Coding detonating control device

A technology of control device and coded controller, which is applied in the direction of mining fluid, wellbore/well components, earthwork drilling and production, etc. It can solve the problems of high temperature resistance and high pressure resistance, so as to prevent accidental detonation, improve work efficiency, and save injection costs. Effect of hole work time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in further detail below in conjunction with accompanying drawing:

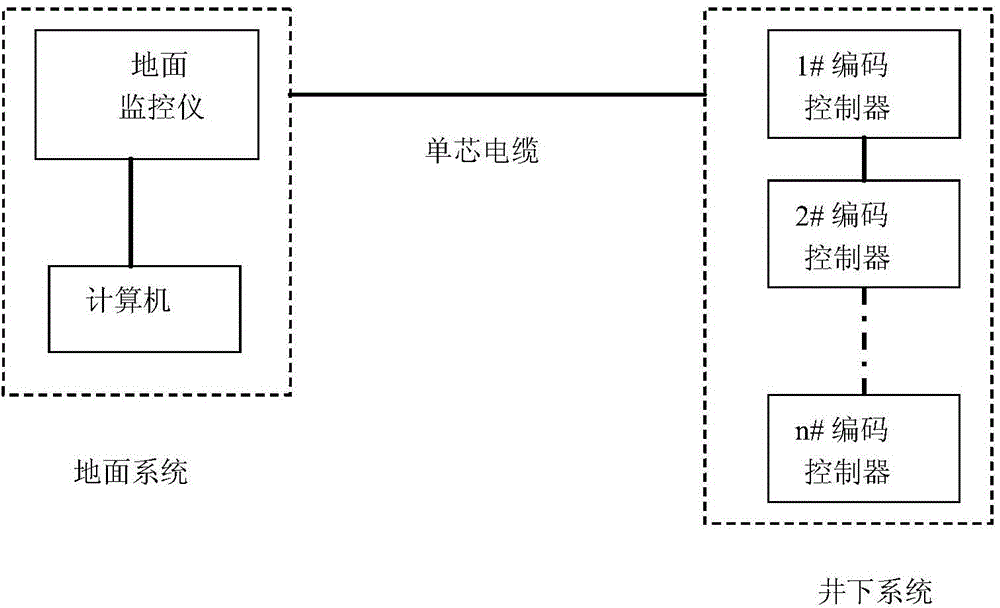

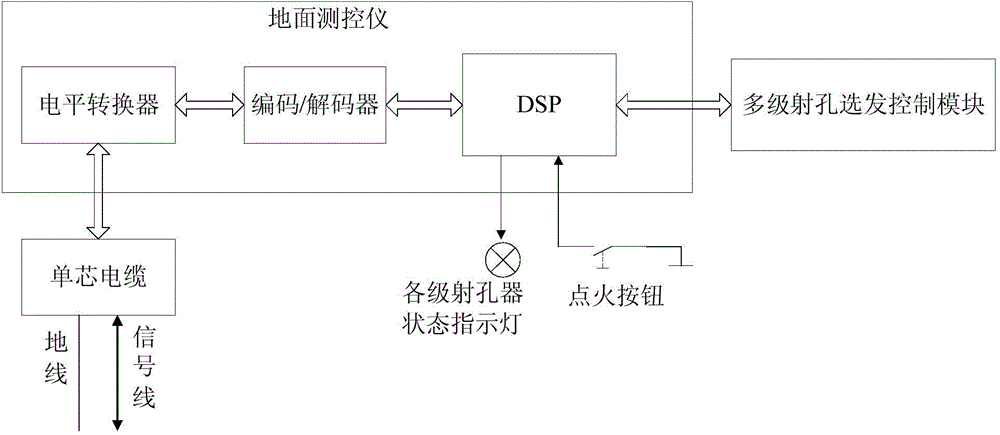

[0026] see Figure 1 to Figure 5 , a coded detonation control device, including a ground system and a downhole system, the ground system includes a ground monitor and a computer containing a graded perforation selection control module, and the downhole system includes a plurality of coded controllers installed in different perforators , the ground monitor is connected to the computer through a USB cable, and a plurality of encoding controllers are connected in series with the output end of the ground monitor through a single-core cable.

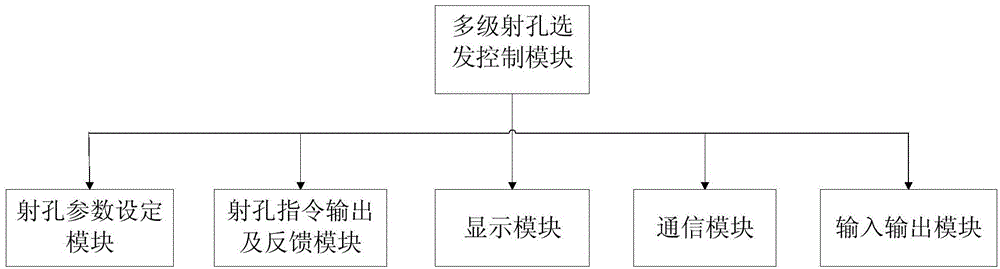

[0027] The hierarchical perforation selection control module is used to set perforation parameters, generate a perforation command sequence according to the set perforation parameters and transmit the perforation command sequence to the ground monitor, and receive feedback from the coding controller at the same time. The perforation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com