Method for extracting vanadium from vanadium-containing ferrophosphor

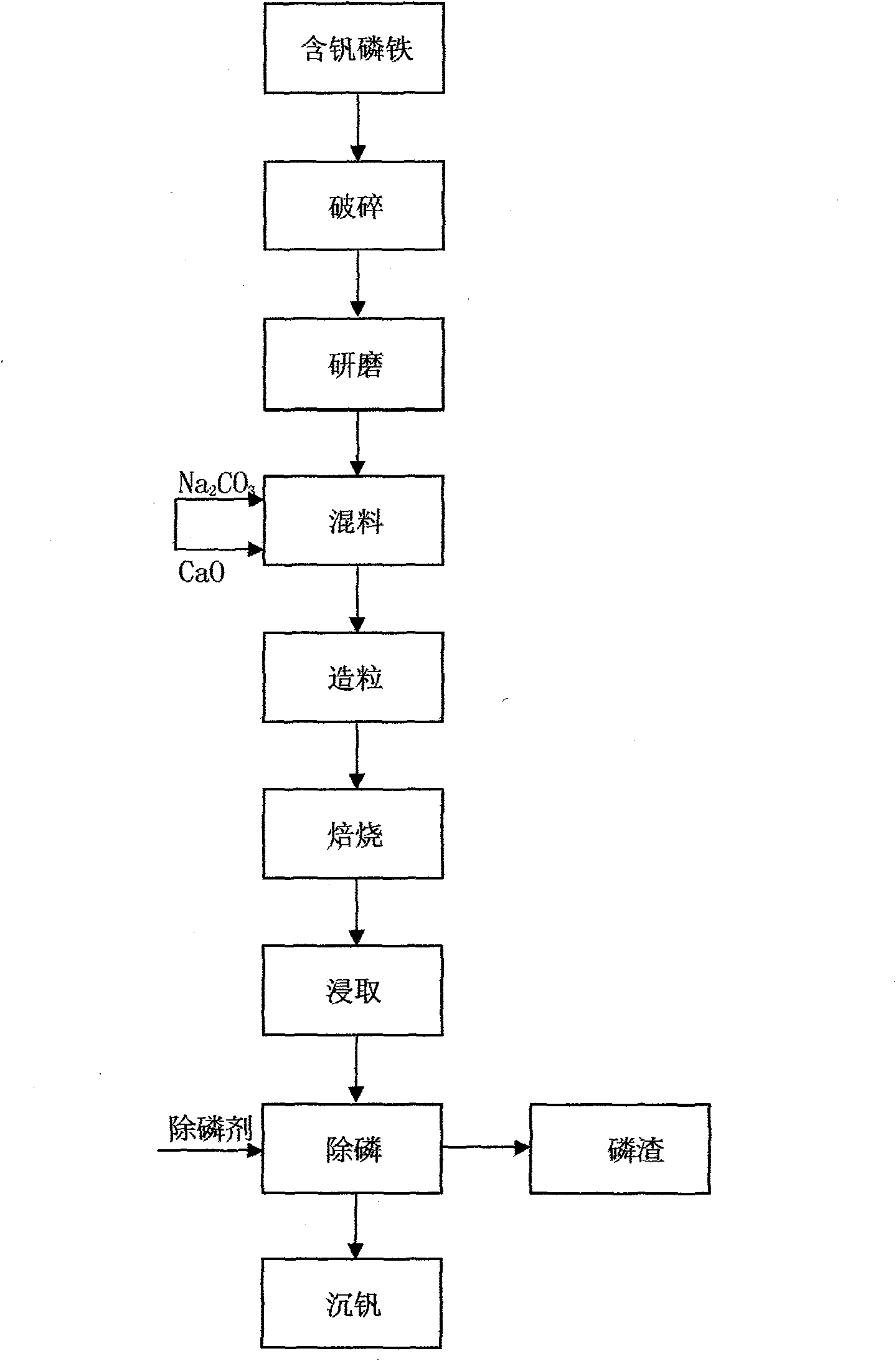

A technology of vanadium-containing ferrophosphorus and vanadium-phosphorus ferrophosphorus, which is applied in the field of vanadium extraction of vanadium-containing ferrophosphorus, which can solve problems such as difficulties, loss of vanadium, high cost, etc., and achieve the effect of saving costs and process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The product that present embodiment produces is vanadium pentoxide, and its step is as follows:

[0050] 1. Crush and grind the vanadium-containing ferrophosphorus, and mix it with Na 2 CO 3 Mix and granulate CaO with 0.1 times the weight of vanadium-containing ferrophosphorus, put the raw material after granulation into the rotary kiln, and roast at 600-700°C, the reaction time is 0.5 hours;

[0051] 2. Grind the roasted clinker by wet ball milling, and then transfer the ground slurry to the leaching tank;

[0052] 3. The water with a solid-to-liquid weight ratio of 1:3 to 4 is used for leaching in the leaching tank for 2 hours, and the temperature in the leaching tank is kept above 70°C to the non-boiling temperature;

[0053] 4. Filter the leached slurry, the leaching solution can obtain 51% vanadium of the vanadium content in the raw material, and the ratio of phosphorus and vanadium in the crude solution after filtering is P / V>0.1;

[0054] 5. Add magnesium chlo...

Embodiment 2

[0056] The product that present embodiment produces is vanadium pentoxide, and its step is as follows:

[0057] 1. Crush and grind vanadium-containing ferrophosphorus, and mix it with 3 times Na 2 CO 3 Mix and granulate CaO with 3 times of vanadium-containing ferrophosphorus, put the raw material after granulation into the rotary kiln, roast at 900-1100℃, and the reaction time is 5 hours;

[0058] 2. Grind the roasted clinker by wet ball milling, and then transfer the ground slurry to the leaching tank;

[0059] 3. The water with a solid-to-liquid weight ratio of 1:3 to 4 is used for leaching in the leaching tank for 2 hours, and the temperature in the leaching tank is kept above 70°C to the non-boiling temperature;

[0060] 4. Filter the leached slurry, 45% of the vanadium content in the raw material can be obtained in the leaching solution, and the ratio of phosphorus and vanadium in the crude solution after filtering is P / V≤0.05;

[0061] Step 5. is the same as in Exampl...

Embodiment 3

[0063] The product that present embodiment produces is vanadium pentoxide, and its step is as follows:

[0064] 1. Crush and grind vanadium-containing ferrophosphorus, and mix with 0.6 times Na 2 CO 3 and 0.6 times of CaO containing vanadium-phosphorus iron are evenly mixed and granulated, and the raw material after granulation is put into the rotary kiln, and roasted at 700-900 °C, and the reaction time is 2 hours;

[0065] 2. Grind the roasted clinker by wet ball milling, and then transfer the ground slurry to the leaching tank;

[0066] 3. The water with a solid-to-liquid weight ratio of 1:3 to 4 is used for leaching in the leaching tank for 2 hours, and the temperature in the leaching tank is kept above 70°C to the non-boiling temperature;

[0067] 4. Filter the leached slurry, 85.5% of the vanadium content in the raw material can be obtained in the leaching solution, and the ratio of phosphorus and vanadium in the crude solution after filtering is P / V≤0.05;

[0068] St...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com