Magnetic pole marking and detecting and stacking device

A stacking device and marking technology, which is applied in the field of machinery, can solve the problems of time-consuming, error-prone, and low efficiency of manual picking and stacking, and achieve the effects of saving process flow time, improving labor efficiency, and speeding up stacking speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the drawings.

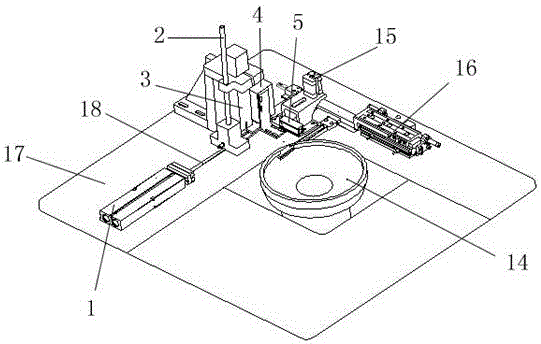

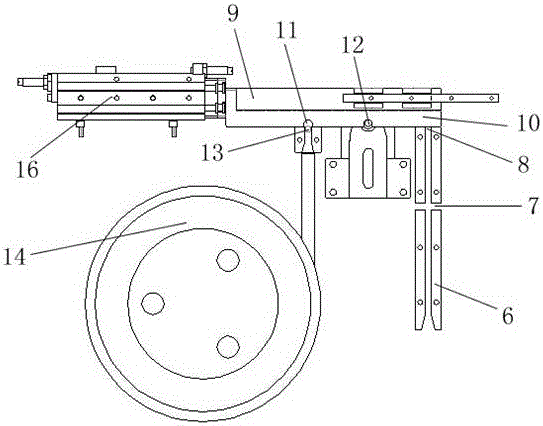

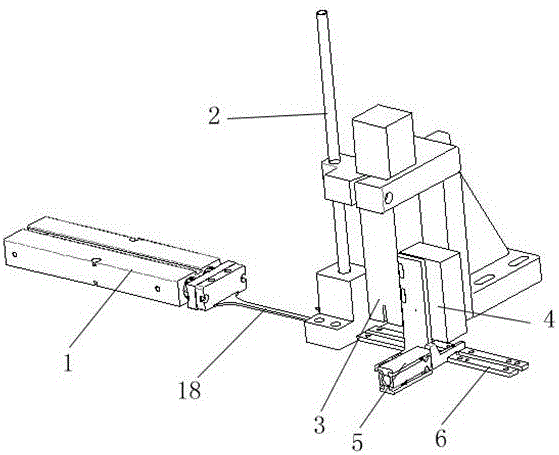

[0024] The present invention includes a worktable 17, a feed rail 6, a laminated rail 9, a material guide tube 2, a printer 3, a color mark sensor 4, a vibration plate 14, a topping cylinder 15, a palletizing cylinder 16, and a feeding cylinder 1; The feeding push rod 18 on the feeding cylinder 1 is arranged on the feeding track 6. The feeding push rod 18 can slide on the feeding track 6 under the driving of the feeding cylinder 1, and the feeding push rod 18 sequentially transfers the magnets to the inkjet printer 3. Below the color mark sensor 4, the magnetic steel can also be sent to the second discharge port 8 or the gap 7 on the feed rail 6. The inkjet printer 3, the color mark sensor 4, and the blanking port on the guide tube 2 are all set above the feed rail 6; the stack rail 9 is provided with a discharge through hole, and the discharge through hole is provided with a stack ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com