Polycrystalline WC film high in stoichiometric ratio and low temperature preparation method thereof

A stoichiometric ratio, thin film technology, applied in ion implantation plating, metal material coating process, coating and other directions, can solve the problems that the feasibility cannot meet the requirements, no reports, etc., achieve excellent crystal quality, improve crystal quality, The effect of dense thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The low-temperature preparation method of a polycrystalline WC film with a high stoichiometric ratio of the present invention, the specific process is: adopt the DC magnetron sputtering method, use the Si sheet as the substrate, and bombard it with Ar plasma before use; select high-purity W metal target and graphite target, using double target co-sputtering method, W target sputtering power 100W, graphite target sputtering power 120W; high-purity Ar-CH 4 The mixed gas is the working gas, when the reaction chamber is evacuated to a background vacuum higher than 1×10 –4 After Pa, pass into Ar-CH 4 Mixed gas, Ar:CH 4 Partial pressure ratio 1:1, gas pressure 1.5Pa; WC thin film in Ar-CH 4 grown in a plasma atmosphere at a growth temperature of 300 °C.

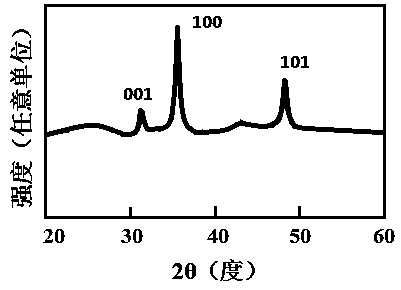

[0024] The obtained polycrystalline WC thin film is subjected to a performance test, and the test results are as follows: figure 1 In the XRD pattern of the WC film prepared in this example, three diffraction peaks appea...

Embodiment 2

[0026] The low-temperature preparation method of a polycrystalline WC film with a high stoichiometric ratio of the present invention, the specific process is: adopt the DC magnetron sputtering method, use the Si sheet as the substrate, and bombard it with Ar plasma before use; select high-purity W metal target and Takamura graphite target, using double-target co-sputtering method, W target sputtering power 100W, graphite target sputtering power 120W; high-purity Ar-CH 4 The mixed gas is the working gas, when the reaction chamber is evacuated to a background vacuum higher than 1×10 –4 After Pa, pass into Ar-CH 4 Mixed gas, Ar:CH 4 Partial pressure ratio 1:1, gas pressure 1.5Pa; WC thin film in Ar-CH 4 grown in a plasma atmosphere at a growth temperature of 400 °C.

[0027]The prepared polycrystalline WC film was tested for performance, and the test results were as follows: the WC film is polycrystalline, the strongest X-ray diffraction peak is (100) diffraction peak, and has...

Embodiment 3

[0029] The low-temperature preparation method of a polycrystalline WC film with a high stoichiometric ratio of the present invention, the specific process is: adopt the DC magnetron sputtering method, use the Si sheet as the substrate, and bombard it with Ar plasma before use; select high-purity W metal target and Takamura graphite target, using double-target co-sputtering method, W target sputtering power 100W, graphite target sputtering power 120W; high-purity Ar-CH 4 The mixed gas is the working gas, when the reaction chamber is evacuated to a background vacuum higher than 1×10 –4 After Pa, pass into Ar-CH 4 Mixed gas, Ar:CH 4 Partial pressure ratio 1:1, gas pressure 1.5Pa; WC thin film in Ar-CH 4 grown in a plasma atmosphere at a growth temperature of 500 °C.

[0030] The prepared polycrystalline WC film was tested for performance, and the test results were as follows: the WC film is polycrystalline, the strongest X-ray diffraction peak is (100) diffraction peak, and ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com