Double-glass photovoltaic module and preparation method thereof

A double-glass photovoltaic and photovoltaic module technology, applied in the field of solar power generation, to save energy and process time, reduce the risk of scratches and contamination, and increase the utilization of gap light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

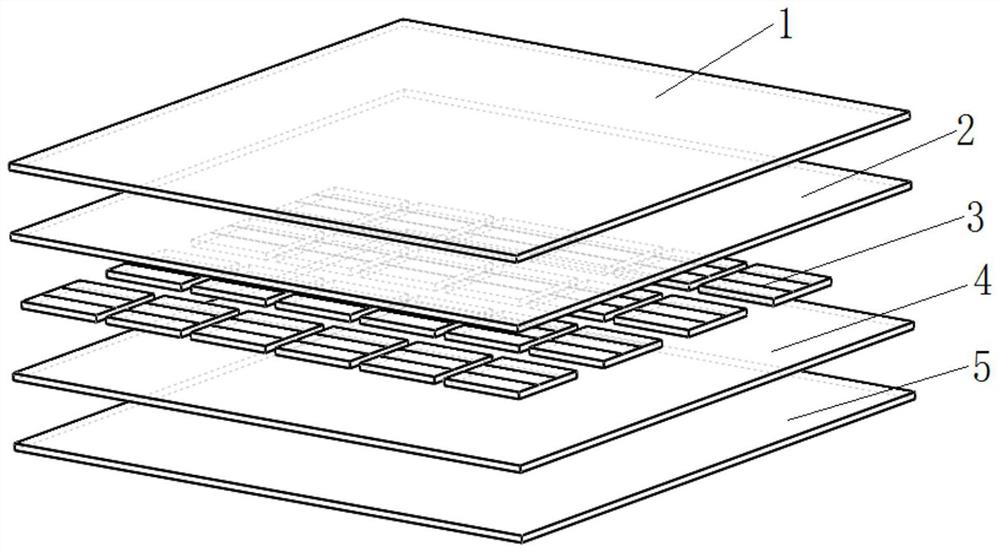

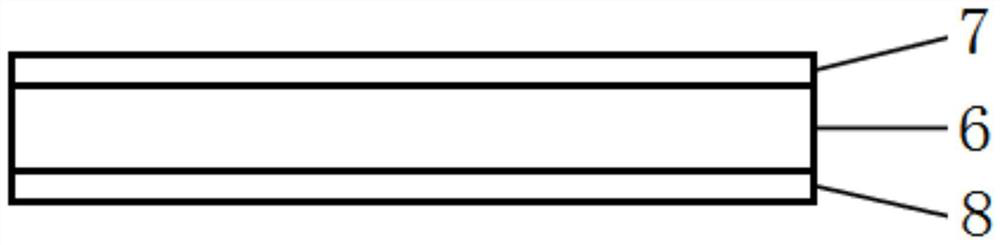

[0037] Such as figure 1As shown, a double-glass photovoltaic module, the photovoltaic module includes a front glass 1, a front sealing adhesive film 2, a battery string 3, a rear sealing adhesive film 4 and a back glass 5 arranged in sequence; the front glass 1 and The back glass 5 adopts double-sided coated glass; the double-sided coated glass includes glass 6 and grid-shaped glaze layer 7 and anti-reflection film layer 8 respectively arranged on two opposite surfaces of glass 6; wherein : the glaze layer 7 on the front glass 1 mainly plays the role of shielding and improving the aesthetics, and the glaze layer 7 arranged on the back glass 5 is coated with a highly reflective material to increase the utilization of interstitial light;

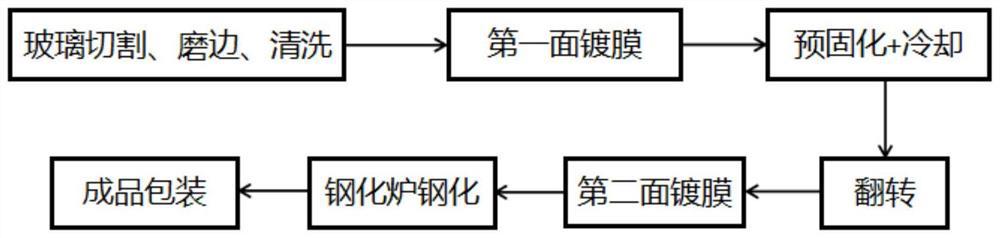

[0038] The preparation process of the above-mentioned double-sided coated glass comprises the following steps:

[0039] S1. Glass pretreatment: cut the glass 6 as required, then polish the surroundings of the glass to make it smooth, and wash...

Embodiment 2

[0046] The difference between embodiment 2 and embodiment 1 is that what the front glass 1 in embodiment 2 adopts is the single-sided coated glass that is only coated with the anti-reflection film layer 8, and the glaze layer 7 is not provided; the remaining conditions of embodiment 2 are all the same. Same as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com