A kind of environment-friendly liquid bromoindigo dye composite additive additive and preparation method thereof

A technology of composite addition and brominated indigo, which is applied in dyeing methods, textiles and papermaking, etc., can solve the problem of lack of high-end liquid brominated indigo, improve the dyeing rate and dye utilization rate, save the cost of dyeing materials and process costs, The effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

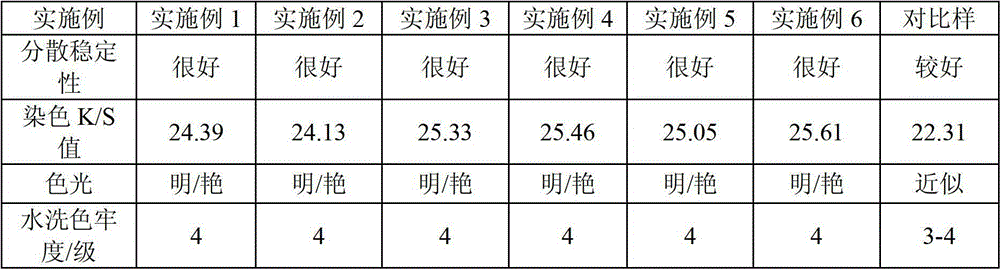

Examples

Embodiment 1

[0037] Embodiment 1, preparation liquid bromine indigo dyestuff is compounded and added auxiliary agent

[0038] Pump 500 parts of deionized water into the homogeneous reactor, start stirring, put in 5 parts of industrial salt, 200 parts of polystyrene maleic anhydride copolymer sodium salt (molecular weight 2000-4000, carboxyl content 25.4%), 20 parts of di Sodium ethylene triamine pentamethylene phosphonate, 100 parts of dispersant NNO and 50 parts of dispersant CNF were heated up to 50°C and stirred homogeneously at a speed of 500 rpm for 1.5 hours. Then put 50 parts of sodium lauryl sulfate, 20 parts of isomeric alcohol polyoxyethylene ether and 50 parts of silicone polyoxyethylene ether into the reaction kettle, keep the temperature at 50° C., and continue stirring for 1 hour. Then put in 1 part of antifoaming agent CTA-791, continue to stir at a speed of 100 rpm for 0.5 hours, and finally add 50 parts of pre-diluted 10% by mass aqueous sodium alginate solution, and conti...

Embodiment 2

[0040] Embodiment 2, preparation liquid bromine indigo dyestuff is compounded and added auxiliary agent

[0041]Pump 500 parts of deionized water into the homogeneous reactor, start stirring, put in 20 parts of industrial salt, 90 parts of sodium polyacrylate (molecular weight 8000-10000, carboxyl content 62.5%), 35 parts of sodium polyaspartate, 270 Part dispersant MF, heated up to 55°C, and stirred homogeneously at a speed of 500 rpm for 1.5 hours. Then put 50 parts of sodium butylnaphthalene sulfonate and 30 parts of fatty alcohol polyoxyethylene ether into the reaction kettle, keep the temperature at 55° C., and continue stirring for 1 hour. Then put in 1.5 parts of defoamer FB-50, continue to stir at a speed of 100 rpm for 0.5 hours, and finally add 50 parts of pre-diluted carboxymethyl cellulose aqueous solution with a mass percentage of 1%, and continue to stir for 0.5 hours. The material is discharged, and the liquid bromoindigo dye is compounded with additives.

[0...

Embodiment 3

[0043] Embodiment 3, preparation liquid bromine indigo dyestuff is compounded and added auxiliary agent

[0044] Pump 500 parts of deionized water into the homogeneous reactor, start stirring, 50 parts of maleic anhydride-acrylic acid copolymer sodium salt (molecular weight 30000-40000, carboxyl content 71.5%), 30 parts of trisodium citrate, 300 parts of dispersed agent CNF, the temperature was raised to 55°C, and the mixture was homogeneously stirred at a speed of 500 rpm for 1.5 hours. Then put 70 parts of dioctyl sulfosuccinate sodium salt and 50 parts of fatty alcohol polyoxyethylene ether into the reaction kettle, keep the temperature at 55° C., and continue stirring for 1 hour. Then put in 0.5 parts of antifoaming agent CTA-791, continue stirring at a speed of 100 rpm for 0.5 hours, and finally add 50 parts of pre-diluted thickener PTF aqueous solution with a mass percentage of 5%, and continue stirring for 0.5 hours. The material is discharged, and the liquid bromoindi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Degree of sulfonation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com