High-elasticity environment-friendly fabric printing and dyeing system and process thereof

A high-elasticity and fabric technology, applied in textile processing machine accessories, textile material processing, and textile material processing equipment configuration, etc., can solve the problems of easy adhesion, poor dye uniformity, upper and lower layers, and poor fabric dyeing. The effect of improving the quality, improving the utilization rate, and improving the dyeing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

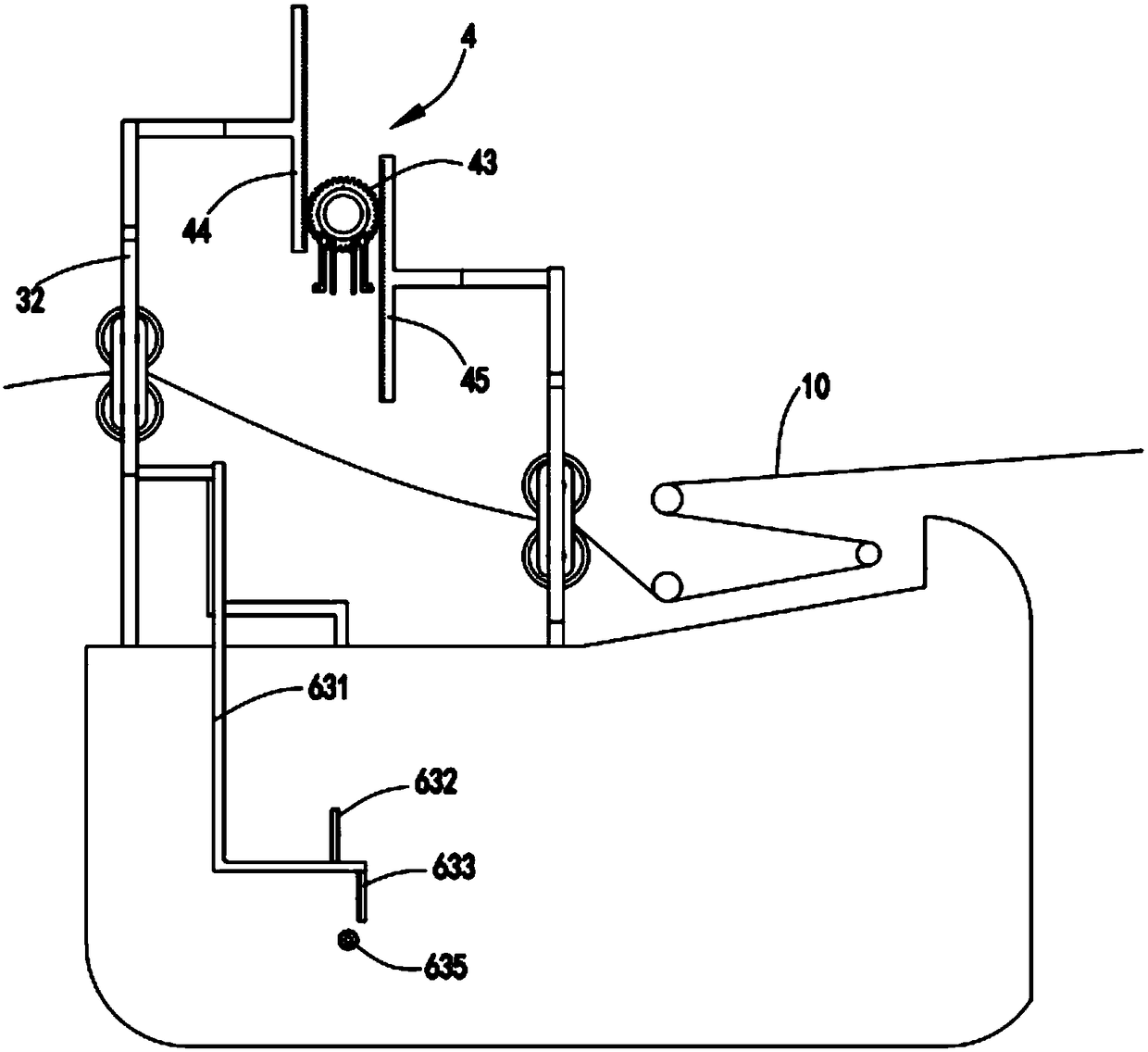

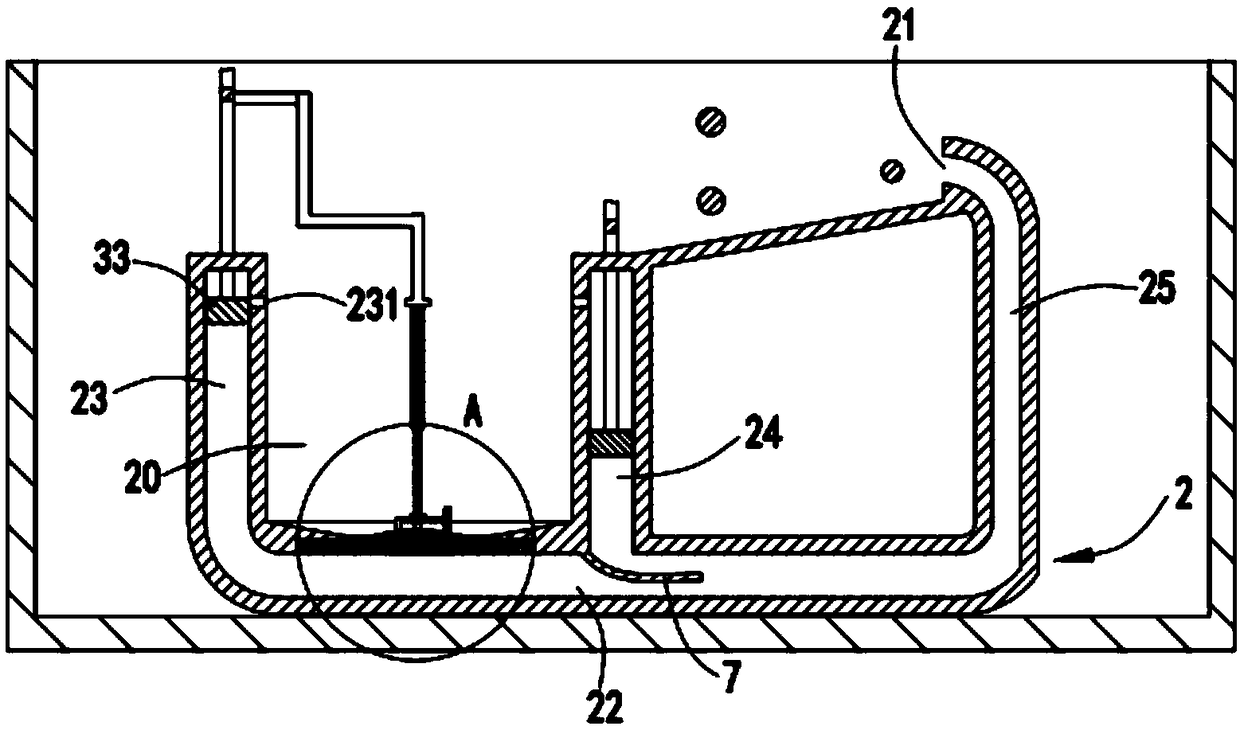

[0049] Such as Figure 1 to Figure 9 As shown, a printing and dyeing system for highly elastic and environmentally friendly fabrics includes a dye box 1, a dye solution guide mechanism 2 is arranged inside the dye solution guide mechanism 2, and a liquid outlet 21 is arranged at the tail end of the dye solution guide mechanism 2. The first extruding mechanism 3, the power mechanism 4 and the second extruding mechanism 5 are successively arranged on the dye liquor guiding mechanism 2; Alternately lift and squeeze the dye liquor in the dye liquor guide mechanism 2 under the drive, so that the dye liquor flows out from the liquid outlet 21 to wash the fabric 10 for printing and dyeing;

[0050] A grinding mechanism 6 is also provided below the power mechanism 4 between the first extrusion mechanism 3 and the second extrusion mechanism 5, and the grinding mechanism 6 includes a lower grinding assembly 61 arranged on the dye liquor guiding mechanism 2, The upper grinding assembly ...

Embodiment 2

[0067] Such as image 3 , Figure 4 and Figure 7 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between the second embodiment and the first embodiment is that: the two sides of the grinding tank 611 are respectively provided with a stopper component a64 and a stopper component b65, and the stopper component a64 and the stopper component b65 are fixed on The guide rod 641 on the side wall of the grinding tank 611, the slider 642 that slides along the guide rod 641 and the lower surface fits the bottom surface of the grinding tank 611, and is arranged between the slider 642 and the side wall of the grinding tank 611 and sleeved on the guide rod 641 The spring 643 on.

[0068] Furthermore, the bottom of the dye solution deposition space 2...

Embodiment 3

[0071] Such as Figure 10 Shown, a kind of printing and dyeing process of high elastic environmental protection fabric comprises the following steps:

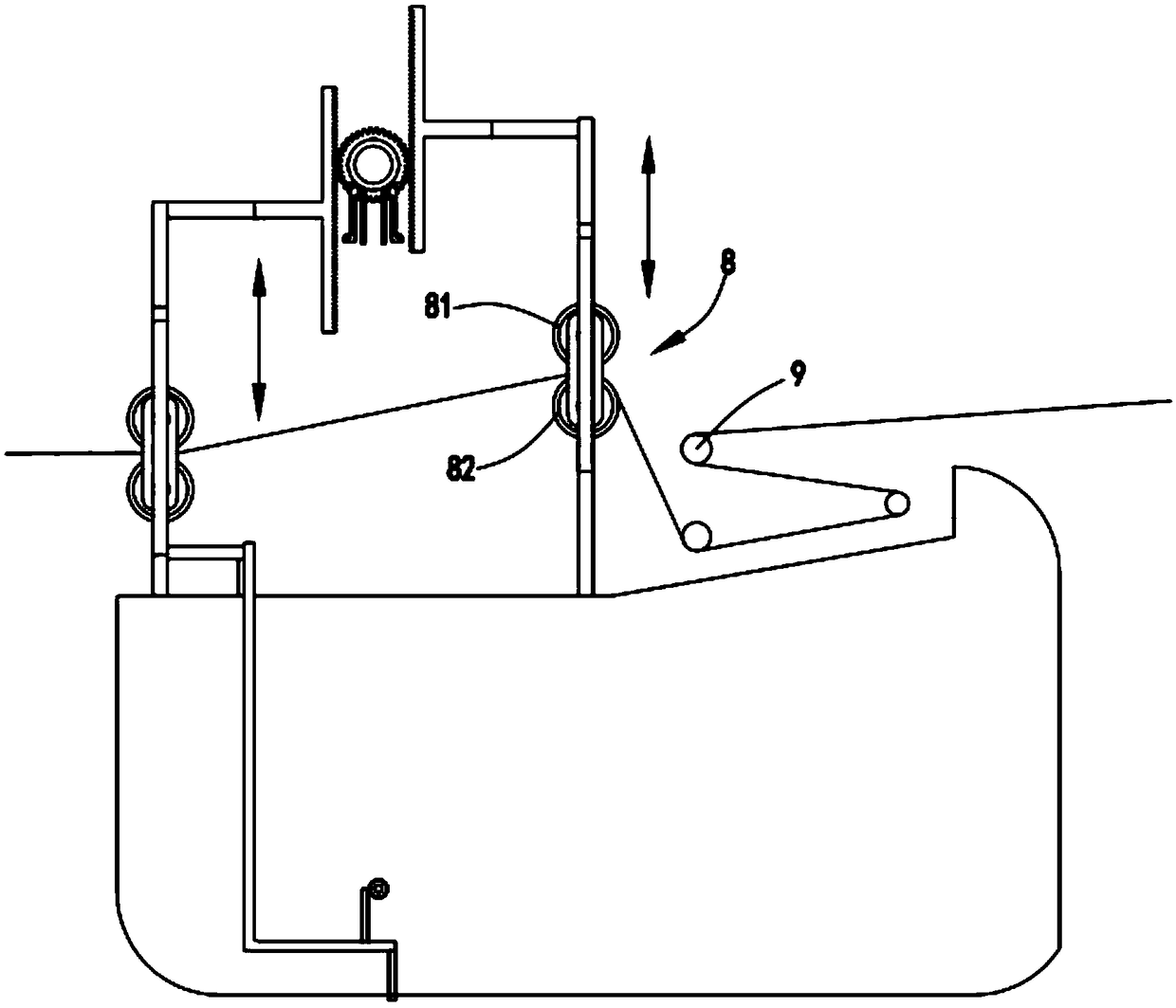

[0072] 1. In the first extrusion process, the power mechanism 4 drives the first extrusion mechanism 3 to move downward, extruding the dye liquor in the first extrusion chamber 23, and the dye liquor flows backward through the guide channel 22;

[0073] 2. One-time dip-dyeing process, the cloth guide roller group 8 on the first extruding mechanism 3 in step 1 drives the fabric to move down synchronously, and the fabric enters the dyeing liquor to carry out one-time dip-dyeing;

[0074] 3. Grinding process. In step 1, when the first extruding mechanism 3 moves downward, it drives the upper grinding assembly 62 to move down to cooperate with the lower grinding assembly 61, and the driving assembly 63 drives the upper grinding assembly 62 to move left and right to the lower grinding assembly 61. Coarse particle dyes are ground; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com