Nylon 6 fishing net dyeing process

A nylon, fishing net technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

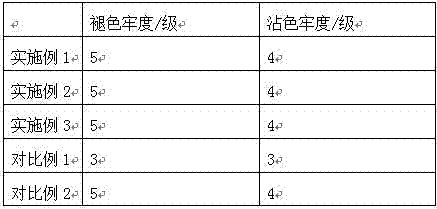

Examples

Embodiment 1

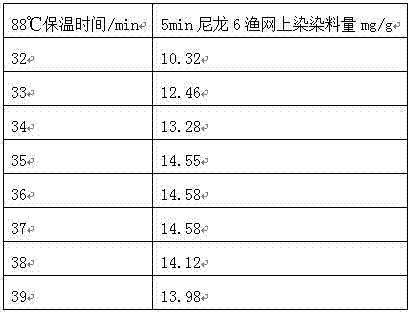

[0018] A nylon 6 fishing net dyeing process, comprising the following steps:

[0019] (1) Pretreatment: Pretreatment of nylon 6 fishing net: soak the nylon 6 fishing net in the pretreatment solution, the quality of nylon 6 and the pretreatment solution is 1:12, soak in a 45°C water bath for 10 minutes, and then soak in a water bath. Heat up at a heating rate of 0.5°C / min. When the temperature rises to 88°C, keep it at this temperature for 35min, then use 450W ultrasonic treatment for 2min, and then cool down the water bath at a rate of 1°C / min. When the temperature drops to 50°C From time to time, continue to keep the temperature for 20 minutes, take out the nylon 6 fishing net, soak the nylon 6 fishing net in 50 °C water for 10 minutes, and after taking it out, dry it in a vacuum at 50 °C to constant weight;

[0020] The pretreatment solution is made of the following components by weight: 2.3 of urea, 1.3 of sodium phosphate, 0.4 of sodium dodecylbenzenesulfonate, 0.2 of hydr...

Embodiment 2

[0029] A nylon 6 fishing net dyeing process, comprising the following steps:

[0030] (1) Pretreatment: Pretreatment of nylon 6 fishing net: soak the nylon 6 fishing net in the pretreatment solution, the quality of nylon 6 and the pretreatment solution is 1:12, soak in a 45°C water bath for 10 minutes, and then soak in a water bath. Heat up at a rate of 0.5°C / min. When the temperature rises to 88°C, keep at this temperature for 37min, then use 450W ultrasonic treatment for 2min, and then cool down at a rate of 1°C / min in the water bath. When the temperature drops to 50°C From time to time, continue to keep the temperature for 20 minutes, take out the nylon 6 fishing net, soak the nylon 6 fishing net in 50 °C water for 10 minutes, and after taking it out, dry it in a vacuum at 50 °C to constant weight;

[0031] The pretreatment solution is made of the following components in parts by weight: 2.6% of urea, 1.5% of sodium phosphate, 0.8% of sodium dodecylbenzenesulfonate, 0.5% of...

Embodiment 3

[0040] A nylon 6 fishing net dyeing process, comprising the following steps:

[0041] (1) Pretreatment: Pretreatment of nylon 6 fishing net: soak the nylon 6 fishing net in the pretreatment solution, the quality of nylon 6 and the pretreatment solution is 1:12, soak in a 45°C water bath for 10 minutes, and then soak in a water bath. Heat up at a rate of 0.5°C / min. When the temperature rises to 88°C, keep it at this temperature for 36min, then use 450W ultrasonic treatment for 2min, and then cool down the water bath at a rate of 1°C / min. When the temperature drops to 50°C From time to time, continue to keep the temperature for 20 minutes, take out the nylon 6 fishing net, soak the nylon 6 fishing net in 50 °C water for 10 minutes, and after taking it out, dry it in a vacuum at 50 °C to constant weight;

[0042] The pretreatment solution is made of the following components by weight: 2.4% of urea, 1.4% of sodium phosphate, 0.6% of sodium dodecylbenzenesulfonate, 0.3% of hydrogen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com