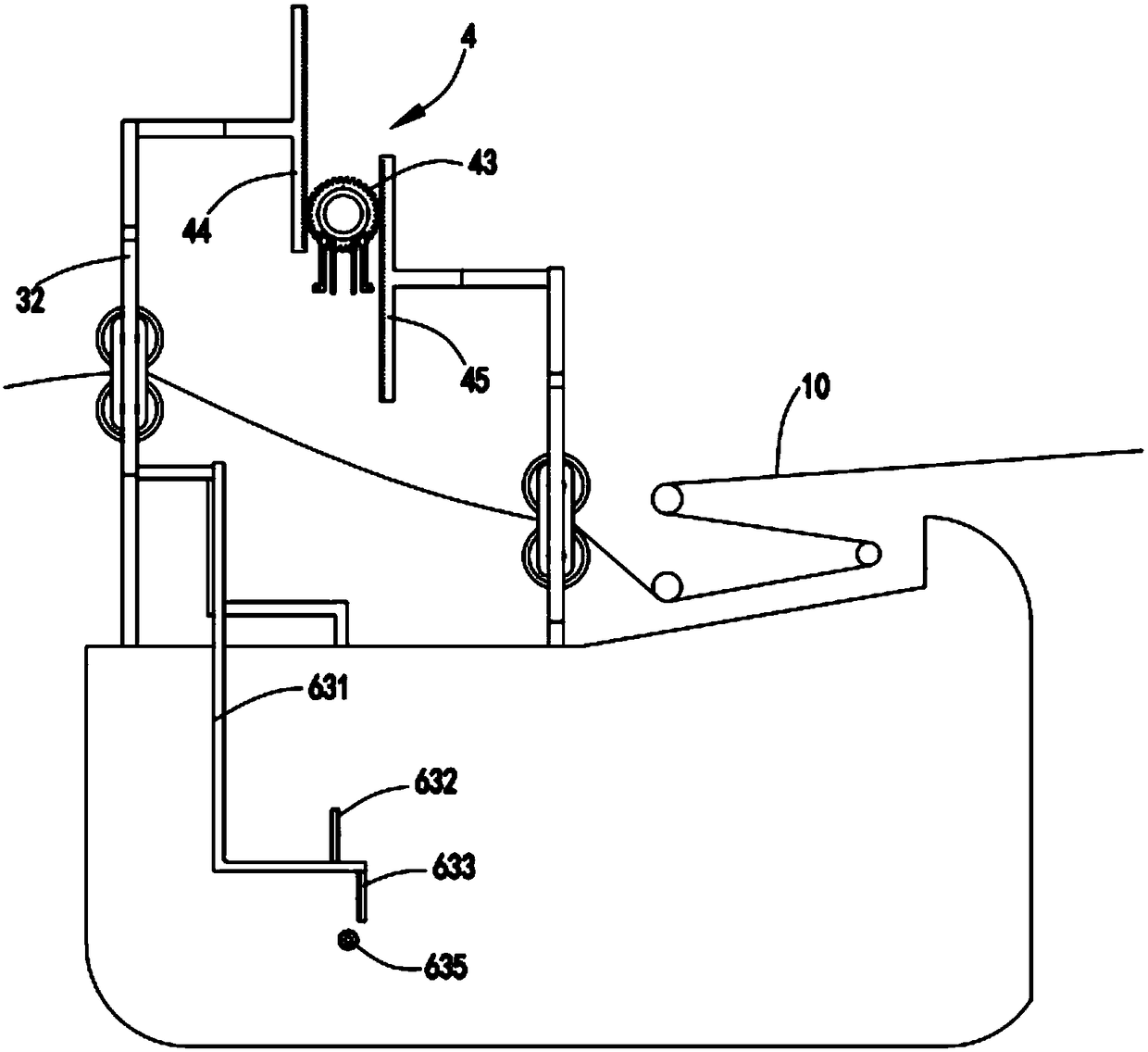

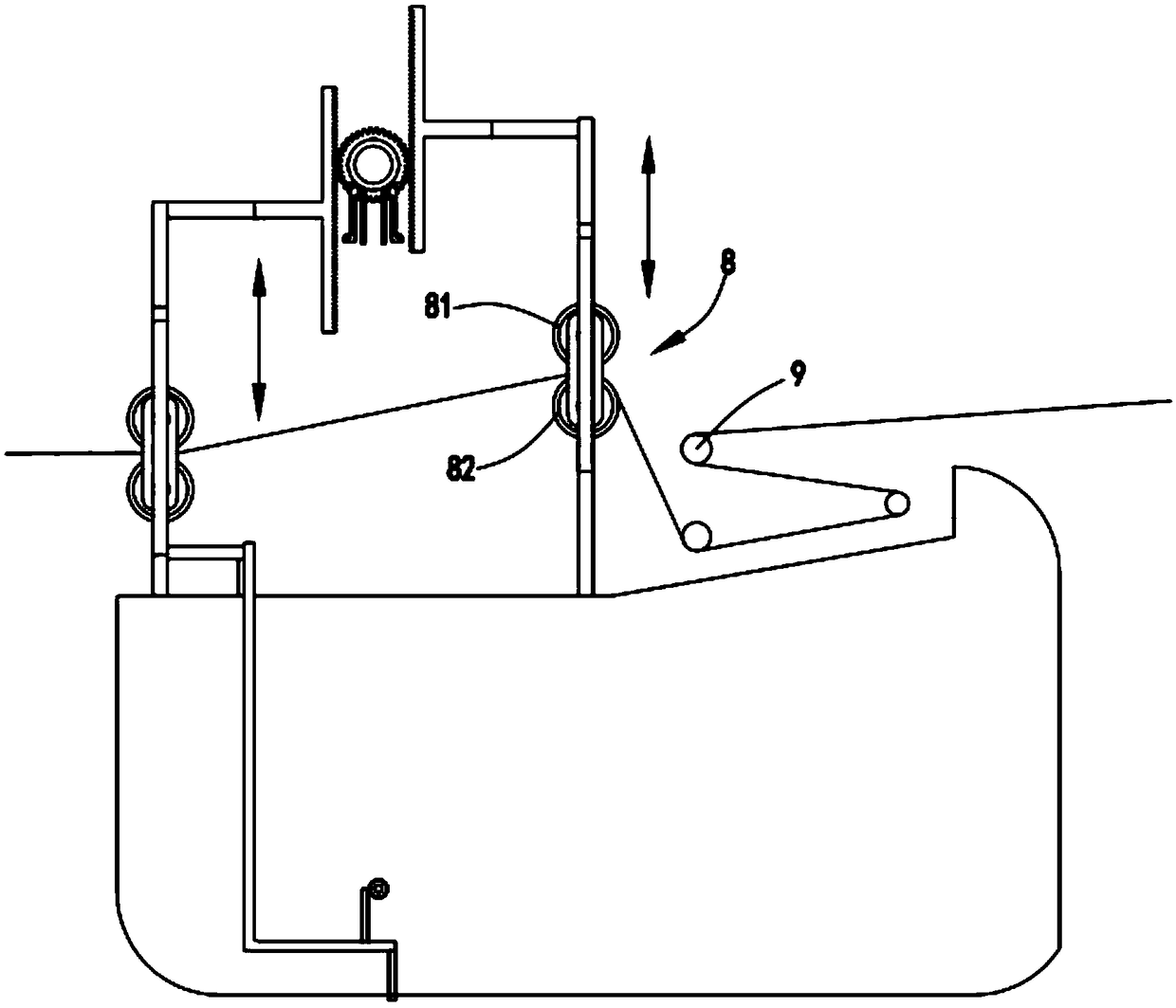

ActiveCN109023762AAvoid the problem that the color is light and affects the dyeing effectImprove dyeing effectTextile treatment machine arrangementsTextile treatment by spraying/projectingEngineeringCoarse particle

The invention relates to a high-efficiency textile fabric printing and dyeing treatment system and process. The process involves a dye box, wherein a first spray dyeing mechanism and a second spray dyeing mechanism are arranged in the dye box, and each of the first spray dyeing mechanism and second spray dyeing mechanism comprises a filtrate assembly fixed on the inner wall of the dye box, a squeezing and grinding assembly arranged in the corresponding filtrate assembly and a spray dyeing assembly arranged at the upper end of the corresponding filtrate assembly; a driving mechanism is arrangedbetween the first spray dyeing mechanism and the second spray dyeing mechanism and drives the two squeezing and grinding assemblies to rise and fall alternately, the filtrate assemblies extract a dyeliquor at the bottom of the dye box when the squeezing and grinding assemblies move upward, the dye liquor in the filtrate assemblies is squeezed to be filtered when the squeezing and grinding assemblies move downward so that the dye liquor is sprayed from a front spray dyeing assembly and a rear spray dyeing assembly to dye a fabric, and the squeezing and grinding assemblies move downward continuously after dye liquor squeezing and spray dyeing are completed to grind the coarse-particle dye remaining in the filtrate assemblies. The high-efficiency textile fabric printing and dyeing treatmentsystem and process solve the problems that the fabric dyeing mode is single, the dye liquor is stratified, the dyeing effect is poor, dyeing is nonuniform, and the dye utilization rate is low.

Owner:浙江盛邦化纤有限公司

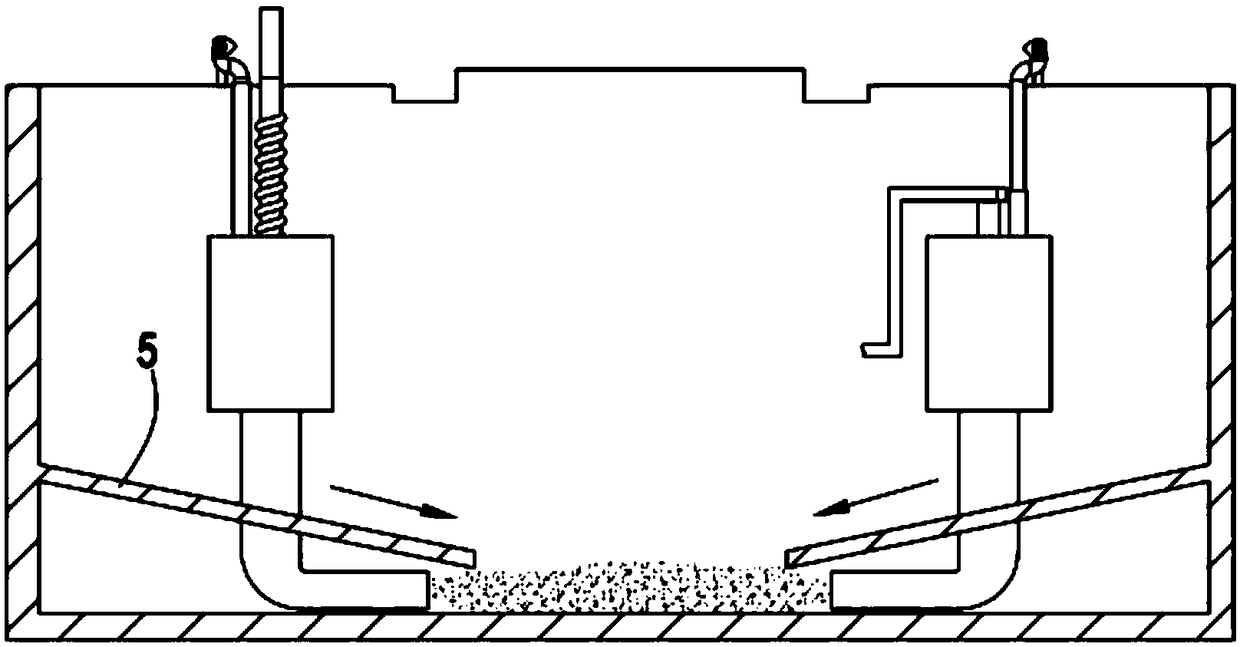

High-elasticity environment-friendly fabric printing and dyeing system and process thereof

ActiveCN108866862AImprove dyeing effectQuality improvementTextile treatment machine arrangementsTextile/flexible product manufactureEngineeringImpurity

The invention relates to a high-elasticity environment-friendly fabric printing and dyeing system and a process thereof. Equipment comprises a dyestuff box in which a dye liquor guiding mechanism is arranged, the tail end of the dye liquor guiding mechanism is provided with a liquid outlet, the dye liquor guiding mechanism is provided with a first squeezing mechanism, a power mechanism and a second squeezing mechanism from front to back; the first squeezing mechanism and the second squeezing mechanism are driven by the power mechanism to go up and down alternately so as to squeeze dye liquor in the dye liquor guiding mechanism, and the dye liquor flows out of the liquid outlet to wash fabric; a grinding mechanism is arranged between the first squeezing mechanism and the second squeezing mechanism and comprises a lower grinding component, an upper grinding component and a driving component, course particle dyestuff is deposited on the lower grinding component, and the first squeezing mechanism drives the upper grinding component downwards to move to the lower grinding component and drives the driving component to move downwards to enable the upper grinding component to grind coarseparticle dyestuff on the lower grinding component; the high-elasticity environment-friendly fabric printing and dyeing system can be used for solving the problems that the dyeing of the fabric is notgood, impurities are easily adhered to dyed fabric, the dyestuff is poor in uniformity and is layered up and down, and the dyestuff use ratio is not high.

Owner:CHANGXING DEHONG MACHINERY CO LTD

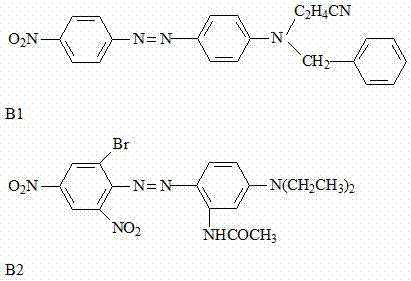

Black liquid dispersing dye with characteristics of high color fastness and low brightness, and preparation method thereof

ActiveCN107163620AReduce usageHigh dye utilization rateOrganic dyesDyeing processNonionic surfactantSURFACTANT BLEND

The invention discloses a black liquid dispersing dye with characteristics of high color fastness and low brightness, and a preparation method thereof, wherein the raw dye of a black dye compound, an anionic surfactant, a nonionic surfactant, a polyacrylate copolymer, amino silicone oil, benzisothiazolinone and water are mixed, and the obtained mixture is grinded to prepare the black liquid dispersing dye. According to the present invention, the prepared black liquid dispersing dye can improve the dyeing depth of the printed fabric, reduce the loose color of the dye, improve the color fastness of the dyed product, save the effective use amount of the dye when the dyeing product having the same brightness is achieved, significantly reduce the reduction washing and water washing tasks after the printing, save the water resource and the energy consumption, and reduce the wastewater treatment cost.

Owner:SUZHOU UNIV

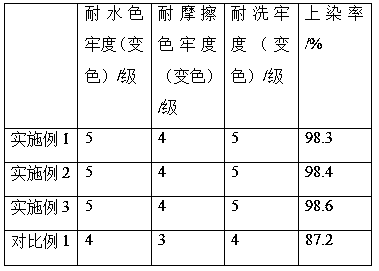

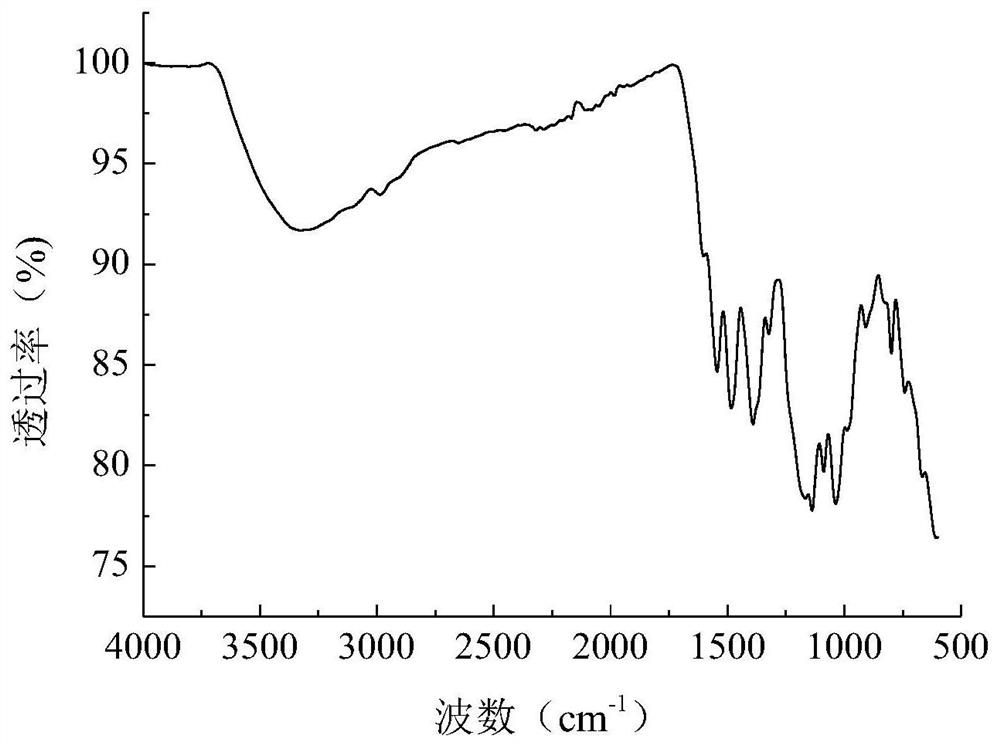

Phthalocyanine-azo double-chromophore activated dye having a high fixation rate and a preparing method and application thereof

ActiveCN109021614AHigh affinityOvercome CompatibilityReactive dyesDyeing processFiberRegenerating fibers

The invention relates to phthalocyanine-azo double-chromophore activated dye having a high fixation rate and a preparing method and application thereof. The method includes copper phthalocyanine chlorosulfonation to prepare a phthalocyanine turquoise blue base, a first time of condensation, a second time of condensation, diazotization and a coupling reaction to obtain the activated dye having a high fixation rate. The dye is suitable for pattern printing for cotton, artificial cotton, linen, regenerated fibers and textiles thereof, and has a high fixation rate, bright color, excellent improving performance, good washable fastness, good color fastness to rubbing and a good application prospect.

Owner:DONGHUA UNIV

Making method of high-color fastness dye-free ultrafine fiber synthetic leather base

The invention relates to a making method of a high-color fastness dye-free ultrafine fiber synthetic leather base. The making method comprises the following steps: base cloth decrement, impregnation in colored aqueous polyurethane, polyurethane solidification and post-treatment. The ultrafine fiber synthetic leather base made in the invention has the advantages of full color, high color fastness and no dyeing. The making method of the ultrafine fiber synthetic leather base has the advantages of small dye use amount in the making process, high dye utilization rate, and no use of toluene, dimethyl formamide or other organic solvents, and is environmentally friendly.

Owner:山东济清科技服务有限公司

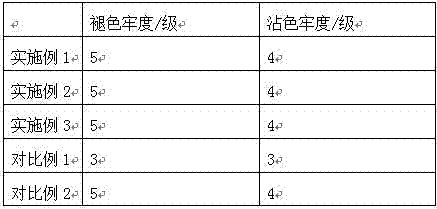

Nylon 6 fishing net dyeing process

InactiveCN107059436ASolve uneven dyeing, dyeing flowersSolve chromatic aberrationDyeing processNylon 6Pulp and paper industry

The invention discloses a nylon 6 fishing net dyeing process. The nylon 6 fishing net dyeing process comprises the following steps: (1) preprocessing, (2) dyeing and (3) color fixing. The problems of uneven dyeing, flower dyeing, aberration and color defect which are easily caused in dyeing of nylon 6 fishing nets can be solved. The utilization rate of dyestuff and the color fastness are improved, dyeing processing risks are reduced, the semi-dyeing time of the dyestuff can be greatly reduced, the dyeing speed is increased, a certain amount of cactus extracting solution is added during dyeing, a dye liquor treatment environment is gentle, damage to the nylon 6 fishing net is small, the use performance of the nylon 6 fishing net is not affected, and meanwhile, the dyeing speed is not reduced.

Owner:CHAOHU XIANGYU FISHING GEAR

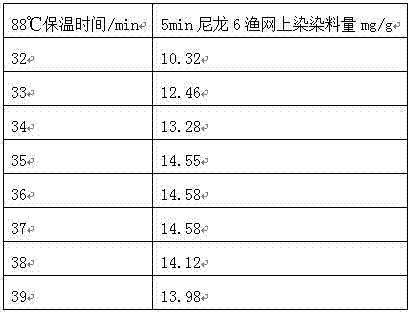

PVA non -woven embroidery dyeing method and its dyeing device

ActiveCN109577043BReduce hydrophilicityHigh color fixing rateTextile treatment machine arrangementsLiquid/gas/vapor removal by gas jetsPolymer scienceNonwoven fabric

The invention discloses a dyeing and finishing method of a PVA non-woven fabric embroidery and a dyeing and finishing device thereof. The dyeing and finishing method includes scouring and bleaching, and comprises the following steps of: firstly, performing raw cloth inspection, cloth turning process and sewing process on the PVA non-woven fabric embroidery; then quickly wiping the PVA non-woven fabric embroidery on a hot metal surface while keeping the temperature of the metal surface to 750-850 DEG C; carrying out desizing treatment on the PVA non-woven fabric embroidery with hydrogen peroxide; then preparing a scouring working solution while controlling the temperature at 45-50 DEG C; putting the fabric having the liquid rolling treatment into a steam box for steaming and then rinsing for 30-50 minutes; finally, preparing 15-20 mol / L sodium hydroxide solution, and putting the fabric into sodium hydroxide solution to react for 15 to 30 minutes. By using the dyeing and finishing method, the cloth is dyed and finished, so that the cloth has good effects of oxidation resistance, wear resistance, sterilization, color fixation, flame retardance and fragrance enhancement. By using the dyeing and finishing device, dyeing color on the cloth is more even, which is more convenient to use.

Owner:汕头市坤兴刺绣有限公司

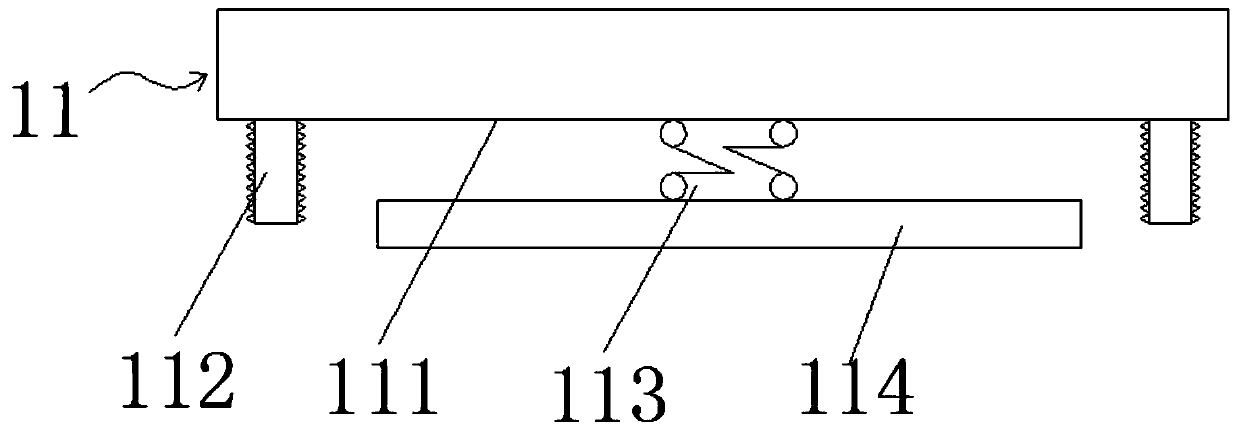

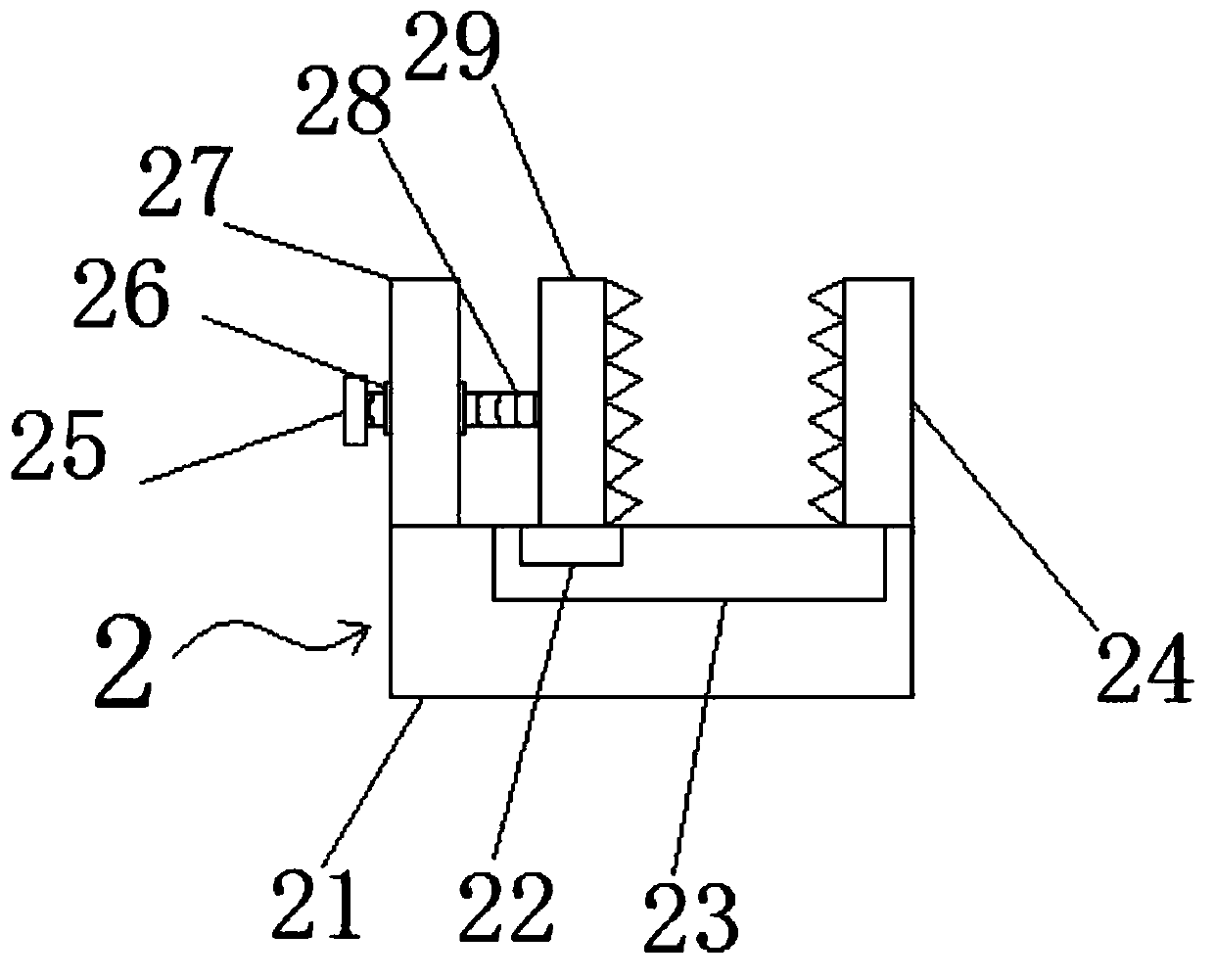

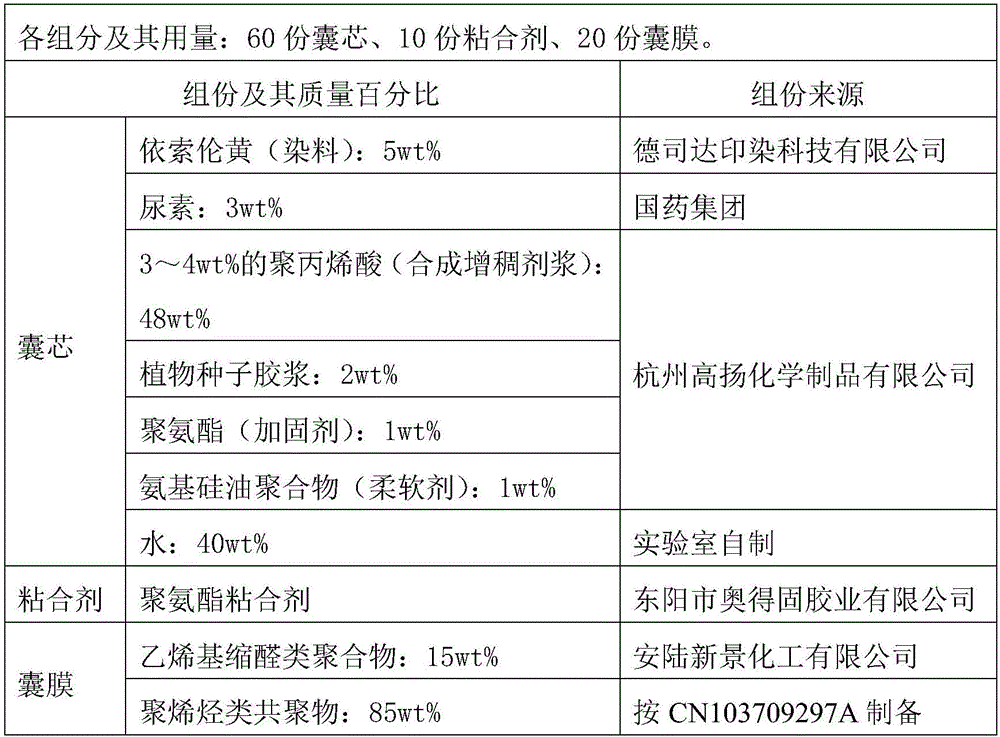

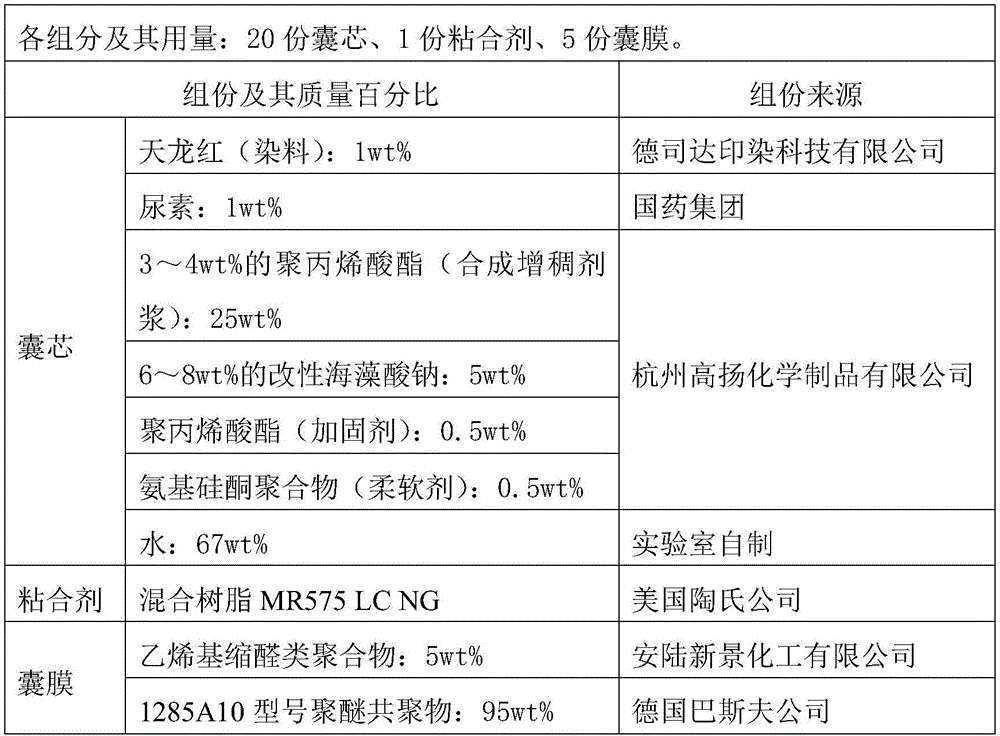

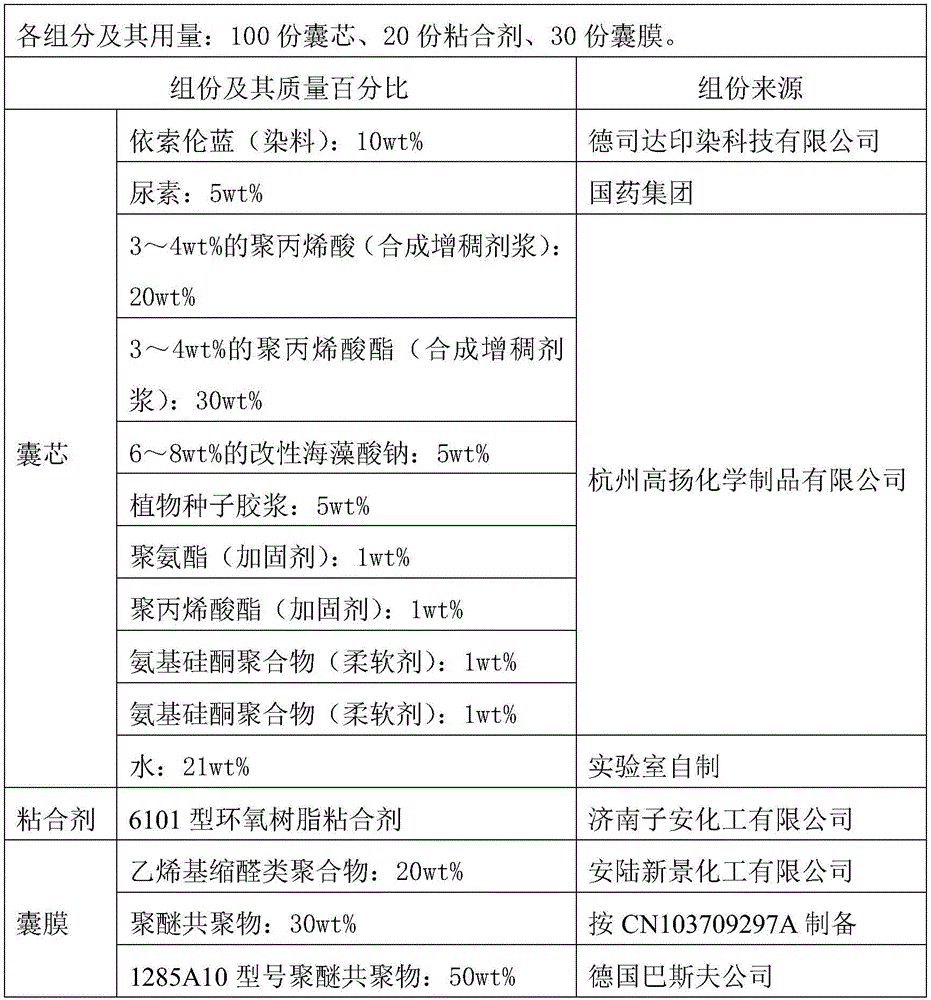

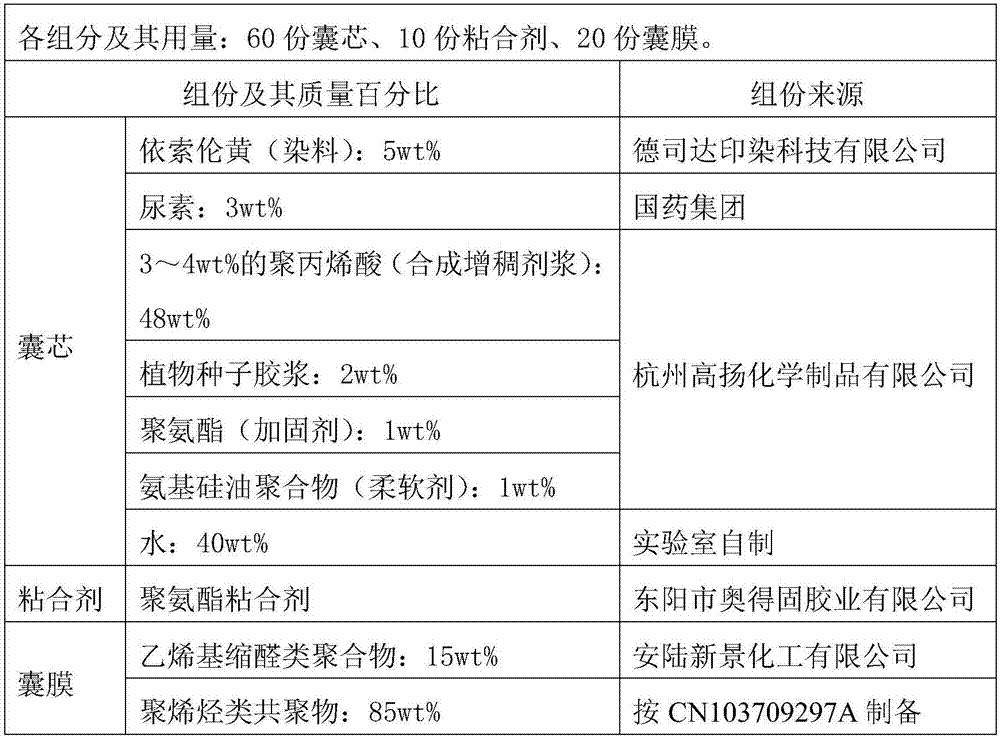

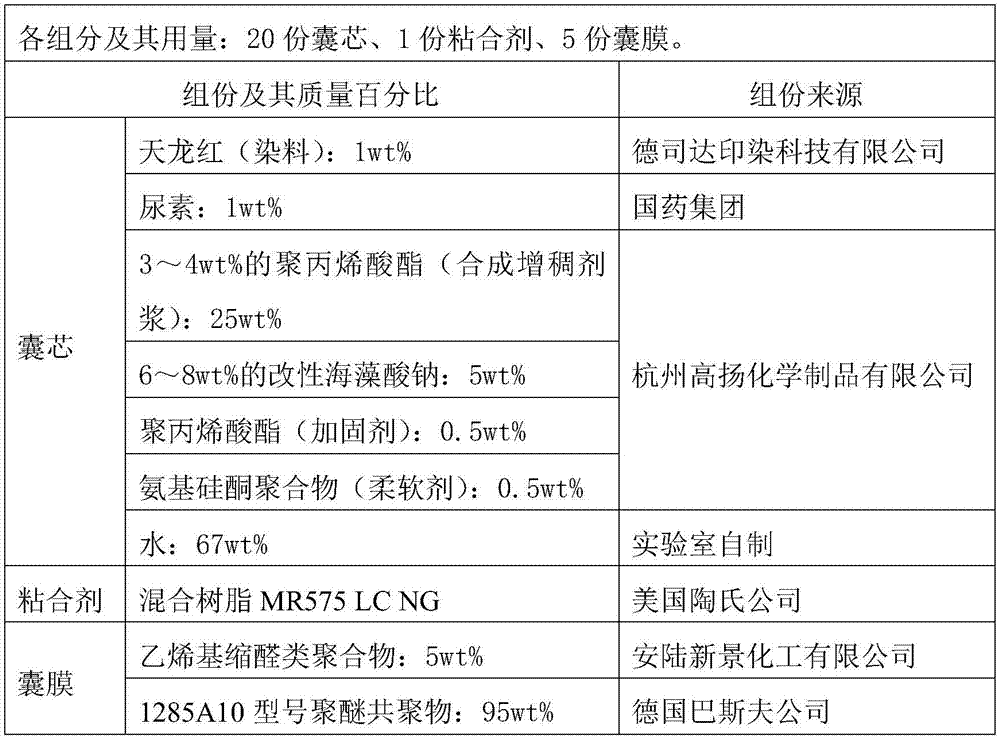

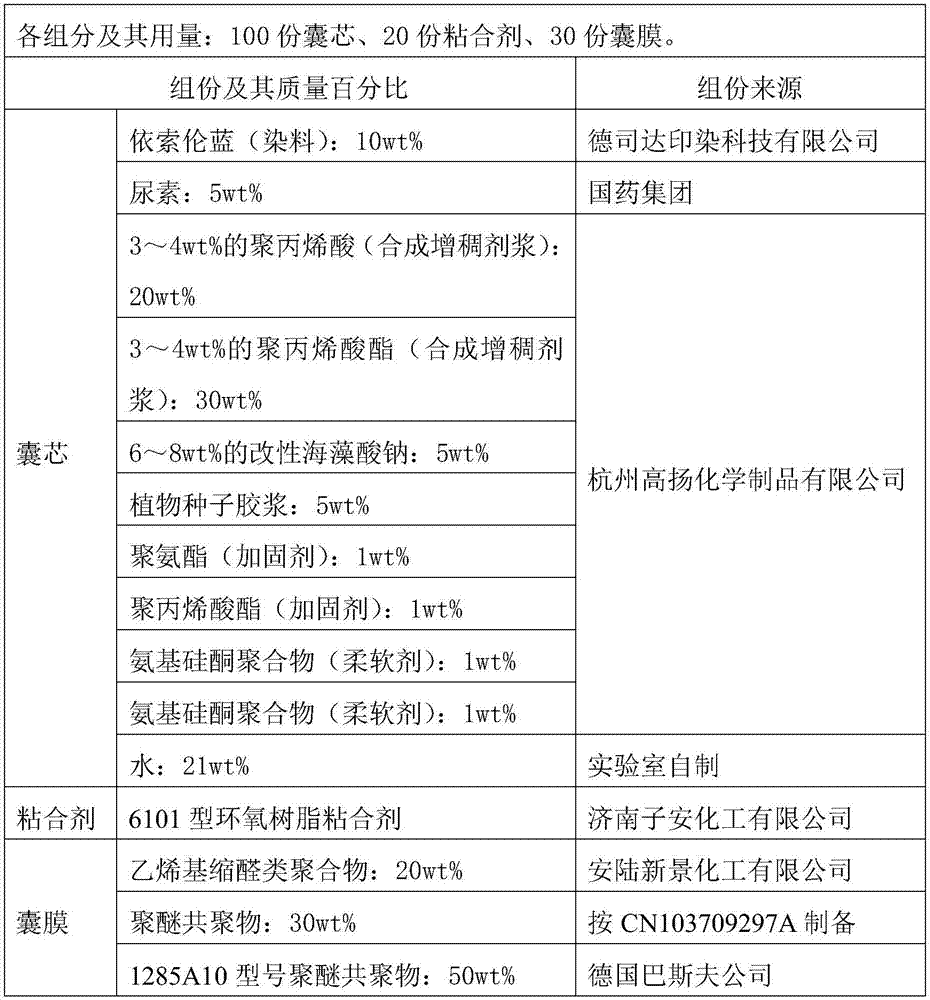

Printing paste for silk fabric and printing technology with printing paste

InactiveCN105862464AReduce the high concentration of capsule coreReduce concentration too lowDyeing processOther printing apparatusUreaPre treatment

The invention aims at providing a printing paste for silk fabric and a printing technology with the printing paste. Dye printing evenness can be improved. The printing paste comprises, by weight, 20-100 parts of capsule cores, 1-20 parts of bonding agent and 5-30 parts of capsule films; the capsule cores comprise, by weight, 1%-10% of dye, 1%-5% of urea and 30%-60% of paste materials; the capsule films comprise, by weight, 5%-20% of vinyl acetal polymers and 80%-95% of polyether and / or polyolefins copolymers. The printing technology with the printing paste includes the following steps that S1, the silk fabric is pretreated; S2, the printing paste is prepared with the method; S3, under the condition that pH is equal to 6.0 to 6.5, the printing paste prepared in the S2 is used for printing the silk fabric pretreated in the S1; S4, the printed silk fabric obtained in the S3 is dried, aged, cleaned and finished.

Owner:李振斌

High quality printing and dyeing mechanism of textile fabric

ActiveCN109056215AIncrease profitImprove uniformityTextile treatment machine arrangementsTextile treatment by spraying/projectingEngineeringGuide tube

The invention relates to a high quality printing and dyeing mechanism of textile fabric, which comprises a dye box. A spray dyeing mechanism is arranged in the dye box, wherein the spray dyeing mechanism comprises a filter assembly, a grinding assembly arranged in the filter assembly and a spray dyeing assembly arranged on the filter assembly; the grinding assembly moves upward so that the filterassembly extracts the dye solution at the bottom of the dye box, and moves downward so that the filter assembly compresses the dye solution in the filter assembly and filters the dye solution. The filtered dye solution sprays out through the spray dyeing assembly. After the solution is sprayed and dyed, the grinding assembly continues to move downwards to grind the coarse particle dye remaining inthe filter assembly. A plurality of cloth guide rollers are arranged in the dye box, and the fabric is transmitted from the dye box from the bottom to the top under the guidance of the cloth guide rollers. The spray dyeing assembly comprises a duct a and a spray dyeing tube a and a spray dyeing tube b. The spray dyeing tube a and the spray dyeing tube b are respectively arranged on both sides ofthe fabric; the high quality printing and dyeing mechanism of textile fabric solves the problems of poor dyeing effect, uneven dyes, easy deposition of dyes at the bottom and staining impurities on the surface of fabric after dyeing.

Owner:浙江盛邦化纤有限公司

Reactive dye moist fixation and dyeing method

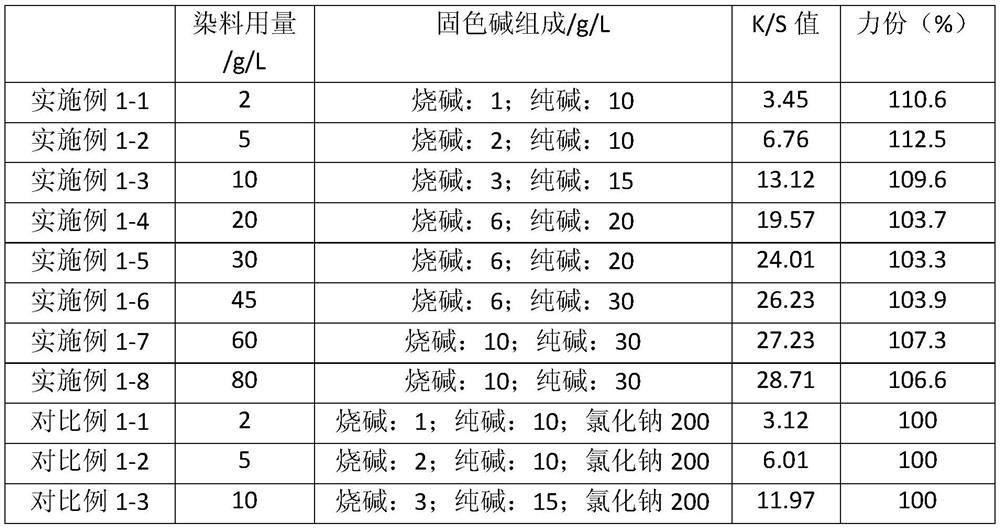

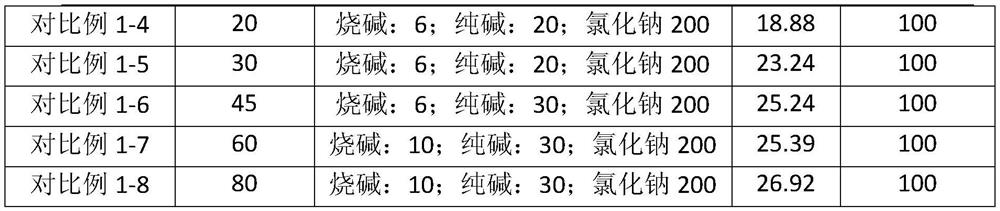

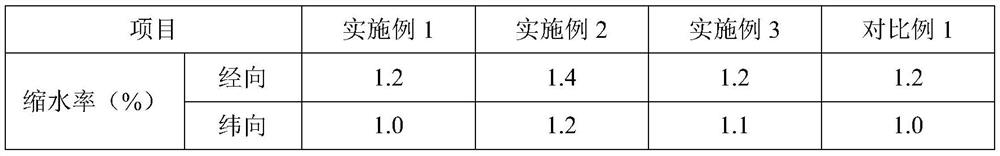

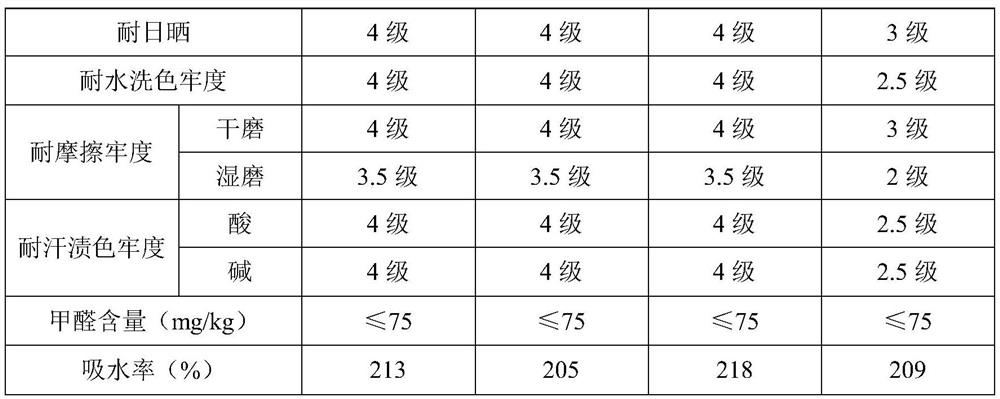

ActiveCN113529440AReduce consumptionReduced activityTextile storage in superimposed formSucessive textile treatmentsFiberInorganic salts

The invention relates to a reactive dye moist fixation and dyeing method. The method comprises the following steps of padding of a fabric in a dye liquor containing a reactive dye and an alkaline agent, pre-drying, rolling and piling. The method can reduce the energy consumption, solves the problem of relatively high inorganic salt consumption in a conventional reactive dye pad-drying pad-steaming process, improves the technical problem of relatively long piling time in a conventional cold pad-batch process, and has the advantages of improved fixation rate, high fabric color yield, no color difference, no phenomenon of seam allowance printing frequently occurring in conventional cold pad-batch dyeing and no seam allowance printing defects. Furthermore, the reactive dye moist fixation and continuous dyeing method can also be used for one-step dyeing of a multi-component fiber fabric, the defects that in the prior art, a two-step dyeing process of the multi-component fiber fabric is complex and low in efficiency are overcome, the technological process is shortened, the environmental pollution is reduced, and the dyed fabric which is uniform in colored light and full in cloth cover can be obtained.

Owner:HUAFANG +2

A kind of preparation method of Yidalun fiber raschel blanket

ActiveCN112030342BRich patternsFeel smooth and comfortableWarp knittingHeating/cooling textile fabricsYarnPolyester

The invention discloses a preparation method of Yidalun fiber Raschel blanket. The steps are as follows: (1) Weaving: using Yidalun fiber as plush yarn, polyester full-drawn yarn as bottom yarn, and using full-wearing same-direction (2) Pre-finishing: Pre-finish the gray cloth after pre-shaping along the wool, pre-ironing against the wool, high combing along the wool, and alternating ironing against the wool to obtain the pre-finishing (3) Printing and softening: the gray cloth after pre-finishing is printed, steamed, washed and softened, and then dehydrated to obtain the printed gray cloth; (4) Finishing: the gray cloth after dyeing and finishing is dried Shaping, combing along the wool, fluffing against the wool, ironing on the front, ironing on the front, ironing on the back, ironing on the back, cutting and sewing the Yidalun fiber raschel blanket. The invention uses Yidalun fiber as a raw material to realize water-less / water-less printing and washing processes, has a high utilization rate of dyestuffs, and finally produces a raschel blanket with rich patterns and fully meets market demands.

Owner:ZHEJIANG TRUELOVE GROUP

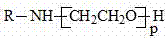

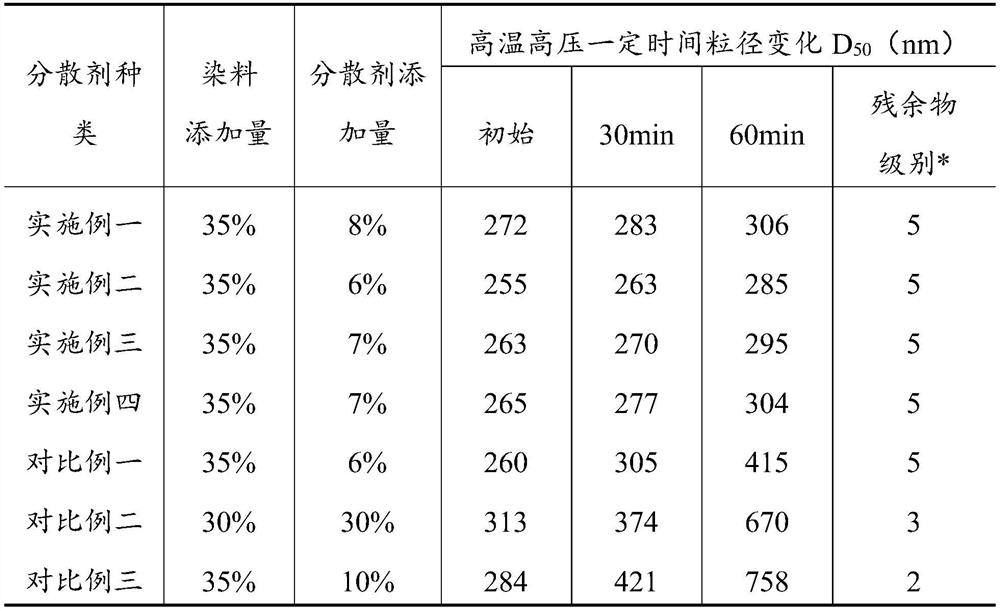

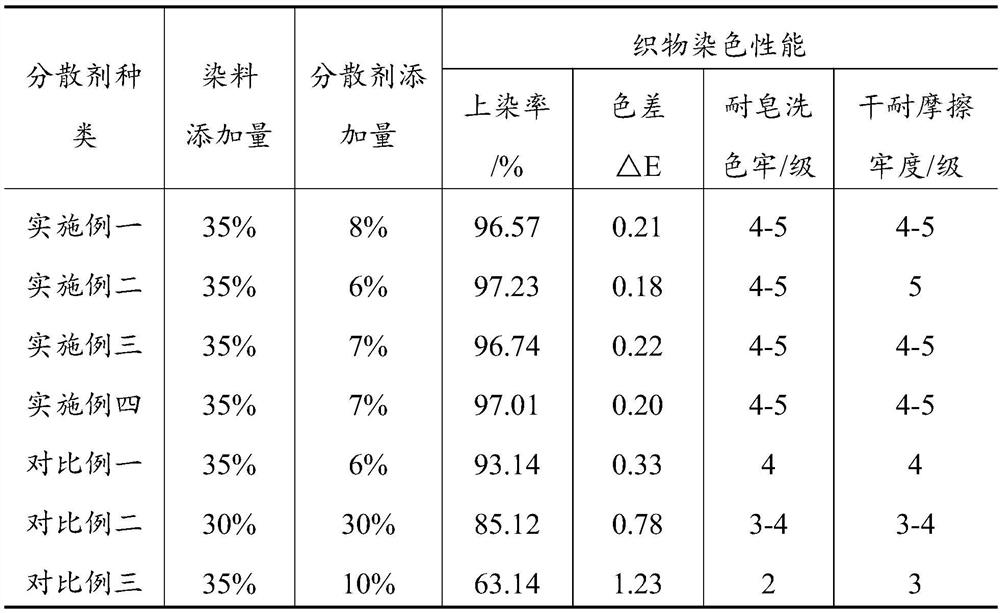

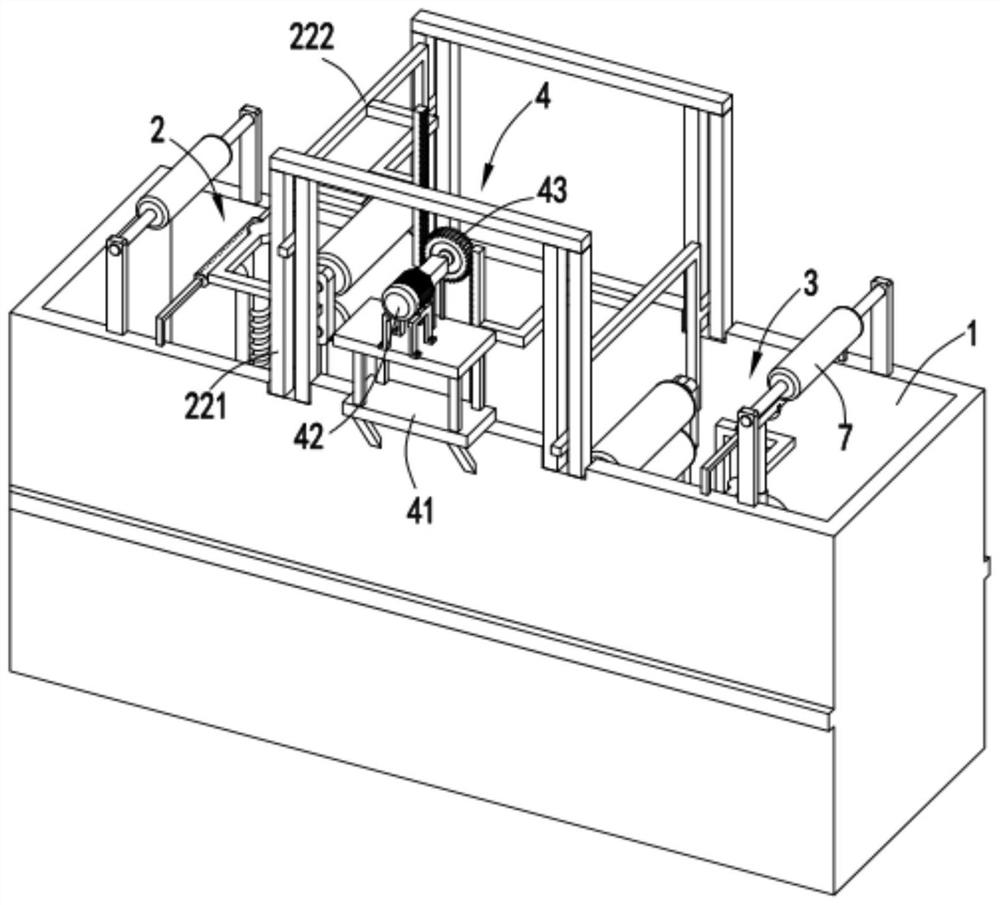

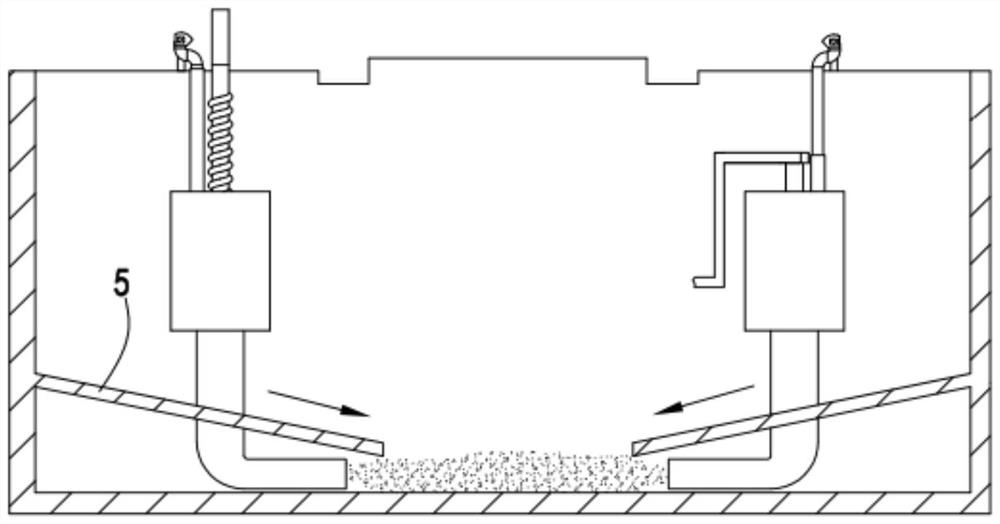

A kind of comb-type disperse dye dispersant and preparation method thereof

ActiveCN111269429BBuild a Triple Dispersion StructureSolve the problem of incomplete cladding and anchoringDyeing processDisperse dyePtru catalyst

The invention provides a comb-type disperse dye dispersant and a preparation method thereof, which has good high temperature and high pressure resistance effect, effectively ensures the stability of dye particles of disperse dyes in the high temperature and high pressure dyeing process, reduces the agglomeration and coagulation of dye particles, and has good System adaptability. Comb-type dispersing dye dispersants include styrene maleic anhydride copolymers, polyethylene glycol ether monoalcohols, cyclic structure-containing alkyl alcohols, modified starches and catalysts. The preparation method includes: under nitrogen protection, adding polyethylene glycol ether monoalcohol and alkyl alcohol containing a cyclic structure, heating to 80-100 DEG C, after completely dissolving, adding styrene maleic anhydride copolymer, and heating up to 120 °C ~140 ℃, dissolve completely; add catalyst, heat preservation reaction for 5 to 10 hours; cool down to 100~120 ℃, add modified starch, heat preservation reaction for 2 to 3 hours; add water, dilute to solid content of 40~60%, use The sodium hydroxide solution is adjusted to pH 5.0 to 7.0, that is, it is obtained.

Owner:SHANGHAI YUKING WATER SOLUBLE MATERIAL TECH

A high-efficiency printing and dyeing treatment system and process for textile fabrics

ActiveCN109023762BImprove dyeing effectIncrease profitTextile treatment machine arrangementsTextile treatment by spraying/projectingPolymer scienceEngineering

The invention relates to a high-efficiency textile fabric printing and dyeing treatment system and process. The process involves a dye box, wherein a first spray dyeing mechanism and a second spray dyeing mechanism are arranged in the dye box, and each of the first spray dyeing mechanism and second spray dyeing mechanism comprises a filtrate assembly fixed on the inner wall of the dye box, a squeezing and grinding assembly arranged in the corresponding filtrate assembly and a spray dyeing assembly arranged at the upper end of the corresponding filtrate assembly; a driving mechanism is arrangedbetween the first spray dyeing mechanism and the second spray dyeing mechanism and drives the two squeezing and grinding assemblies to rise and fall alternately, the filtrate assemblies extract a dyeliquor at the bottom of the dye box when the squeezing and grinding assemblies move upward, the dye liquor in the filtrate assemblies is squeezed to be filtered when the squeezing and grinding assemblies move downward so that the dye liquor is sprayed from a front spray dyeing assembly and a rear spray dyeing assembly to dye a fabric, and the squeezing and grinding assemblies move downward continuously after dye liquor squeezing and spray dyeing are completed to grind the coarse-particle dye remaining in the filtrate assemblies. The high-efficiency textile fabric printing and dyeing treatmentsystem and process solve the problems that the fabric dyeing mode is single, the dye liquor is stratified, the dyeing effect is poor, dyeing is nonuniform, and the dye utilization rate is low.

Owner:浙江盛邦化纤有限公司

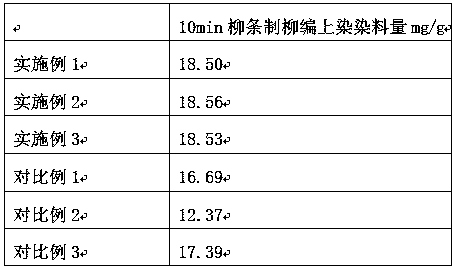

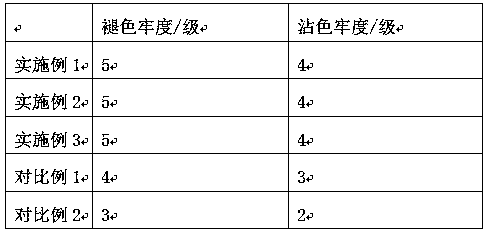

A kind of dyeing method of willow made of wicker

InactiveCN107243968BHigh coloring rateHigh fastnessWood treatment detailsReed/straw treatmentDye uptakeColor difference

Owner:阜南县宏达工艺品厂

A kind of preparation method of dyeing-free superfine fiber synthetic leather base with high color fastness

The invention relates to a making method of a high-color fastness dye-free ultrafine fiber synthetic leather base. The making method comprises the following steps: base cloth decrement, impregnation in colored aqueous polyurethane, polyurethane solidification and post-treatment. The ultrafine fiber synthetic leather base made in the invention has the advantages of full color, high color fastness and no dyeing. The making method of the ultrafine fiber synthetic leather base has the advantages of small dye use amount in the making process, high dye utilization rate, and no use of toluene, dimethyl formamide or other organic solvents, and is environmentally friendly.

Owner:山东济清科技服务有限公司

Composition for one-bath process of woven fabric destaining and preparation method thereof

ActiveCN108486855BSoft feelReduce usageDry-cleaning apparatus for textilesDyeing processCelluloseCarboxymethyl cellulose

The invention belongs to the technical field of textile auxiliary agents, and particularly relates to a composition for a woven fabric desizing and dyeing one-bath technology and a preparation methodthereof. The composition comprises the following raw materials in percent by mass: 15-25% of sodium myristoyl glutamate, 15-25% of sodium cocoyl isethionate, 8-12% of sodium carboxymethyl cellulose, 8-12% of a diffusant MF and the balance of water. The composition can be combined with other auxiliary agents, improves the coloring rate and the color fastness of fabric, has high dyeing rate, can effectively prevent a re-attachment phenomenon of a sizing agent or impurities dissolved or shedding in a water bath, has relatively strong dispersing and level dyeing capabilities, improves the dyeing quality, has a good overall dyeing effect, and can maintain a relatively good soft hand feel of the fabric.

Owner:石狮市万峰盛漂染织造有限公司

A class of high-fixation rate phthalocyanine azo dichromate reactive dyes and its preparation method and application

ActiveCN109021614BHigh affinityNew structureReactive dyesDyeing processTextile printerPhthalocyanine

The invention relates to phthalocyanine-azo double-chromophore activated dye having a high fixation rate and a preparing method and application thereof. The method includes copper phthalocyanine chlorosulfonation to prepare a phthalocyanine turquoise blue base, a first time of condensation, a second time of condensation, diazotization and a coupling reaction to obtain the activated dye having a high fixation rate. The dye is suitable for pattern printing for cotton, artificial cotton, linen, regenerated fibers and textiles thereof, and has a high fixation rate, bright color, excellent improving performance, good washable fastness, good color fastness to rubbing and a good application prospect.

Owner:DONGHUA UNIV

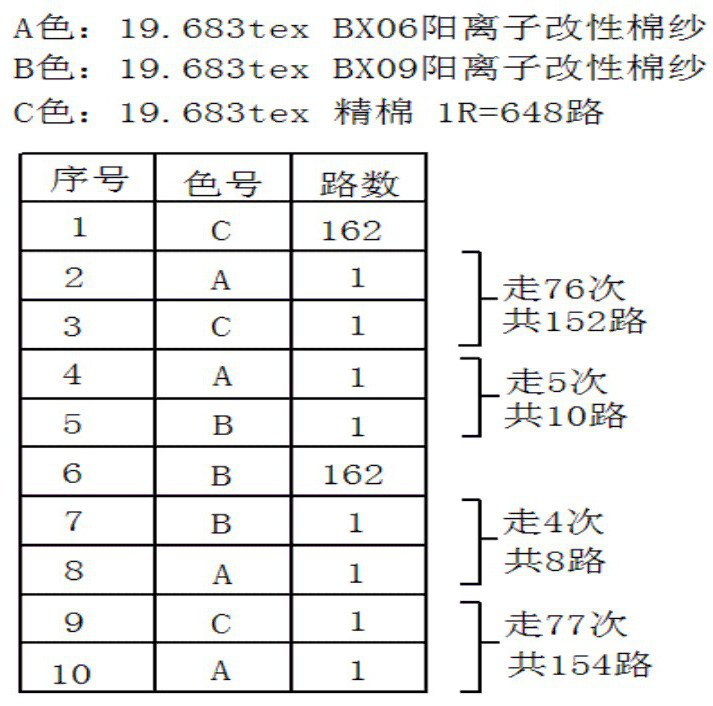

Preparation process of cation modified cotton fiber knitted fabric

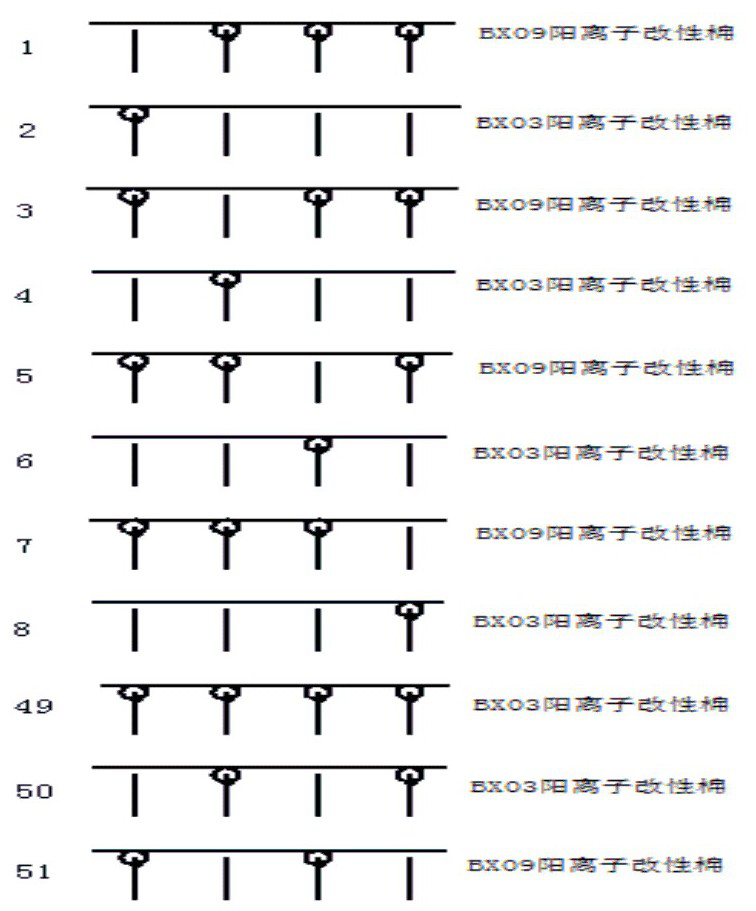

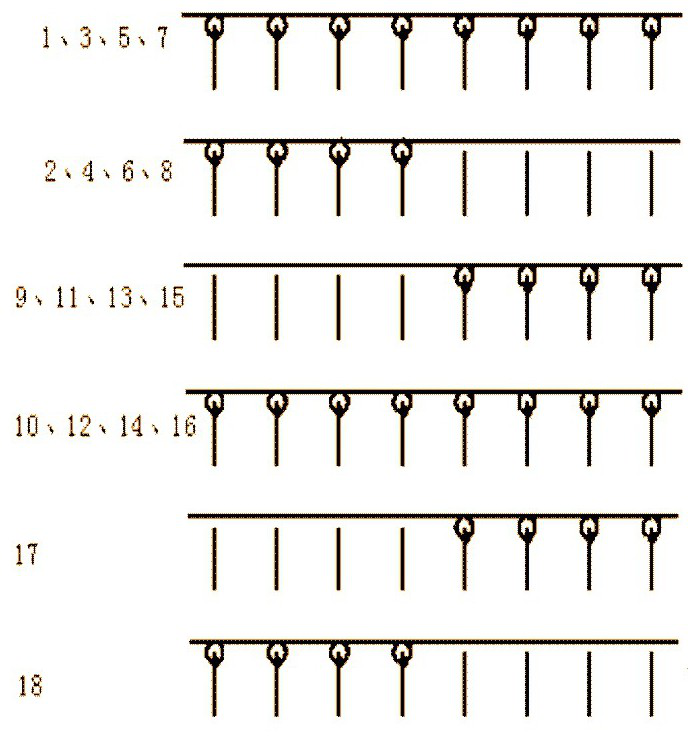

InactiveCN112877877AHigh color fastnessReduce usageWeft knittingHeating/cooling textile fabricsYarnPolymer science

The invention discloses a cation modified cotton fiber knitted fabric. The fabric adopts cation modified cotton yarns, refined cotton and spandex as raw materials; salt-free and alkali-free dyeing and finishing process treatment of the fabric, which is prepared from yarns through a knitting process, is conducted; and according to the dyeing process of the cation modified cotton fabric, salt-alkali-free auxiliary agents do not need to be added, the whole dyeing time is 5 hours, the dyeing time is 3 hours faster than that of a common unmodified cotton knitted fabric, the dyeing fastness is good, and the requirement of wearability of the fabric is met.

Owner:中山国泰染整有限公司 +1

Modified cotton fiber, denim effect cloth and preparation method thereof

The invention discloses a modified cotton fiber, a denim effect cloth and a preparation method thereof. The preparation method of the denim effect cloth comprises the following steps: mixing the modified cotton fiber and other fibers at a mass ratio of 1‑99:99‑1, Spin into yarn, then weave into cloth, and finally carry out dyeing and finishing. In the dyeing and finishing process, no salt is added to obtain the denim effect cloth; the treatment method of the modified cotton fiber is: the cotton fiber is modified with cationic The mixture is mixed with the cationic modifier solution, heated to 20-80°C, and soaked for 1-30min. The mass ratio of the cationic modifier to the cotton fiber is 0.01-0.1:1. By using the method of the invention, the mixed-color fancy denim effect can be dyed at one time, the product delivery period is shortened, the use of dyes and auxiliary agents is reduced, the times of washing and soaping are reduced, and energy saving and emission reduction are achieved. The blended fabric of this environment-friendly and functional fiber also has the advantages of fashion, technology and high added value of the product.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD +1

A kind of environment-friendly liquid bromoindigo dye composite additive additive and preparation method thereof

InactiveCN103628330BImprove storage dispersion stabilityImprove dye uptakeDyeing processDispersion stabilityAdditive ingredient

Provided are an environmental protection-type liquid bromo indigo dye composite addition auxiliary agent and a preparation method therefor. The addition auxiliary agent comprises the following ingredients, by weight, 10-40% of dispersants, 5-20% of polycarboxylate derivatives, 2-10% of chelating agents, 5-20% of anionic surfactants, 2-10% of nonionic surfactants, 0.05-0.2% of antifoaming agents, and 30-80% of deionized water. The environmental protection-type composite addition auxiliary agent of liquid bromo indigo dyes can improve storage dispersion stability of liquid bromo indigo dyes remarkably, and raises the dye-uptake rate and dye utilization rate of bromo indigo dyes during denim dyeing, and the amount of dyes can be decreased when the same dyeing degree is achieved.

Owner:BEIJING CTA NEW CENTURY BIOTECH

Method for pretreating cotton fabrics by adopting glucoamylase/glucose oxidase, pectinase and CBD (cellulose-binding domain)-lignin peroxidase

InactiveCN102154810BImprove qualityImprove dyeing qualityBiochemical fibre treatmentDry-cleaning apparatus for textilesPectinaseChemical treatment

The invention provides a method for pretreating cotton fabrics by adopting glucoamylase / glucose oxidase, pectinase and CBD (cellulose-binding domain)-lignin peroxidase, belonging to the technical field of cotton fabric dyeing and finishing pretreatment. The method is characterized in that the cotton fabrics are firstly treated in mixed enzyme solution containing the glucoamylase and the glucose oxidase and the glucoamylase catalyzes the starch size on the fabrics to be decomposed into glucose so as to eliminate the size; the glucose oxidase catalyzes the glucose and oxygen to act to generate hydrogen peroxide; the generated hydrogen peroxide not only plays a role of bleaching but also can damage the hydrophobic surface structure of the cotton to expose the lower pectic substances; then the cotton fabrics are treated in alkaline pectinase solution to remove the pectic substances through decomposition; and finally the cotton fabrics are treated in CBD-lignin peroxidase solution to finally remove the cotton seed hulls through decomposing the lignin in the cotton seed hulls. The method provided by the invention can replace the traditional chemical treatment method to realize full bio-enzyme pretreatment of the cotton fabrics, and at the same time the traditional hydrogen peroxide can be no longer adopted for bleaching.

Owner:JIANGNAN UNIV +1

Milk protein fiber or its filament or its blended yarn dyeing method and coloured woven fabric producing method

ActiveCN100507129CSolve the problem of not being able to dyeHigh dye utilization rateHeating/cooling textile fabricsWoven fabricsPolyvinyl acetateMilk protein

Owner:SHANGHAI TIQIAO TEXTILE & YARN DYEING

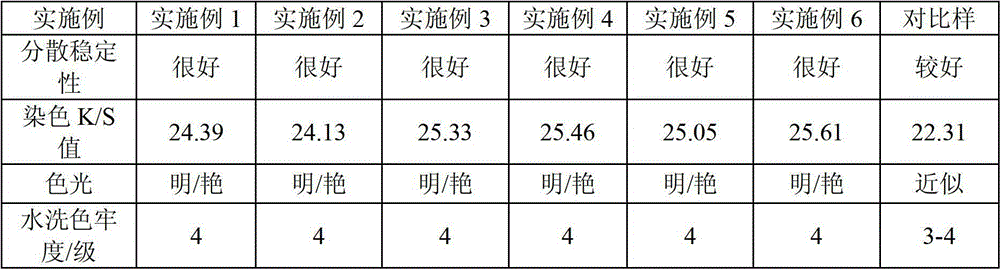

A printing color paste for silk fabrics and a printing process using the printing color paste

InactiveCN105862464BReduction of overconcentrationSpread evenlyDyeing processOther printing apparatusEngineeringCopolymer

The invention aims at providing a printing paste for silk fabric and a printing technology with the printing paste. Dye printing evenness can be improved. The printing paste comprises, by weight, 20-100 parts of capsule cores, 1-20 parts of bonding agent and 5-30 parts of capsule films; the capsule cores comprise, by weight, 1%-10% of dye, 1%-5% of urea and 30%-60% of paste materials; the capsule films comprise, by weight, 5%-20% of vinyl acetal polymers and 80%-95% of polyether and / or polyolefins copolymers. The printing technology with the printing paste includes the following steps that S1, the silk fabric is pretreated; S2, the printing paste is prepared with the method; S3, under the condition that pH is equal to 6.0 to 6.5, the printing paste prepared in the S2 is used for printing the silk fabric pretreated in the S1; S4, the printed silk fabric obtained in the S3 is dried, aged, cleaned and finished.

Owner:李振斌

Dyeing accelerant capable of improving dyeing performance of cotton fabrics

The invention relates to the technical field of novel material research, development and preparation and discloses a dyeing accelerant capable of improving dyeing performance of cotton fabrics. The prepared dyeing accelerant is added into reactive dye diluent to realize dyeing treatment of the cotton fabrics and capable of reducing surface tension of wood in contact with dyes; the dyeing accelerant is high in chemical activity and capable of increasing the degree of freedom of active groups in dye molecules, reducing electrostatic repulsive force and promoting reactive dyes and cotton fabric fibers to form reaction covalent bonds; high leveling performance is achieved, dye hue can be kept, prominent light stability and heat stability are achieved after dyeing, color brightness is guaranteed, and excellent light fastness, fastness to wet rubbing and fastness to sunlight are achieved; besides, water resistance of dyes can be improved, and high fastness to washing and scrubbing is realized.

Owner:安徽竞秀纺织有限公司

A kind of rapid dyeing method of polyester textile

ActiveCN111826972BFast and efficient dyeingAchieve diffusionDyeing processDisperse dyePolymer science

The invention provides a rapid dyeing method for polyester textiles. First, the polyester textiles are washed and dried in a surfactant washing solution to obtain pretreated polyester textiles; then, a disperse dye solution is prepared, a dispersant is added, and the pretreated polyester textiles are put in, followed by Disperse and dry to obtain pretreated polyester textiles; then, put the pretreated polyester textiles into a high boiling point solvent at a predetermined temperature for dyeing to obtain dyed polyester textiles; finally, wash and dry, Complete dyeing of polyester textiles. This method forms an oily "liquid film" on the surface of polyester textiles. Driven by the high-energy oily "liquid film", the disperse dyes quickly enter the polyester textiles. Compared with the traditional polyester dyeing method, the effect of disperse dyes on polyester is significantly improved. Excellent dyeing performance, and the oil bath can be reused, which saves dyeing costs and has the advantages of economical and environmental protection.

Owner:WUHAN TEXTILE UNIV

A high-quality printing and dyeing mechanism for textile fabrics

ActiveCN109056215BIncrease profitImprove uniformityTextile treatment machine arrangementsTextile treatment by spraying/projectingProcess engineeringDyeing

The invention relates to a high-quality printing and dyeing mechanism for textile fabrics, which includes a dye box, and a spraying and dyeing mechanism is arranged in the box, and the spraying and dyeing mechanism includes a filter assembly, a grinding assembly arranged in the filter assembly, and a spraying and dyeing assembly arranged on the filter assembly; The component moves upwards to make the filter component extract the dye liquor at the bottom of the dye tank, squeeze the dye liquor in the filter component and filter the dye liquor when it moves down, the filtered dye liquor is sprayed out through the spraying component, and after the dye liquor spraying is completed The grinding assembly continues to move down to grind the coarse particle dye remaining in the filter assembly; a number of fabric guide rollers are set in the dye box, and the fabric is transported from the bottom to the top under the guidance of the guide rollers to leave the dye box; the spraying assembly includes a conduit a And the dyeing pipe a and the dyeing pipe b arranged at the end of the conduit a, the dyeing pipe a and the dyeing pipe b are respectively arranged on both sides of the fabric; the invention solves the problem of poor dyeing effect of the fabric, uneven dye, and easy deposition at the bottom The problem of impurities attached to the surface of the fabric after dyeing and dyeing.

Owner:浙江盛邦化纤有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com