Patents

Literature

42results about How to "Save process time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

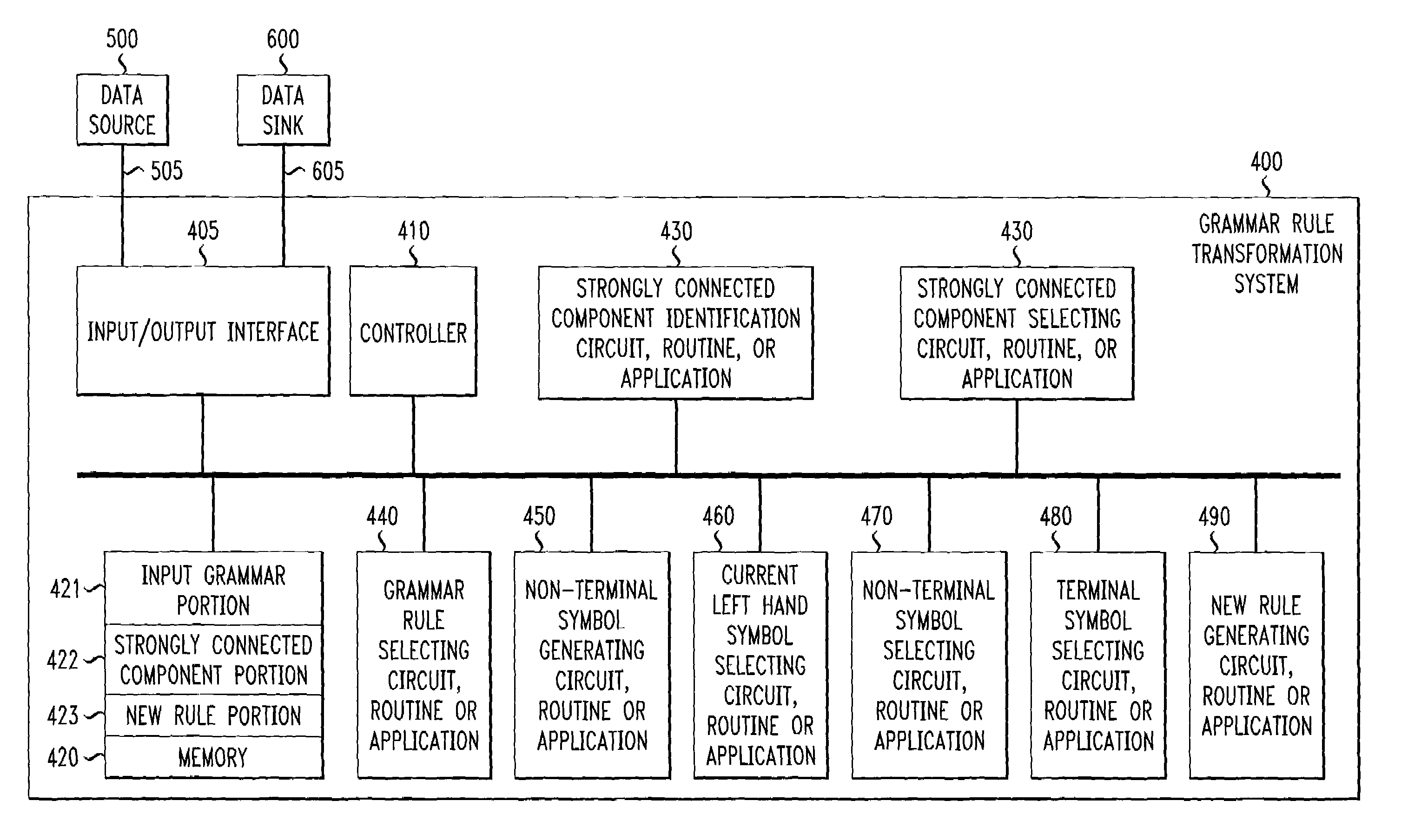

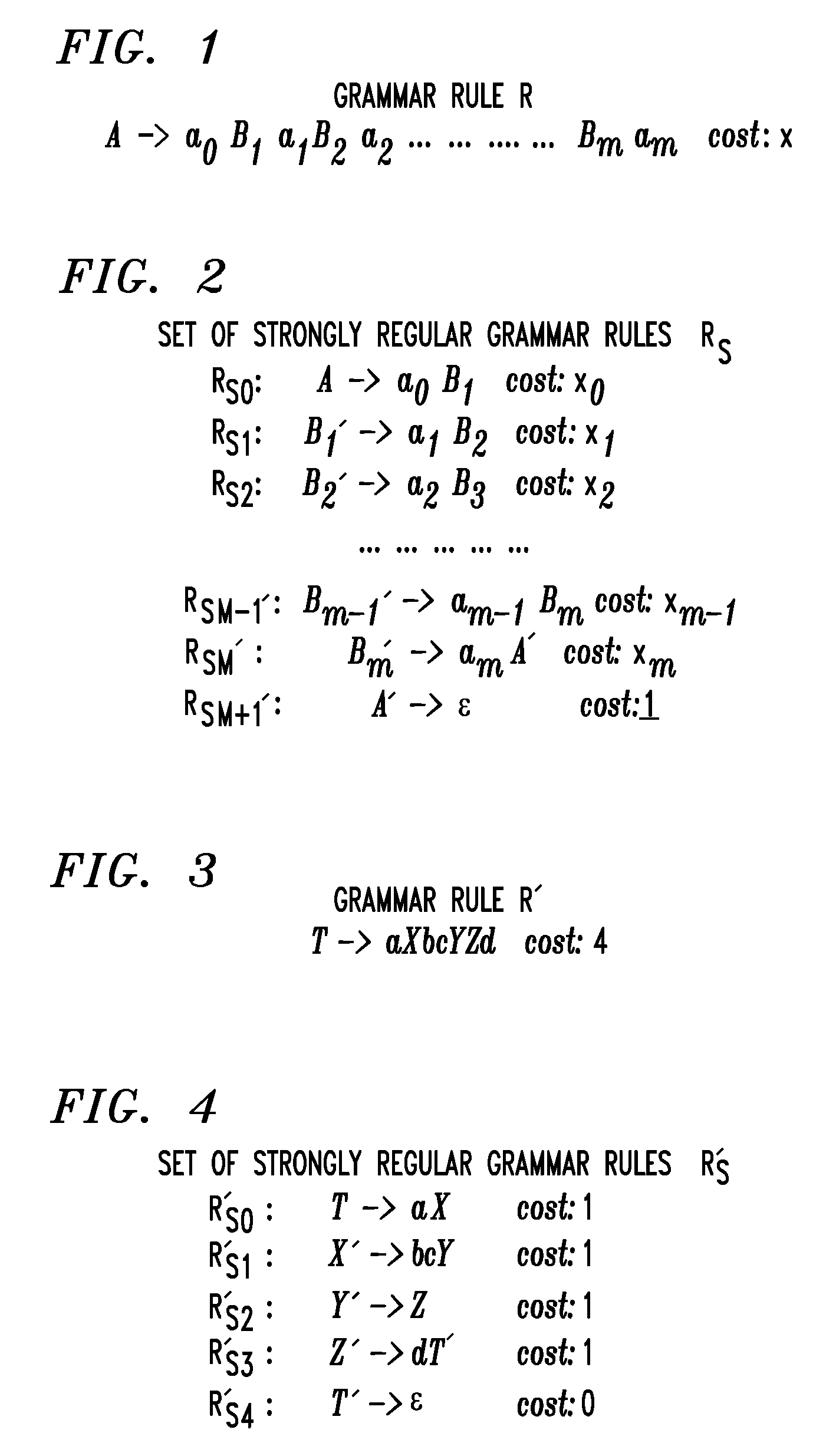

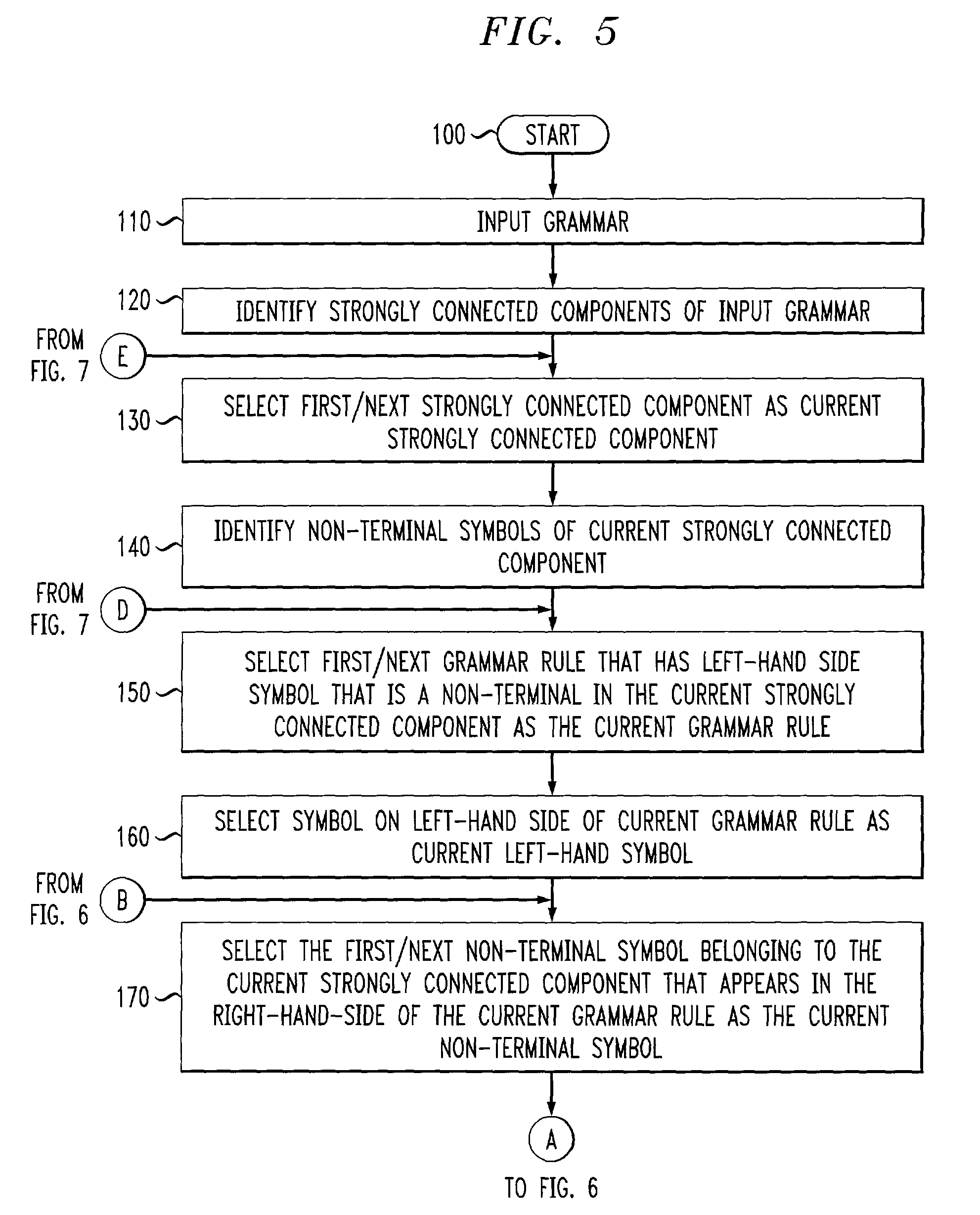

Systems and methods for regularly approximating context-free grammars through transformation

ActiveUS7289948B1Save process timeSave processing timeNatural language data processingSpeech recognitionContext-free grammarRegular grammar

Owner:NUANCE COMM INC

Method for preparing high-specific-surface-area activated carbon from tobacco stalks

InactiveCN103121682AImprove qualityWide variety of sourcesCarbon compoundsSolid waste disposalActivated carbonSlag

The invention discloses a method for preparing high-specific-surface-area activated carbon from tobacco stalks, which comprises the following steps: pulverizing tobacco stalks into granules, mixing the granules and an activating agent according to a mass ratio of (1:8)-(2:1), adding the obtained mixture into water, evenly stirring, and impregnating for 10-14 hours; after impregnation is finished, filtering, drying the filter residue, placing into an electric furnace having a nitrogen protective atmosphere, and carbonizing at 450-750 DEG C for 1-2 hours; and after carbonization is finished, cooling in a nitrogen atmosphere, washing the obtained furnace slag, and drying. According to the method, high-quality activated carbon can be simply and quickly prepared from wastes in the tobacco industry. Thus, the method changes wastes into valuable substances, fully utilizes resources, avoids environmental pollution, has good economic benefits and is beneficial to industrial production.

Owner:CENT SOUTH UNIV

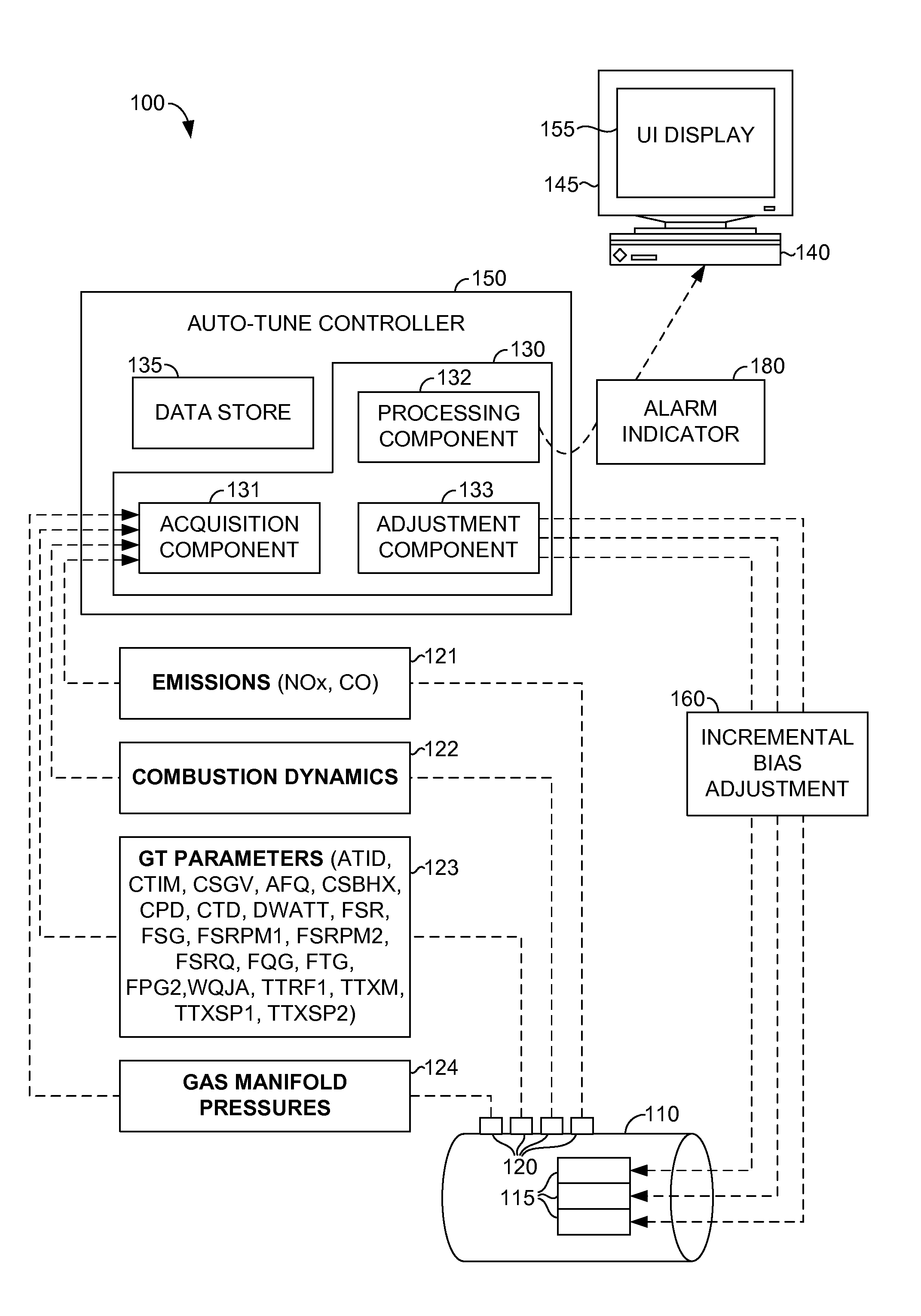

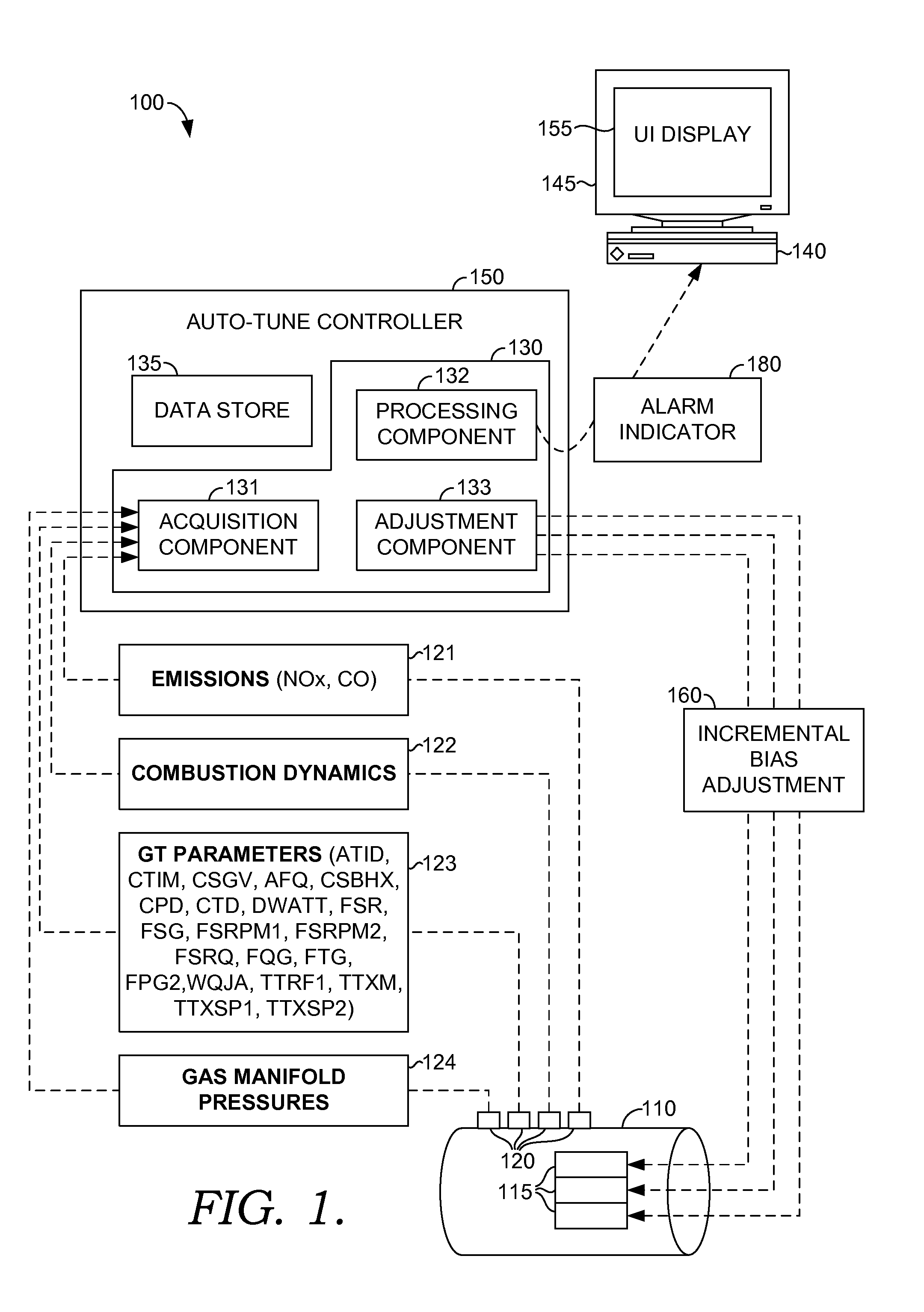

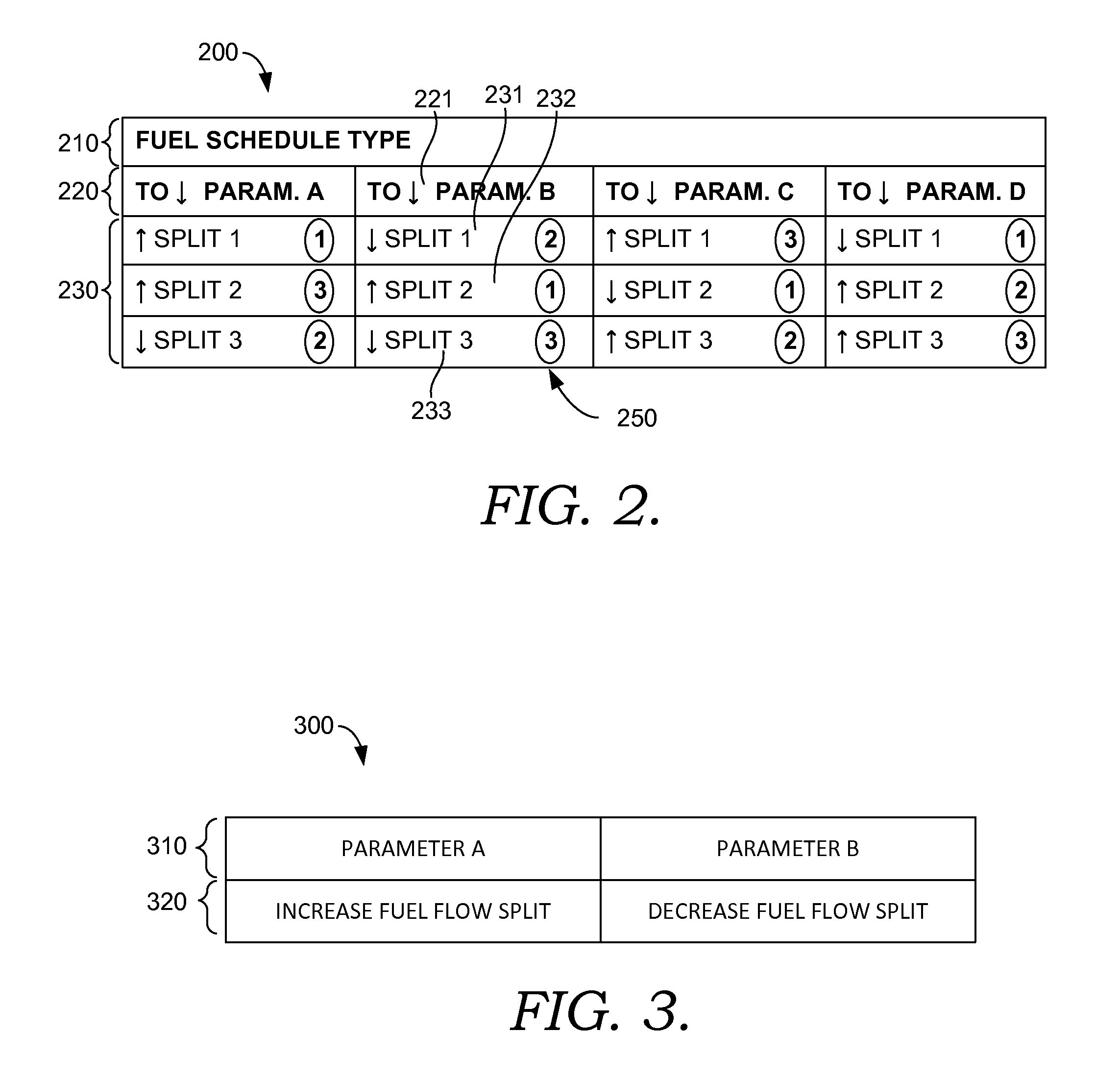

Stabilizing A Gas Turbine Engine Via Incremental Tuning During Transients

ActiveUS20140200721A1Save process timeSave processing timeContinuous combustion chamberFlow control using electric meansAutomotive engineeringGas turbines

Methods and systems are provided for automatically tuning a combustor of a gas turbine engine during a transient period, such as when a state of the gas turbine engine is changing. Once it has been determined whether the state of the gas turbine engine is changing, it is then determined whether a lean blowout is imminent, which is based conditions being monitored. A stability bias is applied to the system if either the state is changing or if lean blowout is imminent until the lean blowout is no longer determined to be imminent. The stability bias monitors operating conditions of the gas turbine engine and determines when one of the operating conditions has overcome a threshold value. Once a threshold value is overcome, a fuel flow fraction is adjusted by a predefined increment. The application of the stability bias is gradually terminated once it is determined that the lean blowout is no longer imminent.

Owner:H2 IP UK LTD

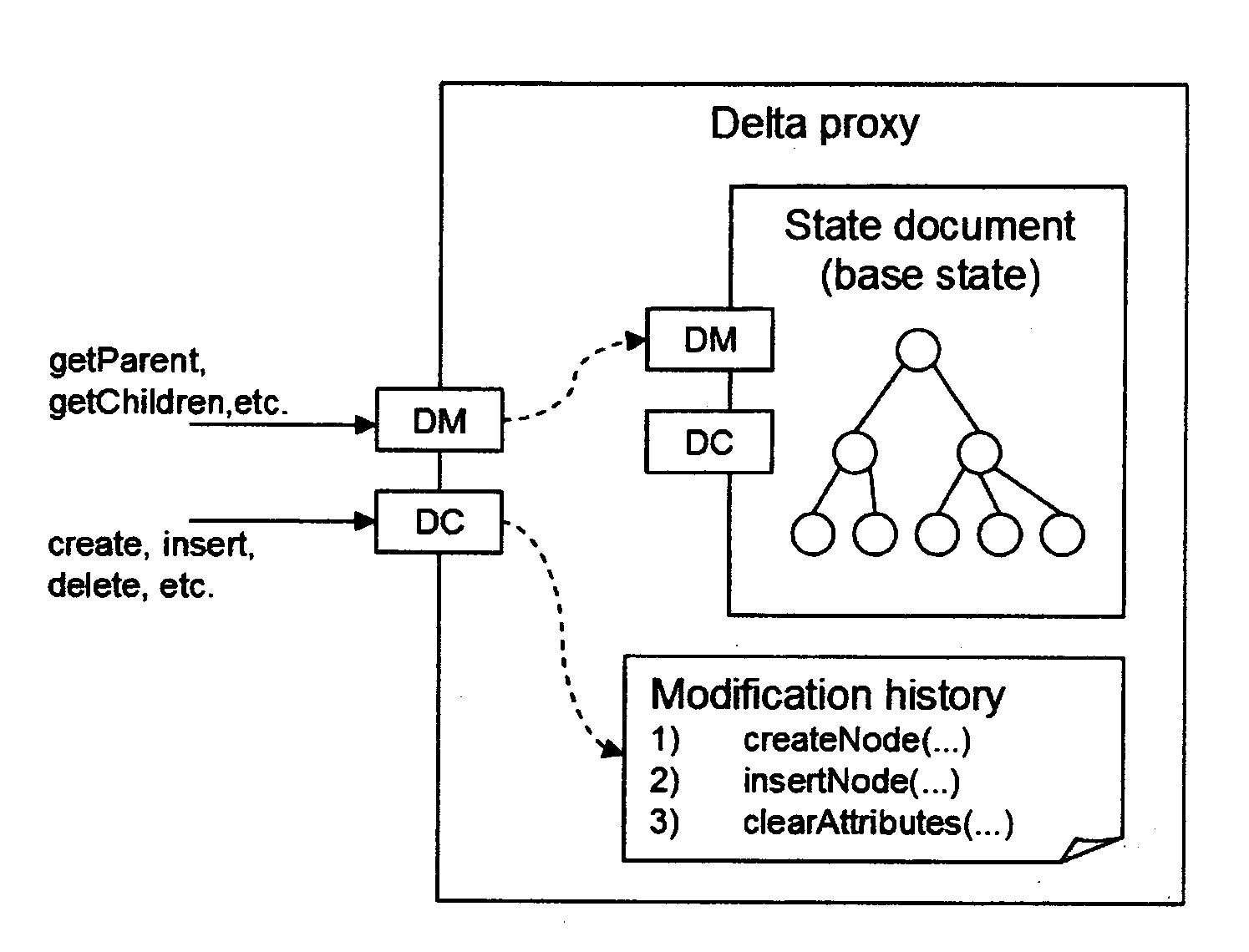

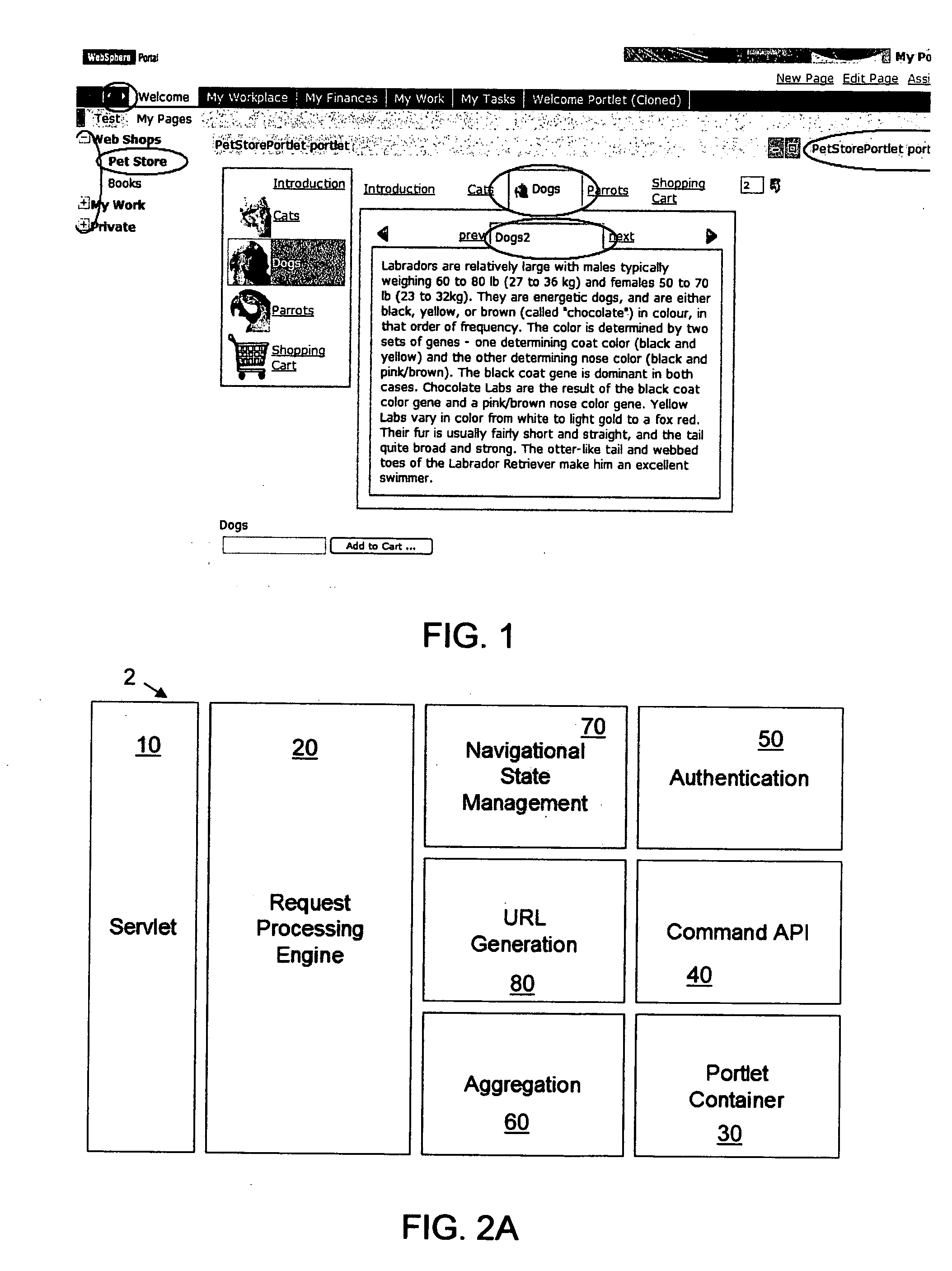

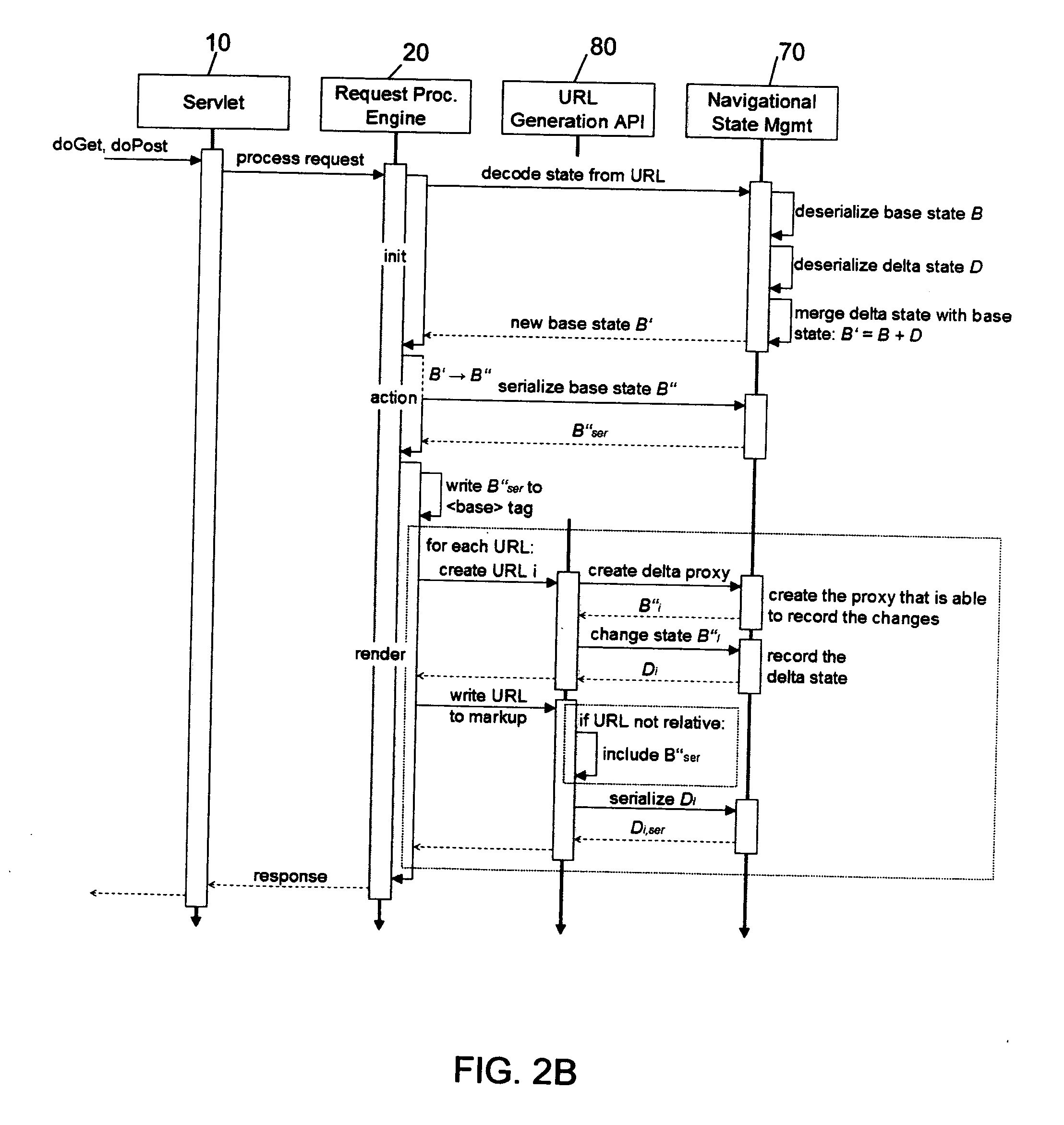

Method and system for efficiently handling navigational state in a portal

InactiveUS20070136415A1Efficiently handleSave process timeMultiple digital computer combinationsWeb data navigationServer-sideSerialization

The present invention provides a method and system for efficiently handling navigational state by separating the latest navigational state into a base navigational state part and a delta navigational state part. The base navigational state which describes that part of the latest navigational state that is identical across all URLs is encoded in the header of the page markup to be submitted to the client's browser. The delta navigational part that describes the semantics of that specific URL is encoded in its associated URL. Each user interaction using such URL causes the browser to submit the base part as well as the delta part. On the server side the base and delta part are being merged resulting in new navigation state serving as a base for the rendering of the new page. The navigational state is represented as a hierarchical tree-like structure that can be serialized efficiently and compressed by prior art compression techniques. The hierarchical tree-like structure is based on a well-defined state model that is optimized in terms of state serialization. The state model arranges the contained navigational state information in character based information. That saves processing time as it avoids type conversion of navigational information. In addition the present invention includes further strategies to reduce the amount of information that must be serialized.

Owner:IBM CORP

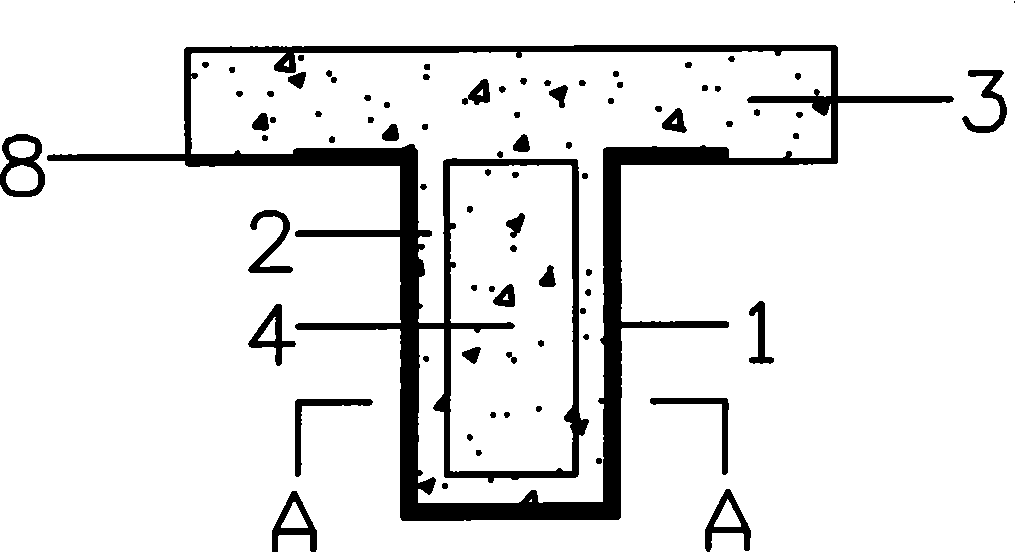

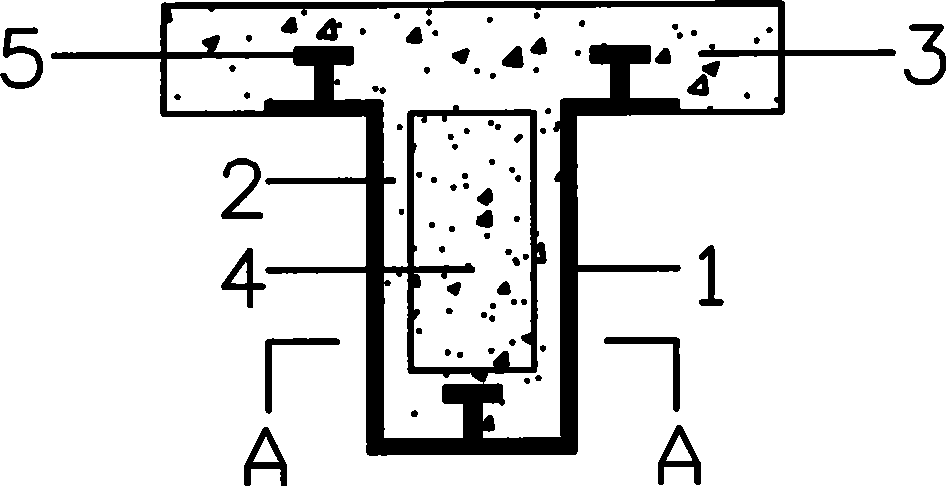

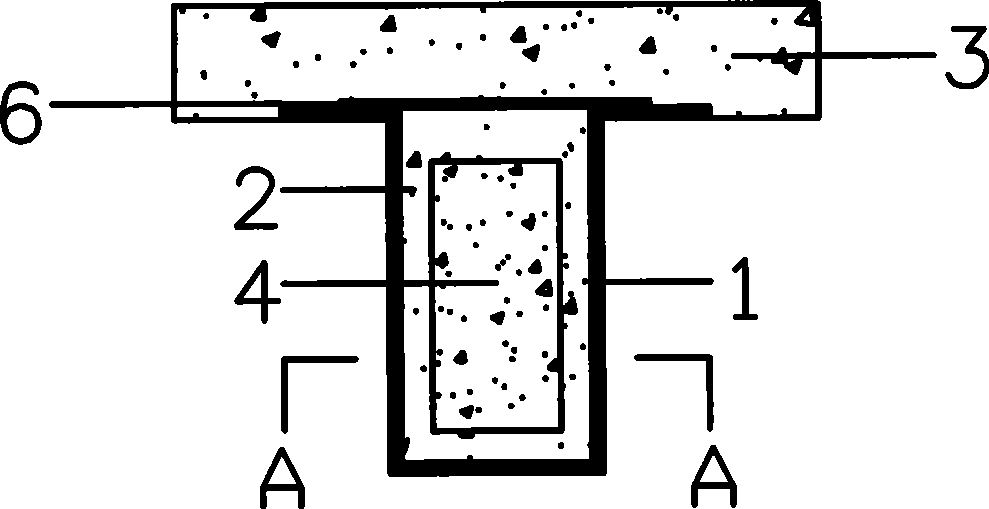

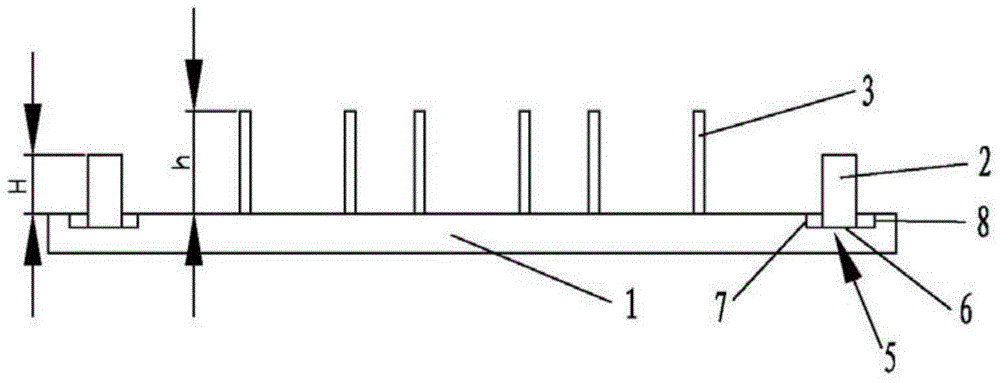

U-shaped steel-coated Regenerated composite beam of and construction method thereof

InactiveCN101418631AIncrease stiffnessImprove ductilityFloorsLoad-supporting elementsFloor slabRebar

The invention discloses a U-shaped steel-encased regenerated composite beam and a construction method thereof. The U-shaped steel-encased regenerated composite beam comprises one or more disused concrete blocks, new concrete, and U-shaped encased steel, the disused concrete blocks are arranged inside the U-shaped encased steel, and the gap between the disused concrete block and the U-shaped encased steel is filled with the new concrete. The method includes the following steps: the U-shaped encased steel is made as the formwork of a beam and is integrated with the formwork of the floor slab or roof slab; a layer of new concrete is first poured into the U-shaped encased steel, then the disused concrete blocks and new concrete are alternately put into the U-shaped encased steel, tamping is utilized then to distributed the disused concrete blocks into the new concrete; steel bars of the floor slab or the roof slab are put into the formwork of the floor slab or the roof slab, and the new concrete is poured into the formwork of the floor slab or the roof slab. The invention can save a great amount of energy consumed in the processes of breaking, screening, purifying and the like for the concrete waste.

Owner:SOUTH CHINA UNIV OF TECH

Method for producing transmission part

InactiveCN101590589ASimple structureHigh densityHeat treatment process controlTurning machinesPunch pressHigh rate

The invention discloses a method for producing a transmission part, which comprises the steps of: 1) adopting a punch press for blanking; 2) performing flat head chamfering on a blanked material; 3) producing the blanked material into a blank which satisfies a pressing machine mold in step 5); 4) performing annealing treatment on the blank; 5) performing cold extrusion thickening on the blank; 6) punching a central hole on the thickened blank, chamfering after the reaming, and then turning an external circle; 7) performing cold extrusion curve molding on the blank; 8) performing cold extrusion spline treatment on a workpiece; 9) then performing plane turning and chamfering on the workpiece; 10) then removing an overlong part of a small diameter end of the workpiece through the turning, rough turning a plane, and then chamfering; 11) turning an external circle of a large diameter end of the workpiece into a needed shape, slotting the position, which is near the end surface, of an external circle surface of the small diameter end, and chamfering a central hole of the small diameter end at the same time; and 12) performing flat head chamfering and inner hole reaming on the treated workpiece to obtain a finished product. Compared with the prior art, the method saves the time of working procedures, saves raw materials, and has higher rate of finished products and lower cost.

Owner:CIXI LONGSHAN AUTOMOBILE PART

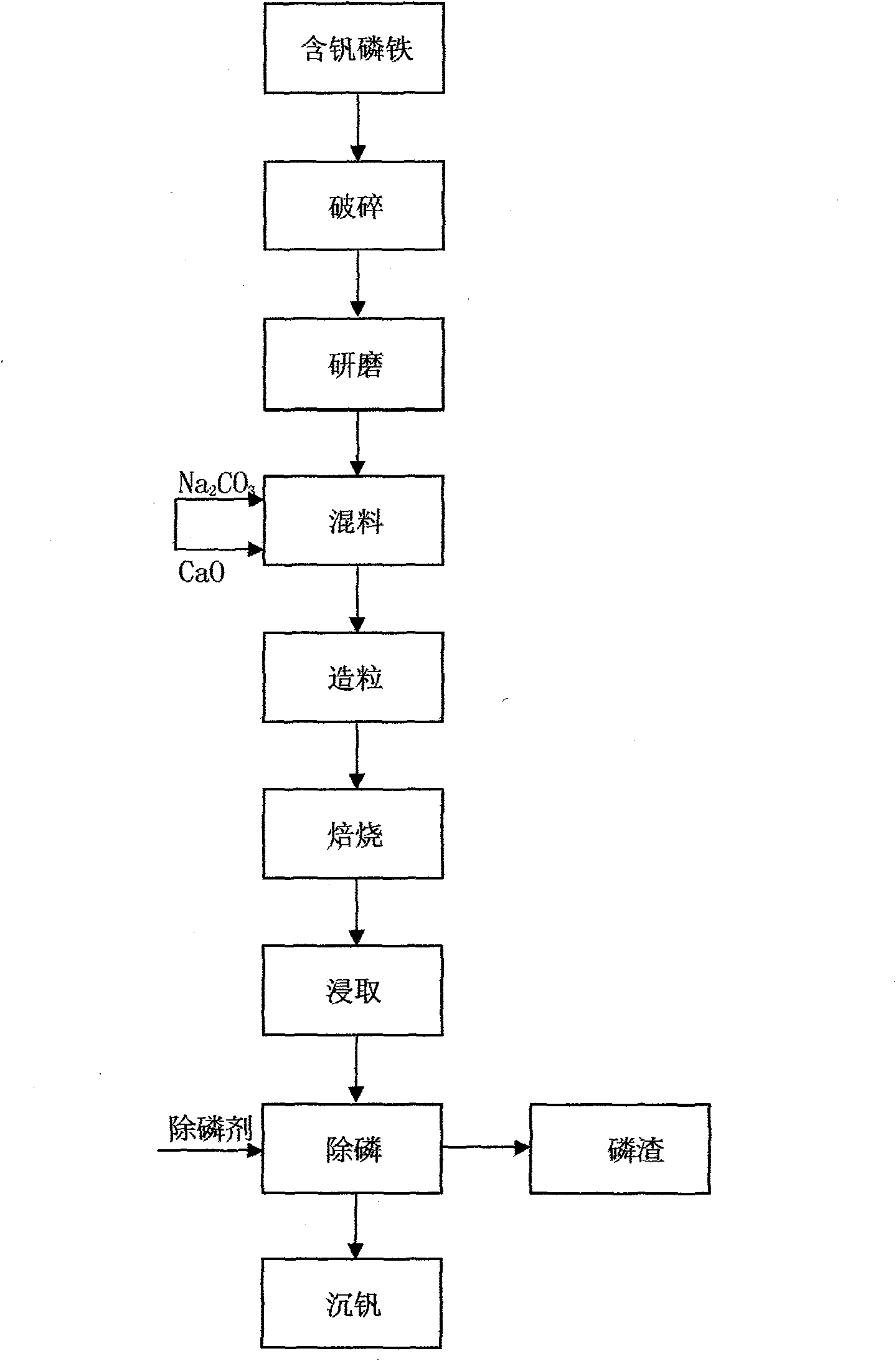

Method for extracting vanadium from vanadium-containing ferrophosphor

The invention discloses a method for extracting vanadium from vanadium-containing ferrophosphor. In the method, vanadium-containing ferrophosphor is used as a raw material, and mixed with Na2CO3 and CaX (such as CaO) to be roasted at one time, the roasted product is leached in water, the leaching solution contains vanadium, a vanadium-containing fine solution is obtained after removing phosphor from the leaching solution with a phosphor-removing agent, and the fine solution is used to extract vanadium to obtain high-purity vanadium pentoxide. The method has the advantages that: the productionprocess is simple and free from coating; a lower ratio of phosphor to vanadium is achieved to reduce the loss of vanadium in the phosphor removal process; the production cost is low, and the investment is small; the method is suitable to extract vanadium from vanadium-containing ferrophosphor with different ingredients; and the leaching rate of the vanadium can reach 80 to 85 percent.

Owner:HONG JING ENVIRONMENT

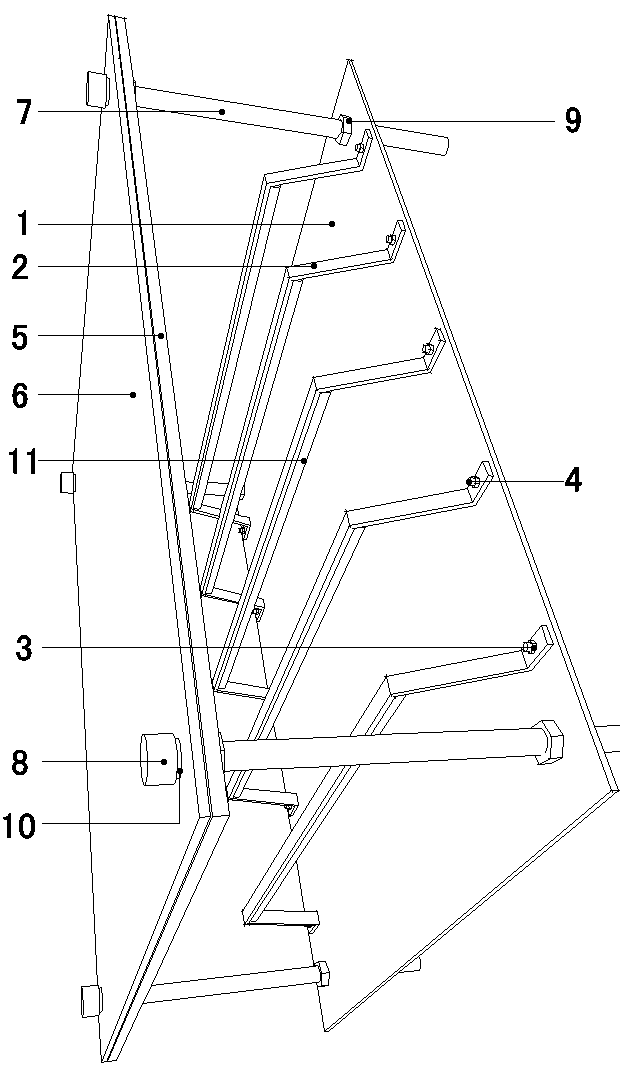

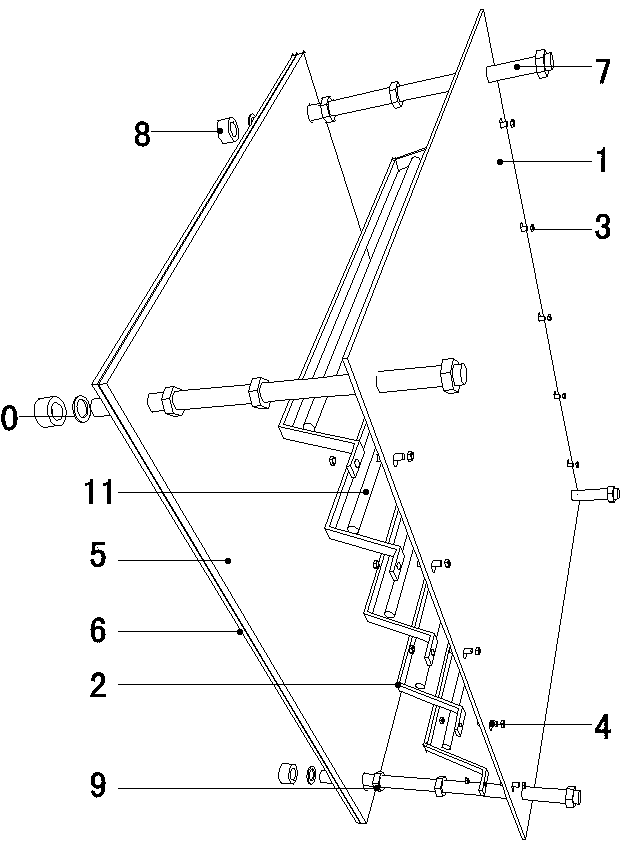

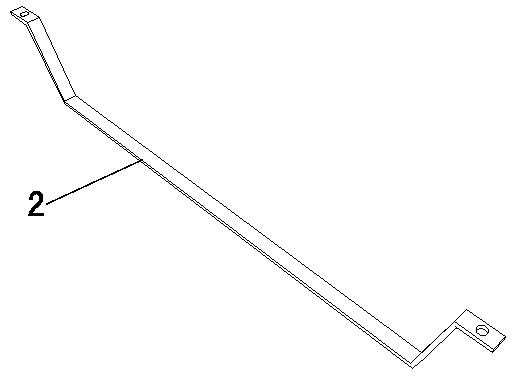

Light-transmitting marble wall face decorating structure

InactiveCN103615080AImprove the decorative effectEasy maintenanceCovering/liningsSafety glassProcedure time

The invention discloses a light-transmitting marble wall face decorating structure which comprises a reflecting plate (1), safety glass (5), a marble piece (6), a fixing rod (7) and a lamp (11). The marble piece (6) and the safety glass (5) form a composite light-transmitting marble plate by interlayer attaching. The composite light-transmitting marble plate is fixed on a building wall body through the fixing rod (7). The reflecting plate (1) is arranged between the composite light-transmitting marble plate and a wall face. The reflecting plate (1) is arranged on the fixing rod (7). A lamp support (2) is arranged on the reflecting plate (1). The lamp (11) is arranged on the lamp support (2). According to the light-transmitting marble wall face decorating structure, the shortcoming that a traditional marble wall face can generate shadows is overcome, the decorating effect of the marble wall face is improved, construction is easy, procedure time is saved, manpower is saved, and marble wall face maintaining is convenient.

Owner:GOLD MANTIS CONSTR DECORATION

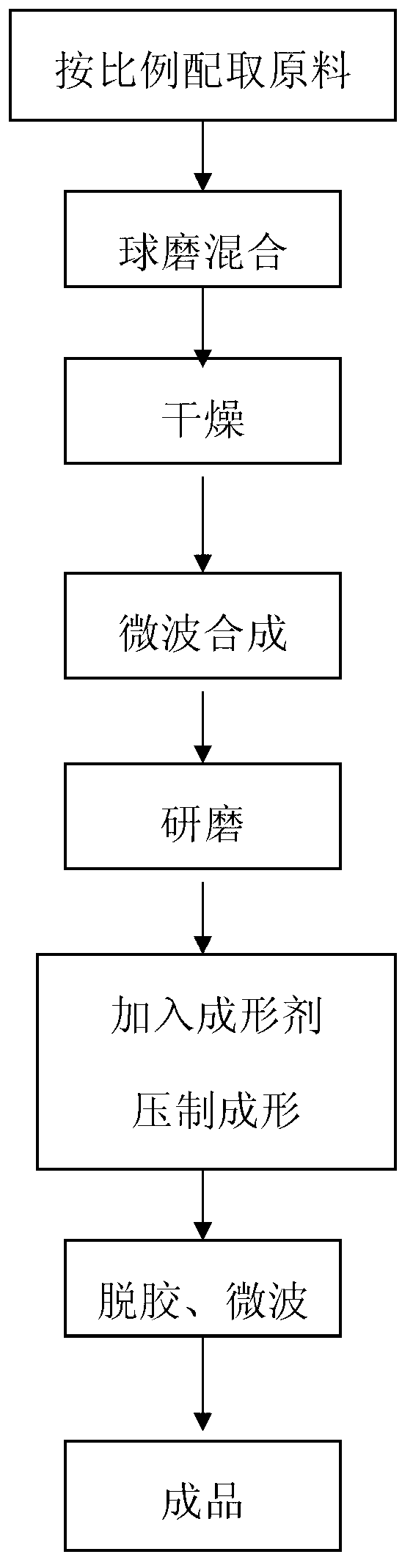

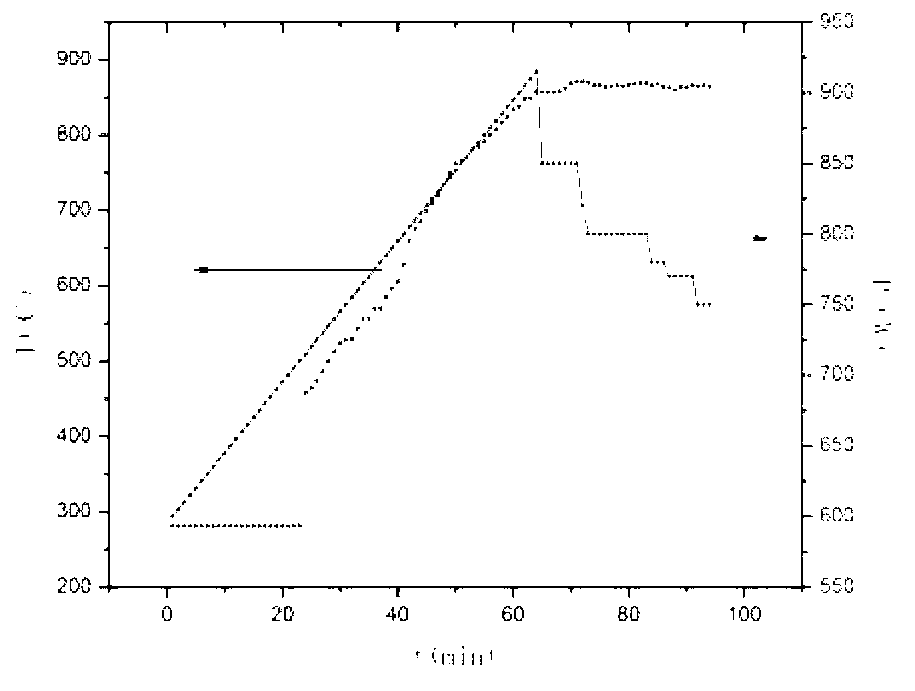

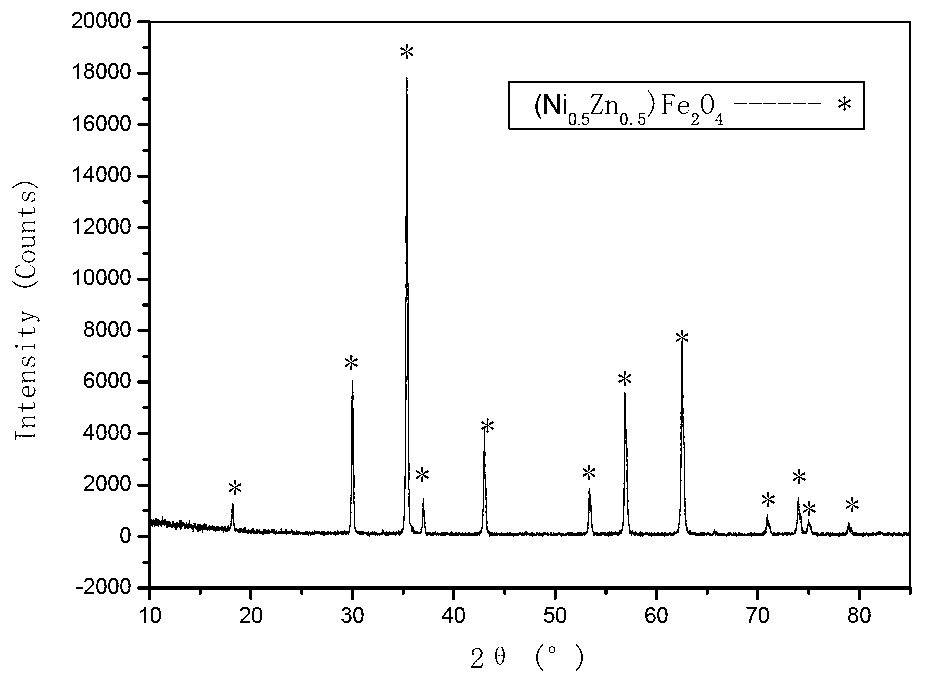

Method for preparing nickel-zinc ferrite by using microwave technology

The invention discloses a method for preparing a nickel-zinc ferrite by using a microwave technology. The method comprises the following steps of: determining a molar ratio of Ni, Zn and Fe in nickel-zinc ferrite components according to a chemical general formula of the nickel-zinc ferrite NixZn1-xFe2O4, wherein x is more than 0 and less than 1; respectively weighing and uniformly mixing oxides of Ni, Zn and Fe according to the proportion, and performing microwave synthesis on the mixture to obtain pre-sintering material powder; grinding the synthesized pre-sintering material powder; adding polyvinyl alcohol into the pre-sintering material powder to compact and mould to obtain a compaction blank; degumming the compaction blank to sinter in a microwave oven to obtain a finished product under a microwave sintering condition that the heating velocity is 10-30 DEG C / min, the sintering temperature is between 1,100-1,300 DEG C and the holding time is between 30 and 180 minutes. The method is simple in process, easy to operate, high in preparation efficiency, low in energy consumption, and environment-friendly, clean and sanitary in preparation process; the time can be greatly saved; the cost is greatly reduced; and the obtained spinel nickel-zinc ferrite is high in purity. The method is suitable for industrial production, has good economic benefit and social benefit, and can promote application of the nickel-zinc ferrite in the industrial and high-end technology.

Owner:CENT SOUTH UNIV

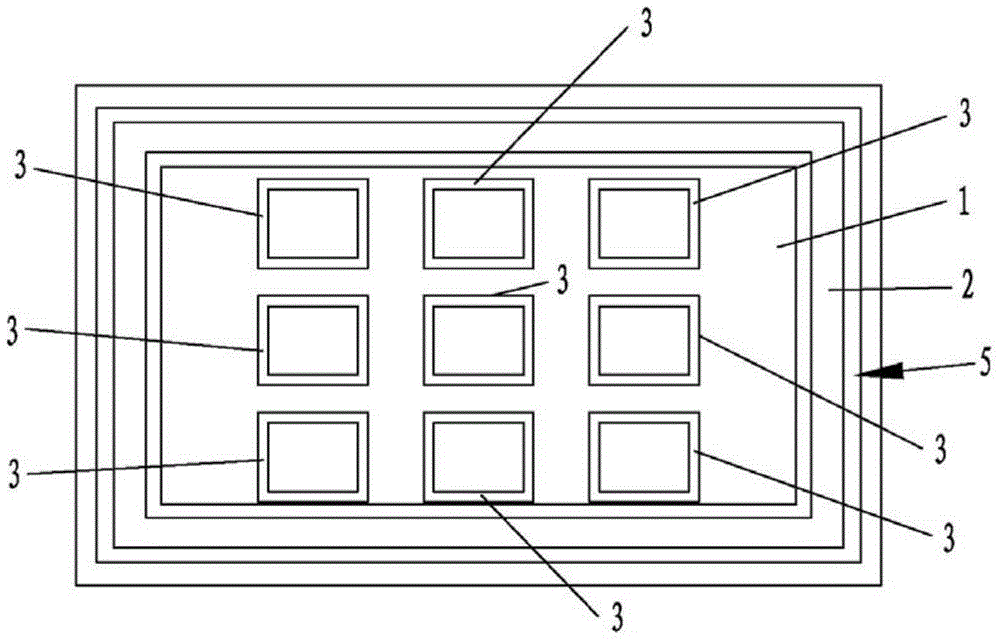

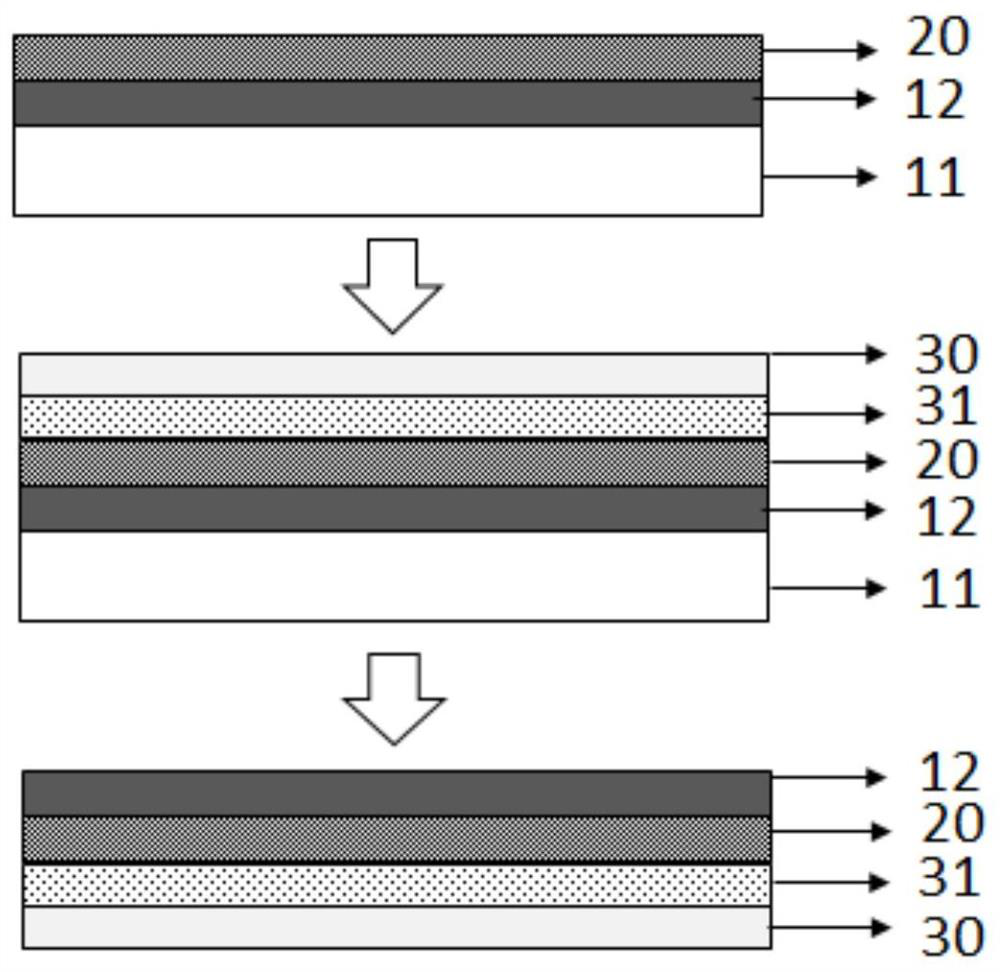

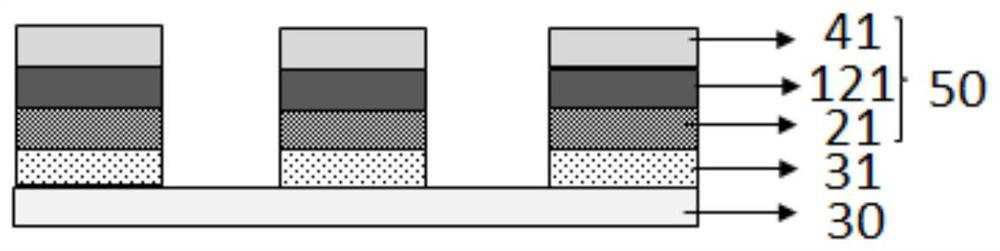

Process for direct imaging growth of graphene on insulation substrate

InactiveCN107012443AAvoid destructionSaving processChemical vapor deposition coatingCopper platingDirect imaging

The invention discloses a process for direct imaging growth of graphene on an insulation substrate, and belongs to the field of preparation of graphene materials. The graphene directly grows on the insulation substrate; and the imaging growth of the graphene is performed on the basis. A layer of copper is firstly plated on the insulation substrate as a catalyst; then, the graphene grows on the surface of the plated copper under catalyst of the copper; the high-temperature annealing is kept to volatilize the copper; and after the copper is volatilized, the graphene can fall to the surface of the insulation substrate to achieve the purpose of directly growing the graphene on the insulation substrate. Based on direct growth, the plated copper has a certain patterns through a photolithography process; and correspondingly, the graphene growing on the copper also has the same patterns to achieve the purpose of direct imaging growth of the graphene on the insulation substrate. The process prevents damage of the graphene in a graphene transfer process through the direct growth process, is lower in cost, and is suitable for large-scale batch production of the graphene.

Owner:BEIJING UNIV OF TECH

Preparation method of L-carnitine nitrate

InactiveCN101817759ALess impuritiesQuality improvementOrganic compound preparationAmino-carboxyl compound preparationNitrateArginine

The invention discloses a preparation method of L-carnitine nitrate, comprising the following steps of: dripping nitric acid into L-carnitine while stirring under the temperature of 10 to 25 DEG C, wherein the mol ratio of the L-carnitine to the nitric acid is 1: 1-1.1; gradually clarifying the solution at the reaction temperature of 40 to 70 DEG C; regulating the pH value of the solution to be 1to 2 by using the nitric acid; continuously stirring the clarified solution, preserving the temperature for 15 to 30min and then compressing and dehydrating, stirring and air-drying at 50 to 70 DEG C, and drying at 75 to 80 DEG C to obtain an L-carnitine nitrate finished product. In the invention, the L-carnitine and the nitric acid are reacted under the ordinary pressure, and therefore, the reaction conditions are mild. In the preparation method, the food-grade L-arginine and the high-purity nitric acid are adopted as raw materials, therefore, the produced L-carnitine nitrate has good quality and high purity up to more than 99 percent without crystallization; not only the quality is ensured, but also the working procedures are saved. The production efficiency is improved and the yield coefficient is high and is up to more than 98 percent. The preparation method has reasonable and simple process and can be suitable for industrial large production.

Owner:TIANJIN TIANCHENG PHARMA

Forming method of dual-damascene structure and semiconductor structure

InactiveCN101996929AImprove yieldSave investment timeSemiconductor/solid-state device detailsSolid-state devicesInsulation layerSemiconductor structure

The invention provides a forming method of a dual-damascene structure and a semiconductor structure, wherein, the semiconductor structure comprises a semiconductor substrate, a metal wiring layer positioned on the semiconductor substrate, a barrier layer positioned on the metal wiring layer, an interlayer insulation layer positioned on the barrier layer, a protective layer positioned on the interlayer insulation layer, a trench which passes through the protective layer and is positioned in the interlayer insulation layer, a bottom antireflection layer which fills up the trench and is positioned on the surface of the protective layer, and an isolation layer positioned on the bottom antireflection layer. In the invention, the bottom antireflection layer can be normally used after rework, thus saving expense and process time.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

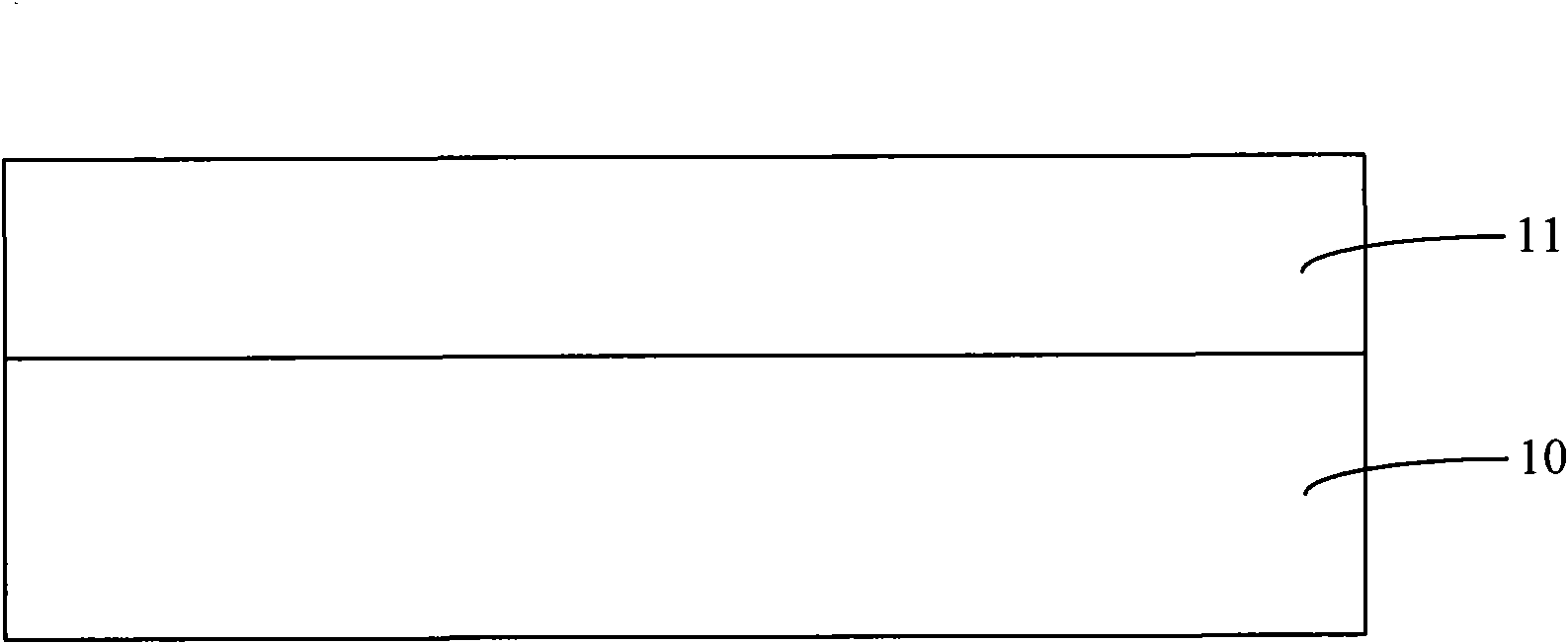

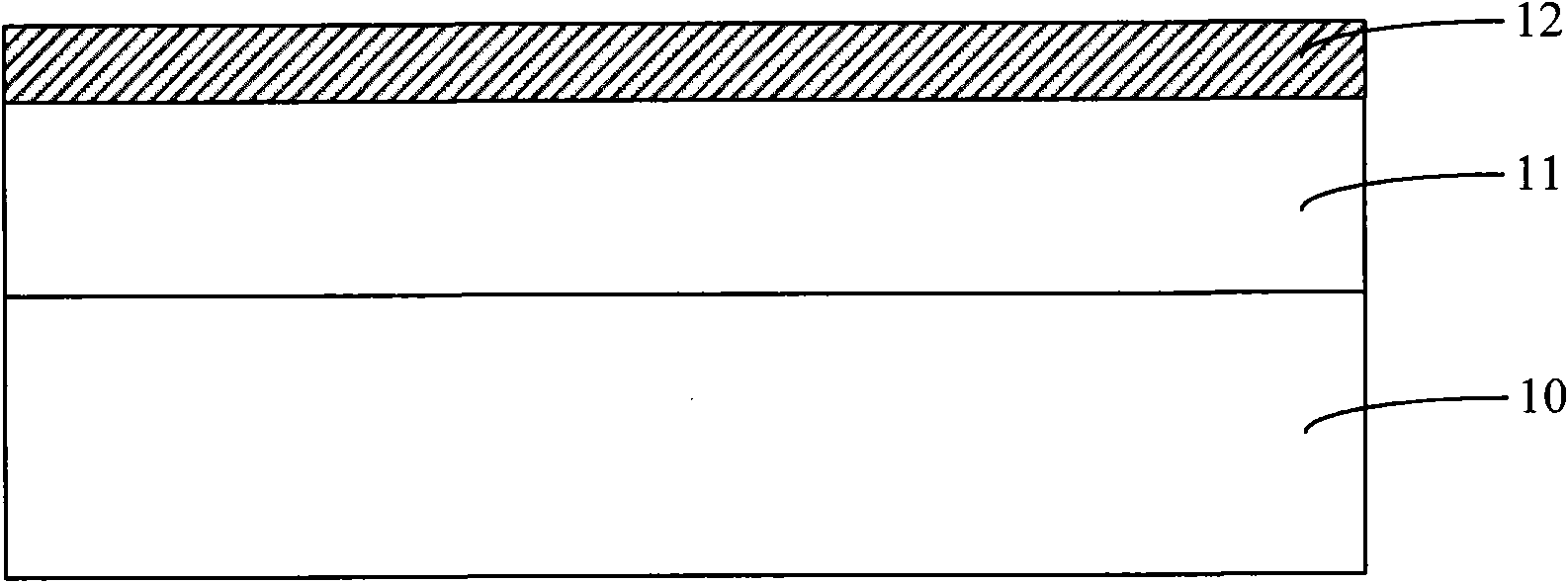

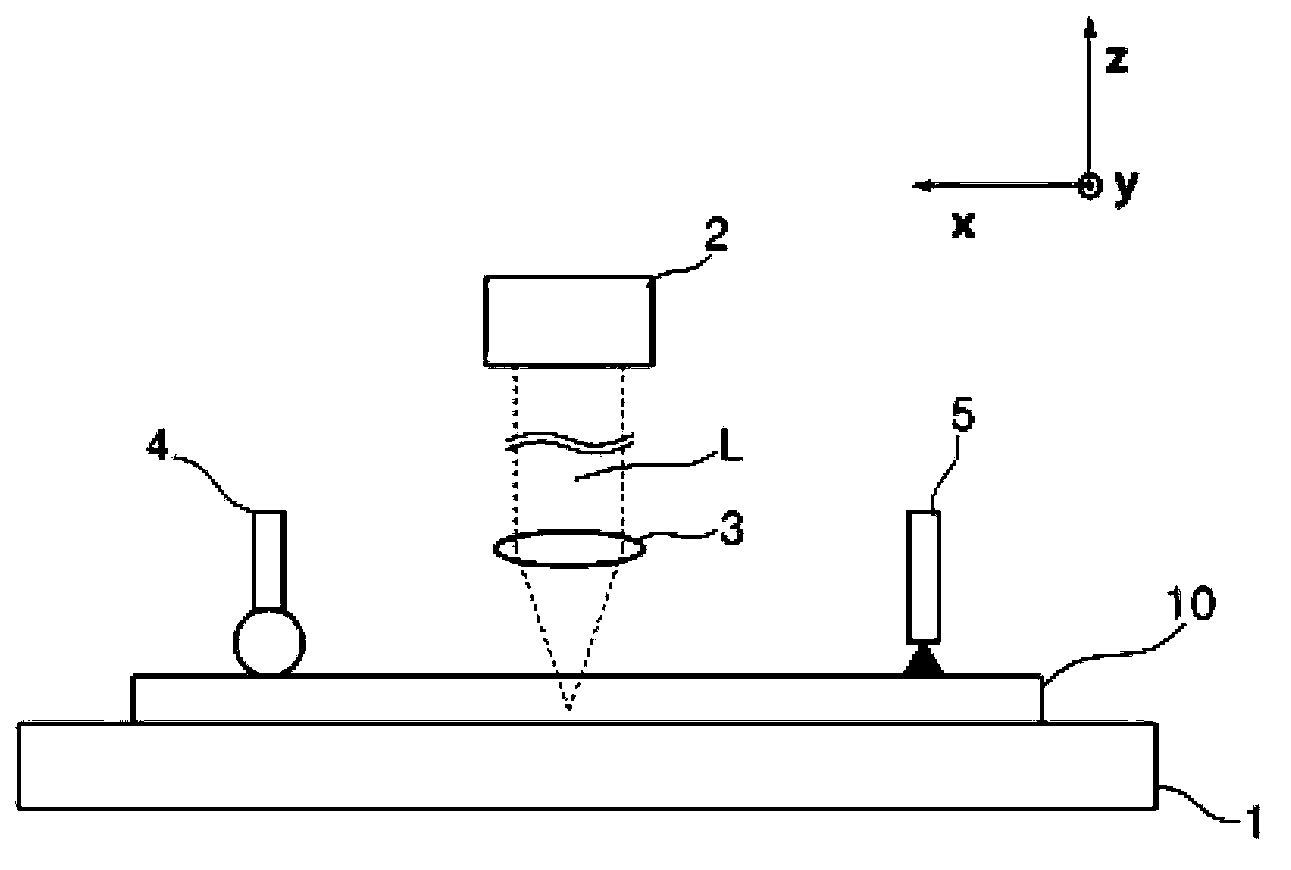

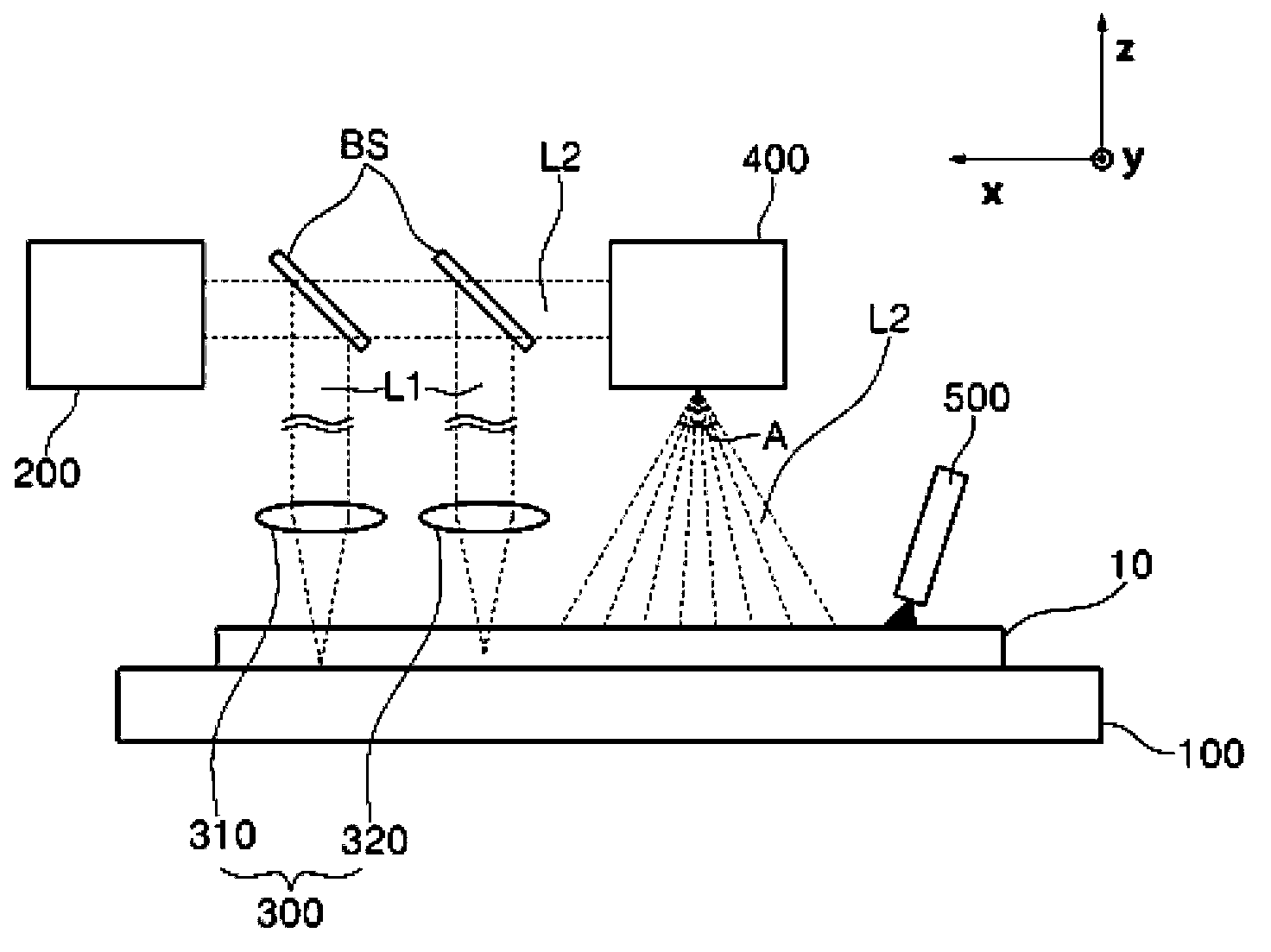

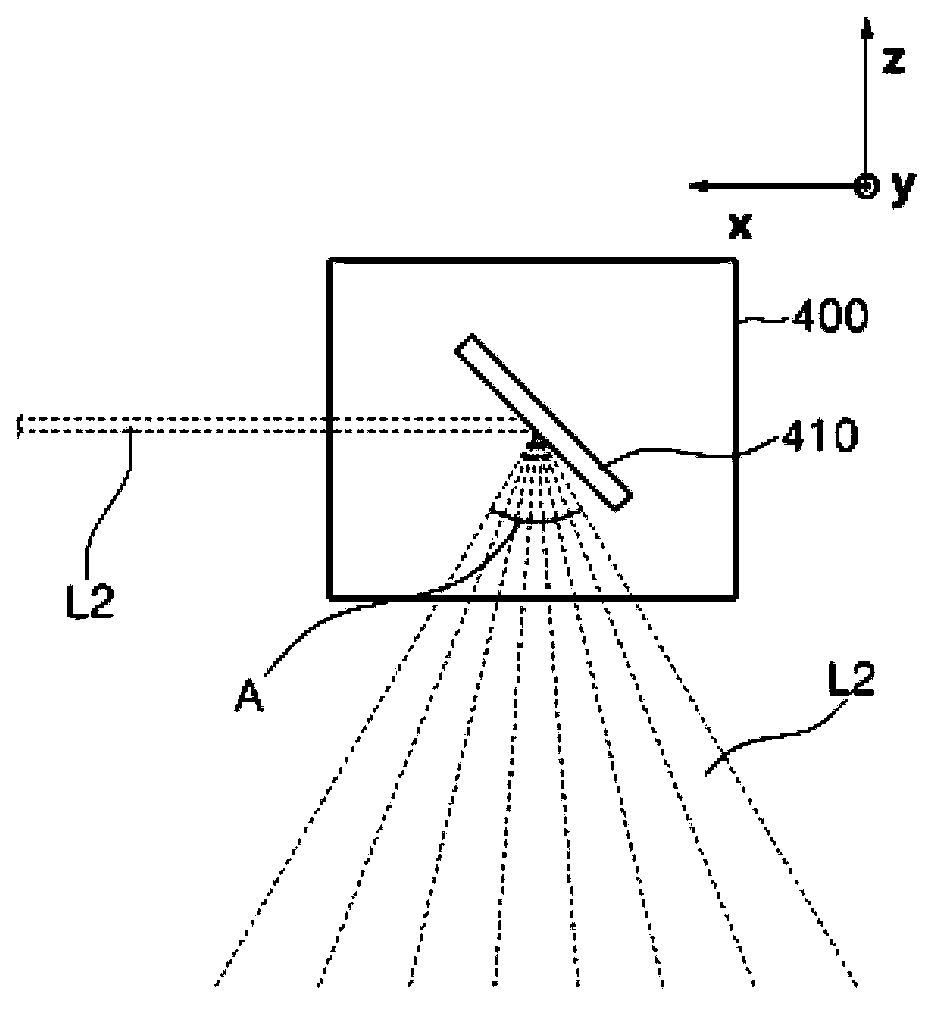

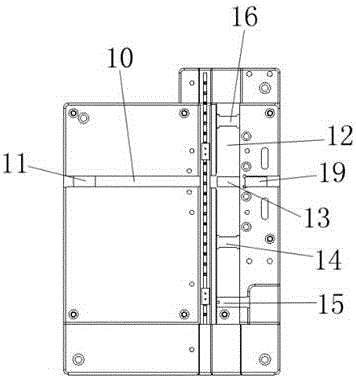

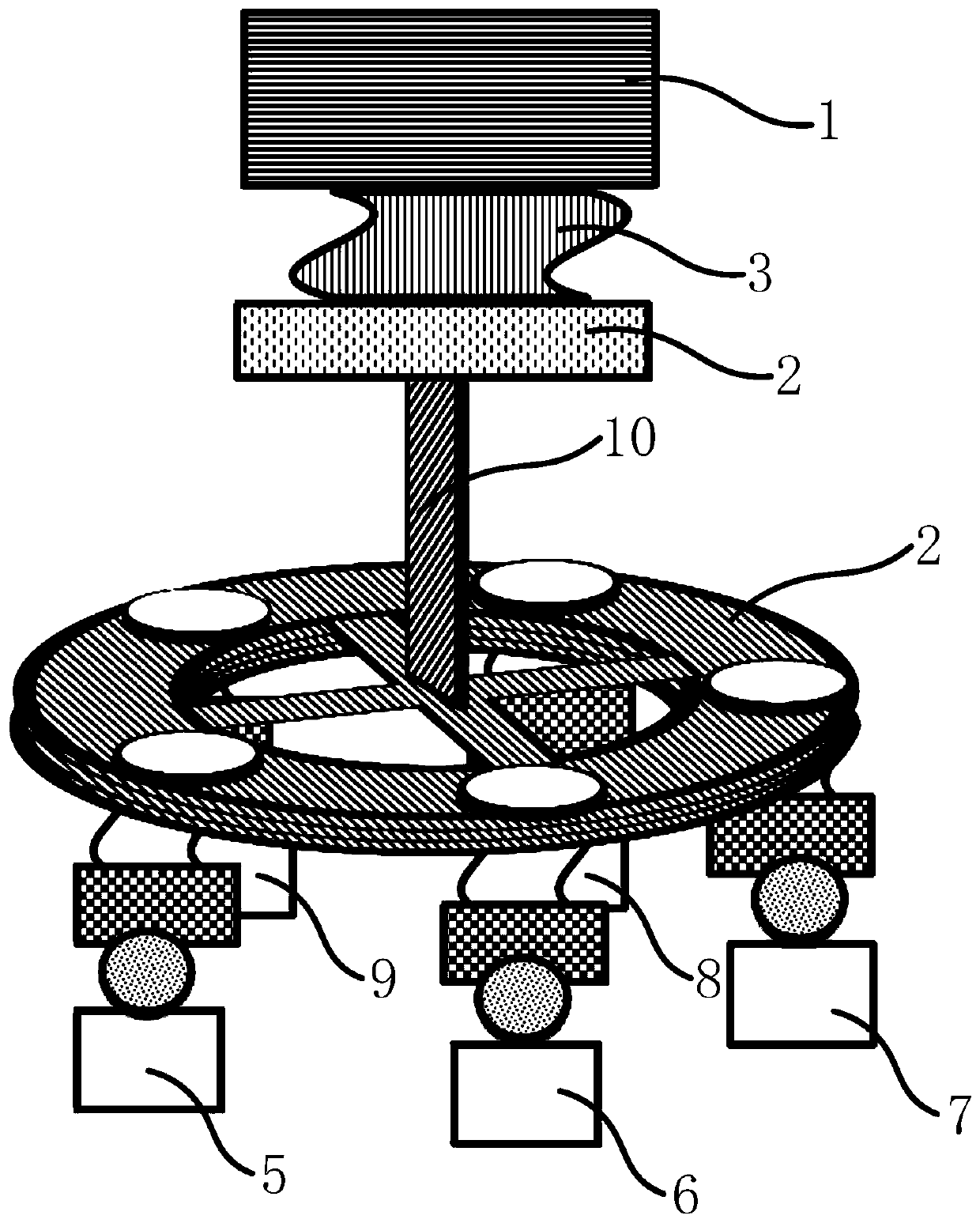

Substrate cutting device and substrate cutting method

ActiveCN103387335AImprove cut qualitySave process timeGlass severing apparatusLaser beam welding apparatusBeam splitterOptoelectronics

The invention relates to a substrate cutting device and a substrate cutting method. The substrate cutting device is characterized by comprising a working table (100) for placing a substrate (10), a laser part (200) for generating laser beams (L1, L2), beam splitters (BS) for splitting the laser beams (L1, L2) into first laser beams (L1) and a second laser beam (L2), a first processing part (300) for subjecting the internal of the substrate (10) to scribing treatment with the first laser beams (L1) to form a first etching part (P1, P2), and a second processing part (400) for subjecting the internal of the substrate (10) to beam swing scribing treatment with the second laser beam (L2) to form a second etching part (P3).

Owner:CHARM ENG CO LTD

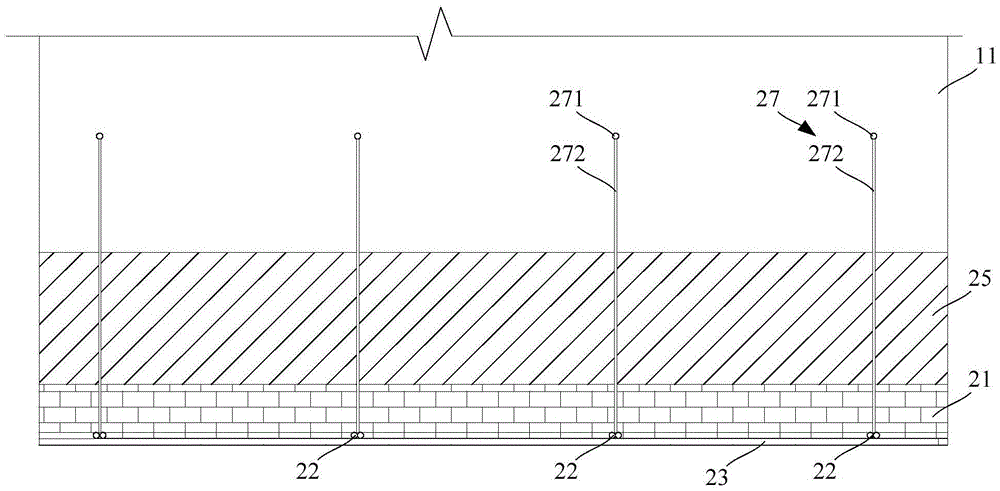

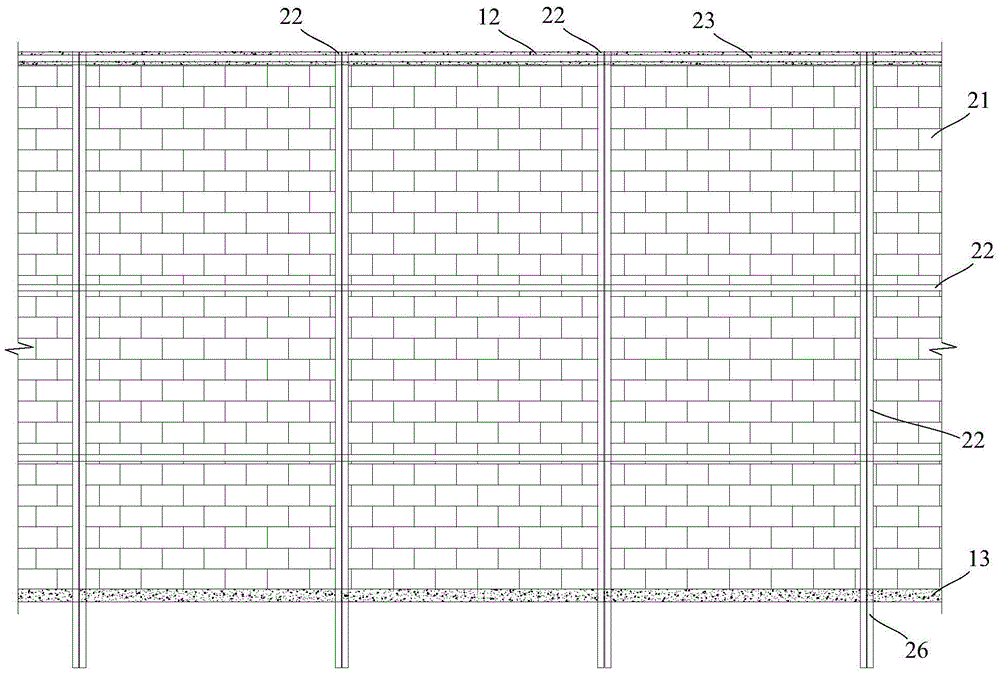

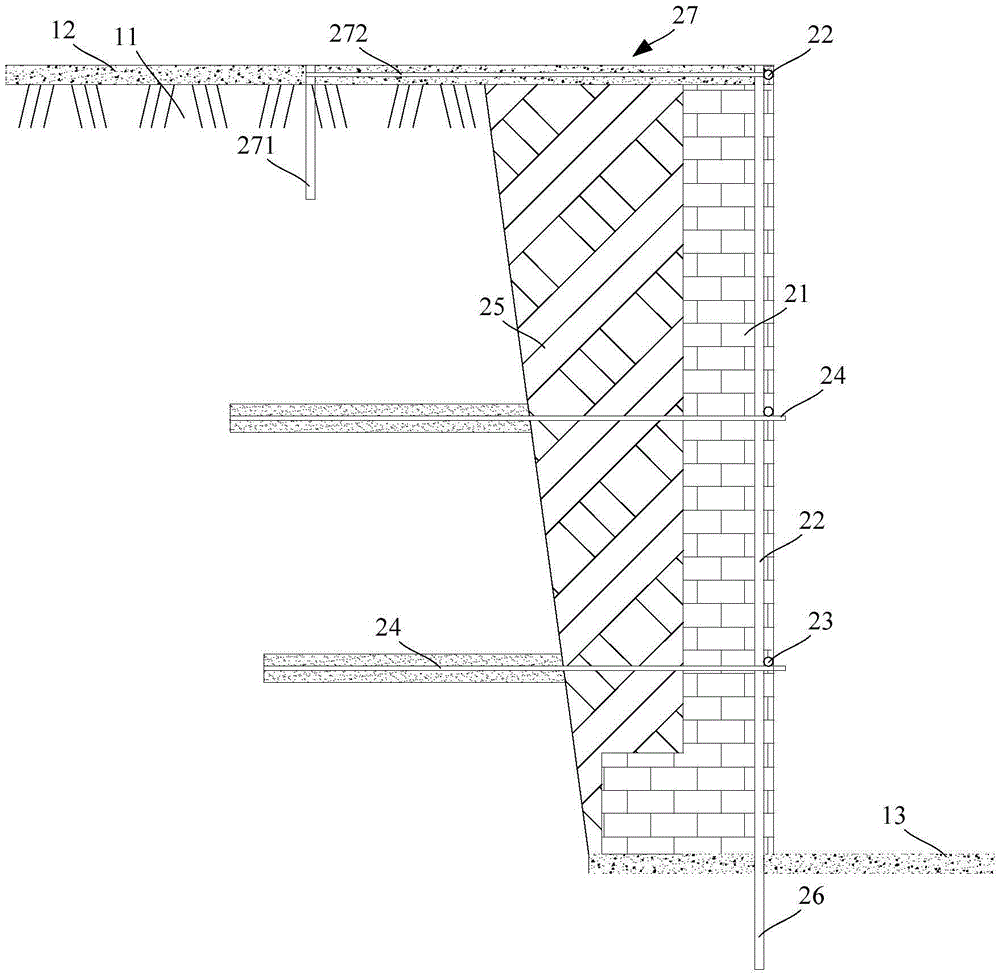

Earth-retaining wall structure with steel tube reinforcing ribs and construction method for earth-retaining wall structure

ActiveCN105649106AHigh strengthImprove economyArtificial islandsUnderwater structuresBusiness efficiencyBrick

The invention relates to an earth-retaining wall structure with steel tube reinforcing ribs and a construction method for the earth-retaining wall structure. The earth-retaining wall structure comprises a brick earth-retaining wall, vertical steel tube reinforcing ribs, transverse steel tube reinforcing ribs, earth nails and backfilled earth, wherein the brick earth-retaining wall is arranged in the side edge of a foundation pit; the vertical steel tube reinforcing ribs are vertically arranged in the brick earth-retaining wall, are close to the inner side surface of the brick earth-retaining wall, are arranged in a spacing manner in a direction of the brick earth-retaining wall, are fixedly connected to the ground, and are internally poured with mortar; the transverse steel tube reinforcing ribs are connected to the vertical steel tube reinforcing ribs; the transverse steel tube reinforcing ribs and the vertical steel tube reinforcing ribs form a vertically-transversely crossed net-shaped structure; the earth nails are arranged in the spacing manner along the height of the vertical steel tube reinforcing ribs; the earth nails pass through the outer side surface of the brick earth-retaining wall and are embedded into rock-soil around the foundation pit; and the gap between the brick earth-retaining wall and the inner wall of the foundation pit is filled with the backfilled earth. The earth-retaining wall structure has relatively high economical efficiency, relatively high reliability and a relatively high efficiency ratio, is simple in structure, and the construction period is shortened.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

Production method for transmission shaft

Disclosed is a production method for a transmission shaft. The production method comprises the following steps that (1) powder metallurgy is conducted; (2) hot extrusion is conducted; (3) a blank according with a press machine die in the step (5) is made; (4) the blank is subjected to annealing treatment; (5) the blank is subjected to cold extrusion to be thickened; (6) a center hole is drilled in the thickened blank, chamfering is conducted after counterboring, and then outer circle turning is conducted; (7) the workpiece is subjected to spline cold extrusion; (8) then the workpiece is subjected to surface turning and chamfering; (9) then the overlong part of a small-diameter end of the workpiece is turned to be removed, and chamfering is conducted after rough surface turning; (10) the outer circle of a big-diameter end of the workpiece is subjected to outer circle turning to form the needed shape, groove cutting is conducted in the position, close to the end face, of the outer circle face of the small-diameter end, and meanwhile, the part, at the small-diameter end, of the center hole is subjected to chamfering; and (11) a finished product is obtained after the treated workpiece is subjected to flat-head chamfering and inner counterboring. Compared with the prior art, the production method has the advantages that working procedure time and raw materials are saved, the finished product rate is high, and the cost is low.

Owner:张理够

Offset print water-borne UV (ultraviolet) photo-sensitive resist jetting plate-making method

InactiveCN102176107AEliminate exposure washoutOmit retouchingPhotomechanical apparatusPrintingResistUltraviolet

The invention discloses an offset print water-borne UV (ultraviolet) photo-sensitive resist jetting plate-making method which comprises the following steps: firstly jetting a water-borne UV photo-sensitive resist on a hydrophilic metal base by using an ink-jet printing device, and forming an oiliness information recording region on the surface of the metal base; and in addition, curing a information recording region on the surface of the metal base by using an ultraviolet lamp, and then printing on the machine. The offset print water-borne UV photo-sensitive resist jetting plate-making method is simple in process, rapid in printing plate drying speed, less in energy consumption, good in printing plate quality, good in printing-resistance rate, and free from environment pollution.

Owner:XIAN UNIV OF TECH

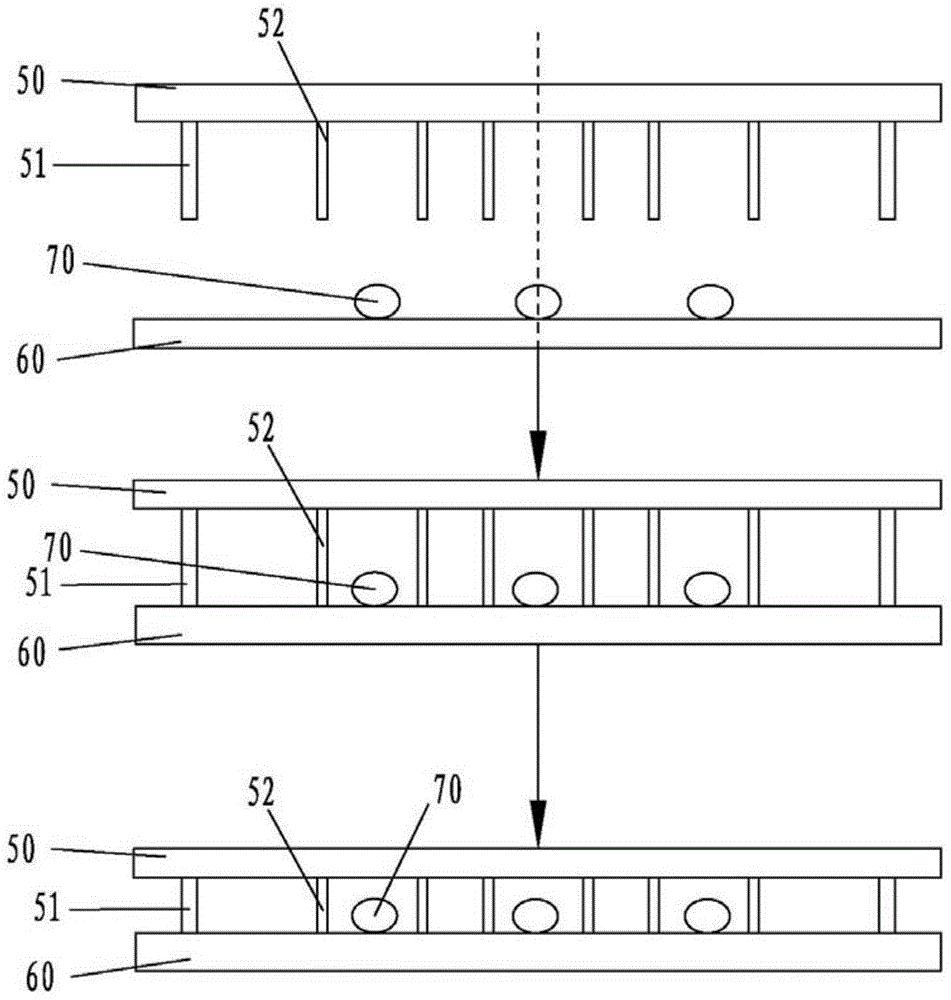

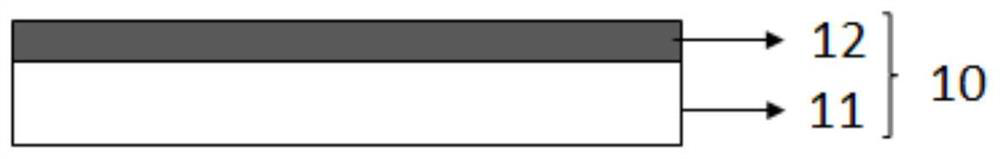

Substrate bonding process and substrate module to be bonded

InactiveCN103955085AAvoid punctureReduce pressure differenceLayered productsElectrical equipmentBonding processEngineering

The invention relates to a substrate bonding process and a substrate module to be bonded, wherein a peripheral rubber frame is arranged on the surface of a substrate of the substrate module to be bonded, boxed rubber frames are arranged in the peripheral rubber frame, and the height of the boxed rubber frames is greater than the height of the peripheral rubber frame. The substrate bonding process includes the following steps that the peripheral rubber frame is arranged on the surface of a first substrate, the boxed rubber frames for sealing liquid crystal are arranged in the peripheral rubber frame, and the height of the boxed rubber frames is greater than the height of the peripheral rubber frame; the air between the first substrate and a second substrate is sucked off; the first substrate and the second substrate are preliminarily bonded; gas is filled in between the first substrate and the second substrate; the first substrate and the second substrate are further bonded. The technical scheme of the invention can prevent the liquid crystal in the boxes from impacting the boxed rubber frames to cause penetration, save process time and cost and decrease the probability that circuit wires and element switches are corroded by acid liquid.

Owner:BOE TECH GRP CO LTD +1

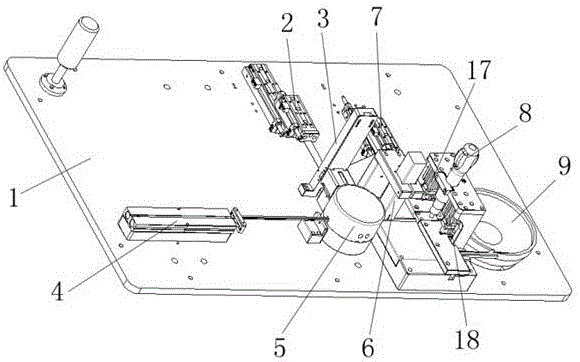

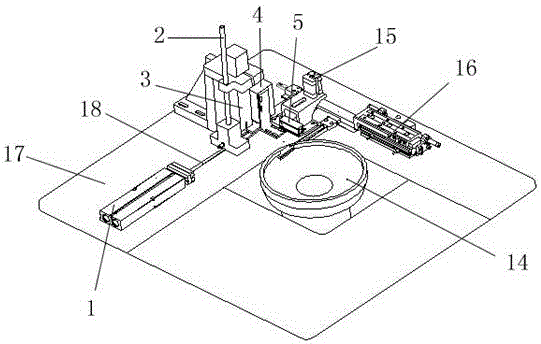

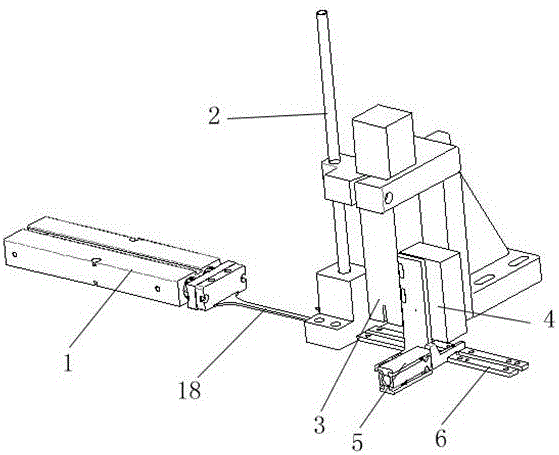

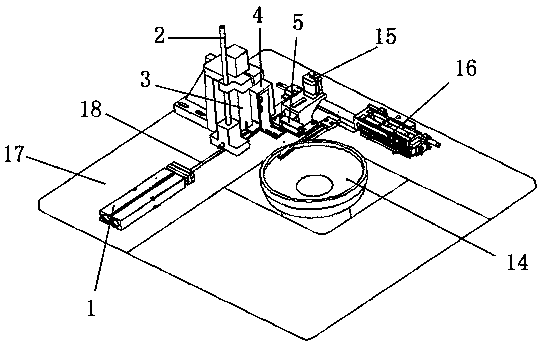

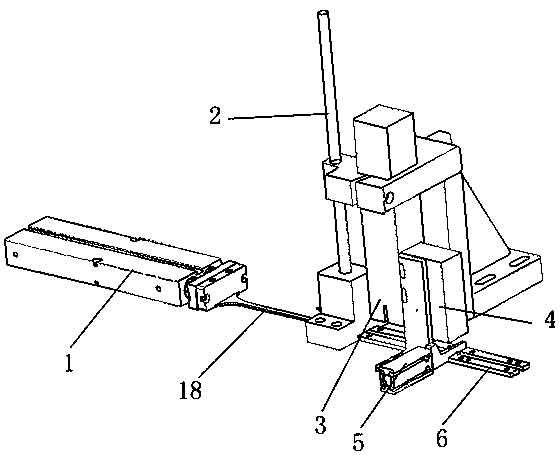

Automatic marking, spacer feeding, stacking, magnetic flux measuring system for magnetic steel

ActiveCN106670129ASave process timeImprove labor efficiencyOther printing apparatusSortingProduction lineMagnetic poles

The invention relates to an automatic marking, spacer feeding, stacking and magnetic flux measuring system for magnetic steel. The automatic marking, spacer feeding, stacking and magnetic flux measuring system for the magnetic steel comprises a workbench, a pushing air cylinder, a feeding air cylinder, a guiding pipe, a magnetic flux detecting instrument, an ink-jet printing device, a sorting air cylinder, a vibrating disk, a first ejecting air cylinder, a second ejecting air cylinder, a first rail, a second rail and a third rail. The guiding pipe is arranged above the first rail. A pushing punch pin of the pushing air cylinder can push the magnetic steel which falls on to the first rail from the guiding pipe to a detecting platform of the magnetic flux detecting instrument under the drive of the pushing air cylinder. The second rail is provided with a first position. By the adoption of the automatic marking, spacer feeding, stacking and magnetic flux measuring system for the magnetic steel, the three working steps of magnetic flux detecting, automatic magnetic pole marking and automatic spacer feeding and stacking are automatically and continuously conducted in a production line manner, the time of working procedure and the flow is saved, the labor efficiency is improved, and the operation efficiency is improved; material falling is conducted through the gravity of the magnetic steel, so that actions executed by devices are simplified; and manual material collecting is not needed, and detecting personnel can operate multiple devices at the same time, or manual participation is not needed in the detecting process.

Owner:杭州科德磁业有限公司

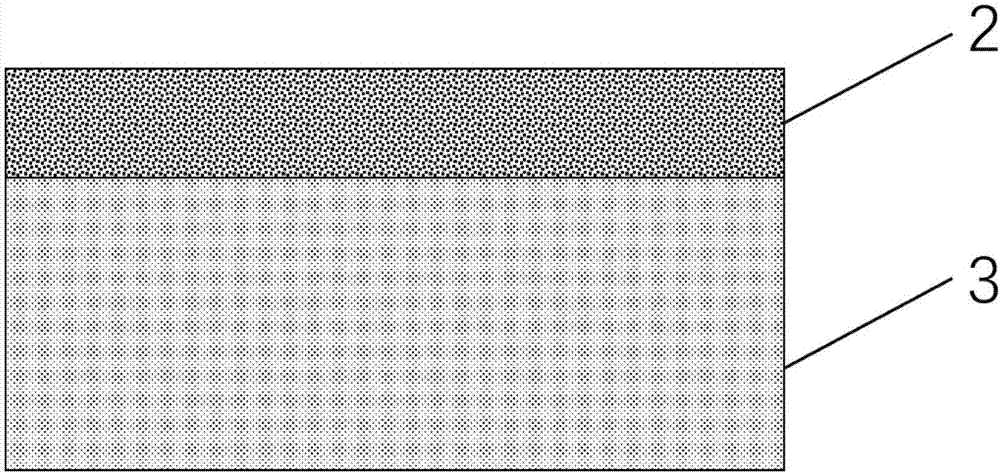

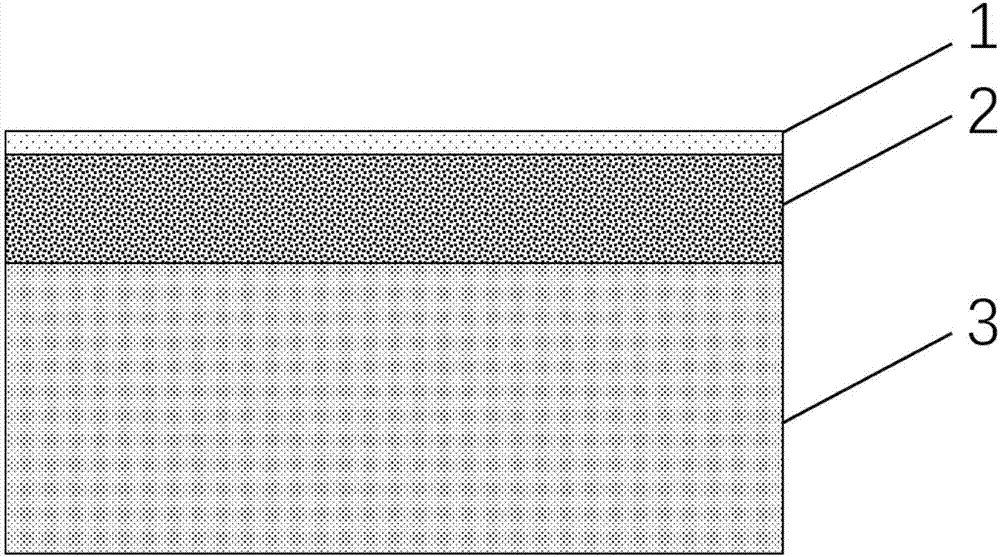

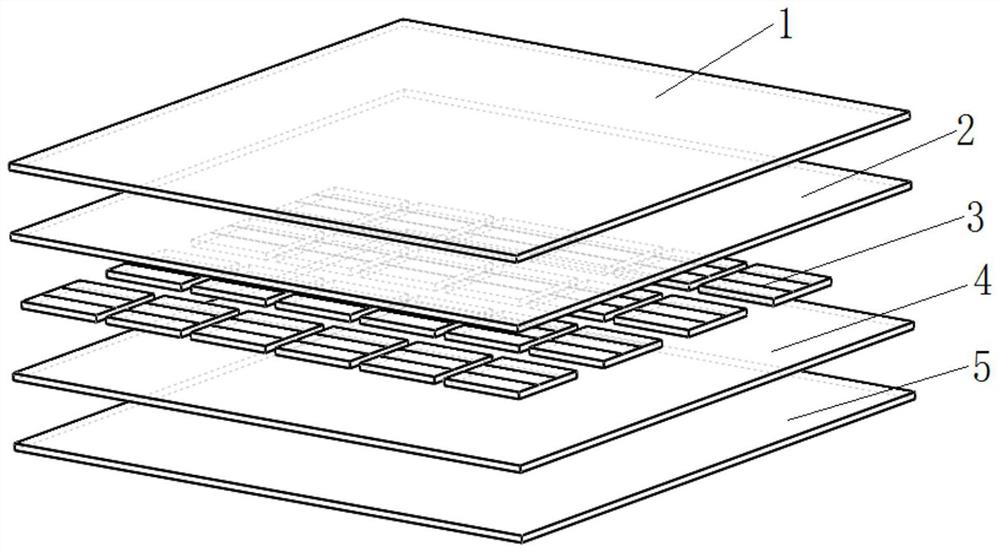

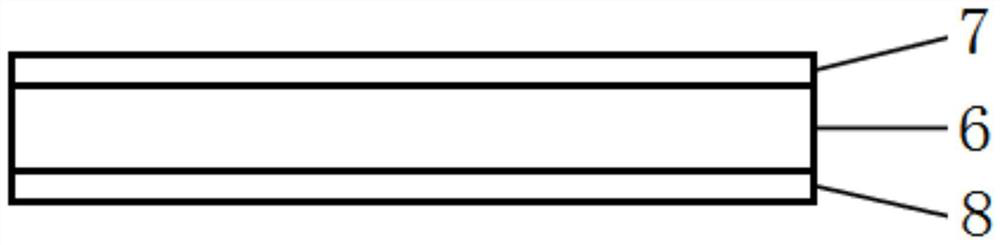

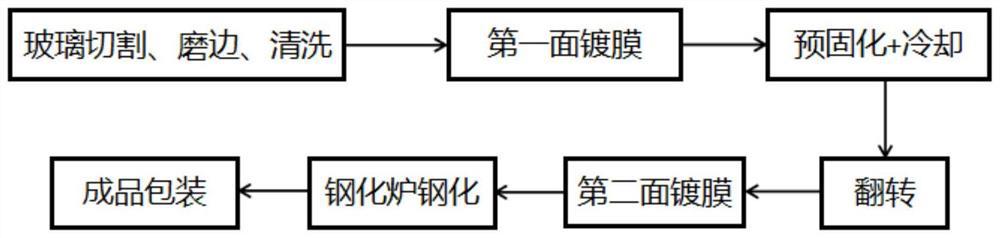

Double-glass photovoltaic module and preparation method thereof

PendingCN114093964ASimple structureReduce manufacturing costPhotovoltaic energy generationSemiconductor devicesCutting glassBattery cell

The invention discloses a double-glass photovoltaic module and a preparation method thereof. The photovoltaic module sequentially comprises front glass, a front packaging adhesive film, a battery string, a rear packaging adhesive film and back glass; the front glass and the back glass adopt double-sided coated glass; the preparation process of the double-sided coated glass comprises the following steps: S1, cutting glass into a required size, carrying out polishing, and carrying out cleaning to remove surface impurities; S2, printing glaze on the surface of the glass to form a glaze layer; S3, curing and cooling the glass; S4, turning over the glass, and then coating the glass with antireflection film coating liquid to form an antireflection film layer; and S5, tempering the glass, detecting a finished product, and packaging the glass. The preparation process of the double-glass photovoltaic module comprises the following steps that a lead hole is formed in the back glass, a front packaging adhesive film, a battery string, a rear packaging adhesive film and the back glass are sequentially laid on the front glass, the front packaging adhesive film and the rear packaging adhesive film are attached to the glaze layers on the front glass and the back glass respectively, positive and negative leads in the battery string are led out from the lead hole, and the double-glass photovoltaic module is manufactured through lamination.

Owner:CHANGZHOU ALMADEN

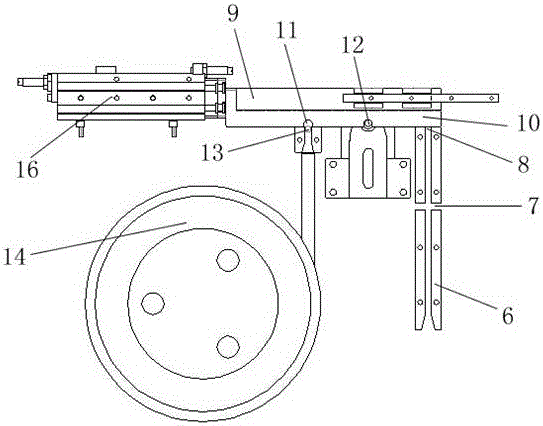

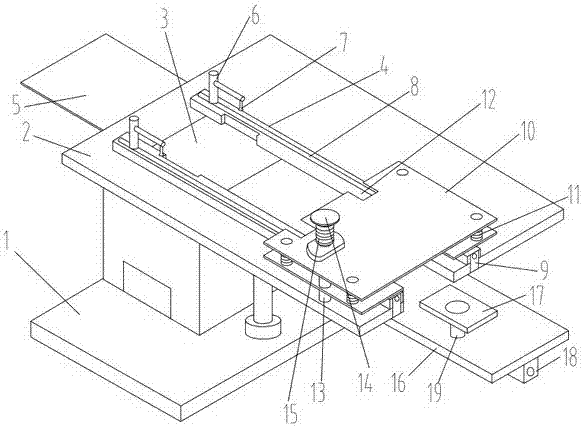

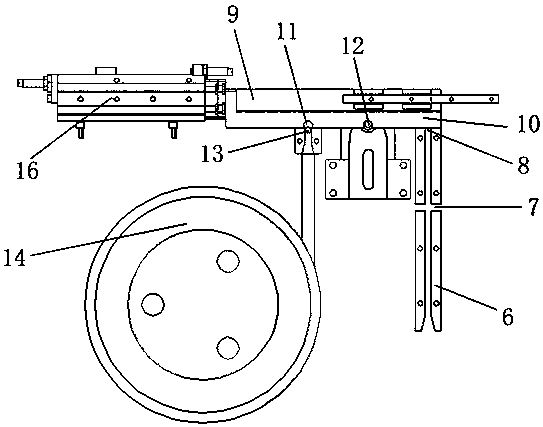

Magnetic pole marking and detecting and stacking device

ActiveCN106140657ANo human intervention requiredLaminating speed is fastStacking articlesSortingMagnetic polesEngineering

The invention relates to a magnetic pole marking and detecting and stacking device. The magnetic pole marking and detecting and stacking device comprises a worktable, a material feeding rail, a stacking rail, a material guiding pipe, an ink jet printer, a color mark sensor, a vibration disc, a material ejection cylinder, a stacking cylinder and a material conveying cylinder, wherein a material conveying push rod on the material conveying cylinder is arranged on the material feeding rail; the material conveying push rod can slide on the material feeding rail driven by the material conveying cylinder; the ink jet printer, the color mark sensor and a blanking port on the material guiding pipe are all arranged above the material feeding rail; the stacking rail is provided with a material discharging through hole, and a stacking pipeline is arranged below the material discharging through hole; and a material ejection push rod on the material ejection cylinder is arranged above the material discharging through hole. Stacking speed is increased by utilizing the material blanking mode of pads and steel magnets during feeding, and one pad is arranged between every two adjacent steel magnets; marking and stacking are finished continuously; process flowing time is saved; working efficiency is improved; and the efficiency of each article of equipment is 12000 pcs / 8h.

Owner:杭州科德磁业有限公司

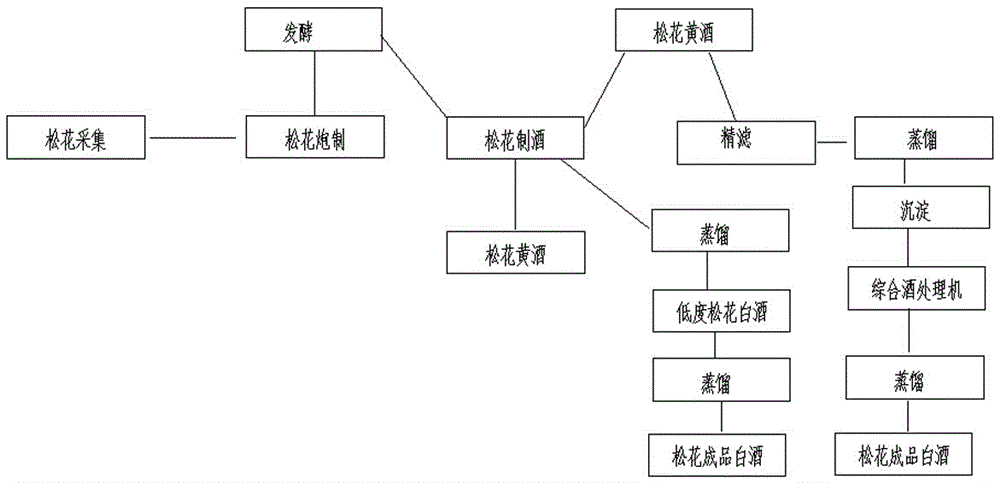

Piny flower wine and preparation method thereof

InactiveCN105670892AHave business valueSave process timeDigestive systemAlcoholic beverage preparationBiotechnologyChinese liquor

The invention relates to a piny flower wine and a preparation method thereof. The invention specifically includes a formula of piny flower original pulp Chinese liquor and piny flower yellow wine and a preparation method thereof. Specifically, according to the formula of the piny flower original pulp wine, the main materials include: 2-5 or 4-7 parts of mountain stream, 5-8 or 3-6 parts of piny flower; or the main materials include: 3-5 parts or 3-6 parts of mountain stream, 1.5-3 parts or 3-6 parts of piny flower, 0.5-2 parts of honey, 0.5-2 parts or 0.5-1 part of Scutellaria baicalensis, and 0.5-3 parts or 0.5-1 part of Rosa roxbunghii; and the auxiliary materials include: 0.5-1.5 parts or 1.5-3 parts of rock sugar. The preparation method consists of piny flower collection, piny flower processing, and piny flower wine making.

Owner:冯泽吉

Automatic copying device

ActiveCN107479344ASolve replacementAutomate operationElectrographic process apparatusCopying mechanismPulp and paper industry

The invention discloses an automatic copying device and relates to the technical field of copying equipment. The automatic copying device comprises a pedestal, a copying mechanism and an executing mechanism; the copying mechanism is arranged on the pedestal; the executing mechanism is positioned on the upper side of the copying mechanism; the executing mechanism is an automatic paper release mechanism; and the paper release end of the automatic paper release mechanism is positioned at the copying window position of the copying mechanism. The automatic copying device can automatically replace paper without tedious manual operation and greatly improve the efficiency.

Owner:滁州云拓互联科技有限公司

Test probe device

ActiveCN109738677ASave process timeSave testing timeElectrical measurement instrument detailsElectrical testingTested timeTest station

The invention relates to the technical field of display equipment, and discloses a test probe device. The test probe device comprises a support, a supporting piece which is mounted on the support in alifting mode, a first driving device for driving the supporting piece to act relative to the support and a test assembly mounted on the supporting piece. The test assembly comprises a mounting plate,a cutting unit, a sucker disc unit, a grinding unit, an auxiliary probe unit and a test probe unit and a second driving device, wherein the cutting unit, the sucker disc unit, the grinding unit, theauxiliary probe unit and the test probe unit are mounted on the mounting plate, and the second driving unit is used for driving the cutting unit, the sucker disc unit, the grinding unit, the auxiliaryprobe unit and the test probe unit to act and to switch between a test station and a non-test station. The test probe device realizes the detection of an effective display area of a display panel, the test process is saved, the test time is shortened, and the cost is saved.

Owner:HEFEI XINSHENG OPTOELECTRONICS TECH CO LTD +1

Formula and construction process of exterior wall thermal insulation putty-free plastering mortar

The invention relates to the field of building materials, particularly to a formula and a construction process of exterior wall thermal insulation putty-free plastering mortar. The exterior wall thermal insulation putty-free plastering mortar comprises bottom-layer plastering mortar and surface-layer plastering mortar, wherein the bottom-layer plastering mortar comprises the following components:30-50 parts of white cement, 5-11 parts of ash calcium, 50-65 parts of white marble machine-made sand, 0.2-0.5 part of hydroxypropyl methyl cellulose, 0.1-0.3 part of wood fiber, 0.1-0.2 part of polypropylene fiber and 0.5-1.5 part of latex powder, and the surface-layer plastering mortar comprises the following components: 40-60 parts of white cement, 5-10 parts of ash calcium, 35-45 parts of white marble machine-made sand, 0.2-0.5 part of hydroxypropyl methyl cellulose, 0.1-0.3 part of wood fiber, 0.1-0.2 part of polypropylene fiber, 0.5-1.5 parts of latex powder and 0.05-0.1 part of cellulose ether. According to the exterior wall thermal insulation putty-free plastering mortar prepared by the formula, materials, procedures and time of a putty layer are saved, and the cost can be better saved.

Owner:赵开磊

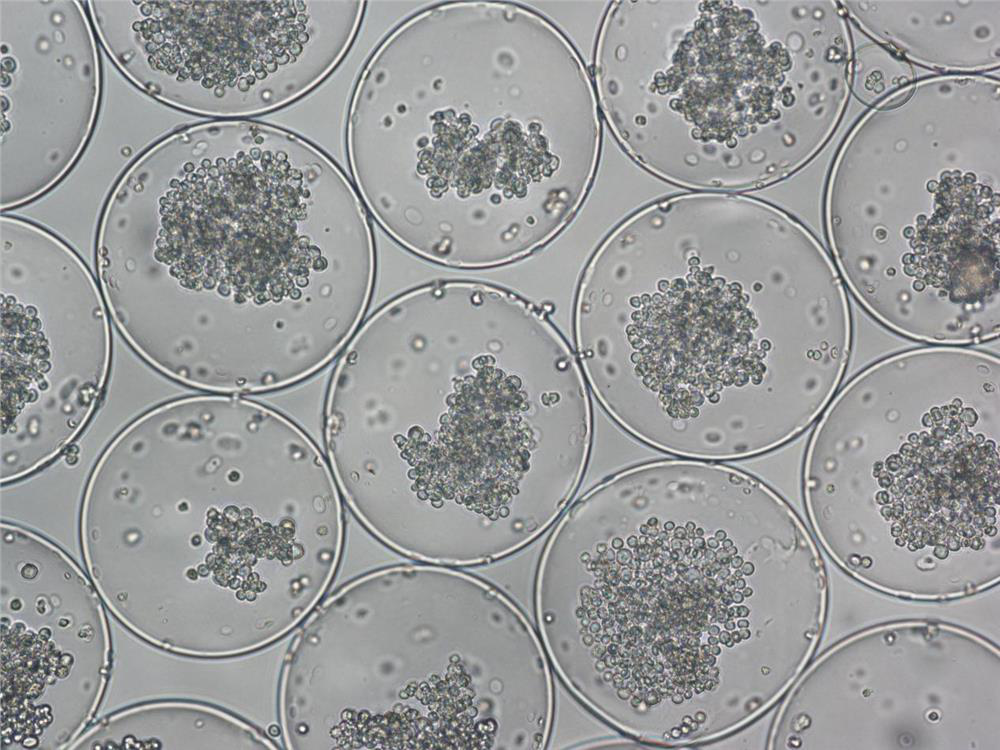

Method for increasing yield of mesenchymal stem cell exosomes, and application of method

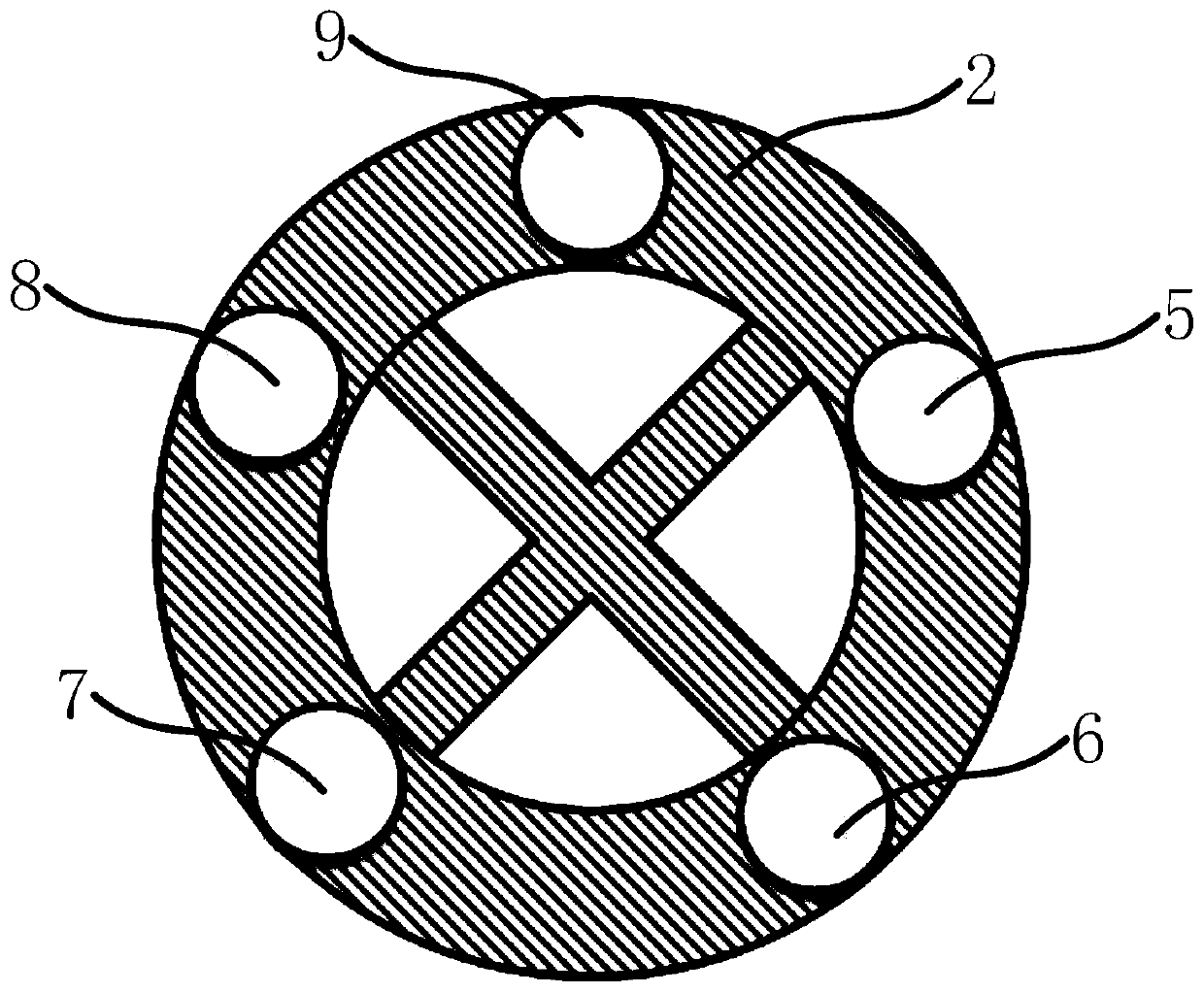

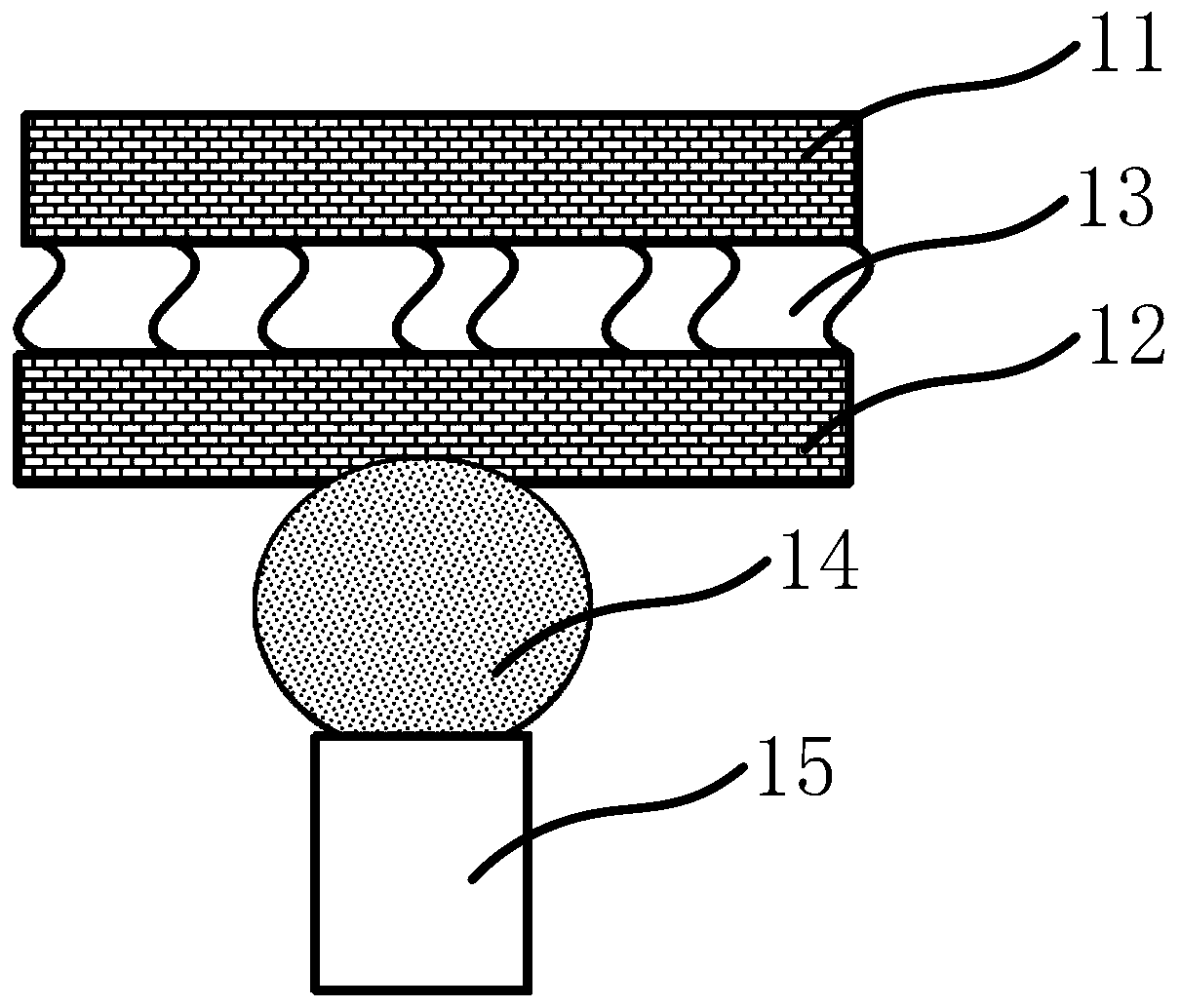

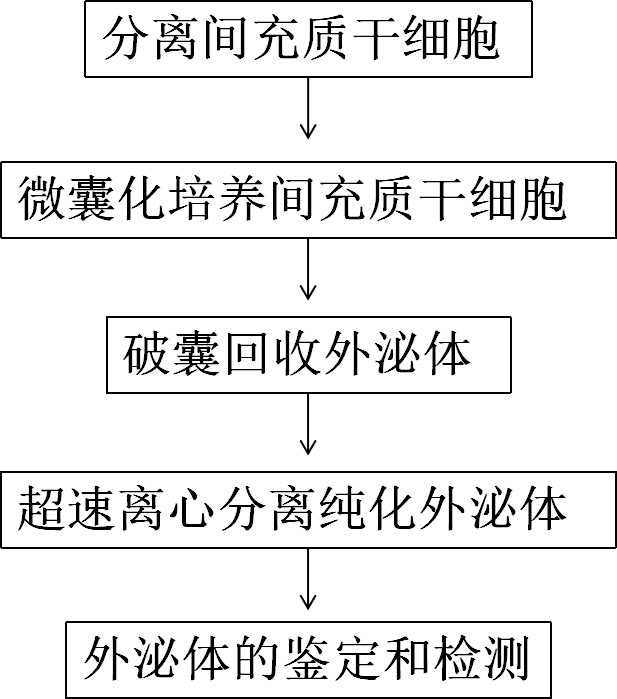

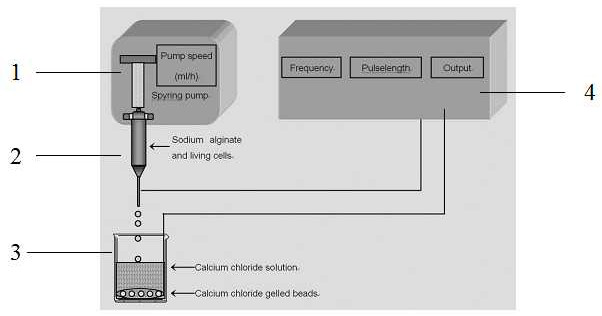

InactiveCN112342190AIncrease production capacityEfficient retentionCell dissociation methodsSkeletal disorderMesenchymal stem cellExosome

The invention provides a method for increasing the yield of mesenchymal stem cell exosomes, and an application of the method. According to the method, a microcapsule is used as a growth system of mesenchymal stem cells, the mesenchymal stem cells are cultured under the three-dimensional condition, the culture environment is closer to the body, and therefore the yield of exosomes secreted by the mesenchymal stem cells can be increased conveniently. A semi-permeable membrane of the microcapsule can effectively intercept the exosomes, the concentration of the exosomes in the microcapsule is improved, and therefore the process cost and time are saved for downstream separation and purification; and exosomes derived from the serum of a culture medium can be prevented from entering the microcapsule, a specific commercial serum-free culture medium is prevented from being used, and therefore the culture cost is reduced. The method for increasing the yield of the mesenchymal stem cell exosomes through three-dimensional culture provided by the invention is expected to solve the technical bottleneck of insufficient exosome yield.

Owner:陈传果

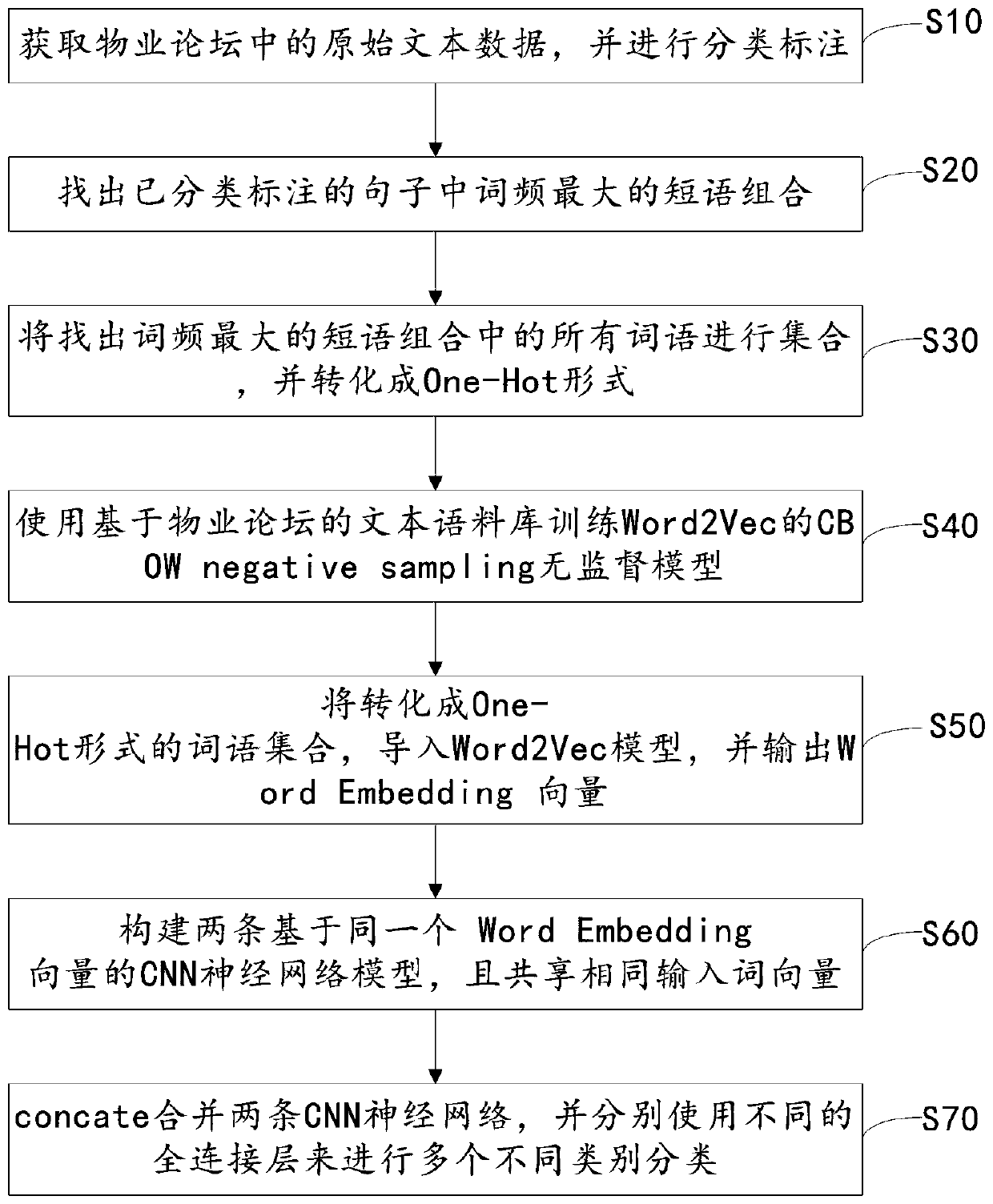

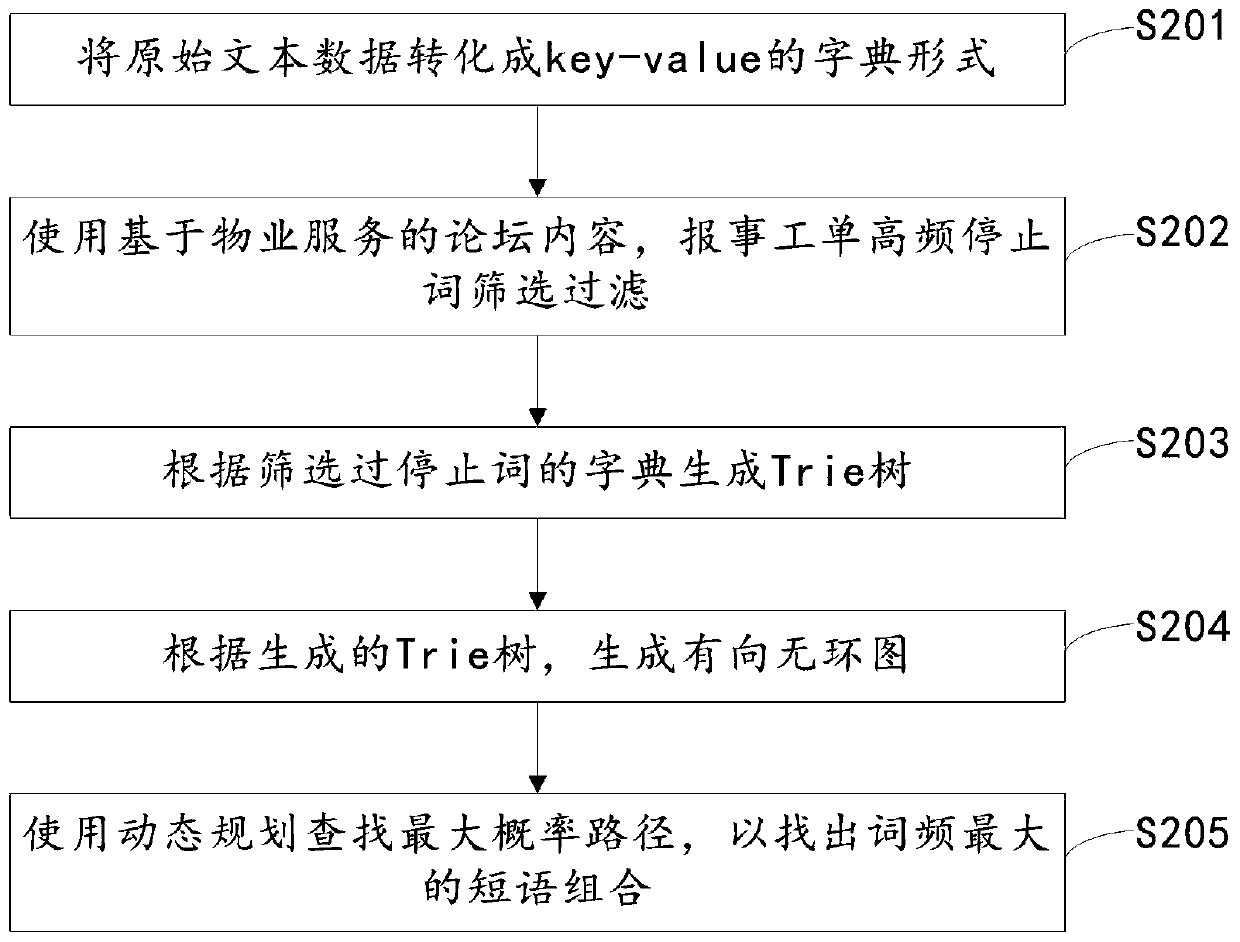

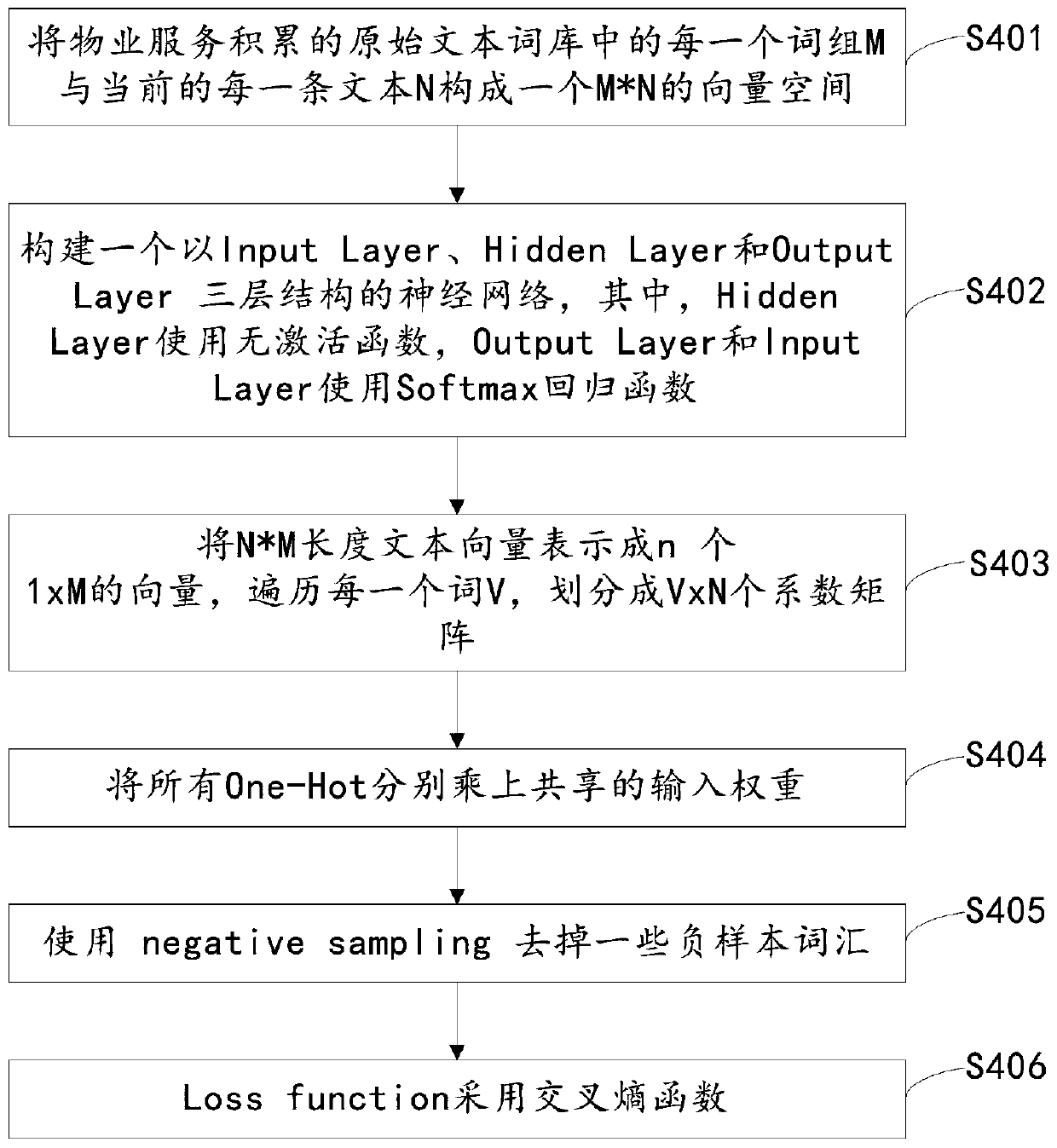

Multi-output text classification model construction method and device, equipment and medium

PendingCN111581386AQuick screeningQuick response to appealsNeural architecturesSpecial data processing applicationsEngineeringNetwork model

The invention discloses a multi-output text classification model construction method and device, equipment and a medium, and the method comprises the following steps: obtaining original text data in aproperty forum, and carrying out the classification marking; finding out a phrase combination with the maximum word frequency in the classified and marked sentences; gathering all words in the phrasecombination with the maximum word frequency, and converting the gathered words into an One-Hot form; using a text corpus based on a property forum for training a CBOWnegative sampling unsupervised model of Word2Vec (Word2Vec); importing the word set converted into the One-Hot form into a Word2Vec model, and outputting a Word Embedding vector; constructing two CNN neural network models based on the same Word Embedding vector, and sharing the same input word vector; and enabling concate to merge the two CNN neural networks, and respectively use different full connection layers to classify a plurality of different categories. According to the invention, quick response to user demands is realized, the flow processing time is saved, the complaint type is quickly discriminated, junk advertisement content is effectively screened, and the property service quality is improved.

Owner:深圳市第五空间网络科技有限公司

Manufacturing method of micro light-emitting diode

InactiveCN112133719AAvoid influenceNo damageSolid-state devicesSemiconductor/solid-state device manufacturingPhysical chemistryLight-emitting diode

The invention provides a manufacturing method of a micro light-emitting diode, relates to the field of micro light-emitting diodes, and changes a traditional process sequence: in the process of manufacturing and transferring the micro light-emitting diode, a photoresist after etching of the micro light-emitting diode is firstly reserved, and the photoresist is used as an intermediate layer for transferring the micro light-emitting diode; and the photoresist is removed after transfer, so that the influence of residual glue on the micro light-emitting diode is avoided, the LED is not damaged, the transfer rate of the LED is also improved, and the process time and cost are saved.

Owner:NANJING CEC PANDA LCD TECH

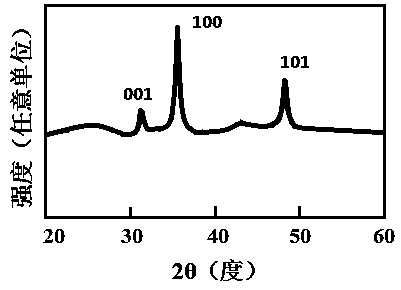

Polycrystalline WC film high in stoichiometric ratio and low temperature preparation method thereof

ActiveCN108165941AImprove crystal qualityHigh stoichiometric ratioVacuum evaporation coatingSputtering coatingX-rayGraphite

The invention discloses a polycrystalline WC film high in stoichiometric ratio and a low temperature preparation method thereof. The X-ray diffraction strongest peak of the polycrystalline WC film isa (100) diffraction peak, and the polycrystalline WC film has a hexagonal phase structure; the atomic percentage of W: C in the WC film is 49.7: 50.3-50.5: 49.5, and a high stoichiometric ratio is achieved; and the microhardness of the WC film is higher than 23 GPa, and the adhesive force with a substrate is higher than 31 N. A direct-current magnetron sputtering method is adopted for the low temperature preparation method of the polycrystalline WC film, a dual-target co-sputtering method of a high-purity W metal target material and a graphite target material is adopted, Ar-CH4 mixed gas is work gas, the Ar: CH4 partial pressure ratio is 1: 1, and the gas pressure intensity is 1.5 Pa; and the WC film grows in a Ar-CH4 plasma atmosphere, and the growing temperature is 300-500 DEG C. According to the dual-target co-sputtering method, the C loss is effectively supplemented, the crystal quality of the low temperature growing WC film is improved, the made WC film is made to be a crystal state film, and the high stoichiometric ratio is achieved.

Owner:ZHEJIANG UNIV

A magnetic pole marking detection and stacking device

ActiveCN106140657BNo human intervention requiredLaminating speed is fastStacking articlesSortingMagnetic polesFlow time

Owner:杭州科德磁业有限公司

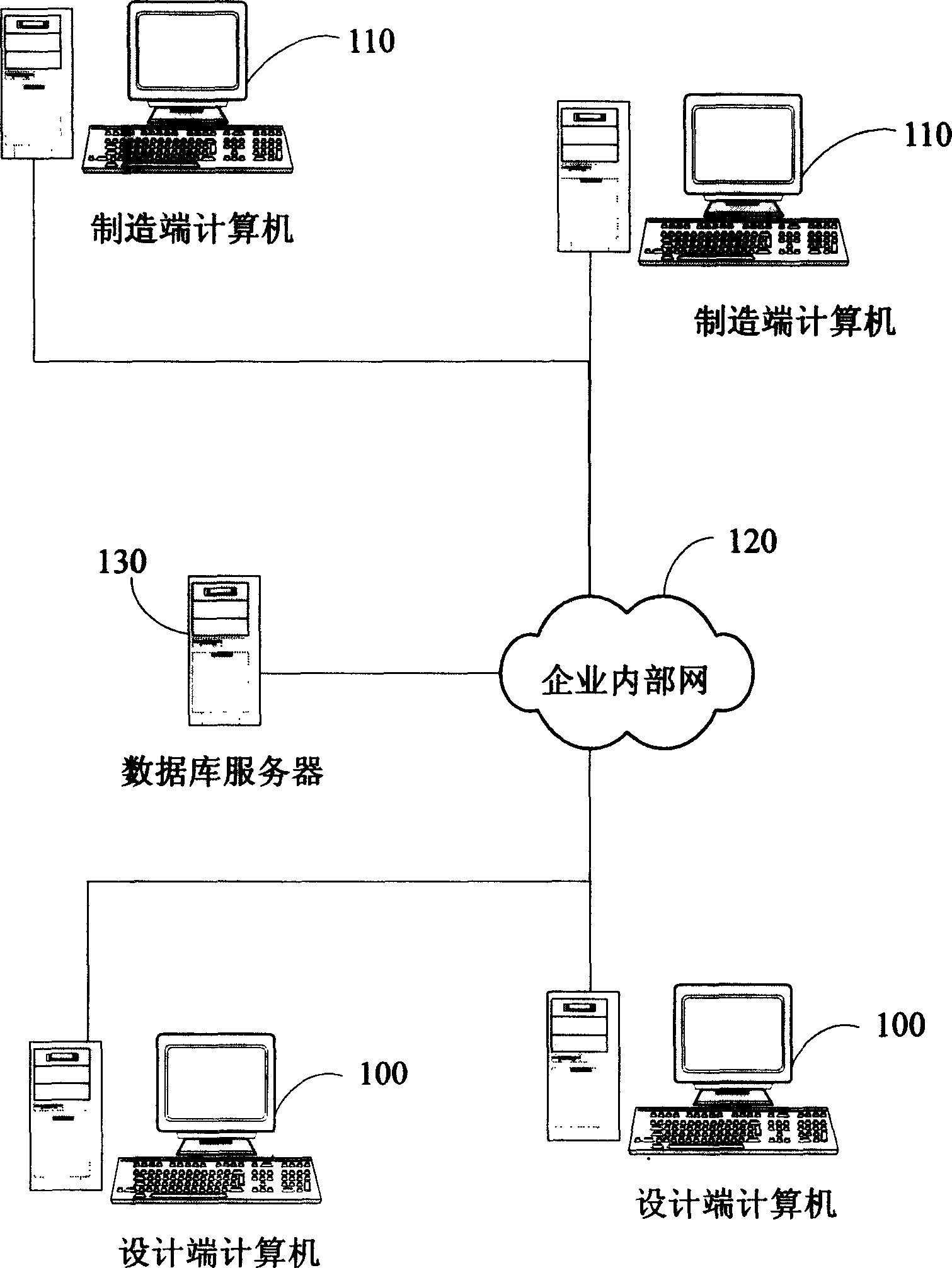

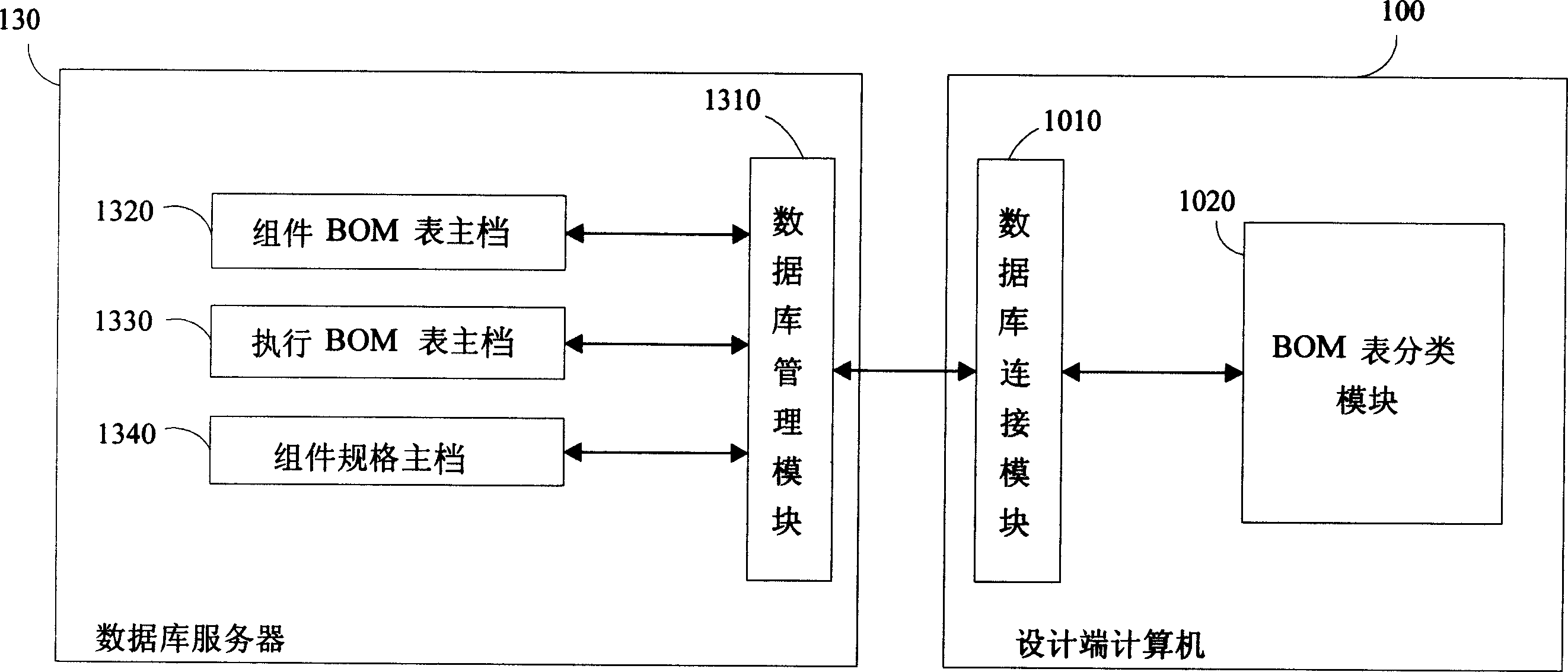

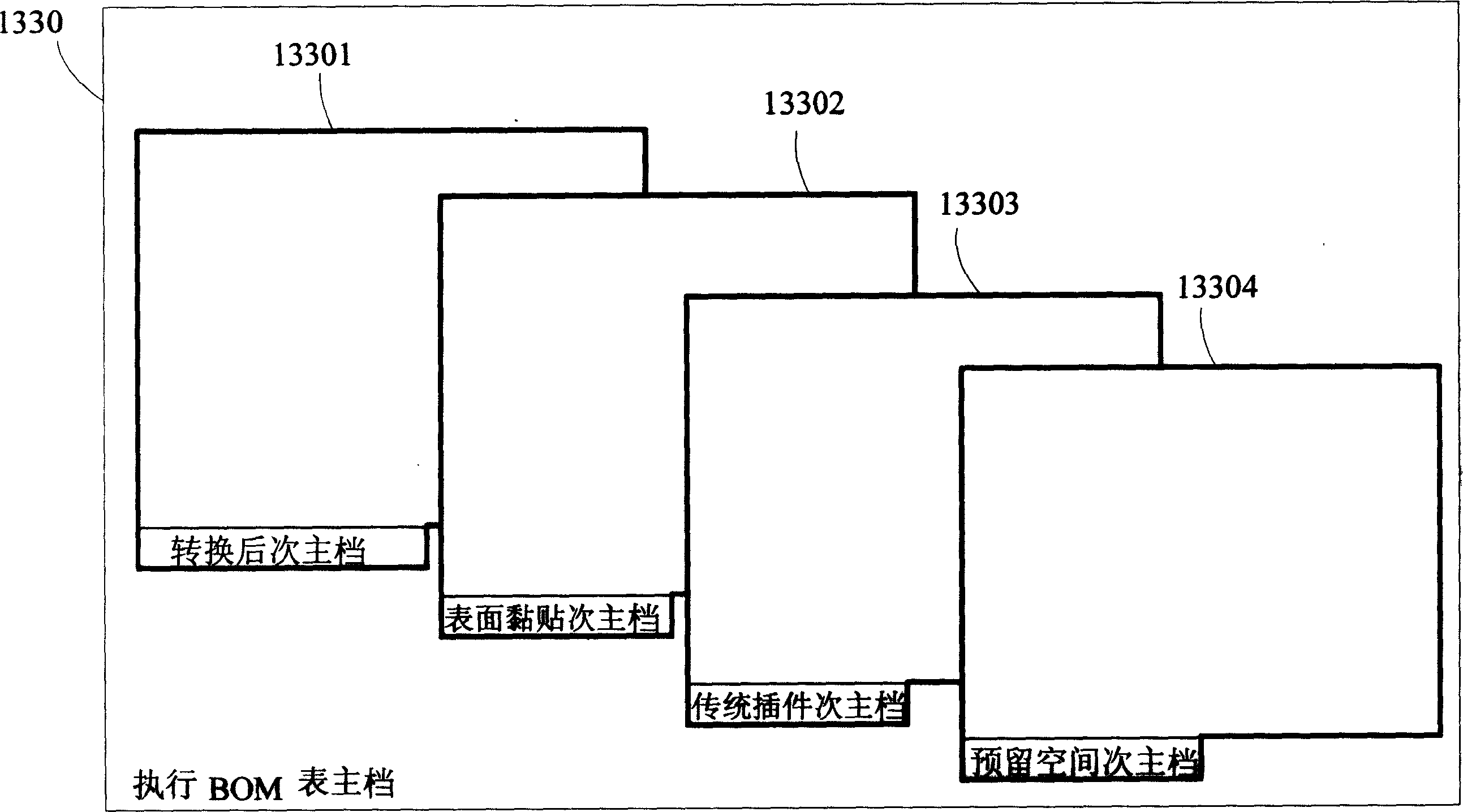

BOM table automatic classification system and method

InactiveCN1532739ASave process timeMultiple digital computer combinationsSpecial data processing applicationsDatabase

The present invention provides automatic BOM classifying system and method. The system includes one module BOM table main file, one module specification main file and one BOM table classifying module, and provides one server data base includes the module BOM table main file and the module specification main file for the connection between the manufacture end computer and the design end computer. The method of the present invention includes the following steps: opening and reading in the module BOM table main file; opening and reading in the module specification main file; converting the information in the BOM table main file into a secondary main file; classifying the converted secondary main file into surface adhered secondary main file, traditional plug-in board assembling secondary main file and preservation space secondary main file; and integrating the secondary main files into one BOM table executing main file and storing.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com