Patents

Literature

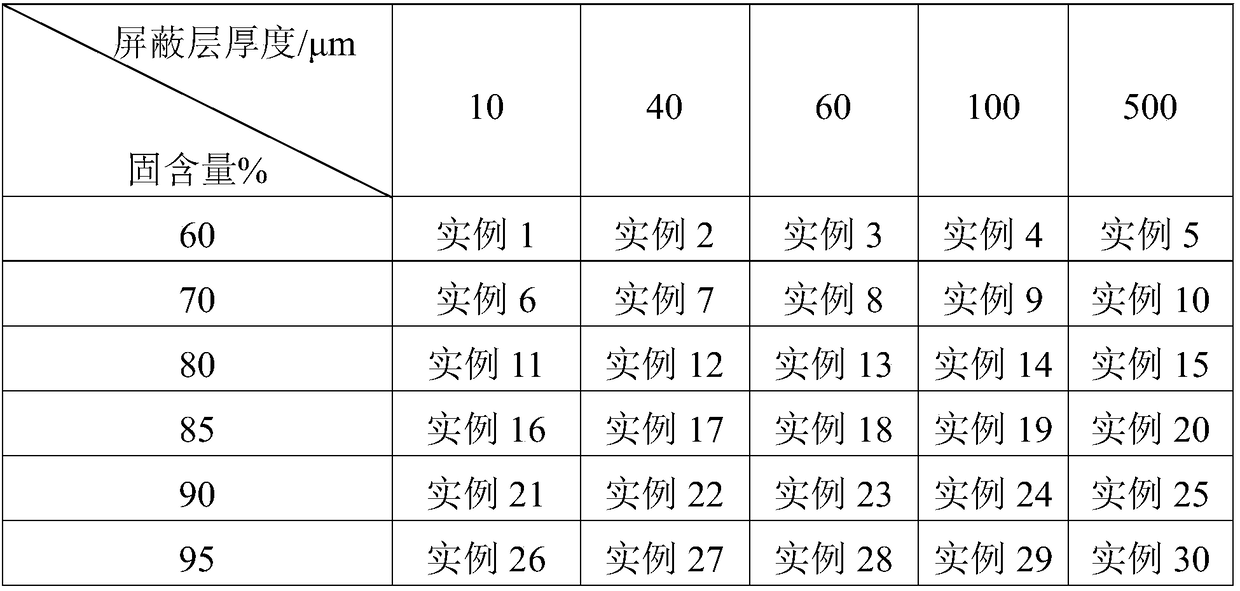

49results about How to "Save process cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

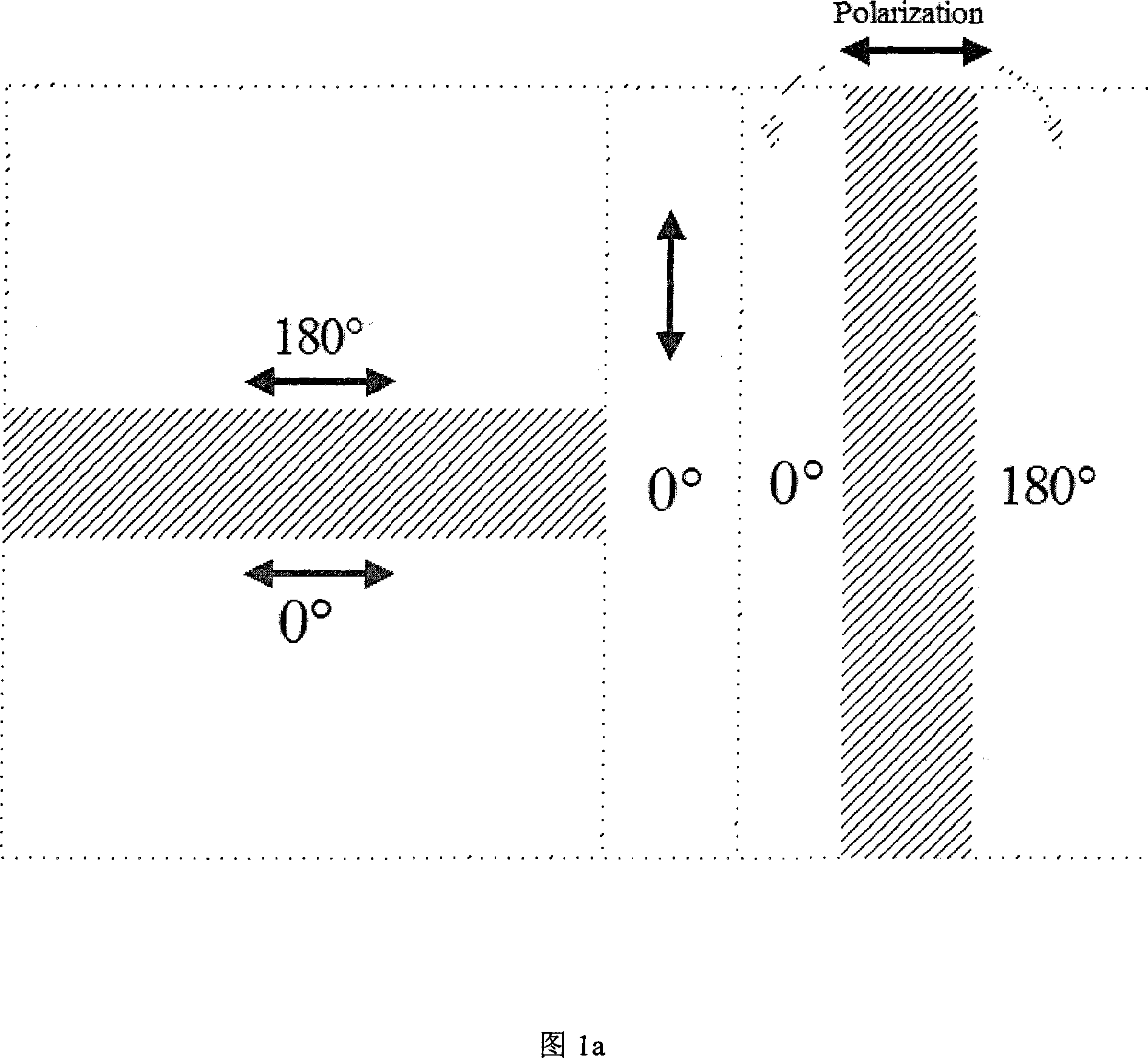

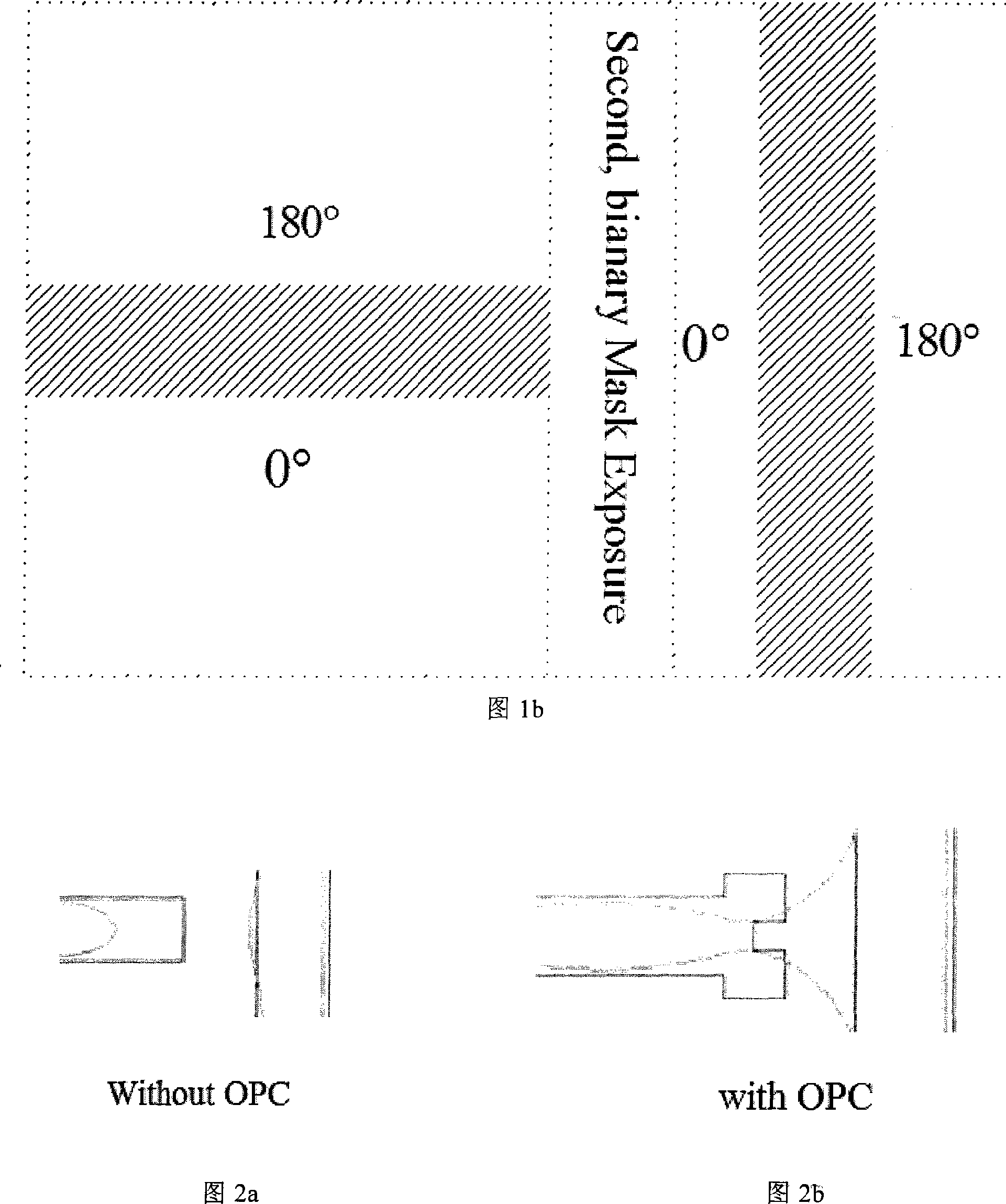

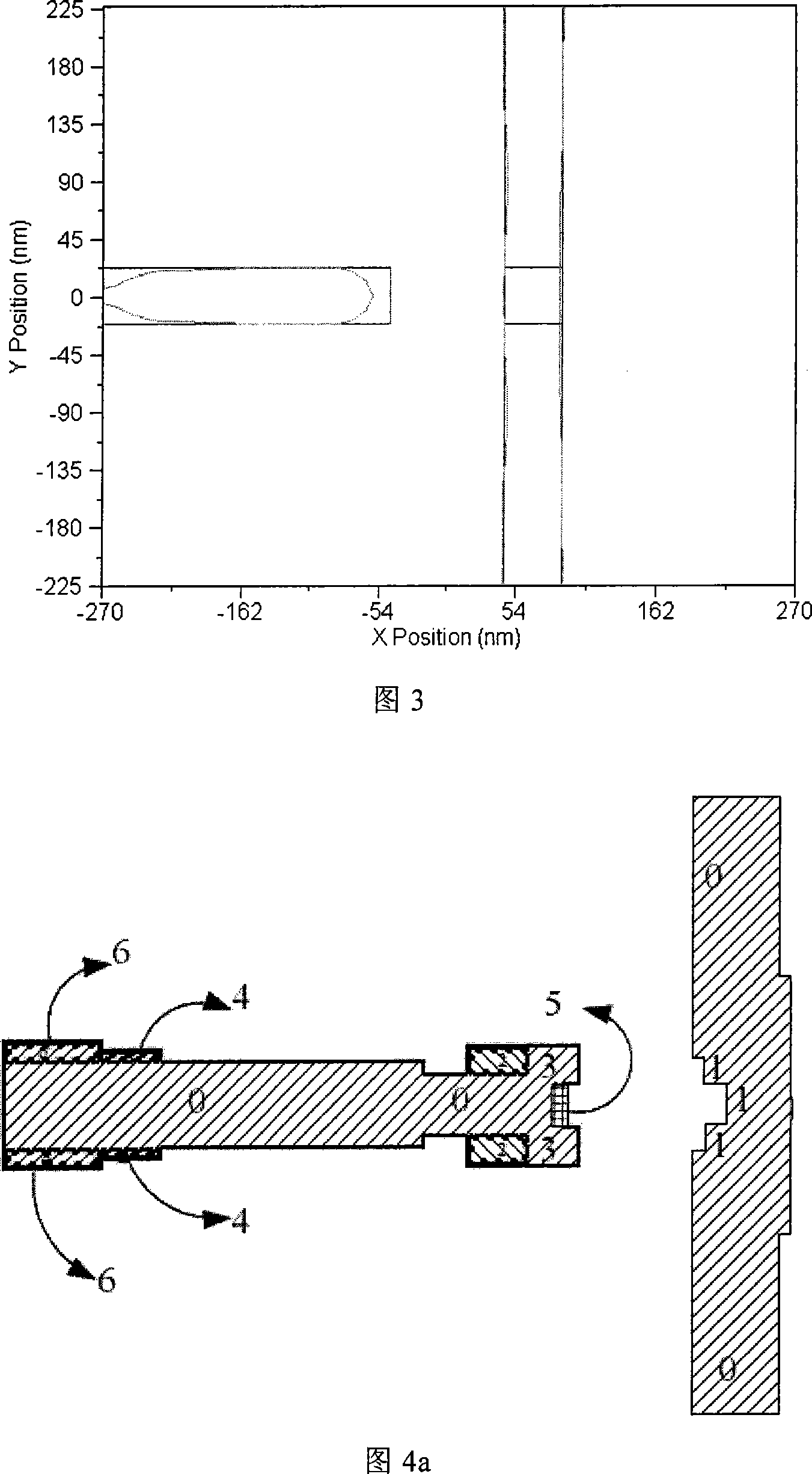

Photoetching system mask proximity effect correction method

InactiveCN101144976AImprove fidelityImprove image contrastOriginals for photomechanical treatmentPhase shiftedButt joint

A mask proximity effect correction method for a lithography system. First, find out the distortion of the final pattern on the silicon wafer compared with the mask design pattern, and correct it according to the proximity effect at the corresponding position of the mask pattern according to the position of the distorted pattern. The method to pre-segment and add the mask graphics: add serifs at the junction of X and Y graphics, and add non-transparent proximity effect correction graphics with 180-degree phase shift on both sides of the serifs, together Constitute the preliminary framework of phase-shift proximity effect correction; then observe the exposure result after adding phase-shift proximity effect correction through lithography simulation method, and according to the exposure result, use simulation software to measure the error between the exposure result and the expected pattern, according to This error adjusts the size, transmittance and other related parameters of the phase-shift proximity effect correction on the reticle until the error between the developed pattern on the silicon wafer and the original design pattern of the reticle is less than the allowable limit of ±10% deviation in industrial lithography .

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

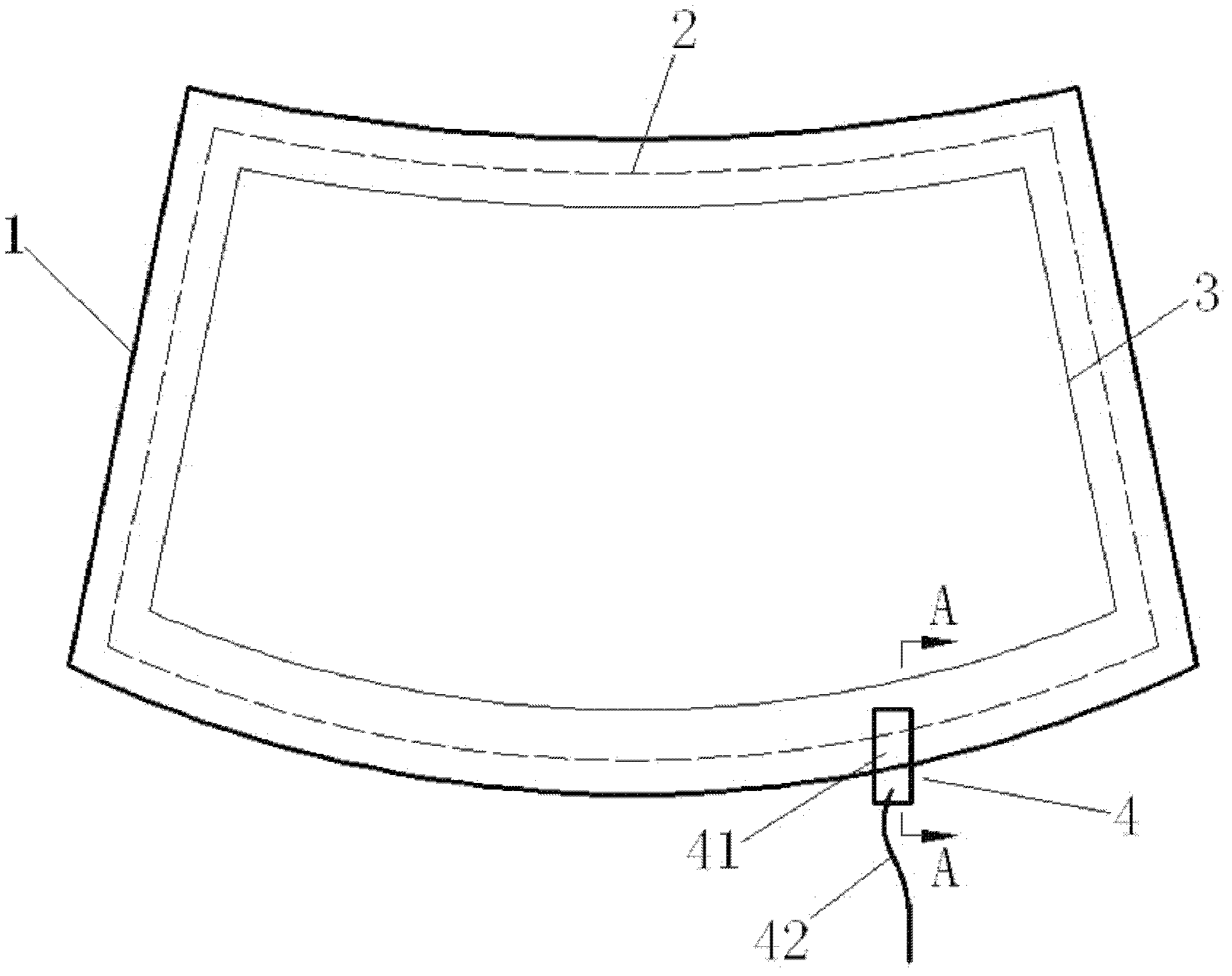

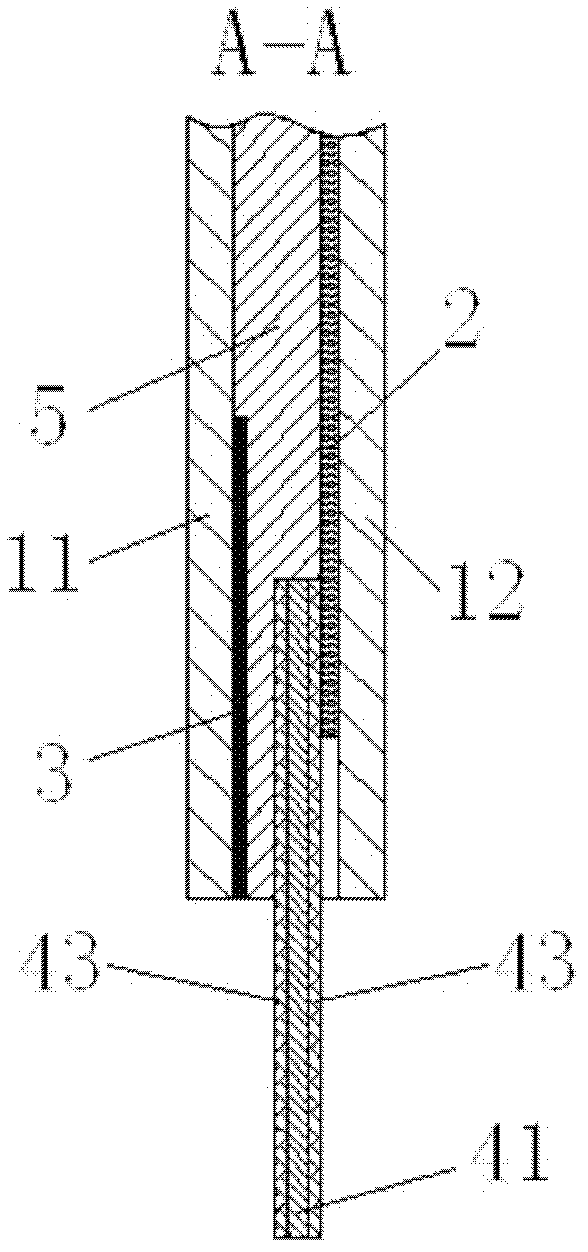

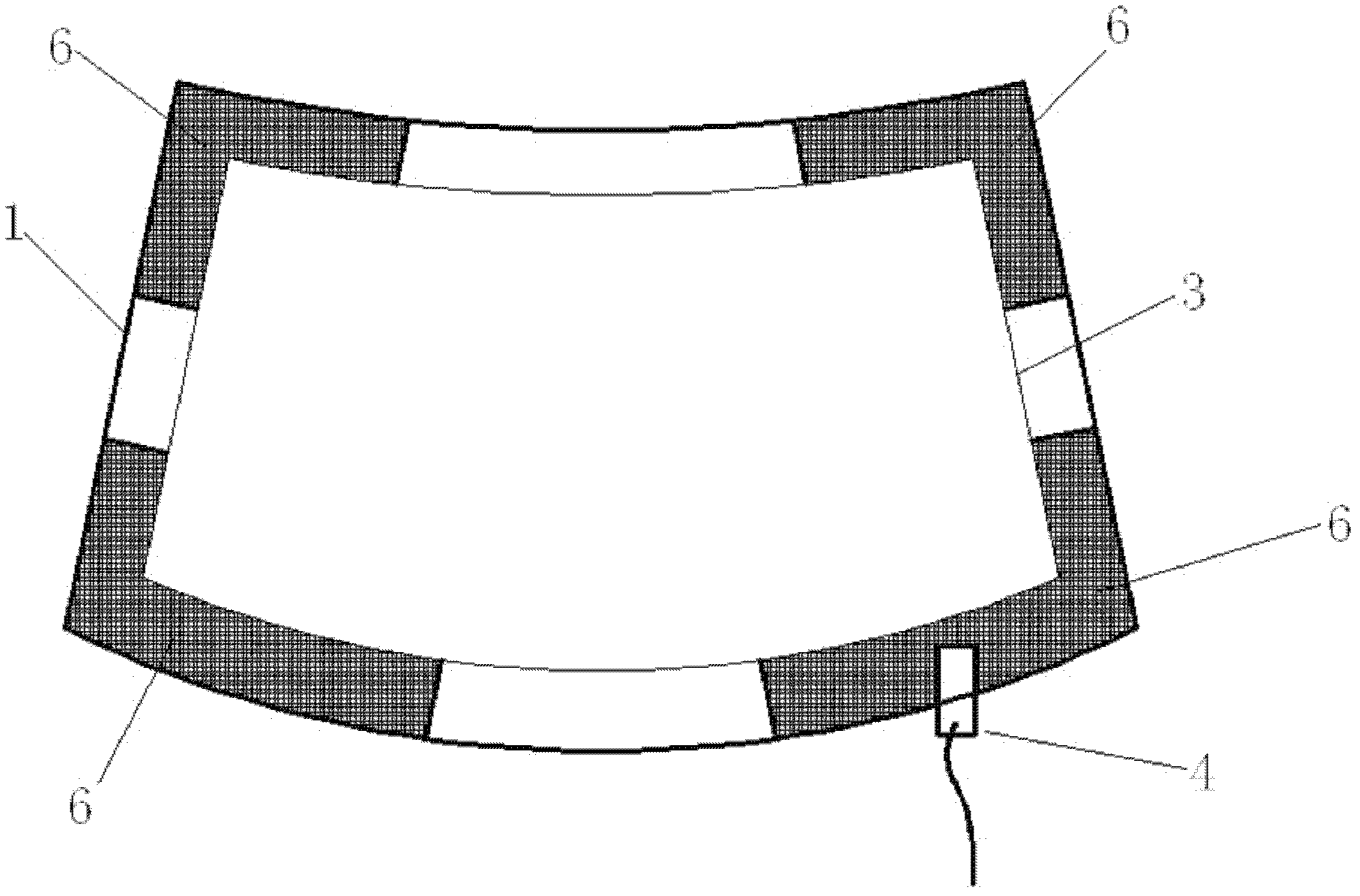

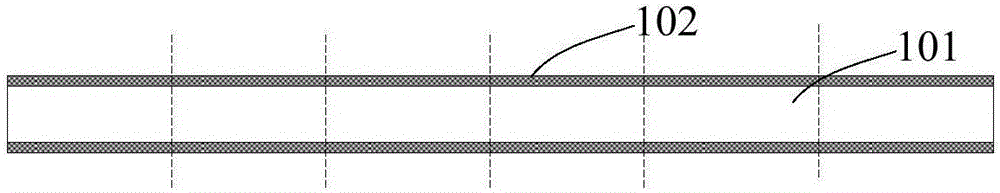

Laminated glass with antenna function

ActiveCN102407753ANot easy to produceSave development costWindowsWindscreensPolyvinyl butyralCapacitance

The invention provides laminated glass with an antenna function, and relates to laminated glass plated with a membrane layer. The laminated glass comprises two pieces of glass, a polyvinyl butyral (PVB) membrane sandwiched between the two pieces of glass, a conductive plating layer which is plated on a glass surface on which the glass is contacted with the PVB membrane and an antenna joint, wherein the antenna joint comprises a metal sheet and an outgoing cable; and the rear end of the metal sheet is fixedly connected with the outgoing cable. The laminated glass is characterized in that: the metal sheet of the antenna joint is used for integrally cladding an insulating layer; one part at the front end of the antenna joint is positioned between the PVB membrane and the conductive plating layer; and the antenna joint is arranged in a corner L-shaped area at the periphery of the laminated glass. The laminated glass has the advantages that: the antenna function is increased on the basis of the existing laminated glass with a membrane plating function, so that the cost is greatly saved; the antenna joint is coupled with the conductive plating layer through the insulating layer, so thatthe distance between the antenna joint and the conductive plating layer is only the thickness of an insulating layer membrane, a superposed part can be manufactured to the minimum extent, a good capacitive coupling effect can be achieved, and a signal can be more stably received; and the sheet is extremely thin, so that a technical process is easy to control in the production process, and bubblesare difficult to generate.

Owner:FUYAO GLASS IND GROUP CO LTD

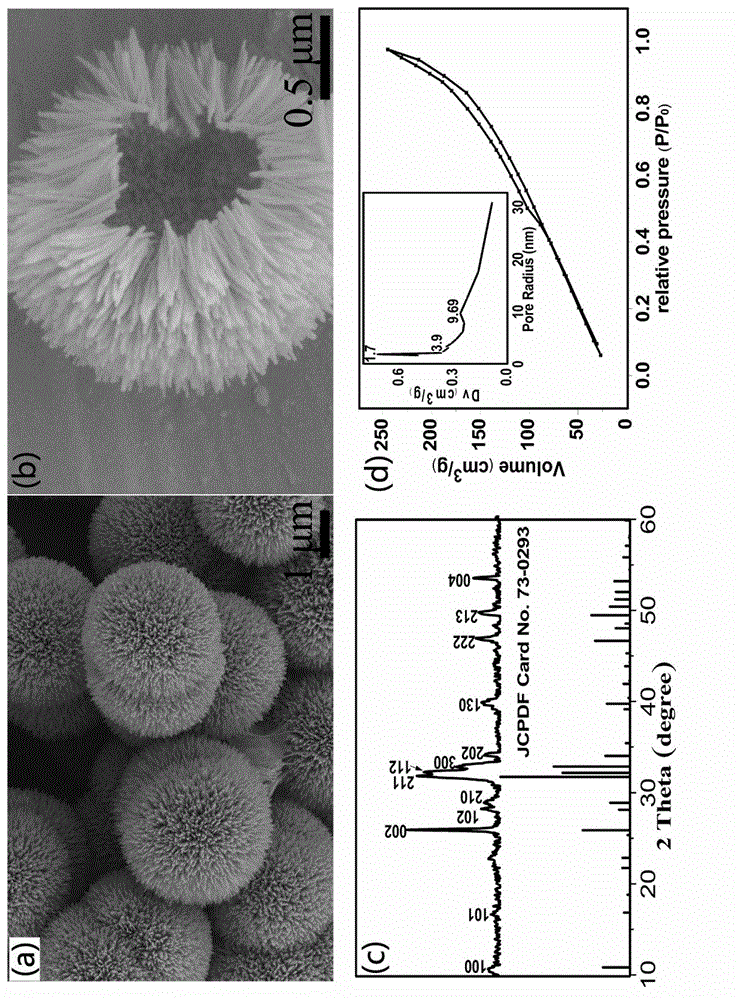

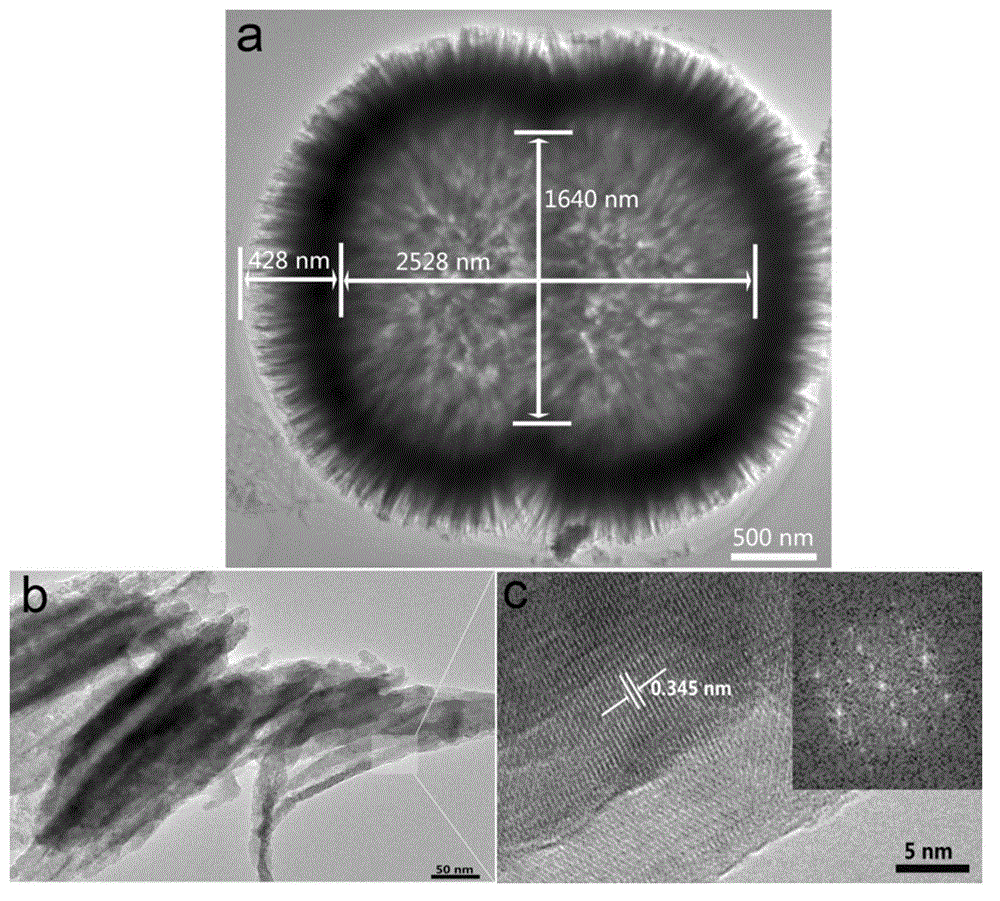

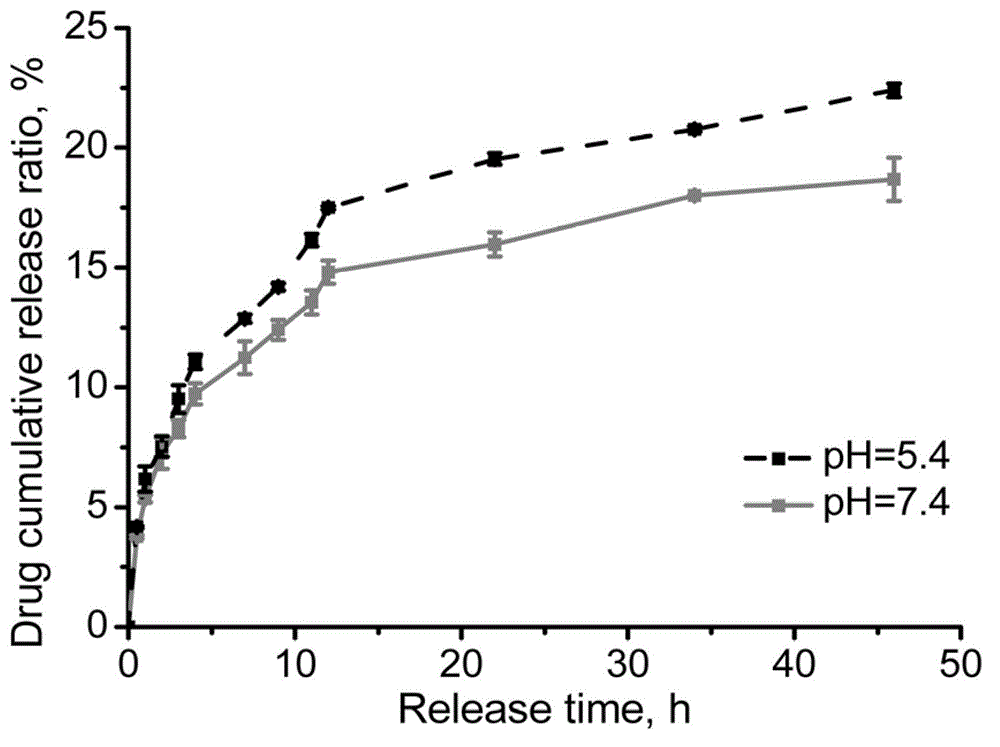

Hollow hierarchical hydroxyapatite microspheres and preparation method and application thereof

ActiveCN103058159ARegulatory HierarchyGood biocompatibilityPowder deliveryPharmaceutical product form changeHydrogen phosphateMicrosphere

The invention discloses hollow hierarchical hydroxyapatite microspheres and a preparation method and application thereof. The preparation method comprises the following steps of: (1) dissolving diammonium hydrogen phosphate into deionized water, adjusting the pH value of the solution to be 5.8 to 6.0 by using nitric acid, adding calcium nitrate so that the molar ratio of Ca<2+> to PO4<3-> in the solution is 1.6 to 1.7, continuously adjusting the pH value of the solution to be 5.0 by using the nitric acid, adding sodium citrate into the mixed solution to ensure that the concentration of the mixed solution is 9 to 20 milligrams per milliliter, and continuously stirring; and (2) transferring the mixed solution of the step (1) to a high pressure reactor, wherein the volume of the mixed solution accounts for 50 to 80 percent of the total volume of the reactor; and reacting for 1 to 12 hours at the temperature of between 80 and 220 DEG C, performing natural cooling, washing for 3 to 5 times, and drying to obtain the hollow hierarchical hydroxyapatite microspheres. The preparation method for the microspheres is simple and low in time consumption; and the microspheres have excellent medicament release property, are suitable for industrial production, and have a good application prospect.

Owner:广州康睿医疗器械有限公司

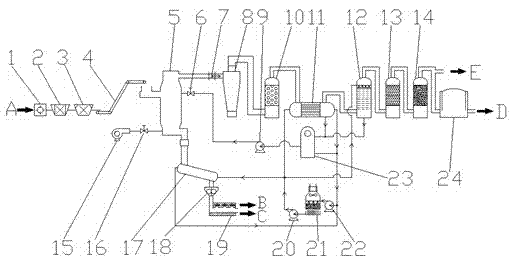

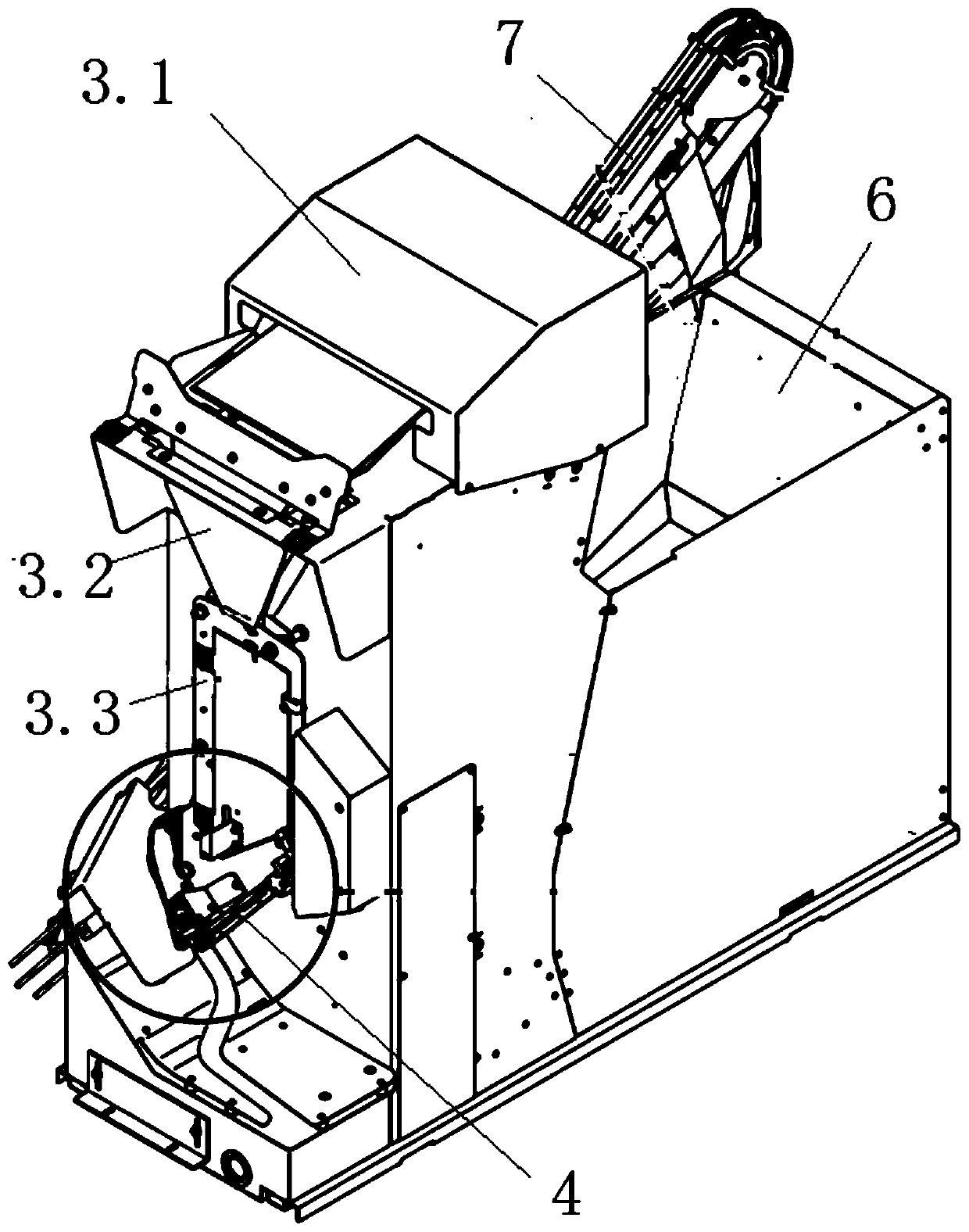

Waste tyre fixed-bed gasification furnace and gasification method

InactiveCN103205279ACost savingsSave process costPlastic recyclingCombustible gas purificationProcess equipmentResource utilization

The invention relates to a waste tyre fixed-bed gasification furnace and a gasification method. The fixed-bed gasification furnace mainly consists of a charging system, a discharging system, an electric-arc type tar decomposer and a furnace body; the gasification method mainly comprises the following steps of: enabling tyre material blocks to react with gasification agent in the fixed-bed gasification furnace to generate a combustible gas; guiding the combustible gas out of the gasification furnace after most of tar in the combustible gas is primarily purified and removed by the electric-arc type tar decomposer on the inner top of the gasification furnace; and converting the combustible gas into the combustible gas with a medium heat value after the subsequent purifying and treating processes including dust-removing, condensing, spraying, sulfur-removing, drying, pressure-stabilizing and the like, wherein the tar separated in the subsequent purifying process is re-introduced to the gasification furnace for being secondarily decomposed. The gasification method is free of an extra heat source, so that the whole system is operated under micro-negative pressure, and no harmful gas is leaked in the process; and the whole process equipment can be continuously operated by virtue of the unique charging structure design and the discharging structure design of the fixed-bed gasification furnace, and therefore, the gasification method is an efficient waste tyre resource utilization method.

Owner:ZHONGSHAN SAIKE ENVIRONMENTAL PROTECTION TECH CO LTD

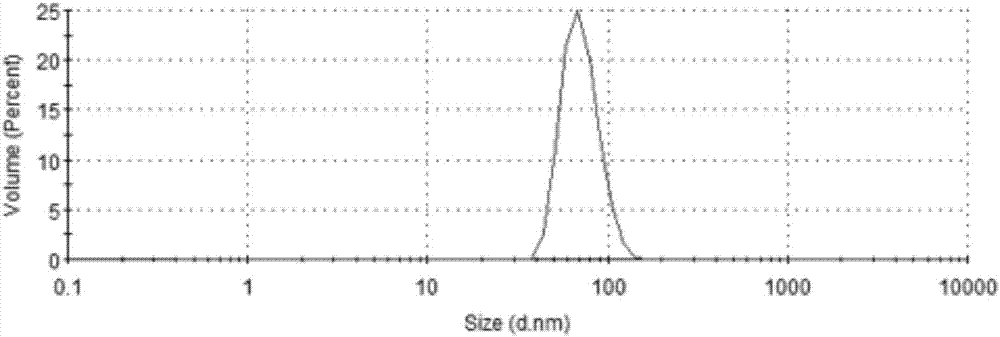

Nano emulsion and preparation method by phase inversion temperature process

InactiveCN106963657AReduce energy consumptionParticle size does not changeCosmetic preparationsToilet preparationsWater bathsPolyol

The invention relates to a nano emulsion, which comprises, by weight percentage, 1-15% of a high HLB value emulsifier, 1-10% of a low HLB value emulsifier, 1-20% of solid grease, 5-25% of liquid grease, 1-15% of polyol and the balance deionized water. The invention also provides a preparation method of the nano emulsion. The method includes: firstly mixing the emulsifiers with grease to obtain an oil phase component, mixing the polyol with deionized water to obtain an aqueous phase component, respectively heating the oil phase component and the aqueous phase component in a water bath pot till complete dissolution, then adding the oil phase component into the aqueous phase component, adjusting the temperature until blue appears in the system obviously, recording the sample temperature at the moment, i.e. PIT (phase inversion temperature), conducting heat preservation for 0-10min, then stopping heating, and performing rapid cooling to room temperature, thus obtaining the nano emulsion prepared by phase inversion temperature method. The nano emulsion prepared by the method provided by the invention has uniform particles and good stability, and the energy consumption is greatly reduced in the preparation process, and the operation process and preparation cost are saved.

Owner:SHANGHAI INST OF TECH

Liquid crystal display, liquid crystal display module and liquid crystal unit thereof

ActiveCN105759491AImprove color expressionEfficient use ofNon-linear opticsQuantum dotMaterials science

The invention provides a liquid crystal display, a liquid crystal display module and a liquid crystal unit thereof. The liquid crystal unit comprises an upper substrate, a lower substrate and a mixture of a quantum dot material and a liquid crystal material, wherein the mixture is arranged between the upper substrate and the lower substrate and comprises a red quantum dot material and a green quantum dot material; the mass ratio of the total doping amount of the two quantum dot materials to the total mass of the mixture is 0.05-5 wt%. According to the liquid crystal display, the liquid crystal display module and the liquid crystal unit thereof, through the introduction of the QD (Quantum Dot) materials, on one hand, the directional arrangement of liquid crystal molecules is promoted, so that an alignment effect is realized, and a traditional alignment film structure can be replaced; on the other hand, the liquid crystal unit is matched with a back light source of a blue or white LED, so that the promotion of a color gamut is realized, and the color expressive force of an LCD can be improved; in combination with a quantum dot and a liquid crystal system, effective utilization of the QD materials can be favorably realized, and compared with a conventional QD film and a QD tube technology, more materials are saved and more process cost is lowered.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

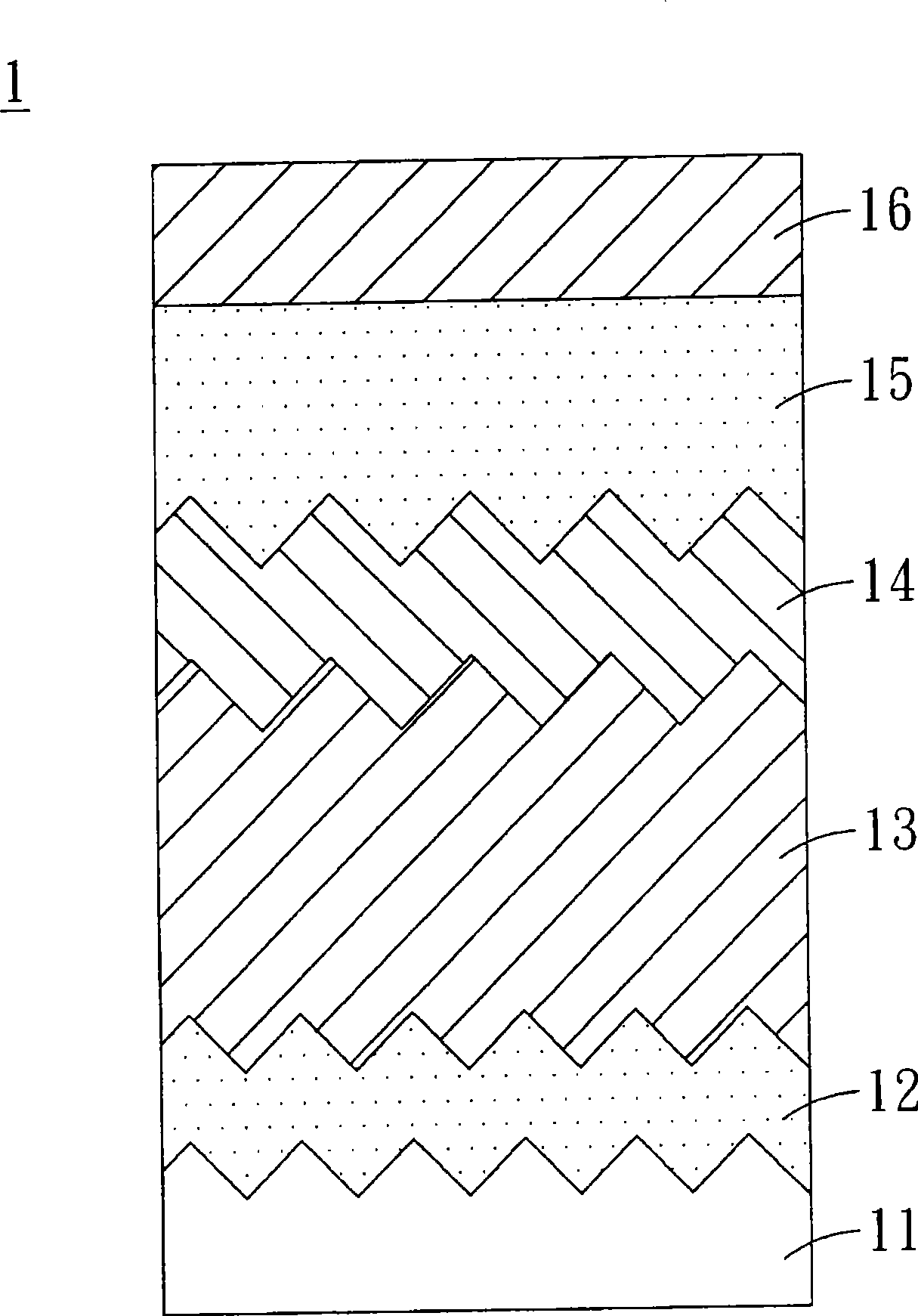

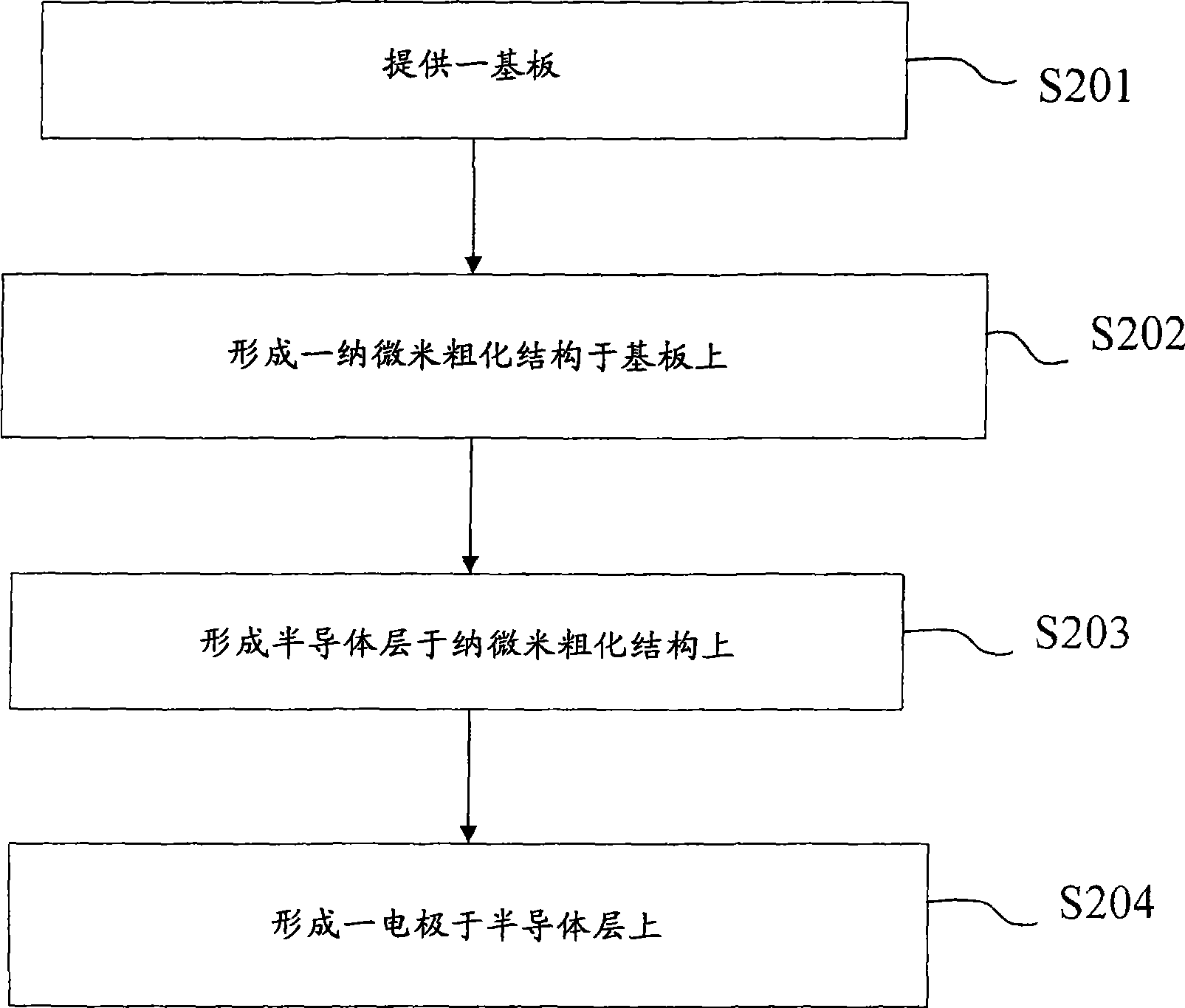

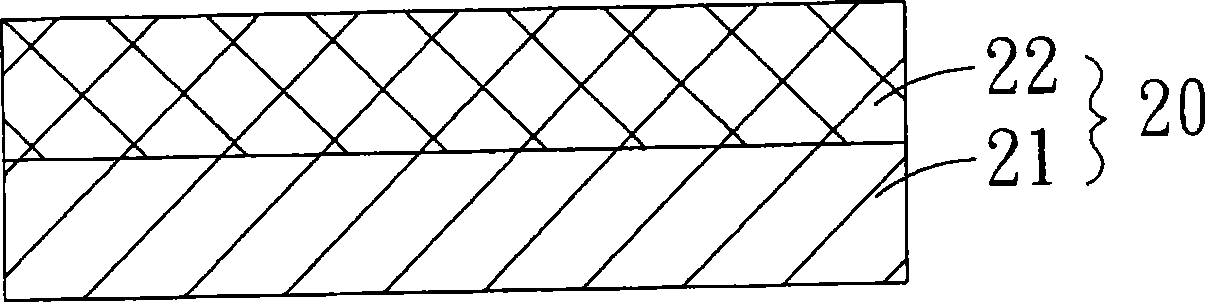

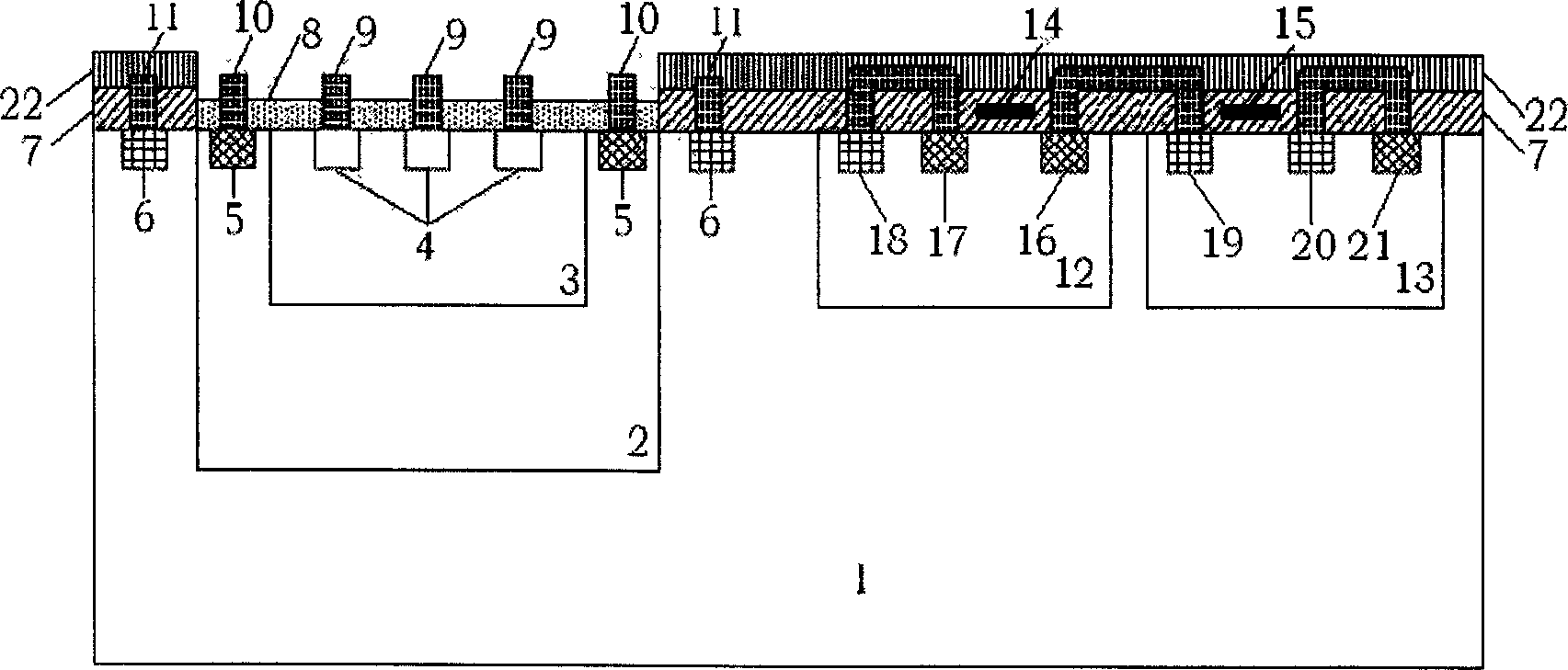

Solar battery and method for manufacturing the same

InactiveCN101459201AAdd Optical PathImprove optical absorption propertiesPhotovoltaic energy generationSemiconductor devicesEngineeringSolar battery

The invention provides a solar cell and a manufacturing method thereof, the solar cell comprises a substrate, a nano-micron coarsening structure and a semiconductor layer, wherein the substrate is provided a first transparent conducting layer, the nano-micron coarsening structure is formed on the first transparent conducting layer, and the semiconductor layer is formed on the nano-micron coarsening structure and is coated on the nano-micron coarsening structure.

Owner:DELTA ELECTRONICS INC +1

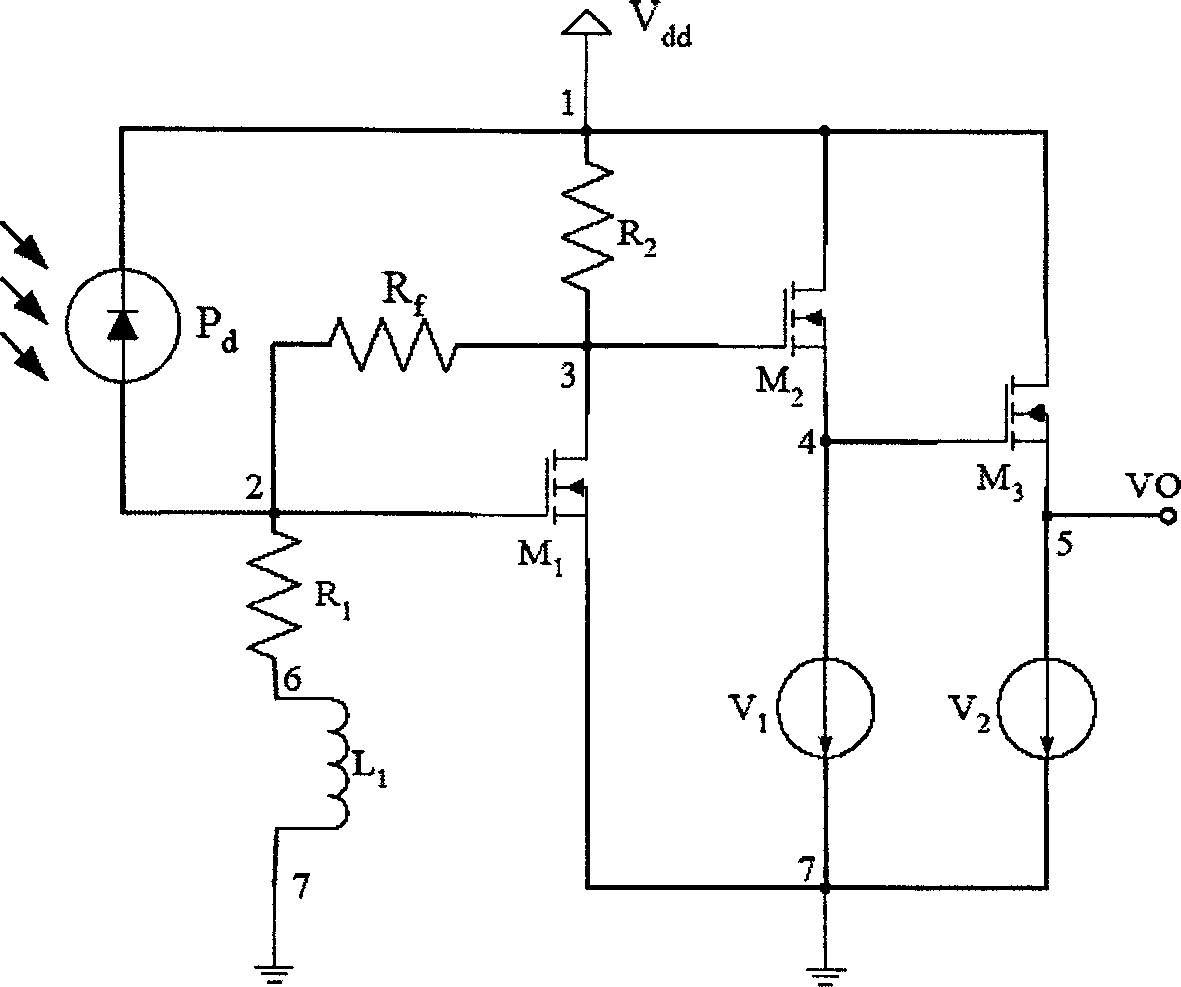

CMOS photoelectric integrated receiver with pre-equalizing circuit

InactiveCN1741278AHigh bandwidthHigh sensitivitySolid-state devicesElectromagnetic receiversCMOSElectrical resistance and conductance

A CMOS photoelectric integrated receiver with front equalizer consists of photo-electric converting component ; front equalizing circuit including buffer resistance , resonant inductance , junction capacity of photoelectric detector and input capacity of preamplifier ; and preamplifier . It is featured as connecting series circuit formed by buffer resistance and resonant inductance to place between input end and earthening end of preamplifier , forming a parallel resonant circuit by connecting said series circuit and junction capacity of silicon photoelectric detector as well as input capacity of preamplifier in parallel.

Owner:TIANJIN UNIV

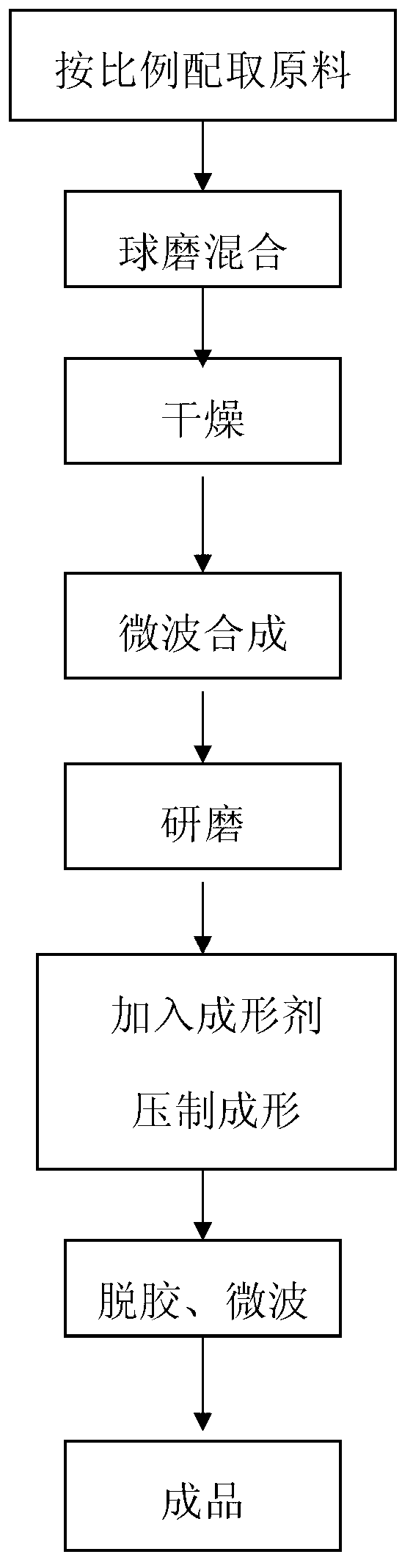

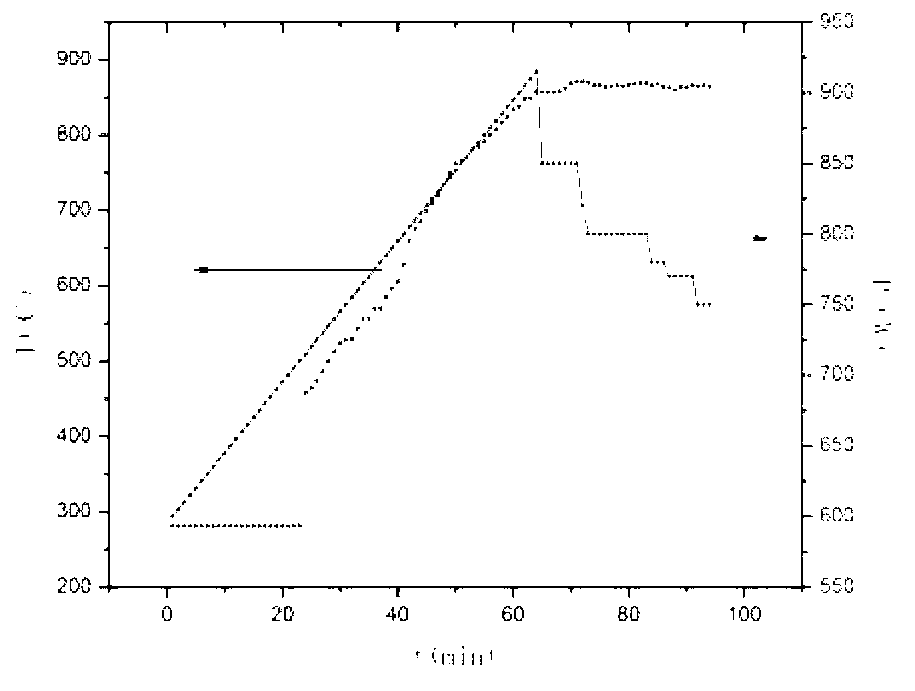

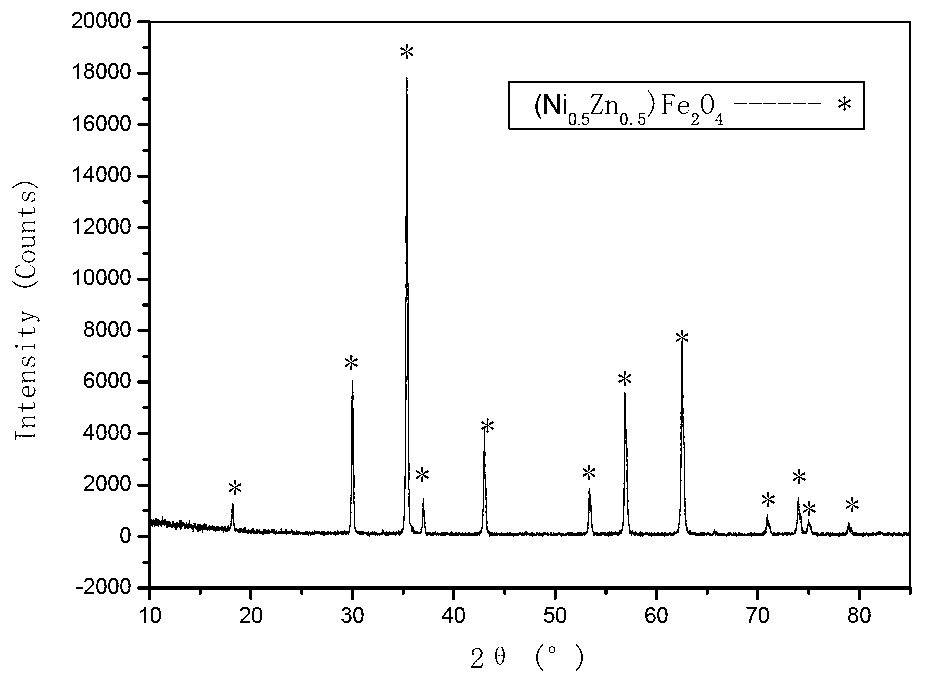

Method for preparing nickel-zinc ferrite by using microwave technology

The invention discloses a method for preparing a nickel-zinc ferrite by using a microwave technology. The method comprises the following steps of: determining a molar ratio of Ni, Zn and Fe in nickel-zinc ferrite components according to a chemical general formula of the nickel-zinc ferrite NixZn1-xFe2O4, wherein x is more than 0 and less than 1; respectively weighing and uniformly mixing oxides of Ni, Zn and Fe according to the proportion, and performing microwave synthesis on the mixture to obtain pre-sintering material powder; grinding the synthesized pre-sintering material powder; adding polyvinyl alcohol into the pre-sintering material powder to compact and mould to obtain a compaction blank; degumming the compaction blank to sinter in a microwave oven to obtain a finished product under a microwave sintering condition that the heating velocity is 10-30 DEG C / min, the sintering temperature is between 1,100-1,300 DEG C and the holding time is between 30 and 180 minutes. The method is simple in process, easy to operate, high in preparation efficiency, low in energy consumption, and environment-friendly, clean and sanitary in preparation process; the time can be greatly saved; the cost is greatly reduced; and the obtained spinel nickel-zinc ferrite is high in purity. The method is suitable for industrial production, has good economic benefit and social benefit, and can promote application of the nickel-zinc ferrite in the industrial and high-end technology.

Owner:CENT SOUTH UNIV

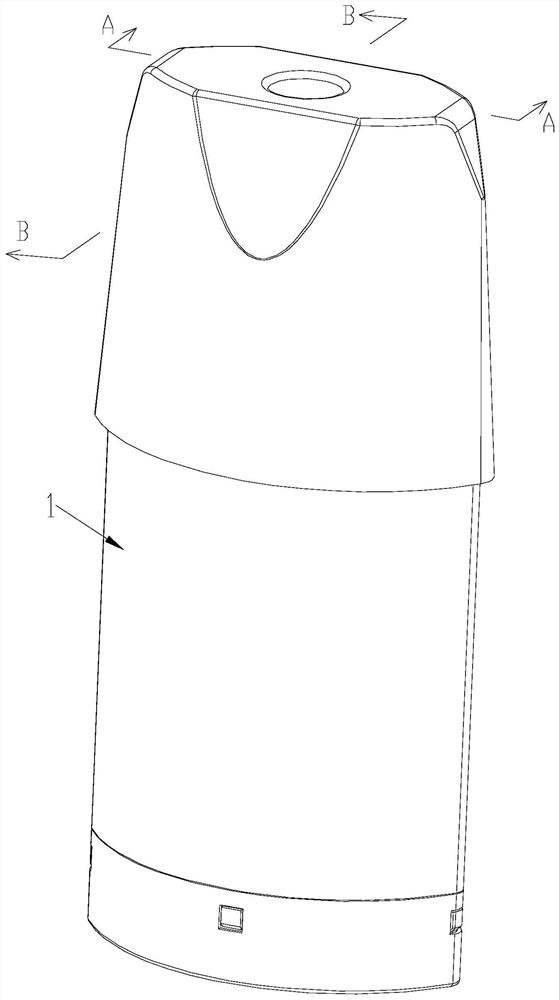

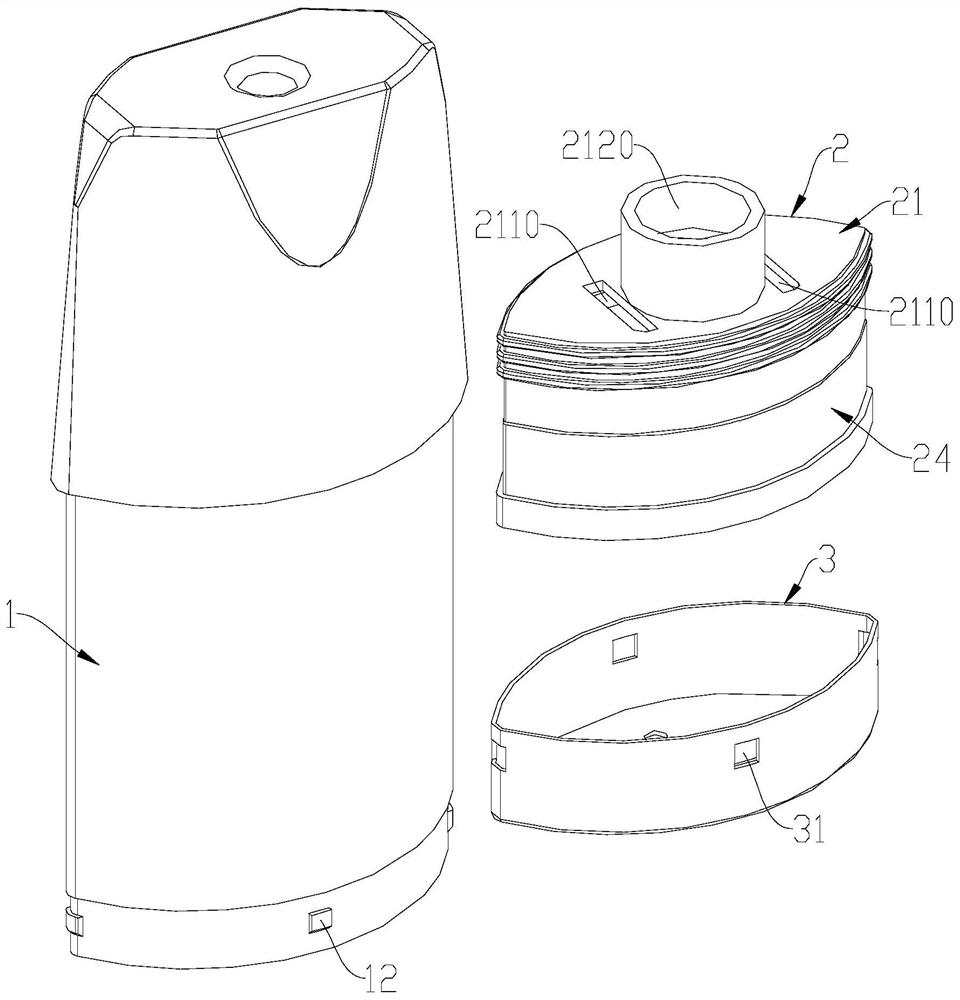

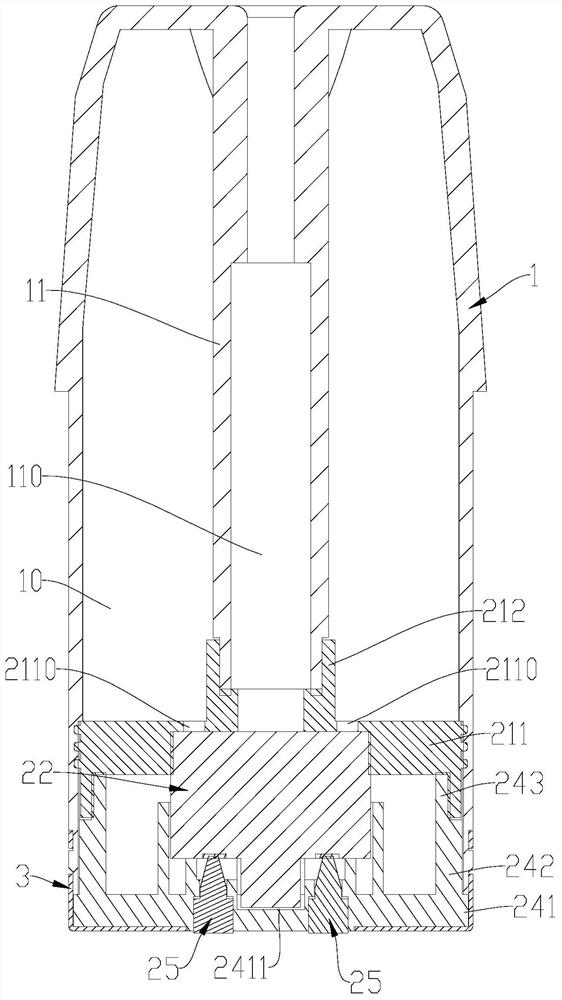

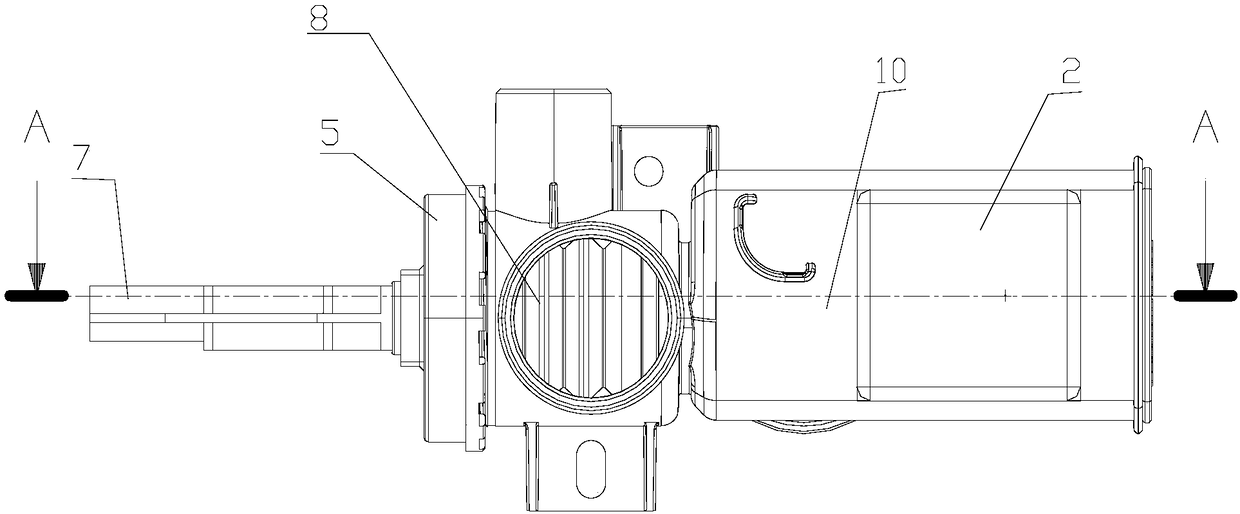

Electronic atomization device and atomizer thereof

PendingCN112493546AFew assembly partsSimple structureMedical atomisersInhalatorsPhysicsLiquid storage

The invention relates to an electronic atomization device and an atomizer thereof. The atomizer comprises a shell and an atomization assembly, wherein a liquid storage cavity is formed in the shell, and the atomization assembly is arranged in the shell. The atomization assembly comprises a base, a liquid guiding body arranged on the base, a heating body arranged on the liquid guiding body and a sealing piece arranged above the liquid guiding body in a sleeving mode. The liquid guide body is provided with a liquid suction face communicated with the liquid storage cavity in a liquid guide mode and an atomization face used for installing the heating body. And the direction of airflow flowing through the atomizing surface is parallel to the atomizing surface, so that the atomization is more sufficient. The atomizer is simple in structure and few in assembly parts, and materials and process cost are saved.

Owner:SHENZHEN HUACHENGDA PRECISION IND CO LTD

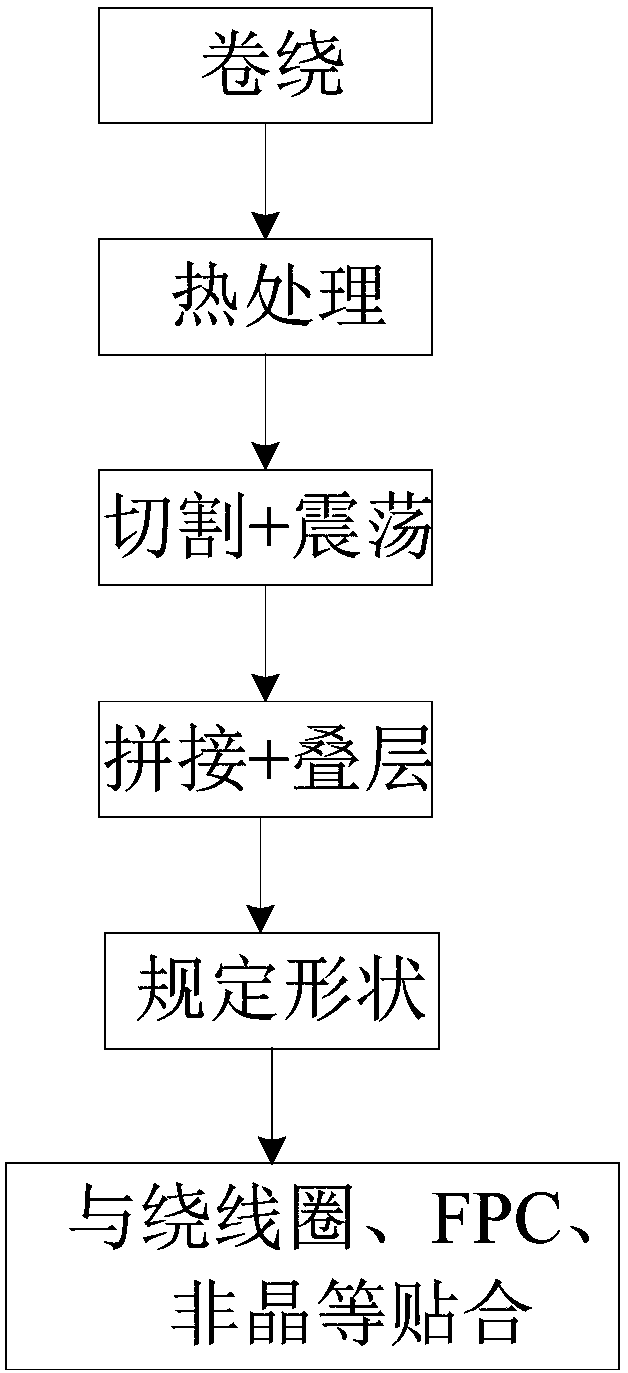

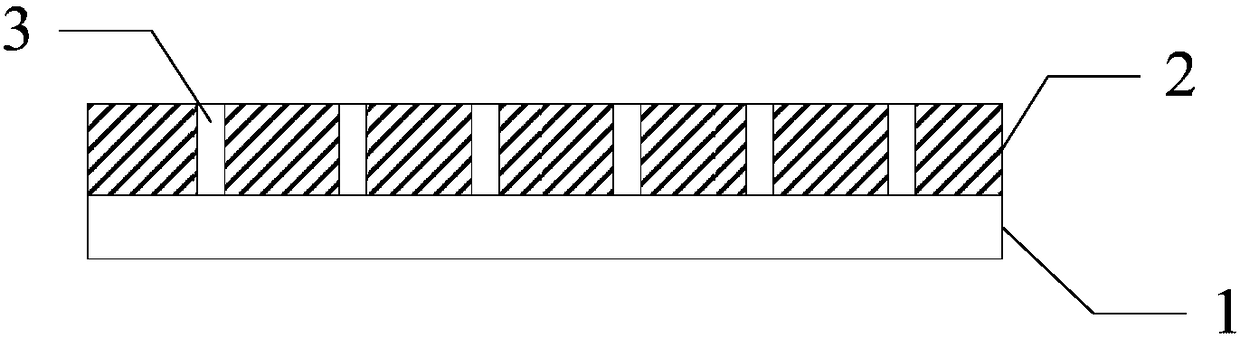

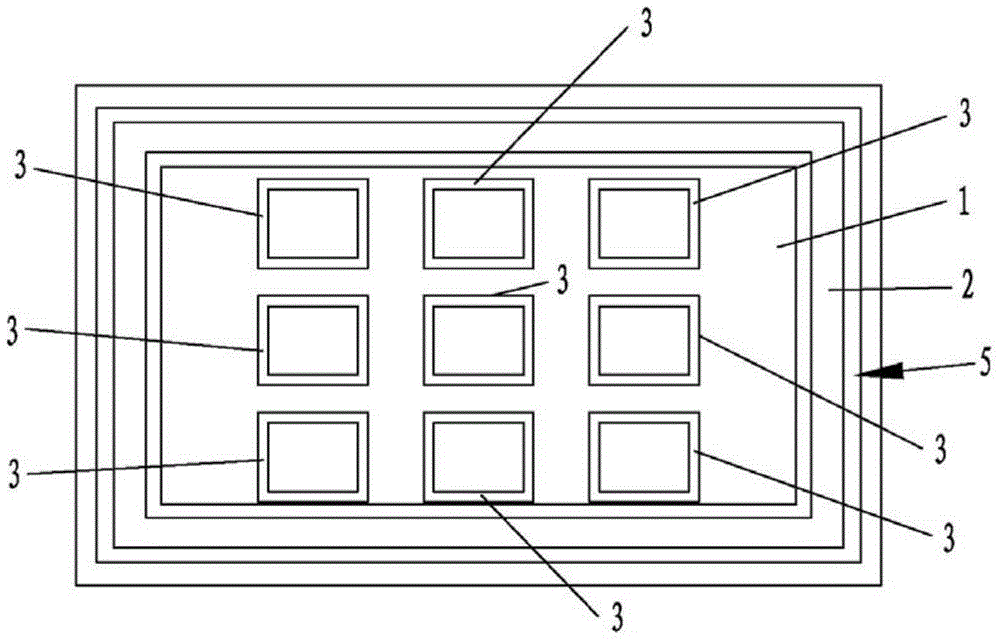

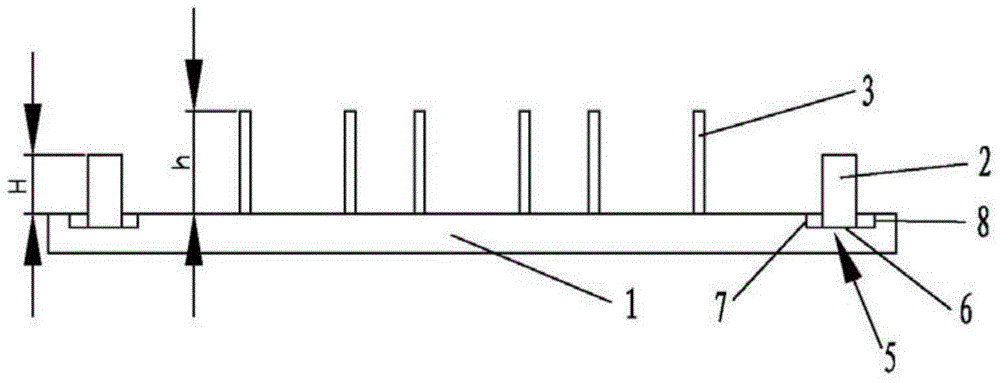

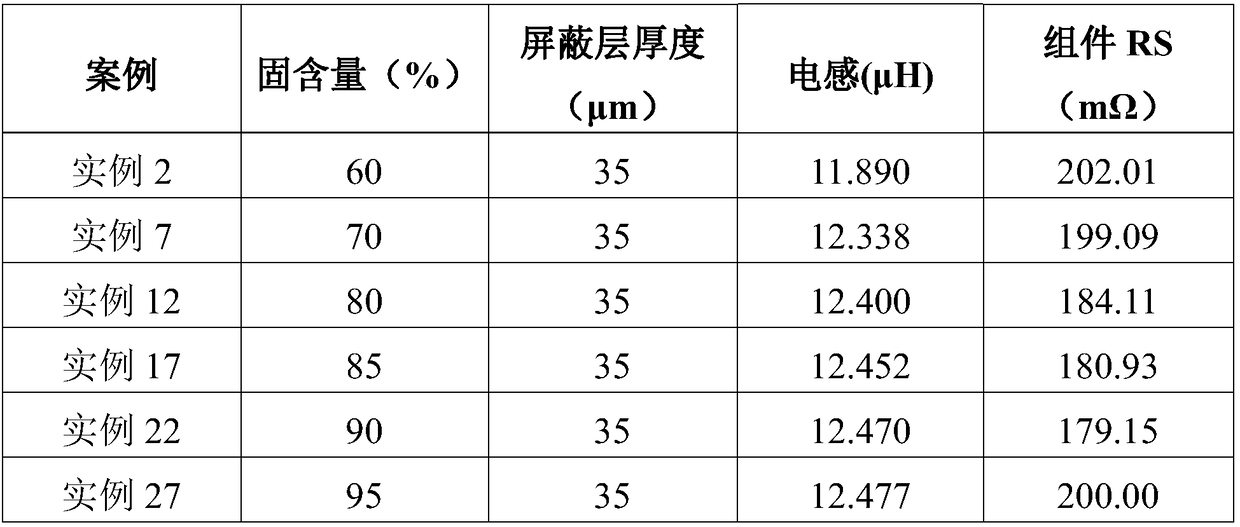

Preparation process of wireless charging application shielding sheet and shielding sheet

InactiveCN108235676AElectromagnetic Properties Permeability AverageReduce magnetic lossMagnetic/electric field screeningCircuit arrangementsTectorial membraneAdhesive

The invention discloses a preparation process of a wireless charging application shielding sheet. The wireless charging application shielding sheet comprises at least one longitudinally superposed shielding layer, wherein each shielding layer is formed by transversely splicing at least one soft magnetic shielding unit. The preparation process comprises the following steps: selecting soft magneticmaterials, and performing winding and heat treatment on the soft magnetic materials sequentially to obtain a substrate with two exposed surfaces; coating one exposed surface of the substrate with a double-sided adhesive tape, and cutting and vibrating the other exposed surface of the substrate by combining energy wire cutting and acoustic wave vibration to decompose the substrate into a pluralityof thin sheets in uniform shapes and certain size and obtain a soft magnetic shielding unit. The invention further discloses the wireless charging application shielding sheet. The wireless charging application shielding sheet comprises at least one shielding layer, a colloidal protective film and a PET film. The preparation process is simple and feasible, the shielding sheet is thin, good in shielding capability, high in charging efficiency and stable in work, and the process cost and the material cost are greatly saved.

Owner:SHANGHAI LINEPRINTING MATERIALS CO LTD

Elastic knitted fabric and preparation method thereof

ActiveCN109797480AGuaranteed permanenceHigh boiling water shrinkageWeft knittingWarp knittingEngineeringCompanion animal

The invention provides elastic knitted fabric, and solves problems in existing elastic knitted fabric that spandex is easily aged after multiple times of stretching because the spandex is added, so that fabric elasticity is greatly lost, and a plush structure can be obtained only through napping raising treatment, fabric processing procedures and processing cost are increased. A fabric rough blankof the fabric is formed by interweaving a high F-number yarn and an elastic shrinking yarn, or formed by co-interweaving the high F-number yarn, a common yarn and the elastic shrinking yarn. The highF-number yarn is a yarn of which a D / F range is within 0.5-1.6. The elastic shrinking yarn is a PTT / PET blending filament or a PBT / PET blending filament. The fabric rough blank is shrunk on the surface of an inner layer after dyed so as to form naps. In addition, the invention further provides a preparation method for the fabric.

Owner:WUXI HANUO TEXTILE TECH

Near-distance copper needle packaging structure and preparation method thereof

ActiveCN105719978AImprove performanceReduce distanceSemiconductor/solid-state device detailsSolid-state devicesCopper atomCopper wire

The invention provides a near-distance copper needle packaging structure and a preparation method thereof. The near-distance copper needle packaging structure comprises chips and copper needle structures, wherein the copper needle structures are fixedly connected with the chips in a welded manner; the surfaces of the copper needle structures are wrapped by diffusion baffle layers; and metal convex blocks are formed at the upper ends of copper needles in a backflow manner. According to the near-distance copper needle packaging structure, copper wires are wrapped by an inert metal and are separated into a great amount of copper needles, and subsequently the copper needles are directly inserted in positions where copper pillar bumps are to be manufactured on the chips, so that a conventional process that copper pillars are manufactured in an electroplating manner is replaced, the process time is greatly shortened, and the process cost is greatly reduced. As the surfaces of the copper needles are wrapped by inert metal protecting layers, diffusion of copper atoms can be reduced, the distance among the copper pillar bumps can be reduced, and the copper pin packaging and stacking capability can be greatly improved. The near-distance copper needle packaging structure is simple in process and structure, can effectively improve the chip performance, and has wide application prospects in the field of semiconductor packaging.

Owner:SJ SEMICON JIANGYIN CORP

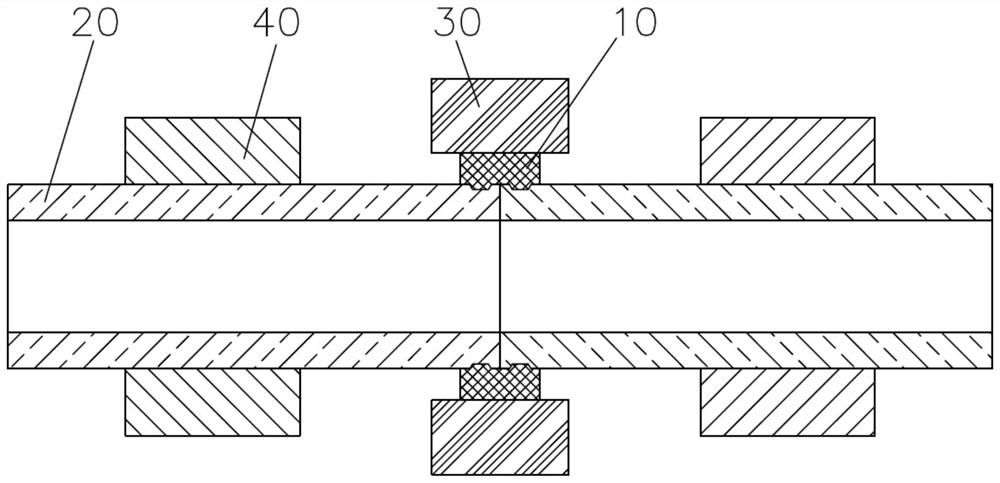

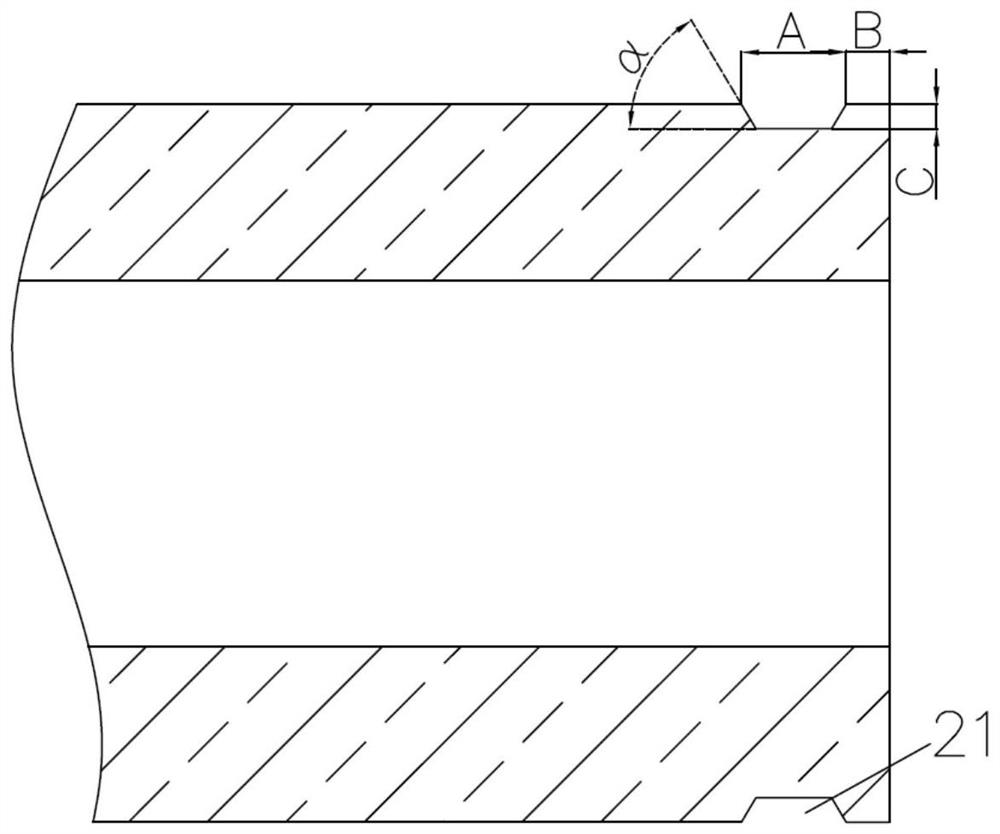

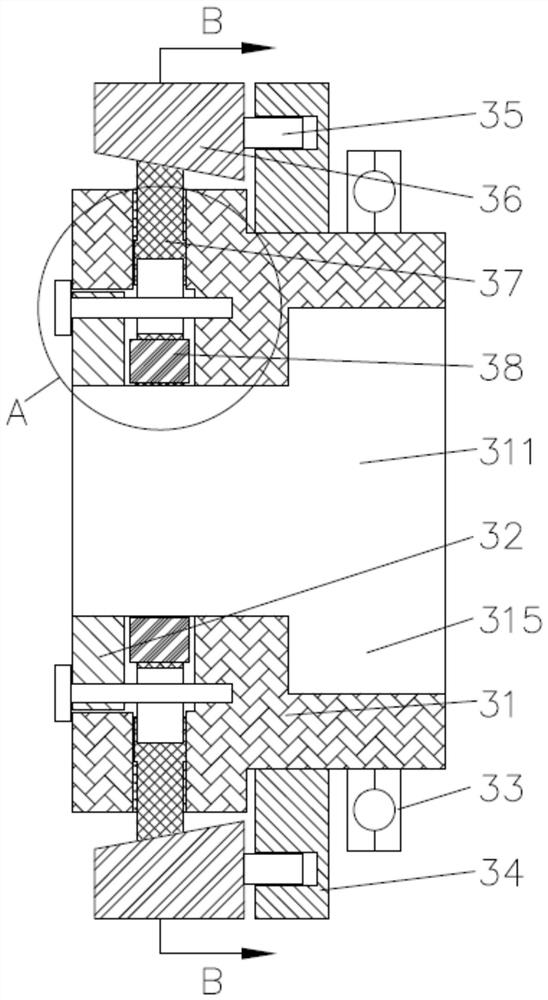

High-strength and high-reliability-sealing radial friction welding method for steel pipe fitting

ActiveCN113770507AAchieve Radial Friction WeldingImprove coaxialityNon-electric welding apparatusFriction weldingPipe fitting

The invention provides a high-strength and high-reliability-sealing radial friction welding method for a steel pipe fitting. According to the method, a clamping mode that a rotary pressurizing tool (30) clamps a steel ring welding blank (10) and fixed clamping tools (40) clamp two steel pipe welding blanks (20) respectively is adopted, and the radial friction welding mode that the steel pipe welding blanks (20) at the two ends do not rotate, the steel ring welding blank (10) rotates and pressurizes, and annular grooves (21) are formed in the welding positions of the steel pipe welding blanks (20) at the two ends is adopted; radial friction welding of a large-length steel pipe is achieved, high coaxiality of the welded steel pipe is guaranteed, meanwhile, radial run-out caused by self-rotation of the large-length steel pipe is effectively avoided, welding flashes or weld beading and the like in the pipe are avoided, the welding quality is guaranteed, the annular grooves (21) form a double-spigot locking structure, and the welding strength and the high-reliability-sealing performance of a weldment are ensured.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

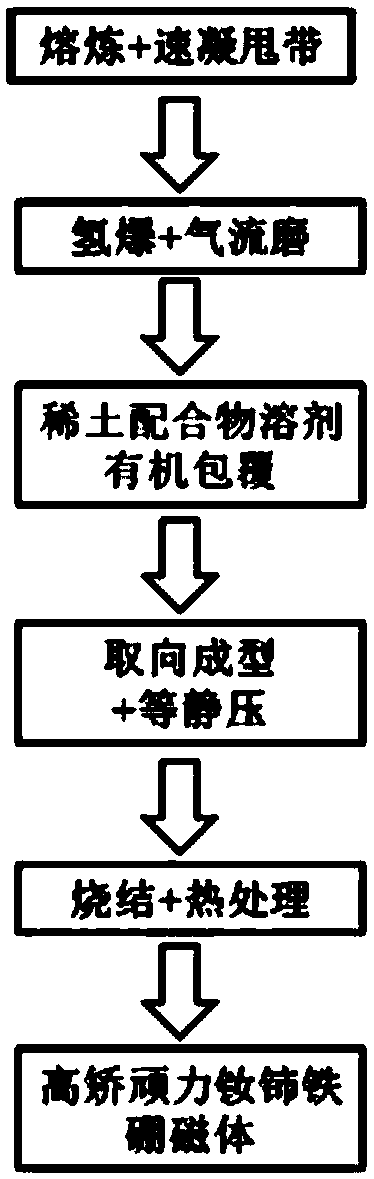

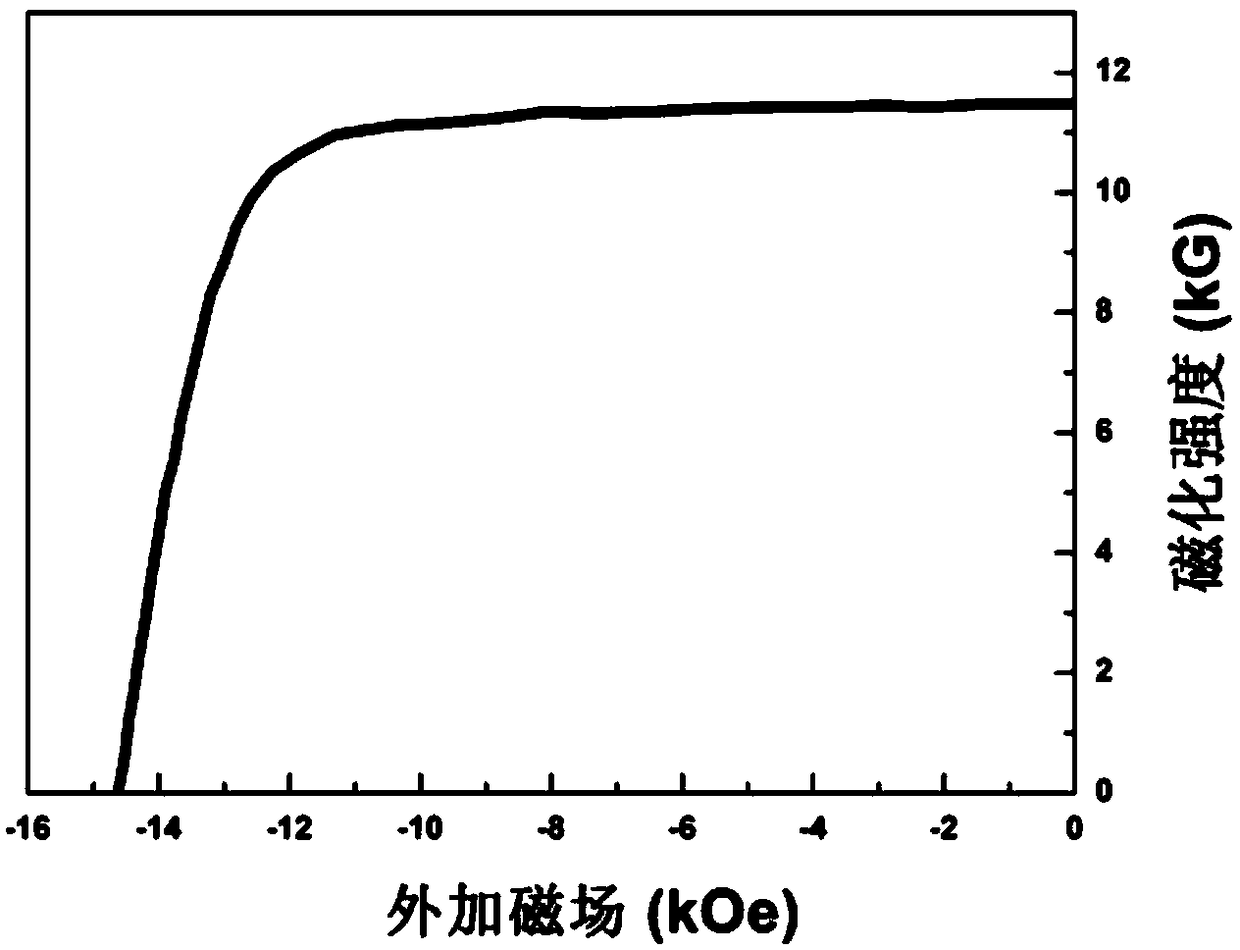

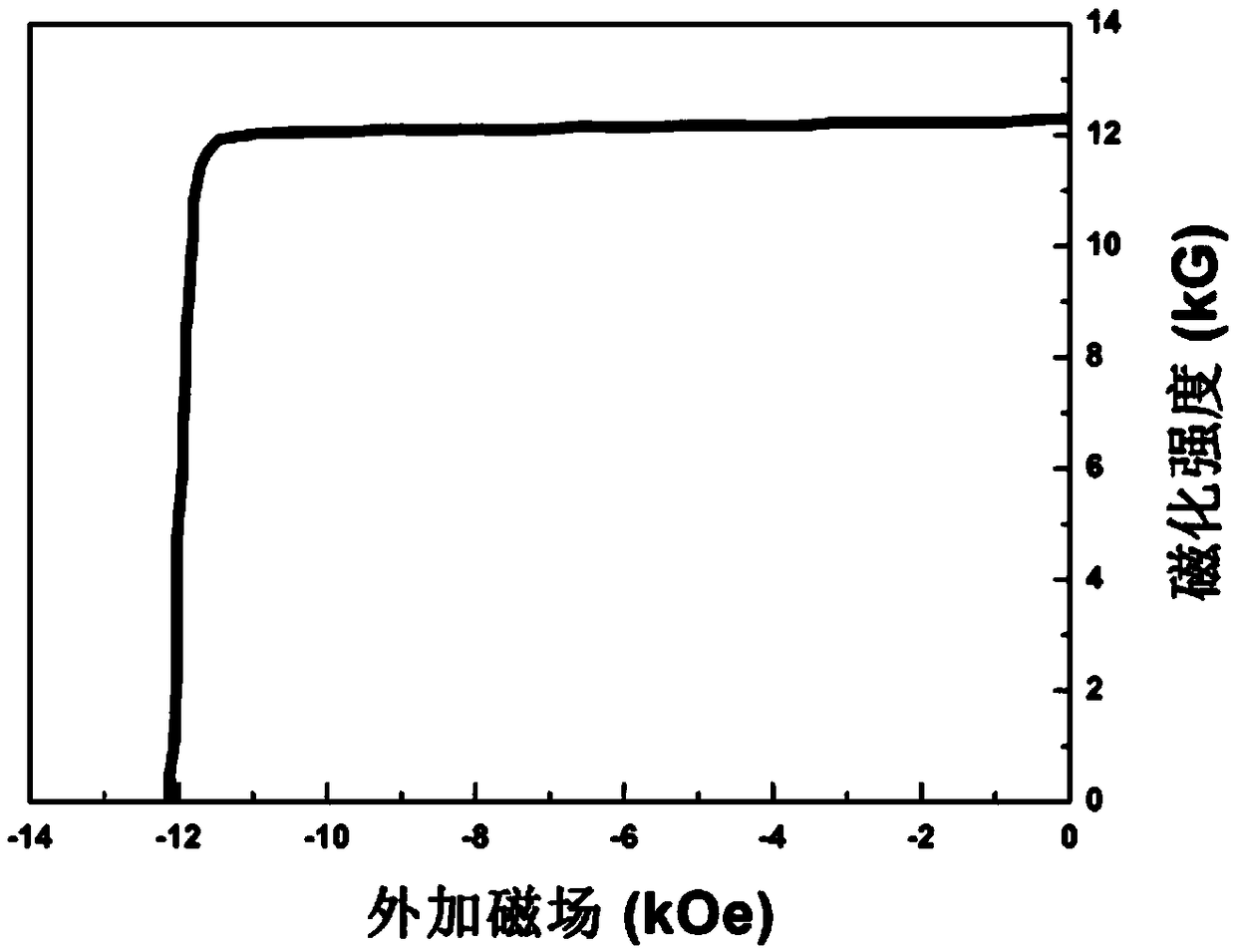

Fabrication method of high-coercivity Nd-Ce-Fe-B sintered magnet

InactiveCN108922714AInhibit high oxidation reactivityPrevent oxidationInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementOrganic solvent

The invention belongs to the technical field of a permanent-magnet material, and particularly discloses a fabrication method of a high-coercivity Nd-Ce-Fe-B sintered magnet. According to the method, surface wetting and coating is performed on magnet powder by employing a rare-earth complex organic solvent during mixing, the oxidization of Ce-rich magnetic powder is effectively controlled; meanwhile, elements C and H become gas and are escaped during the high-temperature sintering and decomposition process of a rare-earth complex on a surface of the magnetic powder, heavy rare-earth elements Pr / Nd / Tb / Dy / Ho resided on surfaces of alloy powder particles are used as diffusion sources and are diffused towards a grain surface, magnetic hardening on a main-phase grain surface is achieved, the local magnetocrystalline anisotropy is improved, and the coercivity of the Nd-Ce-Fe-B magnet is improved. The Nd-Ce-Fe-B sintered magnet fabricated by the method is relatively high in coercivity, a traditional sintered magnet fabrication technology is improved, and the technology is simple in process and low in cost and is suitable for mass production.

Owner:NANJING UNIV OF SCI & TECH

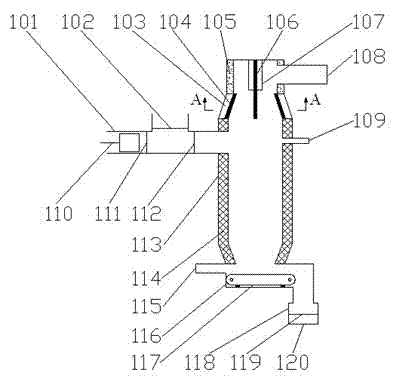

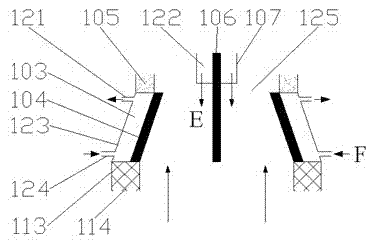

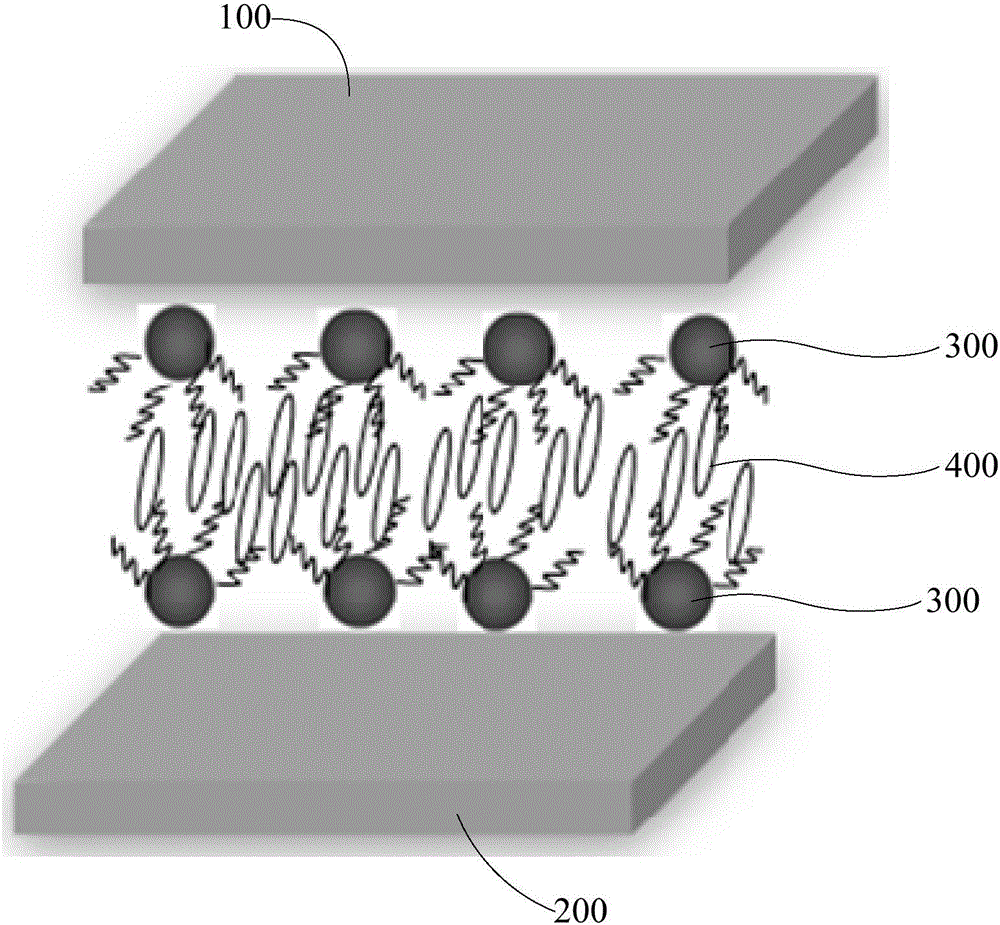

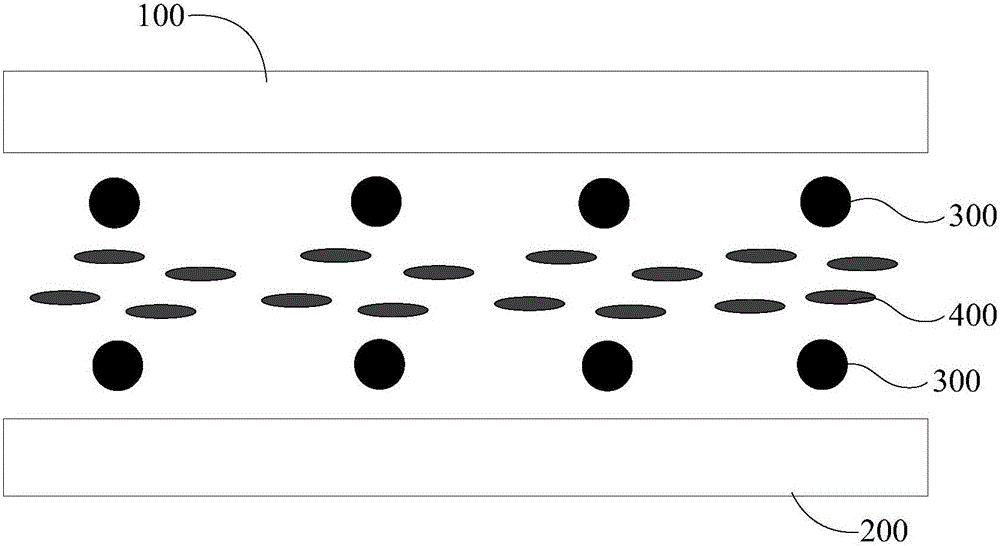

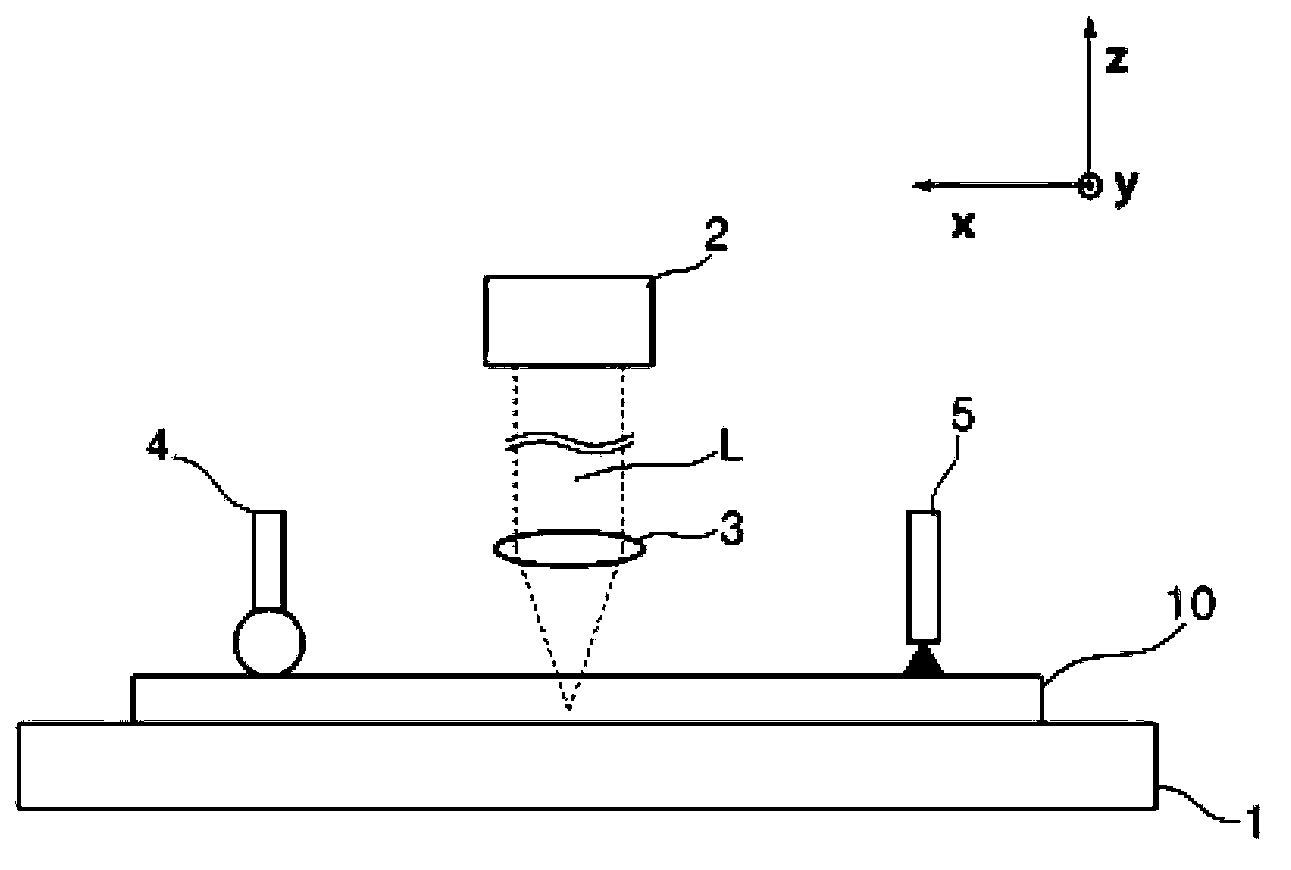

Substrate cutting device and substrate cutting method

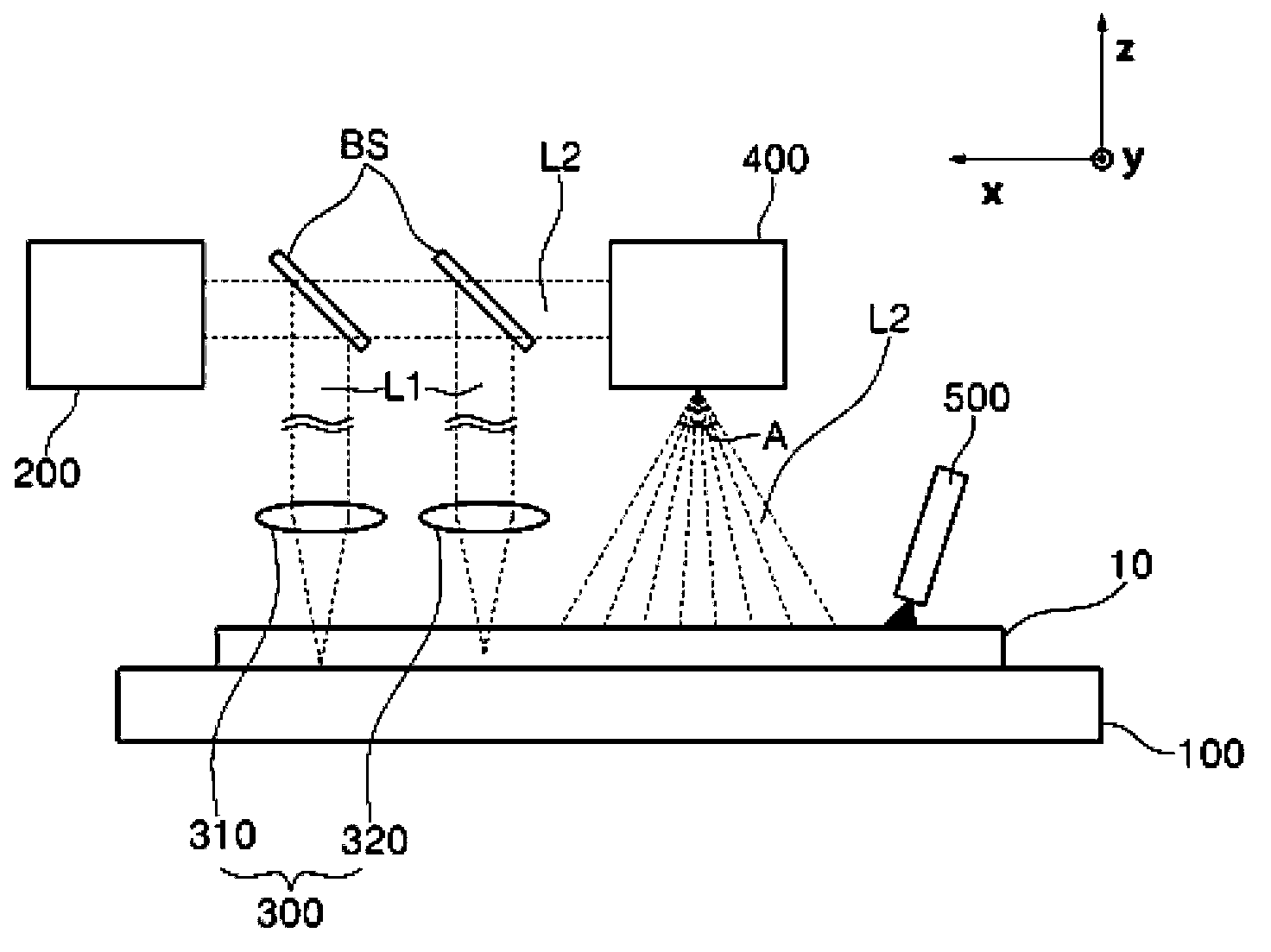

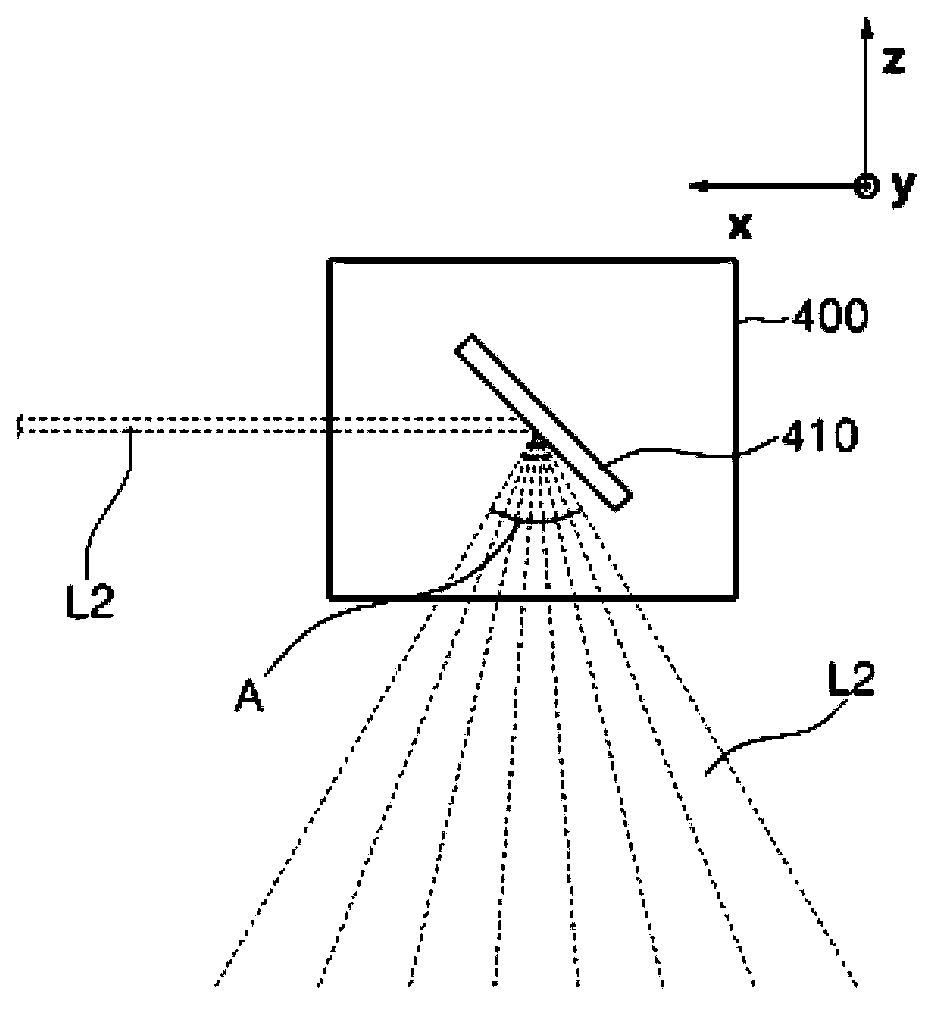

ActiveCN103387335AImprove cut qualitySave process timeGlass severing apparatusLaser beam welding apparatusBeam splitterOptoelectronics

The invention relates to a substrate cutting device and a substrate cutting method. The substrate cutting device is characterized by comprising a working table (100) for placing a substrate (10), a laser part (200) for generating laser beams (L1, L2), beam splitters (BS) for splitting the laser beams (L1, L2) into first laser beams (L1) and a second laser beam (L2), a first processing part (300) for subjecting the internal of the substrate (10) to scribing treatment with the first laser beams (L1) to form a first etching part (P1, P2), and a second processing part (400) for subjecting the internal of the substrate (10) to beam swing scribing treatment with the second laser beam (L2) to form a second etching part (P3).

Owner:CHARM ENG CO LTD

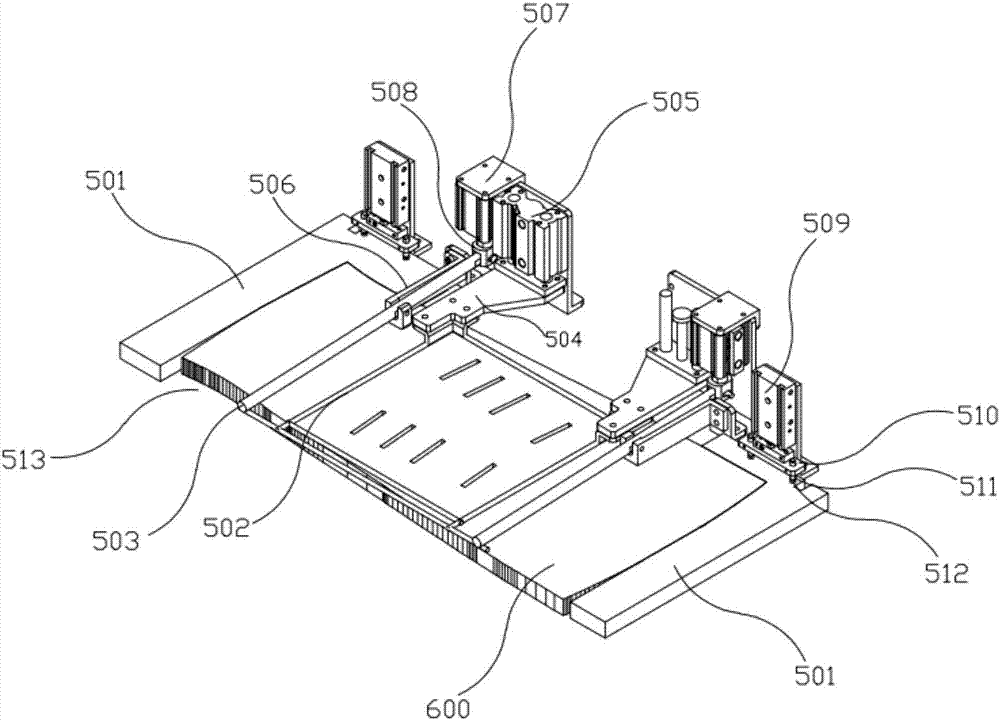

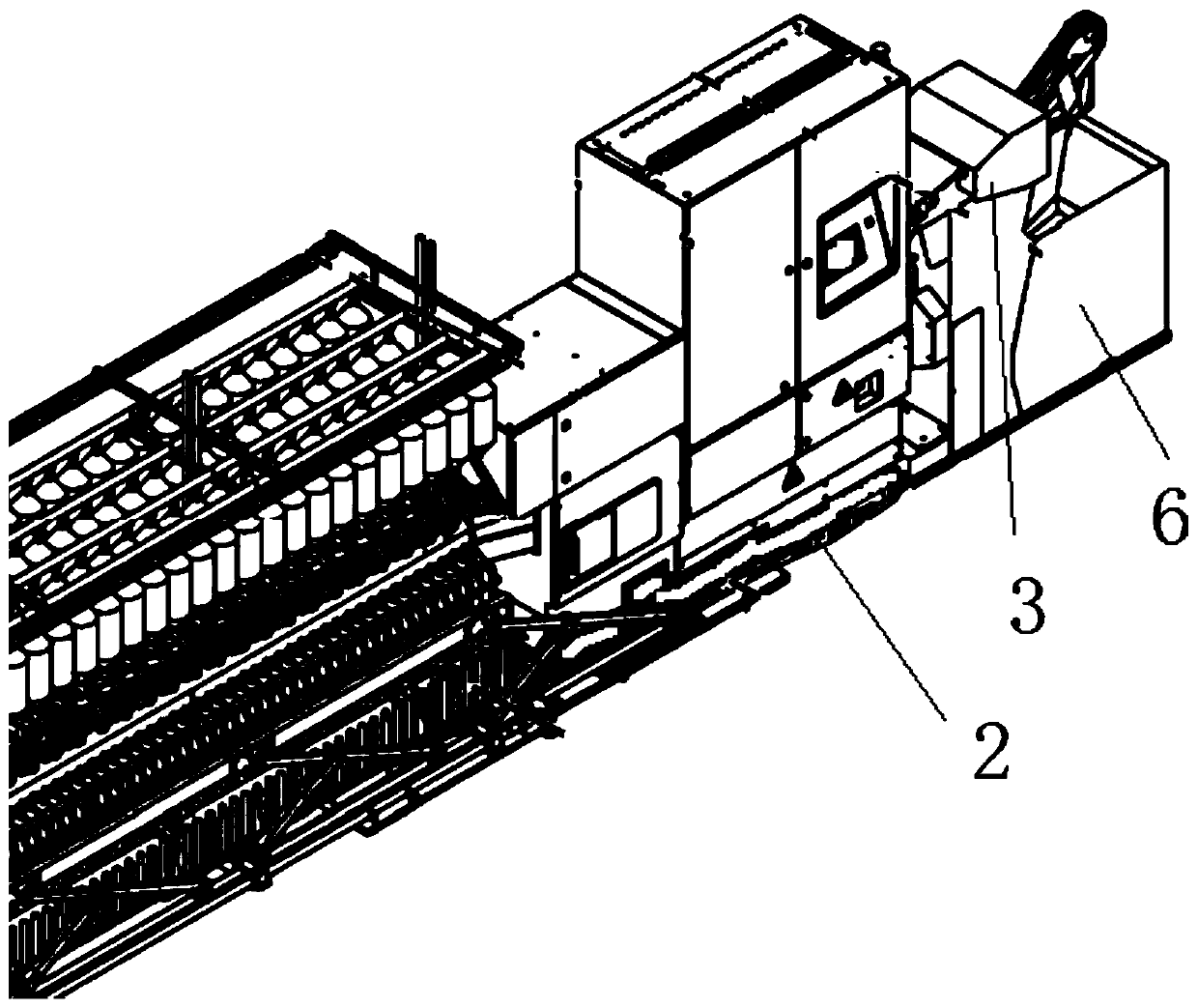

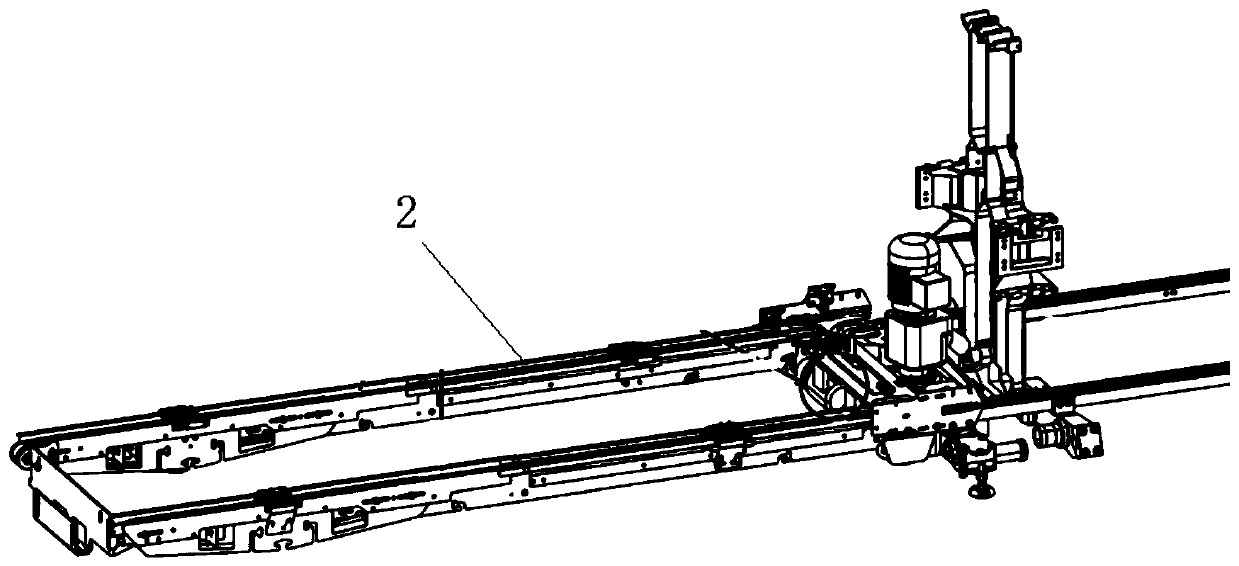

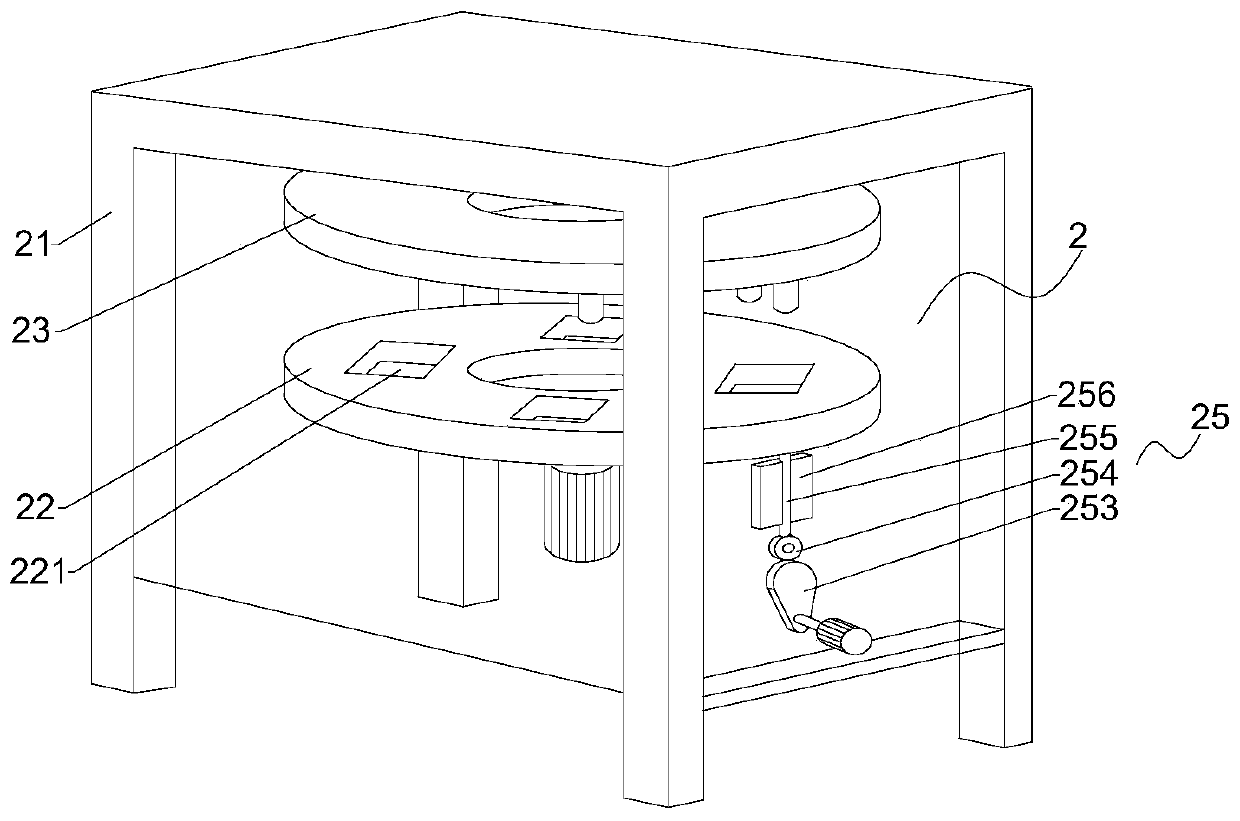

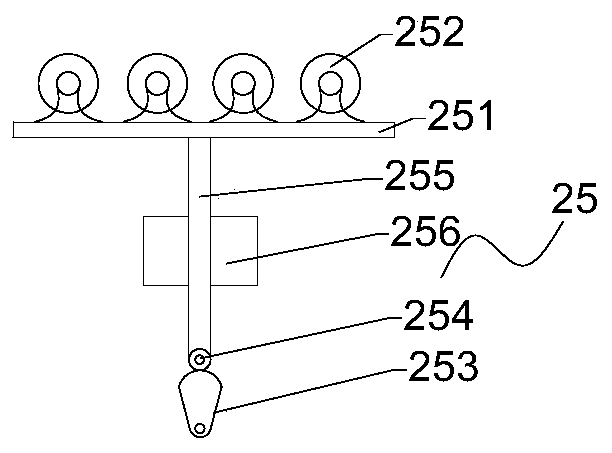

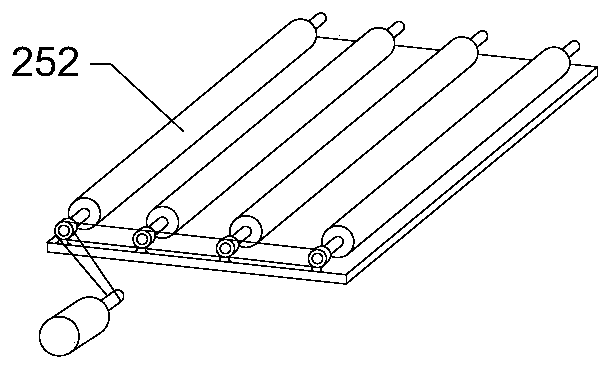

Cooperative automatic sewing workstation

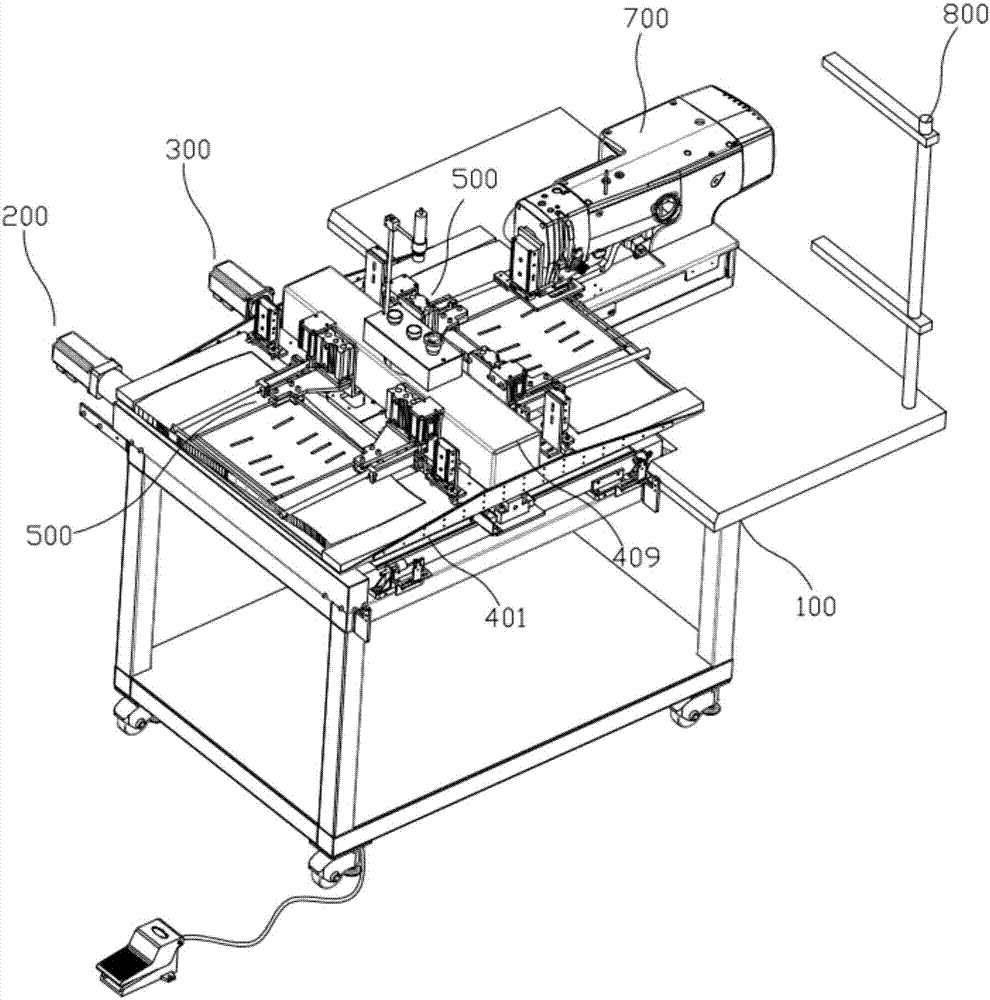

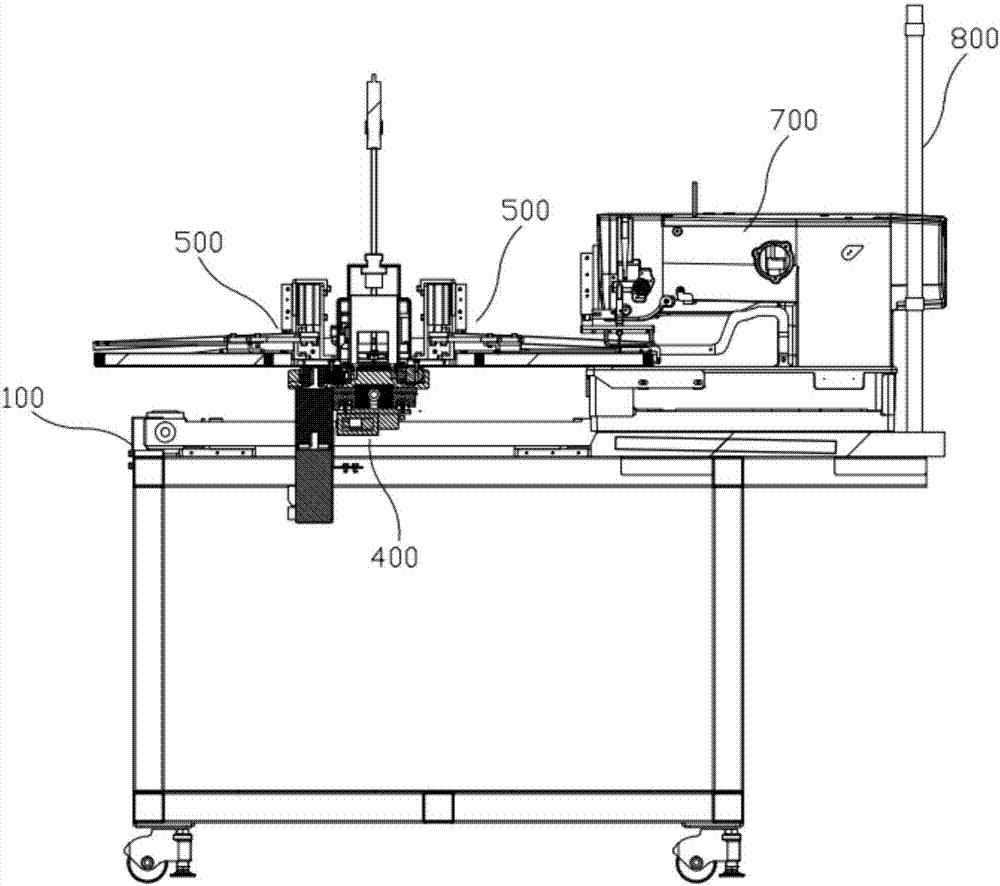

ActiveCN107447376AImprove sewing effectSave process costWork-feeding meansSewing-machine control devicesReciprocating motionEngineering

The invention discloses a cooperative automatic sewing workstation. The workstation comprises a rack, and the rack is provided with a sewing machine, a thread frame and a moving platform for clamping and fixing sewing materials; the moving platform is used for making the sewing materials automatically sewn by the sewing machine and comprises a Y-axis moving platform which can make reciprocating movement relative to the sewing machine, an X-axis moving platform arranged on the Y-axis moving platform and a Z-axis rotating platform arranged on the X-axis moving platform; the Z-axis rotating platform is provided with at least one sewing fixture. According to the cooperative automatic sewing workstation, the automatic moving platform is additionally arranged on an original straight buttonholing machine, so that the various sewing positions and sewing angles in the sewing process of the straight buttonholing machine are synchronized according to set sewing specifications, multiple straight holes can be sewn in one time, and the operation of returning back to a material changing position is automatically completed; the sewing effect and the sewing quality are improved, the marking process are omitted, operation personnel are saved, and one person can operate multiple machines.

Owner:福恩达机器人(昆山)有限公司

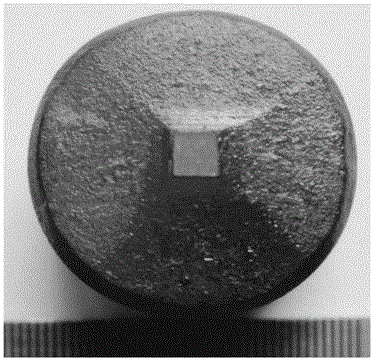

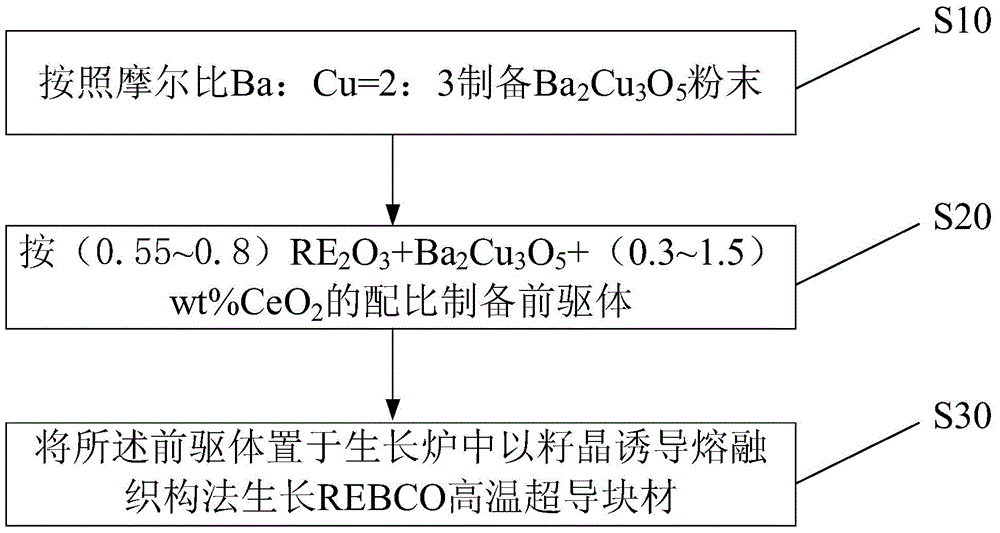

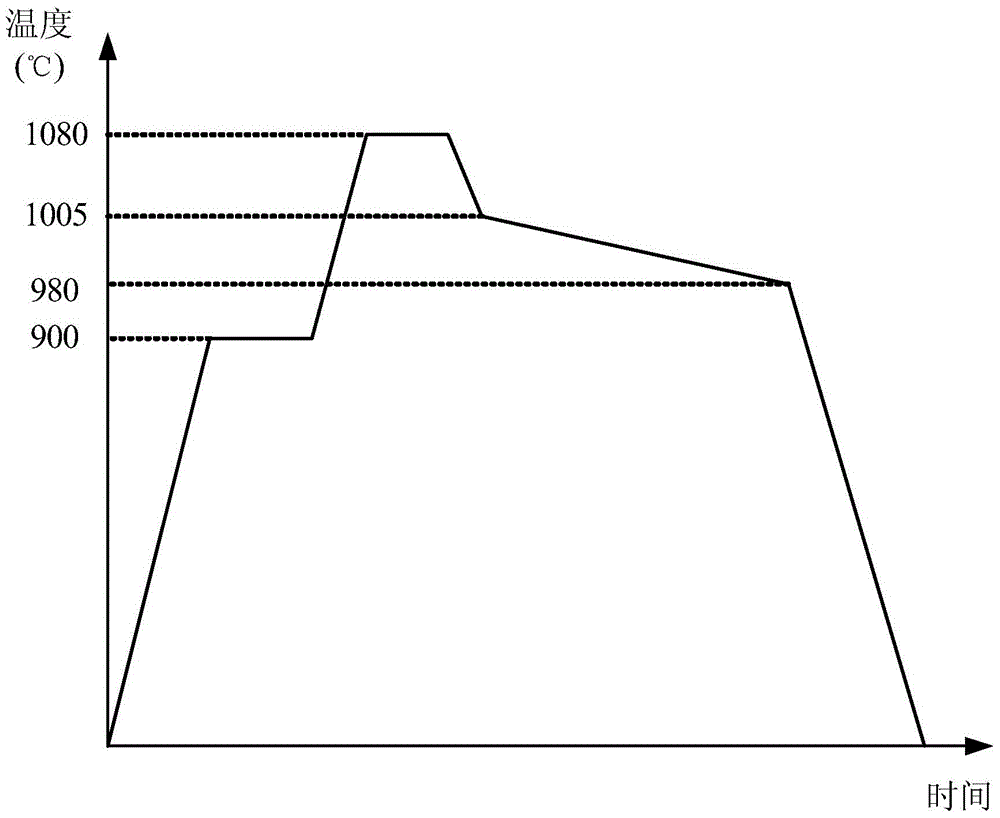

Method for growing REBCO high-temperature superconductor

InactiveCN105177712AImprove thermal stabilityIntegrity guaranteedPolycrystalline material growthFrom solid stateSeed crystalMaterials science

The invention provides a method for growing an REBCO high-temperature superconductor, which comprises the following procedures: (a) preparing Ba2Cu3O5 powder according to the molar ratio of Ba:Cu=2:3; (b) preparing a precursor according to the proportion of (0.55-0.8)RE2O3+Ba2Cu3O5+(0.3-1.5)wt% CeO2; and (c) putting the precursor in a growth furnace, and growing the REBCO high-temperature superconductor by a seed crystal-induced melting texturing method, wherein the precursor in the procedure (b) is a cylindrical precursor formed by uniformly mixing the Ba2Cu3O5 powder obtained in the procedure (a) according to the proportion of (0.55-0.8)RE2O3+Ba2Cu3O5+(0.3-1.5)wt% CeO2 and then pressing. According to the invention, the Ba2Cu3O5 powder prepared according to the molar ratio of Ba:Cu=2:3 is directly used in the precursor, and RE123 powder and RE211 powder are not prepared, so that the time and process costs are saved, and the proportion of all elements in the whole growing process keeps that the molar ratio of RE123 to RE211 is approximately equal to 1:(0.1-0.4), thereby obtaining the REBCO high-temperature superconductor.

Owner:SHANGHAI JIAO TONG UNIV

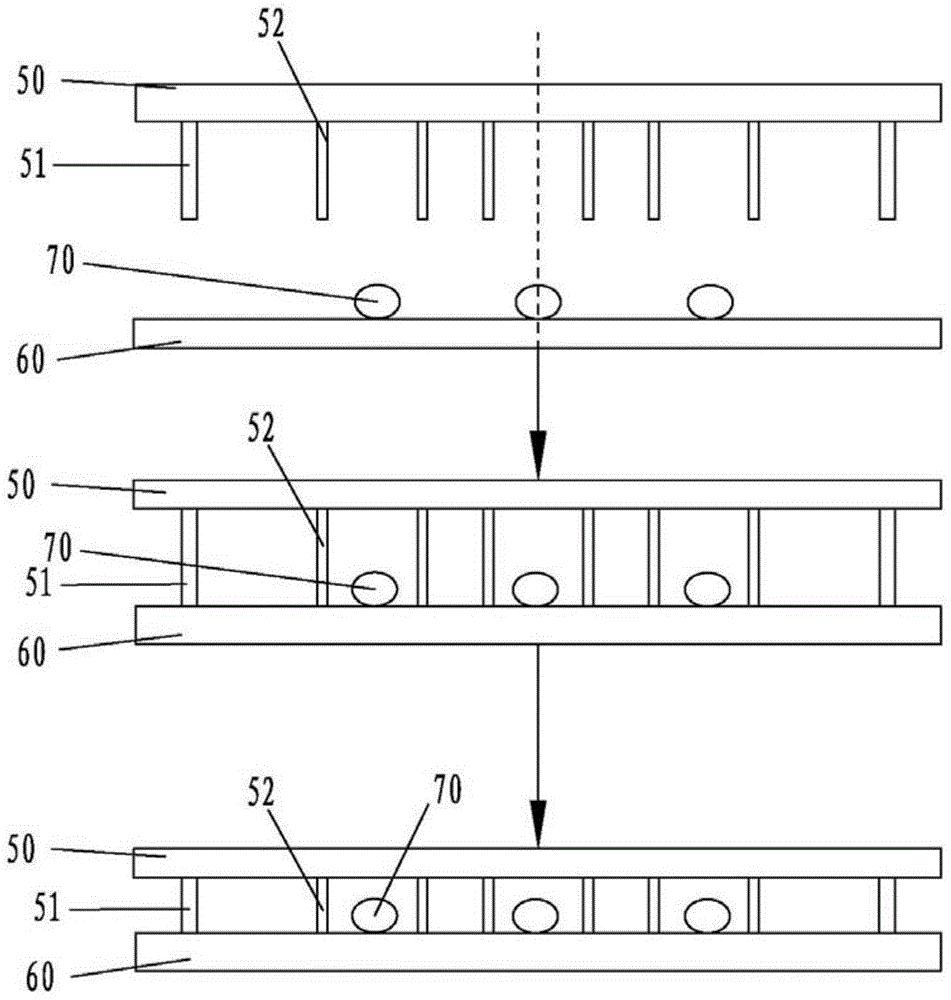

Substrate bonding process and substrate module to be bonded

InactiveCN103955085AAvoid punctureReduce pressure differenceLayered productsElectrical equipmentBonding processEngineering

The invention relates to a substrate bonding process and a substrate module to be bonded, wherein a peripheral rubber frame is arranged on the surface of a substrate of the substrate module to be bonded, boxed rubber frames are arranged in the peripheral rubber frame, and the height of the boxed rubber frames is greater than the height of the peripheral rubber frame. The substrate bonding process includes the following steps that the peripheral rubber frame is arranged on the surface of a first substrate, the boxed rubber frames for sealing liquid crystal are arranged in the peripheral rubber frame, and the height of the boxed rubber frames is greater than the height of the peripheral rubber frame; the air between the first substrate and a second substrate is sucked off; the first substrate and the second substrate are preliminarily bonded; gas is filled in between the first substrate and the second substrate; the first substrate and the second substrate are further bonded. The technical scheme of the invention can prevent the liquid crystal in the boxes from impacting the boxed rubber frames to cause penetration, save process time and cost and decrease the probability that circuit wires and element switches are corroded by acid liquid.

Owner:BOE TECH GRP CO LTD +1

Quick collection and changing device for spinning frame cones

The invention relates to a quick collection and changing device for spinning frame cones. A yarn roll is placed on a rail mechanism and is conveyed along with a conveyer belt; when the yarn roll is conveyed to the discharge end of a rail, the yarn roll drops into a spool collection box automatically under the action of its gravity. The quick collection and changing device is simple in structure and convenient to operate; removing yarn rolls manually is not required, so that steps and manpower cost are saved, and manual operation mistakes are avoided; when a conveyer moves to the rear of a coneconveyer box, cones can be placed automatically on the conveyer in sleeving manner; the cones are continuously conveyed to a yarn region along with the conveyer belt; the quick collection and changing device is simple in structure and convenient to operate; manually placing the cones is not required, so that steps and manpower cost are saved, and manual operation mistakes are avoided.

Owner:JIANGSU NIJIAXIANG GROUP WORSTED TEXTILE

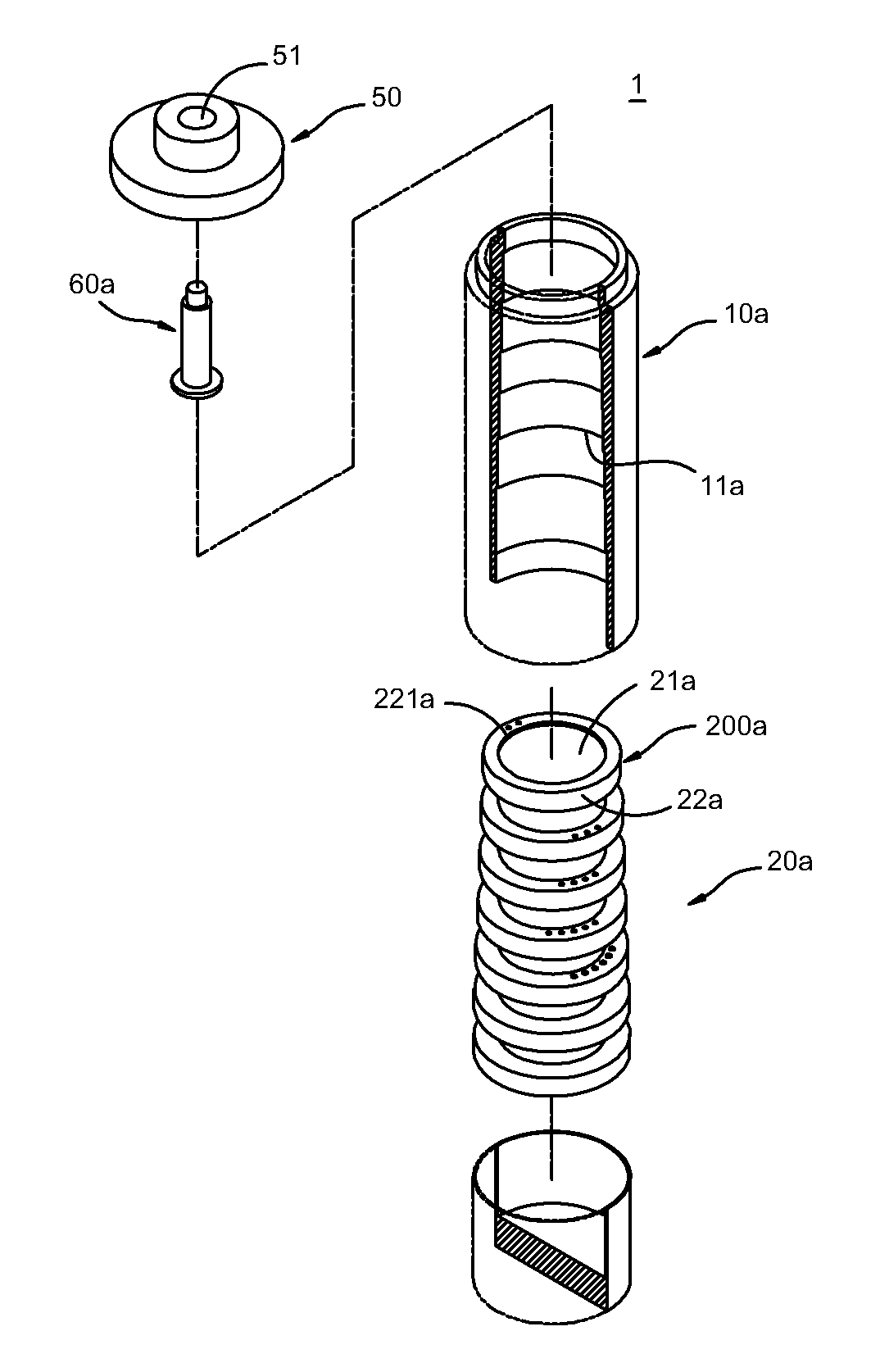

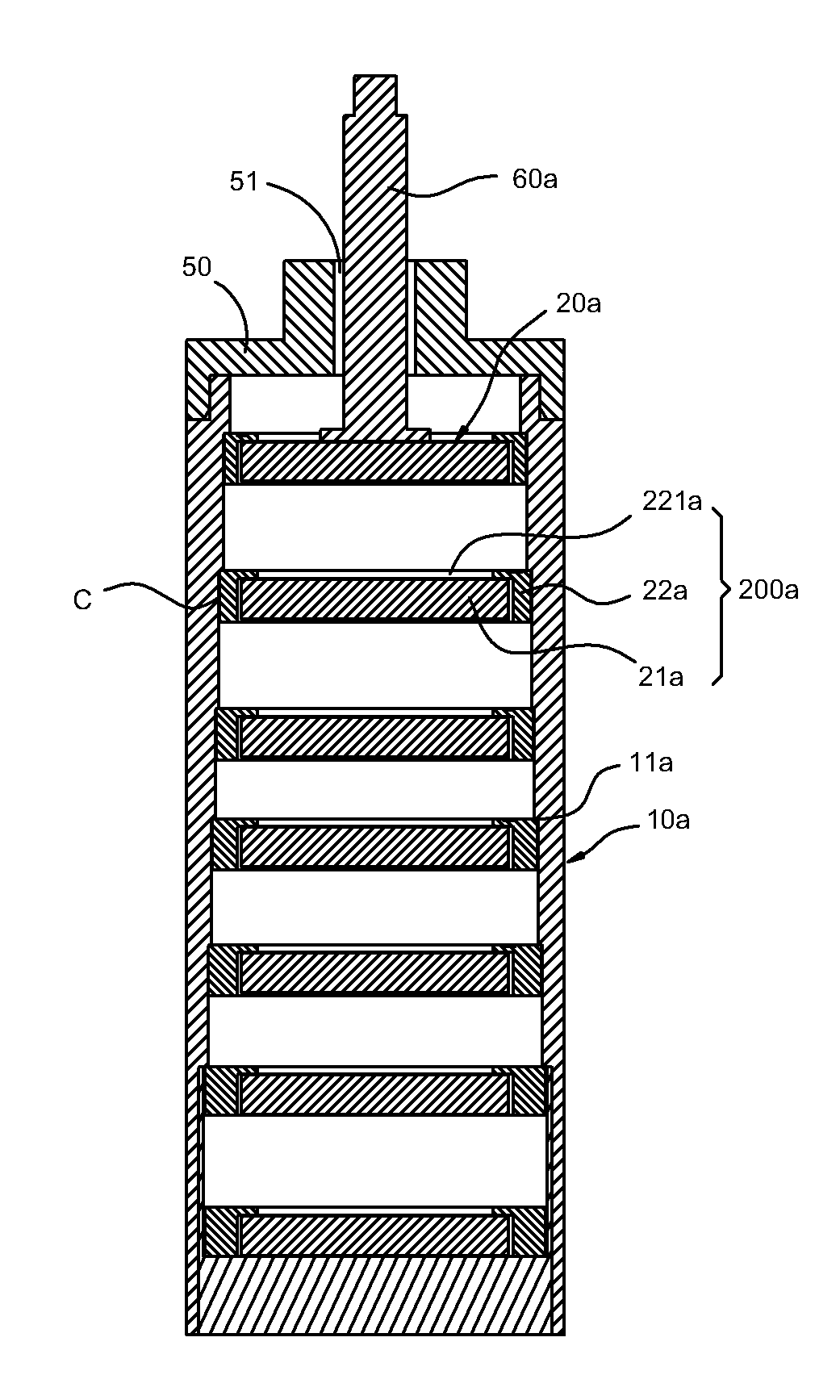

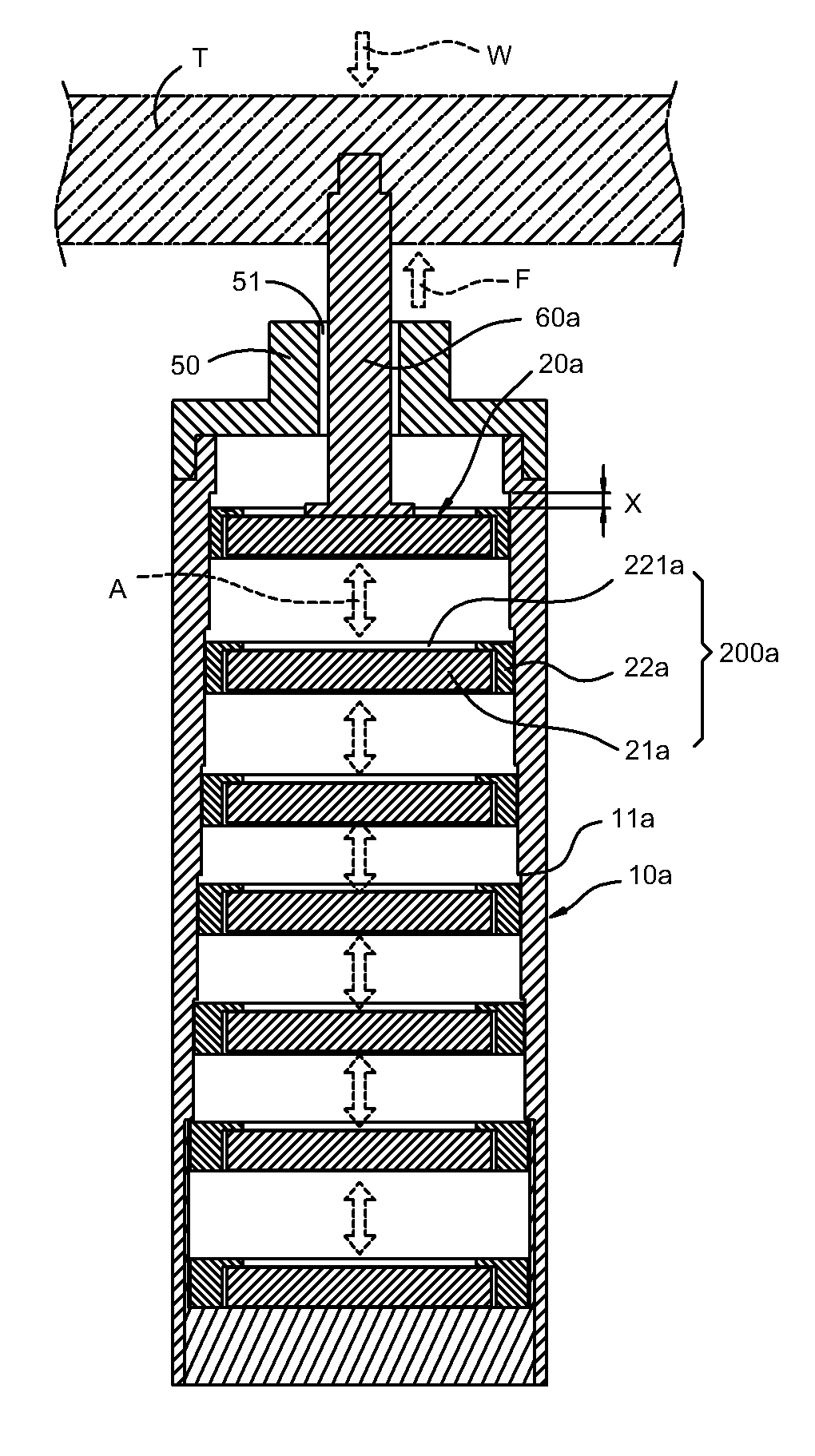

Magnetic shock-absorption device

InactiveCN103322103AIncrease or decrease quantityNo elasticity fatigue problemMagnetic springsMagnetic tension forceAbsorption effect

The invention discloses a magnetic shock-absorption device which comprises a cylinder base and a magnetic group, wherein the magnetic group comprises a plurality of magnetic units; each magnetic unit comprises a magnet and a protective sleeve for wrapping the magnet; holes are formed in two surfaces of each protective sleeve respectively; and the magnetic units are arranged in the cylinder base in a serial manner, so that magnetic repulsive force is generated between opposite surfaces of every two adjacent magnetic units. Accordingly, damping force is generated by utilizing the magnetic repulsive force generated by the magnetic units in the magnetic group, and the shock-absorption effect is realized.

Owner:李宗仕

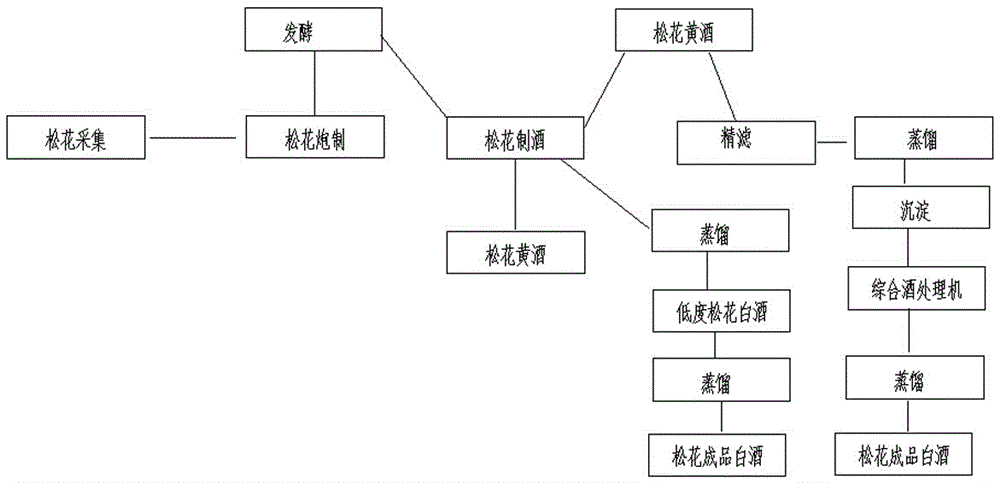

Piny flower wine and preparation method thereof

InactiveCN105670892AHave business valueSave process timeDigestive systemAlcoholic beverage preparationBiotechnologyChinese liquor

The invention relates to a piny flower wine and a preparation method thereof. The invention specifically includes a formula of piny flower original pulp Chinese liquor and piny flower yellow wine and a preparation method thereof. Specifically, according to the formula of the piny flower original pulp wine, the main materials include: 2-5 or 4-7 parts of mountain stream, 5-8 or 3-6 parts of piny flower; or the main materials include: 3-5 parts or 3-6 parts of mountain stream, 1.5-3 parts or 3-6 parts of piny flower, 0.5-2 parts of honey, 0.5-2 parts or 0.5-1 part of Scutellaria baicalensis, and 0.5-3 parts or 0.5-1 part of Rosa roxbunghii; and the auxiliary materials include: 0.5-1.5 parts or 1.5-3 parts of rock sugar. The preparation method consists of piny flower collection, piny flower processing, and piny flower wine making.

Owner:冯泽吉

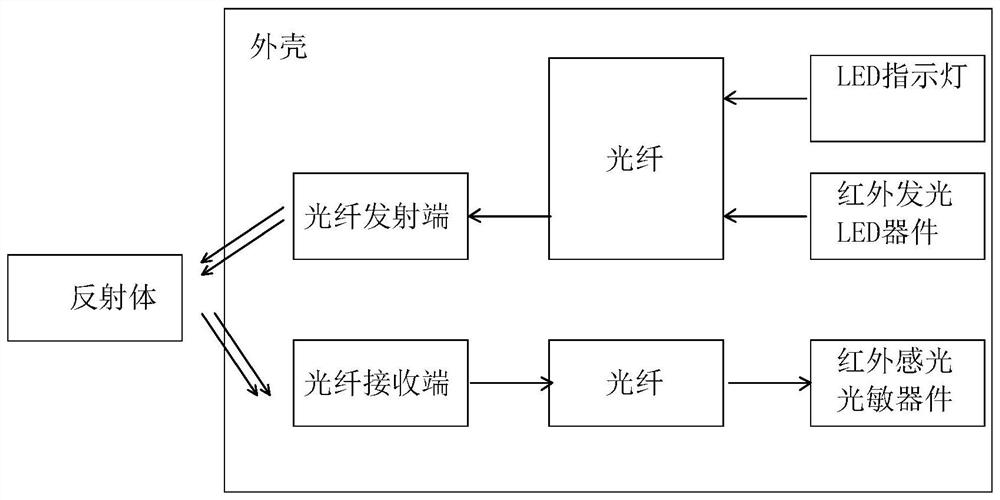

Electronic element for realizing integration of IR remote control and infrared light reflection induction

PendingCN112367548AImprove aestheticsRealize switch machineNon-electrical signal transmission systemsSelective content distributionIr reflectionRemote control

The invention discloses an electronic element capable of realizing integration of IR remote control and infrared light reflection induction, which comprises a shell, and an infrared transmitting module, an infrared receiving module and an LED indicating lamp which are packaged in the shell, and is characterized in that the infrared transmitting module is used for outputting an infrared signal to the outside from a television, wherein the infrared receiving module is used for receiving reflected infrared signals through a reflector or receiving infrared signals sent by an external remote controller, and the LED indicator lamp is used for indicating the working state of the television or responding to receiving of the infrared signals by the infrared receiving module. According to the scheme, the infrared transmitting module, the infrared receiving module and the LED indicator lamp are integrally packaged, so that the working procedures and labor cost of structural design, manufacturingand mounting can be saved, and the attractiveness of the television mounted on the television is improved. Compared with a traditional control method, the scheme does not need a remote controller, andthe startup, shutdown and menu functions can be achieved only by collecting the duration of the infrared reflection signals.

Owner:GUANGDONG CHANGHONG ELECTRONICS

Cleaning ball and washing machine

InactiveCN108568437AReduce wearReduce noise pollutionHollow article cleaningOther washing machinesWater infusionFree state

The invention belongs to the technical field of the decontamination device and washing machine, and particularly relates to a cleaning ball and washing machine. The cleaning ball comprises a magneticmaterial, and the cleaning ball can be attracted by a magnetic field and demagnetize when the magnetic field disappears. The cleaning ball can be relatively stably collected in the drain valve deviceused in the laundry dehydration process, so as to avoid the cleaning ball bounce back between the inner and outer barrels, and the noise that occurs frequently between the inner and outer barrel wallsduring the dehydration process can be avoided because the cleaning ball is bounced back into the inner and outer barrels; after the dehydration is completed, the cleaning ball returns to the free state, and returns to the inner and outer barrels of the washing machine with the water infusion process, and continues to clean the inner and outer barrels. The cleaning ball not only extends the service life of cleaning ball, but also improves the cleaning effect of the inner and outer barrels of the washing machine, and the noise is low, which improves the user experience.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

Touch control sensor and preparing method thereof and touch control display device

InactiveCN107291297AFlexible settingsLow costInput/output processes for data processingElectricityAdhesive

The invention provides a touch control sensor and a preparing method thereof and a touch control display device. The method comprises the steps that a first flexible substrate is covered with a first conductive material, so that a first conductive layer is formed, the surface, away from the first flexible substrate, of the first conductive layer is subjected to first etching processing, so that one or more first binding points are formed, and the first binding points are used for being electrically connected with an external circuit; a second flexible substrate is covered with a second conducive material, so that a second conductive layer is formed, one or more second binding points are formed on the surface, away from the second flexible substrate, of the second conductive layer, and the second binding points are used for being electrically connected with the external circuit; the first conductive layer is attached to the second conductive layer through adhesives, a circuit board to be salified is obtained and subjected to hot pressing processing, and the touch control sensor is obtained. By adoption of the preparing method, the position of the binding points of the obtained touch control sensor can be flexibly arranged, and accordingly the technology cost and time cost are greatly saved.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

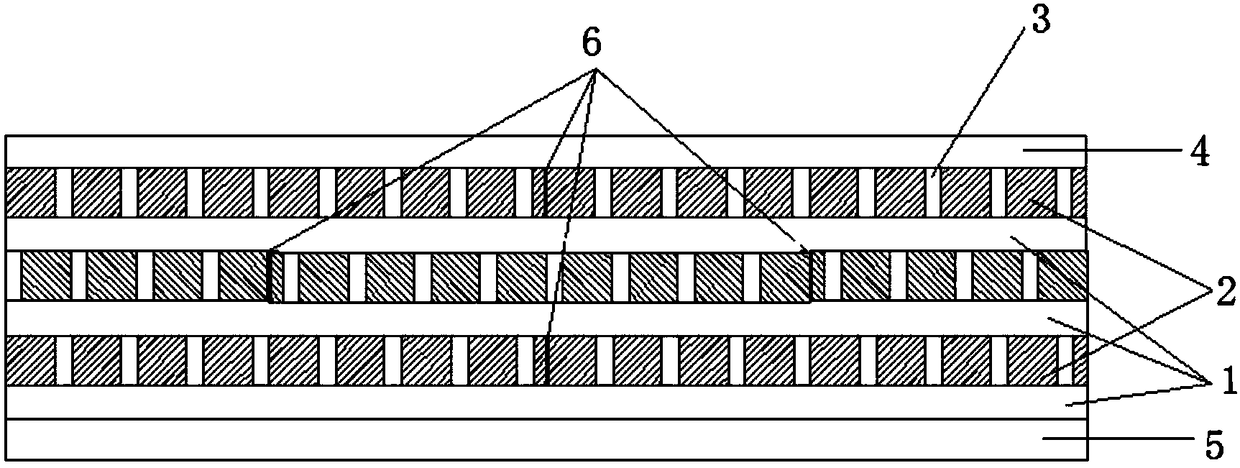

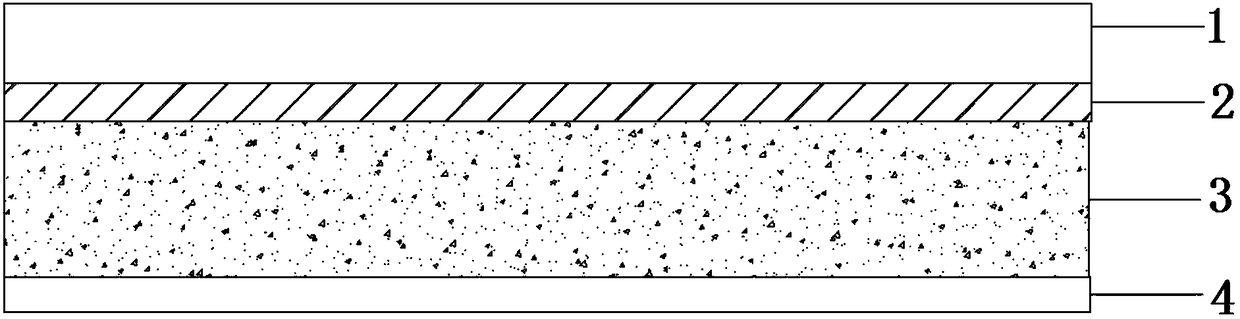

Preparation technology of ceramic shielding sheet for wireless charging and ceramic shielding sheet

InactiveCN108249958AGood electromagnetic performanceAverage permeabilityMagnetic/electric field screeningClaywaresPolyethylene terephthalate glycolPolyethylene terephthalate

The invention discloses a preparation technology of a ceramic shielding sheet for wireless charging. The preparation technology comprises the following steps: step 1, carrying out heat treatment on awound soft magnetic material strip; step 2, crushing the wound soft magnetic material strip subjected to the heat treatment into powder and preparing the powder into slurry; step 3, coating a naked surface of a ceramic substrate with the slurry to form a shielding layer with a certain thickness; sintering the ceramic substrate with the shielding layer to obtain the ceramic shielding sheet. The invention further discloses the ceramic shielding sheet; the ceramic shielding sheet comprises the ceramic substrate, the shielding layer and a PET (Polyethylene Terephthalate) film, wherein one naked surface of the ceramic substrate is coated with the shielding layer by utilizing a coating technology or a printing technology; the PET film is stuck on the outer surface of the shielding layer. The preparation technology of the ceramic shielding sheet, provided by the invention, is simple and feasible and high in integration automatic degree; the produced ceramic shielding sheet has thin thickness,a good shielding capability and high charging efficiency; the product has high working stability, and procedures and material cost are greatly saved.

Owner:SHANGHAI LINEPRINTING MATERIALS CO LTD

Soft and thin stone patch production technology, outer wall laying technology and production line

PendingCN110227618AReduce weightNot easy to fall offCovering/liningsSpraying apparatusProduction lineLacquer

The invention belongs to the technical field of decorative material production and discloses a soft and thin stone patch production technology, an outer wall laying technology and a production line. The soft and thin stone patch production technology comprises the following steps: S1, laying a protective film on a template to obtain a waterproof layer; S2, spraying colorful stone-like paint on theprotective film to obtain a stone-like paint layer; S3, heating and drying the stone-like paint; S4, laying fireproof mesh cloth on the surface of the colorful stone-like paint to obtain a fireprooflayer; S5, spraying priming paint to obtain a soft and thin stone patch; S6, separating the soft and thin stone patch from the template; and S7, cutting and rolling. Through the technical scheme, theproblem in the prior art that a decorative ceramic tile is likely to fall off and hurts a people is solved.

Owner:HEBEI DESEN BUILDING MATERIAL TECH INC

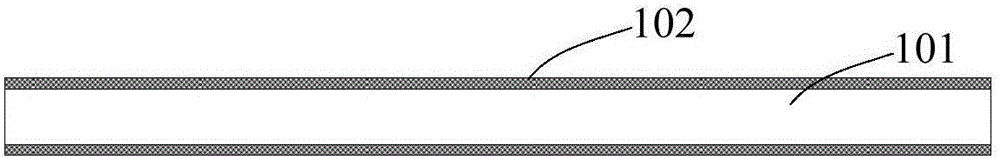

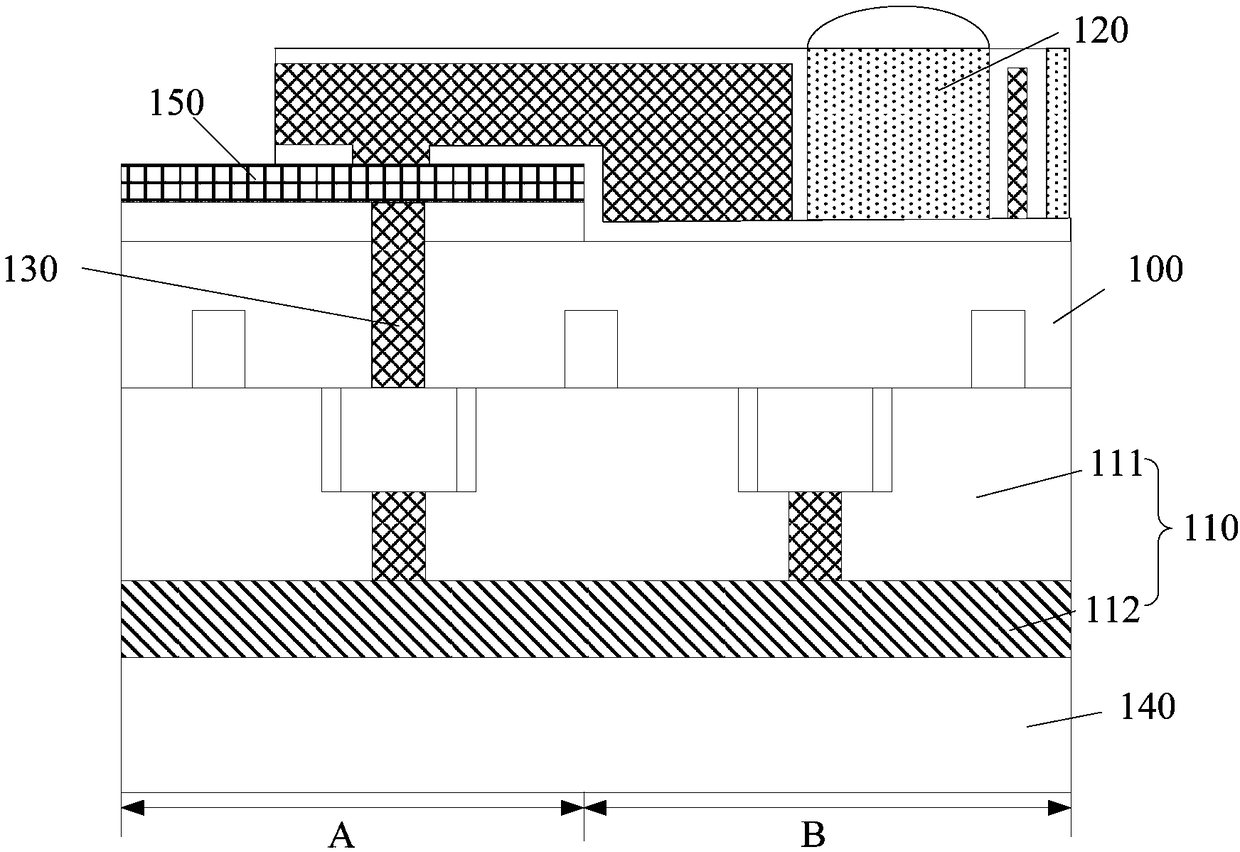

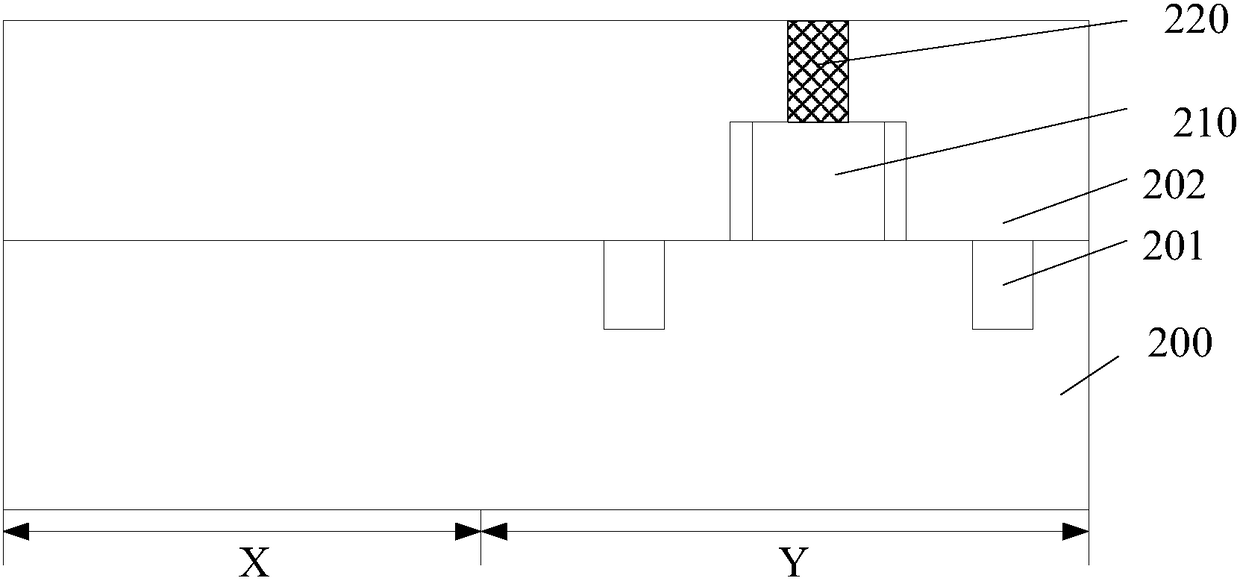

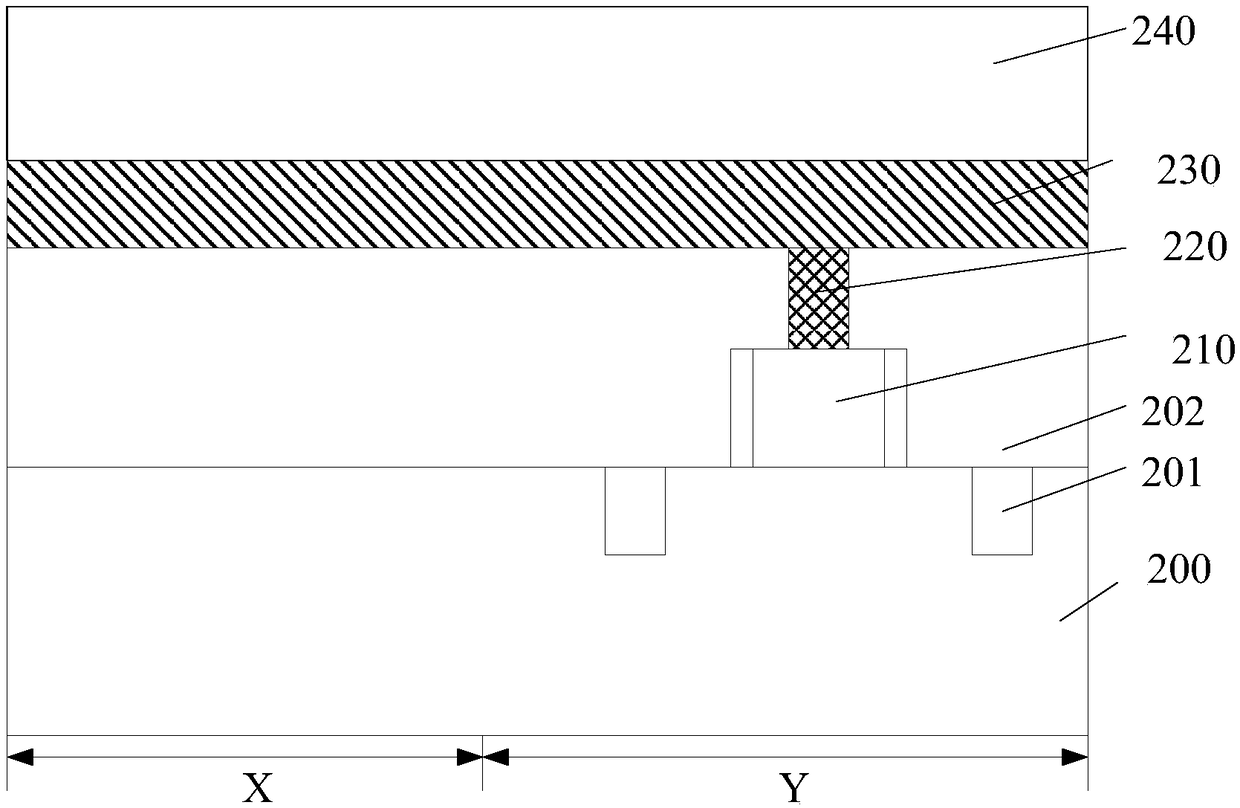

Back lighting type image sensor and formation method thereof

InactiveCN108183114AReduce power consumptionSave material costSolid-state devicesDiodeEffect lightPhotoelectric conversion

The present invention relates to a back lighting type image sensor and a formation method thereof. The formation method of the back lighting type image sensor comprises the steps of providing a backboard substrate; providing a main body substrate, wherein the main body substrate comprises a first area, a second area, a photoelectric sensing layer and a metal conducting wire structure located on the surface of the photoelectric sensing layer, a photoelectric conversion element is arranged in the photoelectric sensing layer in the second area, the photoelectric sensing layer comprises the relative first and second surfaces, and the metal conducting wire structure is located on the first surface; bonding the metal conducting wire structure and the backboard substrate; then removing the photoelectric sensing layer in the first area from the second surface, exposing the metal conducting wire structure of the first area of the main body substrate, and forming an opening in the photoelectricsensing layer; and then forming a metal grid layer on the second surface of a part of the photoelectric sensing layer of the second area; forming a metal gasket on the surface of the metal conductingwire structure exposed from the opening, and connecting the metal gasket and the metal grid layer; forming a light acceptance structure on the second surface of the photoelectric sensing layer in thesecond area of the main body substrate. The method enables the performance of the back lighting type image sensor to be improved.

Owner:HUAIAN IMAGING DEVICE MFGR CORP

Anti-scale metal valve and manufacturing method thereof

InactiveCN110153372AStrong costGood casting performanceFoundry mouldsFoundry coresDisiloxaneLotus effect

The invention discloses an anti-scale metal valve and a manufacturing method thereof. A base body of the anti-scale metal valve is cast through ZG03Cr18Ni10, staggered structures of grooves with the coverage rate not lower than 99% and spiral-stripe-shaped width of 5-8 microns are densely distributed on the inner surface, and a hexamethyl disiloxane hydrophobic membrane layer is fixed; and the anti-scale metal valve takes austenitic stainless steel as a base material, the process is simple and mature, the inner surface has a lotus effect, and cleaning is easy.

Owner:ZHEJIANG COLLEGE OF ZHEJIANG UNIV OF TECHOLOGY

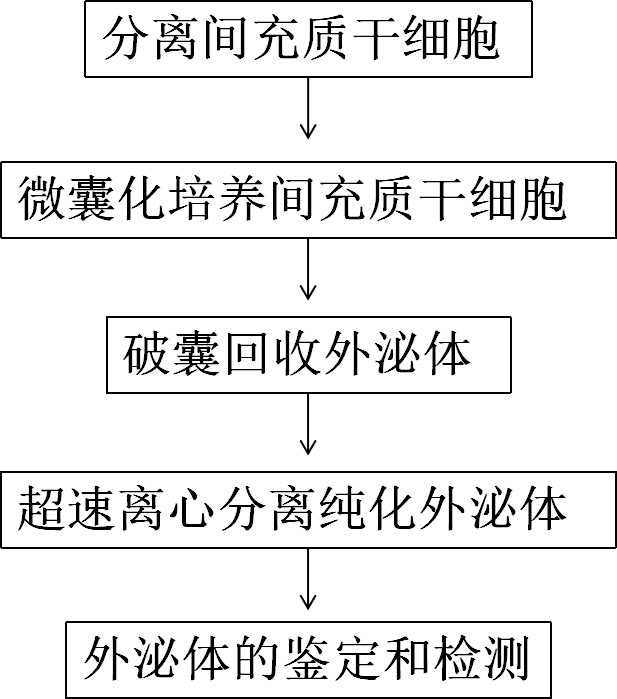

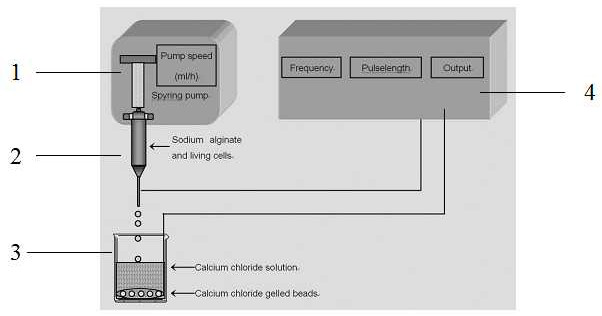

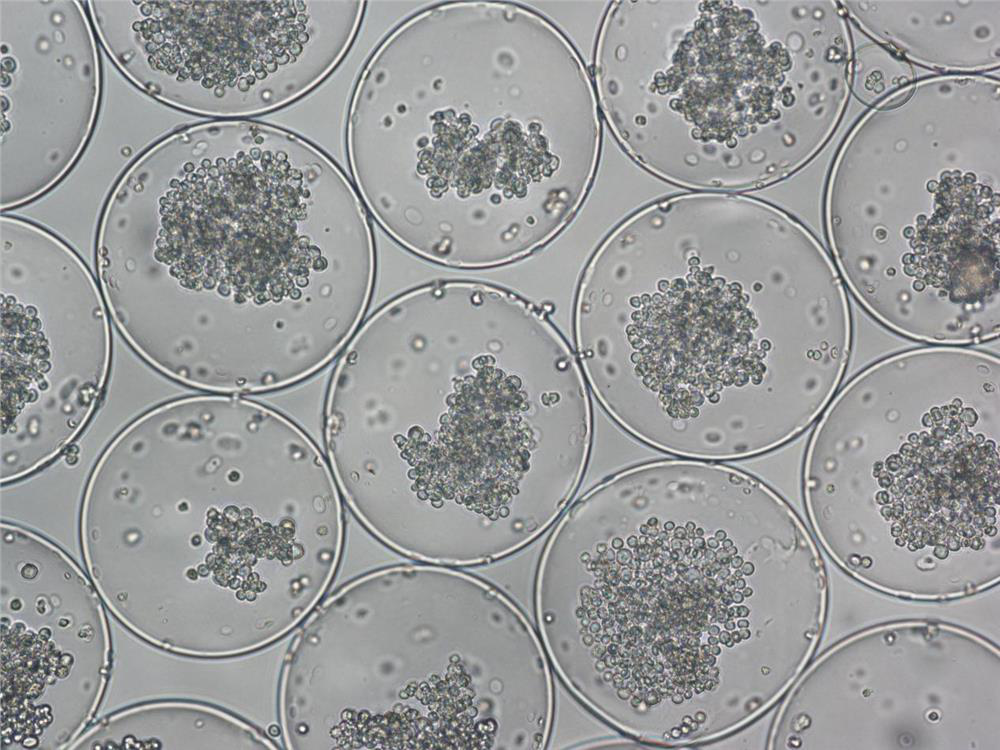

Method for increasing yield of mesenchymal stem cell exosomes, and application of method

InactiveCN112342190AIncrease production capacityEfficient retentionCell dissociation methodsSkeletal disorderMesenchymal stem cellExosome

The invention provides a method for increasing the yield of mesenchymal stem cell exosomes, and an application of the method. According to the method, a microcapsule is used as a growth system of mesenchymal stem cells, the mesenchymal stem cells are cultured under the three-dimensional condition, the culture environment is closer to the body, and therefore the yield of exosomes secreted by the mesenchymal stem cells can be increased conveniently. A semi-permeable membrane of the microcapsule can effectively intercept the exosomes, the concentration of the exosomes in the microcapsule is improved, and therefore the process cost and time are saved for downstream separation and purification; and exosomes derived from the serum of a culture medium can be prevented from entering the microcapsule, a specific commercial serum-free culture medium is prevented from being used, and therefore the culture cost is reduced. The method for increasing the yield of the mesenchymal stem cell exosomes through three-dimensional culture provided by the invention is expected to solve the technical bottleneck of insufficient exosome yield.

Owner:陈传果

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com