Earth-retaining wall structure with steel tube reinforcing ribs and construction method for earth-retaining wall structure

A construction method and retaining wall technology, which is applied in the direction of basic structure engineering, underwater structures, artificial islands, etc., can solve the problems of long construction time, low efficiency ratio, poor economy and reliability, etc., so as to save construction period and high Cost-effective, structurally reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

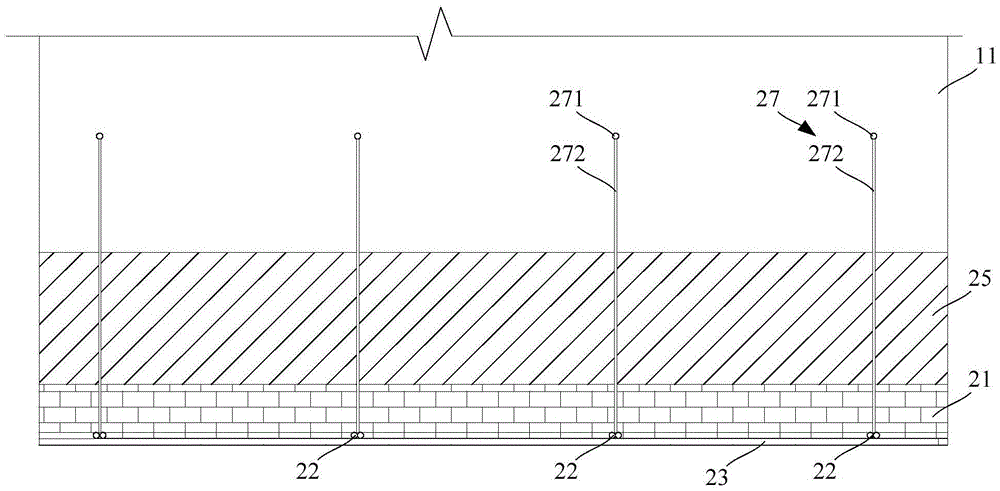

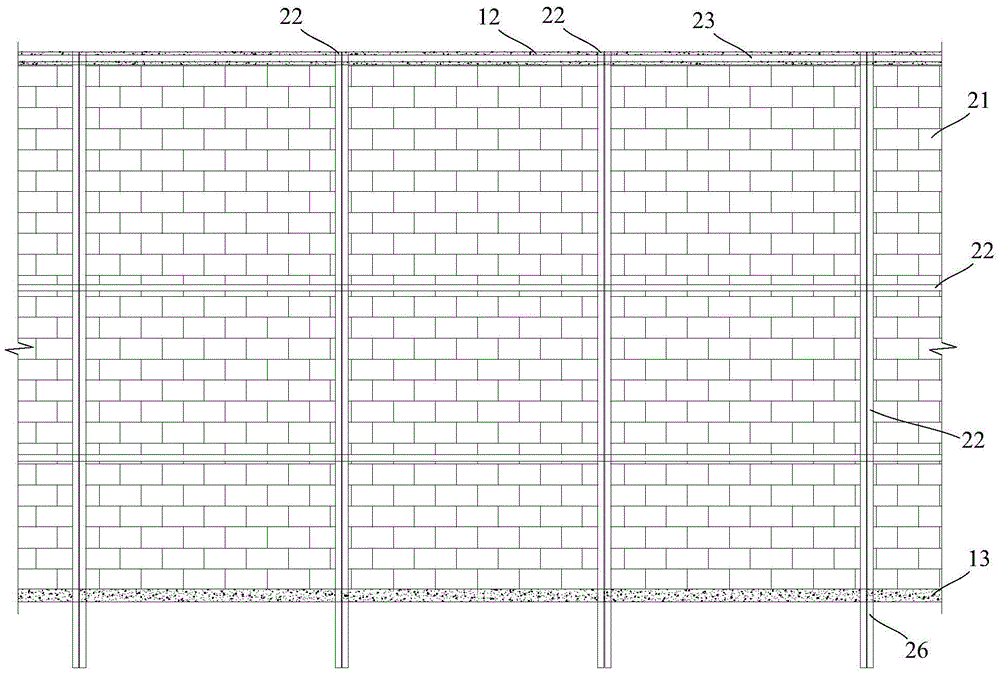

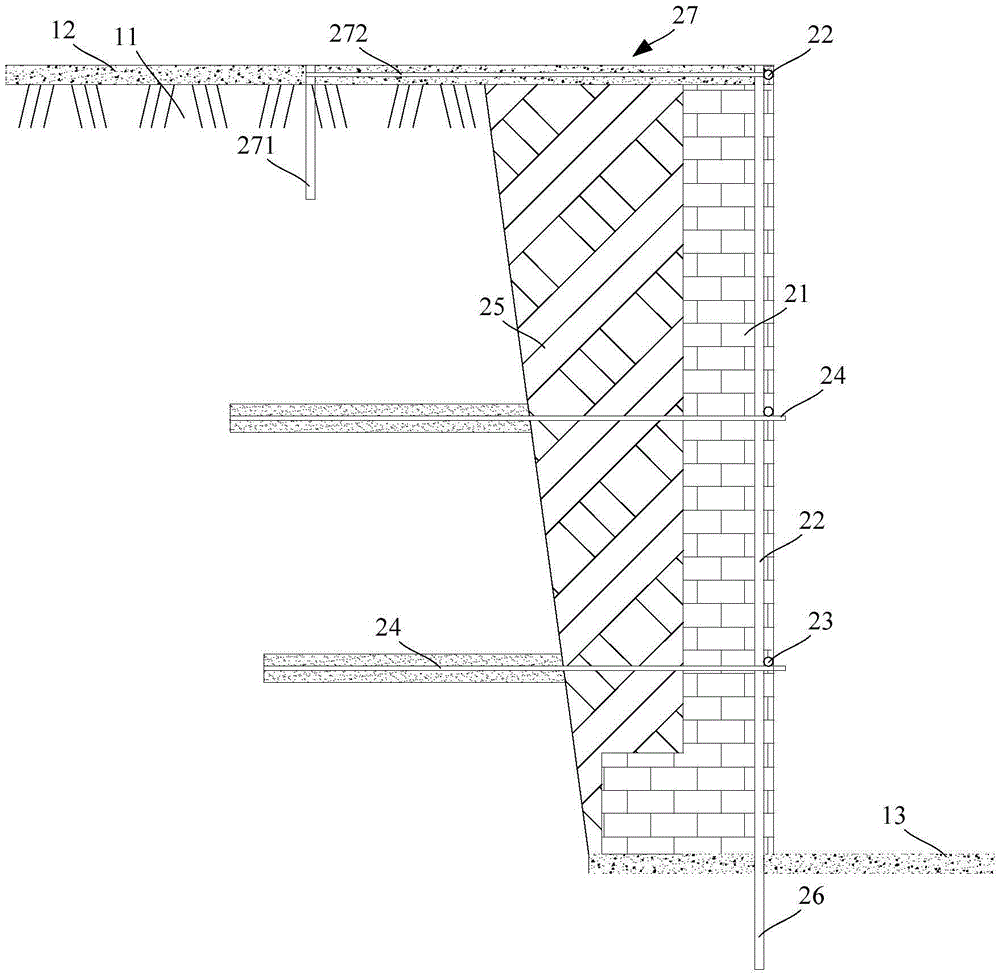

[0037] The invention provides a retaining wall structure with steel pipe ribs and a construction method thereof. The method of using steel pipe ribs instead of structural columns and ring beams reduces the amount of formwork support, steel bar binding and concrete pouring in the construction process, which is effective The construction period is shortened, and the cost is saved to a certain extent. In the present invention, through the connection of horizontal and vertical steel pipe ribs, a mesh-like overall stiffening frame with a certain rigidity is formed, which constrains the retaining wall and achieves the functions of structural columns and waist beams. Below in conjunction with accompanying drawing, the retaining wall structure and construction method of steel pipe rib of the present invention are described.

[0038] refer to figure 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com