Hollow hierarchical hydroxyapatite microspheres and preparation method and application thereof

A technology of structural hydroxyapatite and microspheres, which is applied in chemical instruments and methods, medical preparations of non-active ingredients, and devices that make drugs into special physical or ingestible forms, and can solve the problem of reducing the use value of materials, The preparation process takes a long time and is unfavorable for industrial production, and achieves the effects of large-scale industrial production, excellent drug release performance, and time and process cost savings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. Preparation of hollow hierarchical microspheres:

[0027] First, dissolve 0.473g of diammonium hydrogen phosphate in 300ml of deionized water, adjust the pH of the solution to 6.0, then add 1.41g of calcium nitrate tetrahydrate, and stir for 2 minutes. After the calcium nitrate tetrahydrate is completely dissolved, continue to use 2mol / L nitric acid to adjust the solution After the pH reaches 5, weigh 4.5g of calcium citrate hexahydrate and add it to the above mixture, and stir for 10min at a stirring speed of 200rpm. The solution was transferred to a 100ml polytetrafluoroethylene-lined autoclave, the volume of the mixed liquid accounted for 60% of the total volume of the autoclave, and reacted in an oven at 180°C for 2 hours. Cool naturally, wash with water for 3-5 times, and freeze-dry to obtain hydroxyapatite microspheres with hollow hierarchical structure.

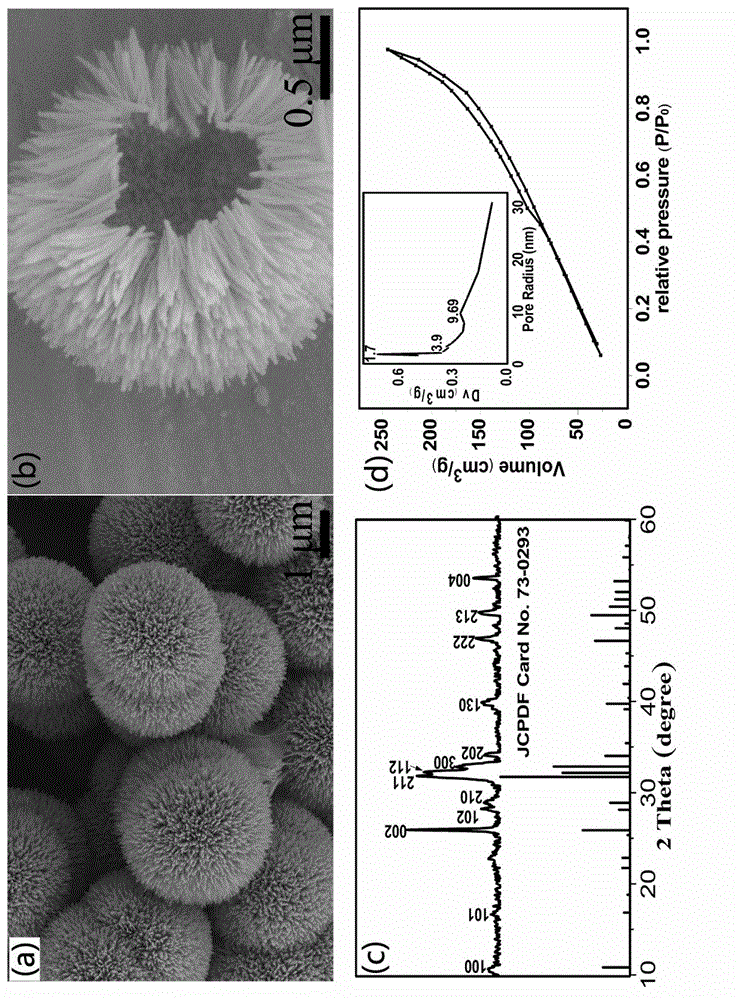

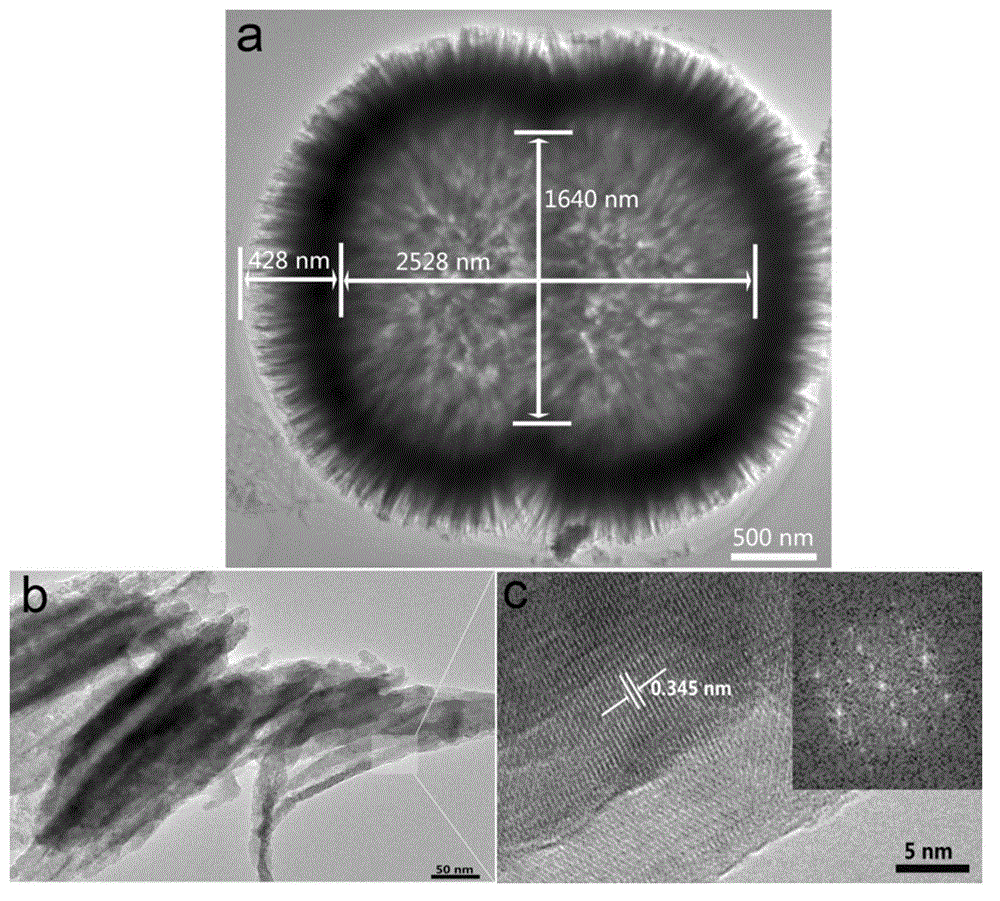

[0028] figure 1 The microspheres have an obvious hollow structure, and the XRD pattern shows that the di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| mesopore | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com