A kind of comb-type disperse dye dispersant and preparation method thereof

A technology of disperse dyes and dispersants, which is applied in the fields of dyeing, textiles and papermaking, etc. It can solve the problems of self-dispersion reduction, dispersant release, and intensified hydration, so as to improve anchoring stability, improve steric hindrance, Tolerance-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

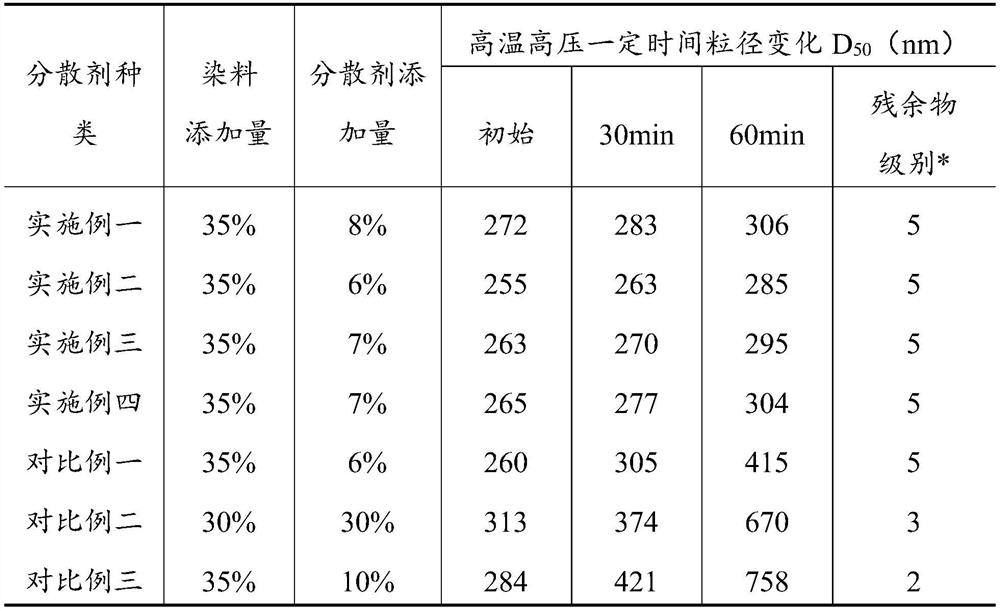

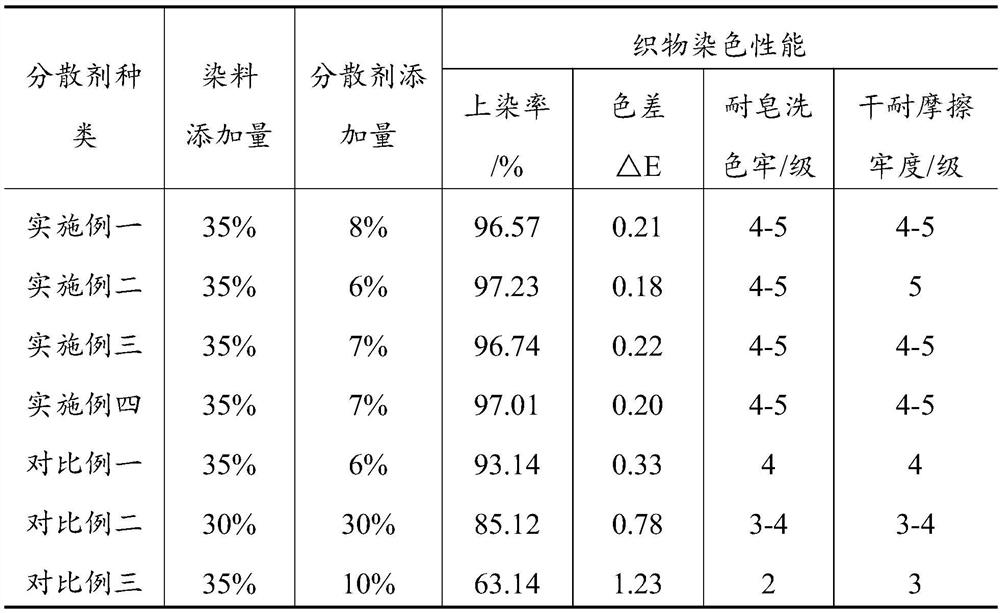

Examples

Embodiment 1

[0027] 1. Under nitrogen protection, add 70 parts of polyethylene glycol ether monomethyl ether (EO=40) and 5 parts of cyclopentanol, heat to 80°C, after completely dissolving, add 10 parts of styrene maleic anhydride copolymer, Mn=2000, MA accounted for 35%, the temperature was raised to 120°C, and the dissolution was complete.

[0028] 2. Add 1 part of catalyst propionic acid, and keep the reaction for 5 hours.

[0029] 3. Cool the temperature to 100°C, add 0.1 part of cross-linking agent carboxymethyl starch, and keep the temperature for 2 hours.

[0030] 4. Add water, dilute to a solid content of 40%, and adjust pH to 5.0 to obtain the comb-shaped dispersant.

Embodiment 2

[0032] 1. Under the protection of nitrogen, add 60 parts of polyethylene glycol ether monobutyl ether (EO=70) and 10 parts of ethyl cyclohexanol, heat to 90°C, and after complete dissolution, add 20 parts of styrene maleic anhydride copolymer. parts, Mn=7500, MA accounted for 20%, and the temperature was raised to 130°C, and the dissolution was complete.

[0033] 2. Add 3 parts of catalyst sulfamic acid, and keep the reaction for 10 hours.

[0034] 3. Cool the temperature to 110°C, add 0.25 part of cross-linking agent carboxymethyl starch, and keep the temperature for 2 hours.

[0035] 4. Add water, dilute to a solid content of 60%, and adjust pH to 6.0 to obtain the comb-shaped dispersant.

Embodiment 3

[0037] 1. Under the protection of nitrogen, add 80 parts of polyethylene glycol ether monohexanol (EO=50) and 7.5 parts of butyl cyclooctanol, heat to 100 ° C, after complete dissolution, add 40 parts of styrene maleic anhydride copolymer, Mn=5000, MA accounted for 30%, and the temperature was raised to 120°C, and the dissolution was complete.

[0038] 2. Add 5 parts of catalyst 4-toluenesulfonic acid, keep the temperature for 8.5 hours.

[0039] 3. Cool the temperature to 120°C, add 0.2 part of cross-linking agent carboxymethyl starch, and keep the temperature for 3 hours.

[0040] 4. Add water, dilute to a solid content of 50%, and adjust pH to 6.5.0 to obtain the comb-shaped dispersant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com