Magnetic shock-absorption device

A magnetic force and magnet technology, applied in the field of shock absorbers, can solve the problems of uneven spring material area, waste of manufacturing process and material costs, assembly man-hours and cost, etc., to achieve better shock absorbing effect and shock absorbing function Reinforcement and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The device of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments of the present invention.

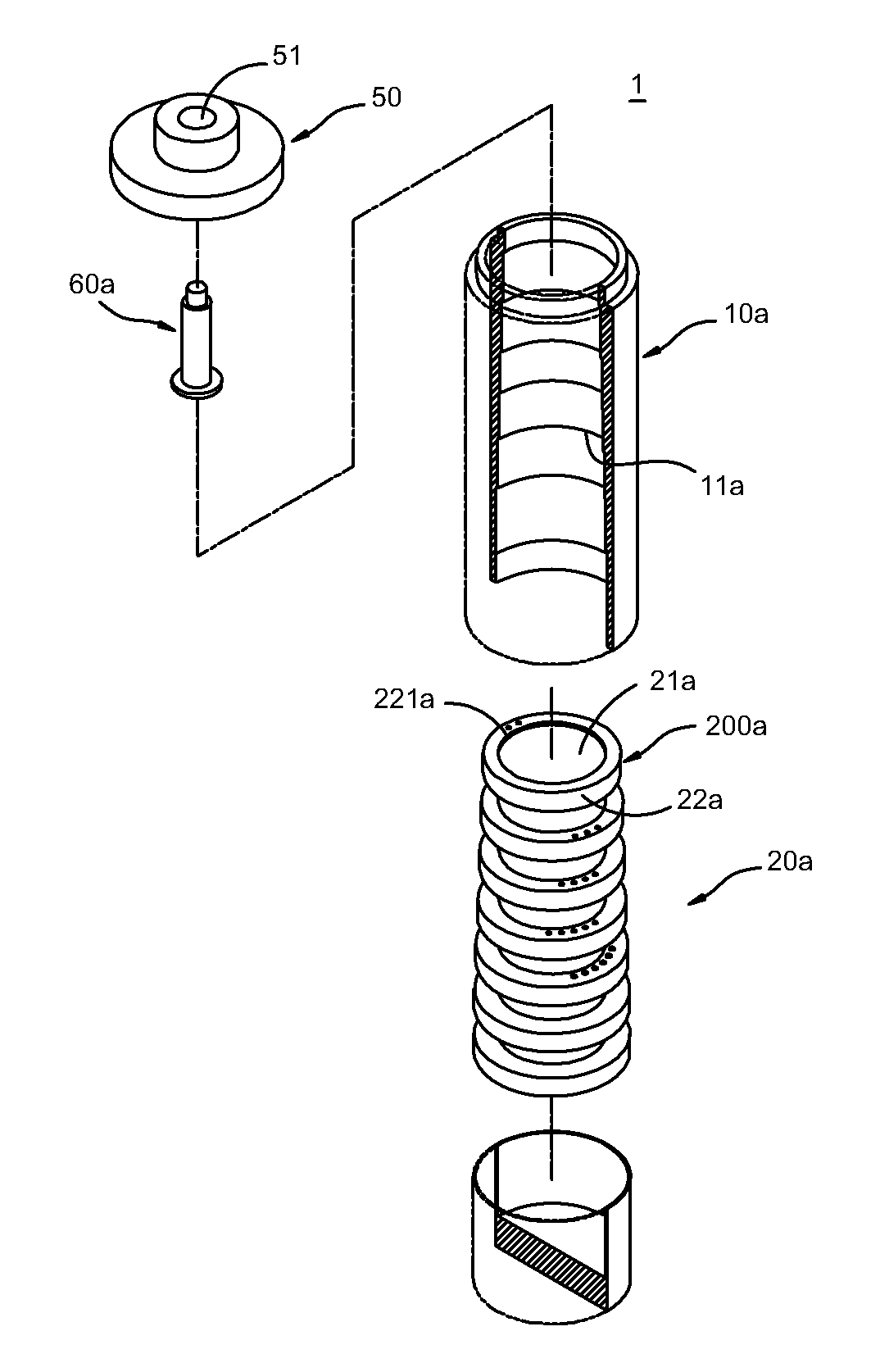

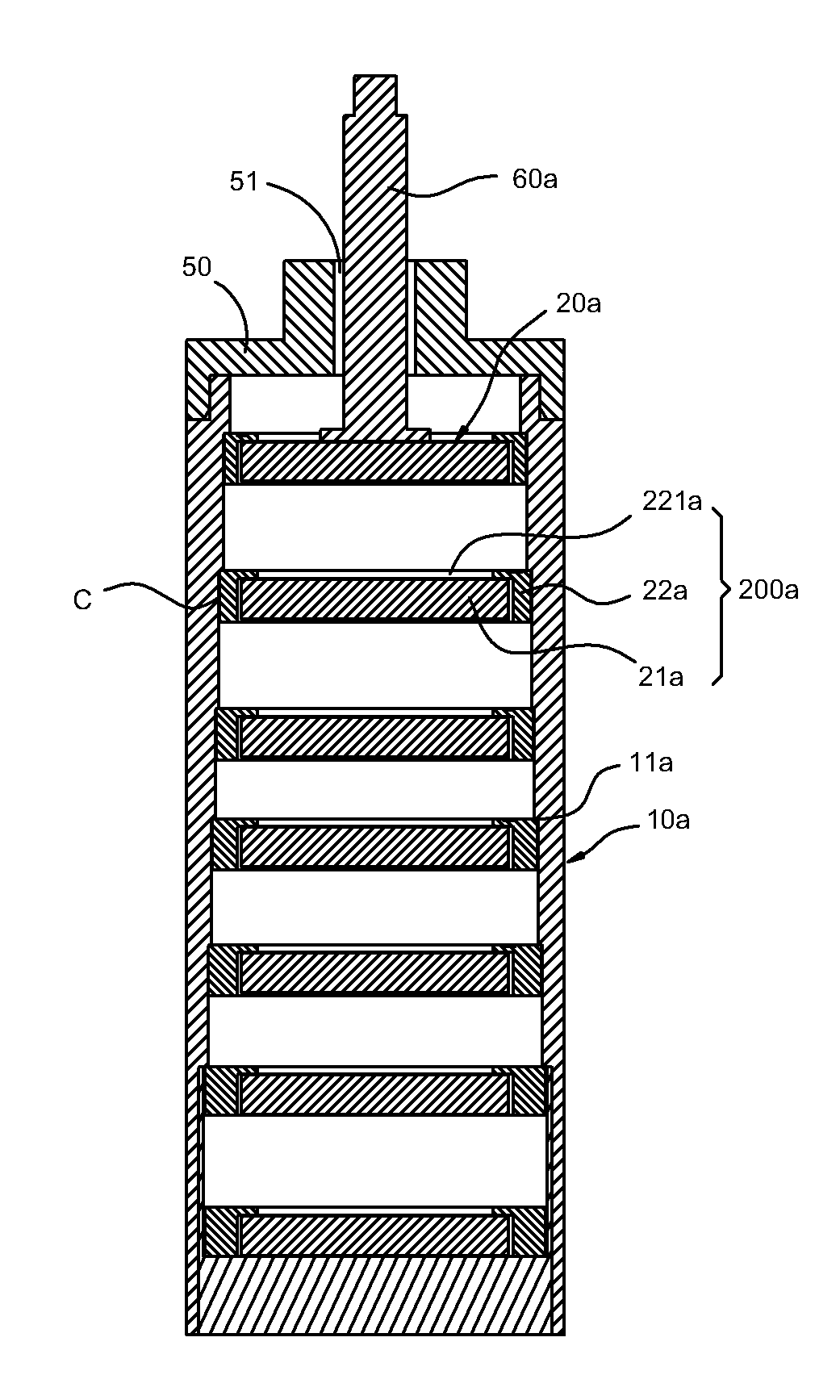

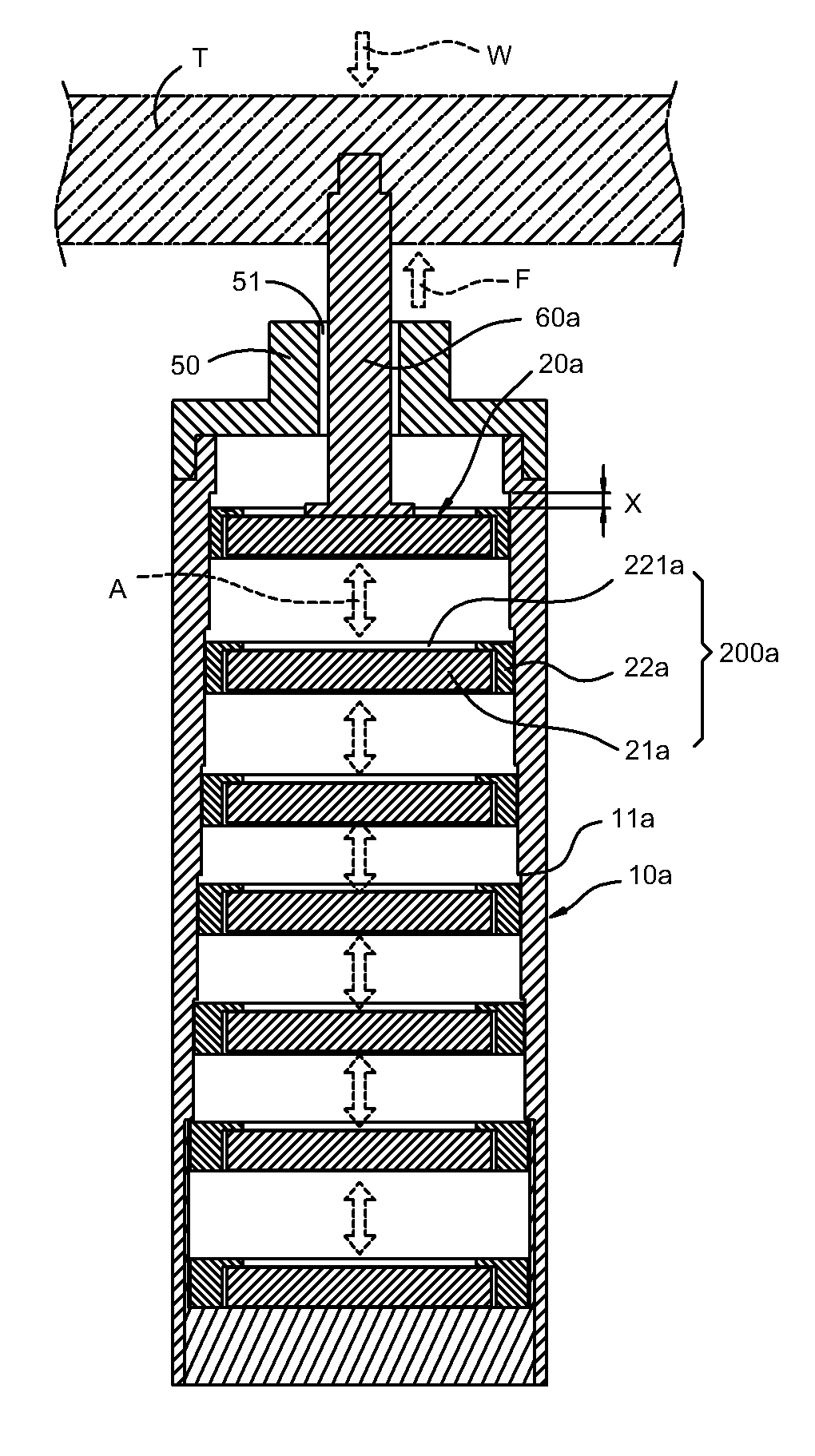

[0063] Please refer to figure 1 Shown is a three-dimensional exploded view of the first embodiment of the present invention. The present invention provides a magnetic shock absorber 1, which mainly includes a cylinder base 10a and a magnetic assembly 20a.

[0064]The base 10a can be a component made of plastic, metal or composite material, but not limited thereto; the base 10a can be cylindrical, square, hexagonal or pentagonal, etc. Multiple stepped grooves 11a of equal size.

[0065] The magnetic group 20a includes a plurality of magnetic units 200a, each magnetic unit 200a includes a magnet 21a and a protective cover 22a, each protective cover 22a covers each magnet 21a, and an opening is respectively provided on the two sides of each protective cover 22a. Holes 221a; each magnetic unit 200a is dispo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com