Composition for one-bath process of woven fabric destaining and preparation method thereof

A technology of composition and woven fabrics, applied in dyeing, textiles, papermaking, dry-cleaning fiber products, etc., can solve the problems of fabric dyeing and reattachment, and achieve high dyeing rate, various effects, and good dyeing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

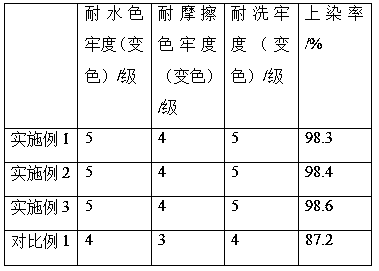

Examples

Embodiment 1

[0018] A composition for one-bath process of woven fabric dedyeing, its raw materials are calculated by mass percentage: sodium myristoyl glutamate 15%, sodium cocoyl isethionate 15%, sodium carboxymethyl cellulose 8%, diffuser MF 8%, and the balance is water.

[0019] The preparation method of the composition that is used for the one-bath process of woven fabric destaining, comprises the following steps:

[0020] (1) Weigh each raw material according to the formula ratio;

[0021] (2) Add sodium myristoyl glutamate and sodium cocoyl isethionate into the reaction kettle, then add water, and mix and stir for 20 minutes;

[0022] (3) Add sodium carboxymethylcellulose and stir for 20 minutes, then raise the temperature to 50°C, continue stirring for 10 minutes, and wait for the foam to disappear;

[0023] (4) Add the diffusing agent MF to the mixture in step (3), and then fully stir for 10 minutes to prepare the composition.

Embodiment 2

[0025] A composition for one-bath process of woven fabric dedyeing, its raw materials are calculated by mass percentage: sodium myristoyl glutamate 20%, sodium cocoyl isethionate 20%, sodium carboxymethyl cellulose 10%, diffusing agent MF 10%, the balance is water.

[0026] The preparation method of the composition that is used for the one-bath process of woven fabric destaining, comprises the following steps:

[0027] (1) Weigh each raw material according to the formula ratio;

[0028] (2) Add sodium myristoyl glutamate and sodium cocoyl isethionate into the reaction kettle, then add water, and mix and stir for 20 minutes;

[0029] (3) Add sodium carboxymethylcellulose and stir for 30 minutes, then raise the temperature to 55°C, continue stirring for 10 minutes, and wait for the foam to disappear;

[0030] (4) Add the diffusing agent MF to the mixture in step (3), and then fully stir for 10 minutes to prepare the composition.

Embodiment 3

[0032] A composition for one-bath process of woven fabric dedyeing, its raw materials are calculated by mass percentage: sodium myristoyl glutamate 25%, sodium cocoyl isethionate 25%, sodium carboxymethyl cellulose 12%, diffusing agent MF 12%, the balance is water.

[0033] The preparation method of the composition that is used for the one-bath process of woven fabric destaining, comprises the following steps:

[0034] (1) Weigh each raw material according to the formula ratio;

[0035] (2) Add sodium myristoyl glutamate and sodium cocoyl isethionate to the reaction kettle, then add water, and mix and stir for 30 minutes;

[0036] (3) Add sodium carboxymethylcellulose and stir for 30 minutes, then raise the temperature to 60°C, continue stirring for 10 minutes, and wait for the foam to disappear;

[0037] (4) Add the diffusing agent MF to the mixture in step (3), and then fully stir for 10 minutes to prepare the composition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com