U-shaped steel-coated Regenerated composite beam of and construction method thereof

A technology of regenerative composite beams and construction methods, applied in the direction of structural elements, building components, and long-strip structural components for load-bearing, etc., can solve the problems of cumbersome process, high cost, and large energy consumption, so as to improve the bonding ability , Improve the overall bending resistance and facilitate the construction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation of the present invention will be further described below in conjunction with the drawings and embodiments.

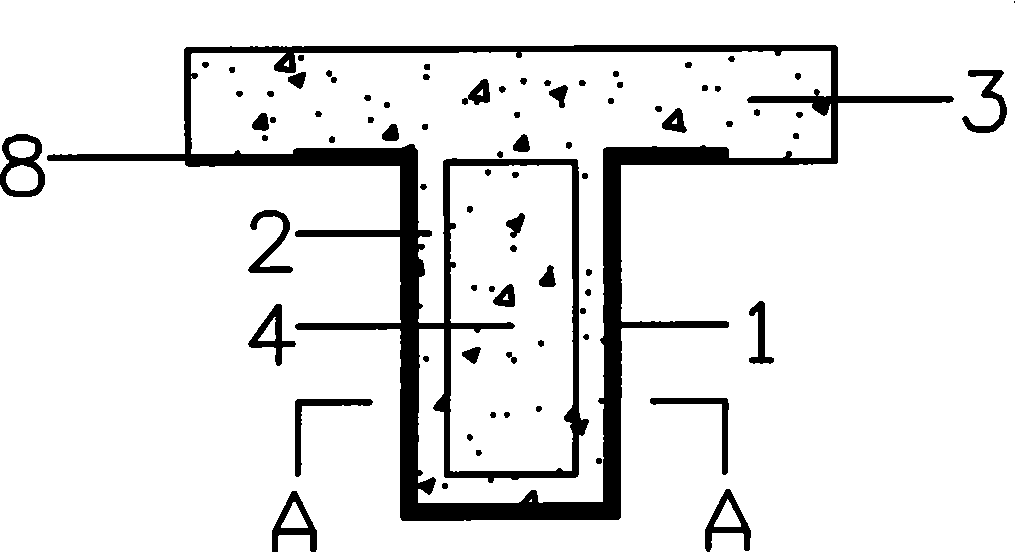

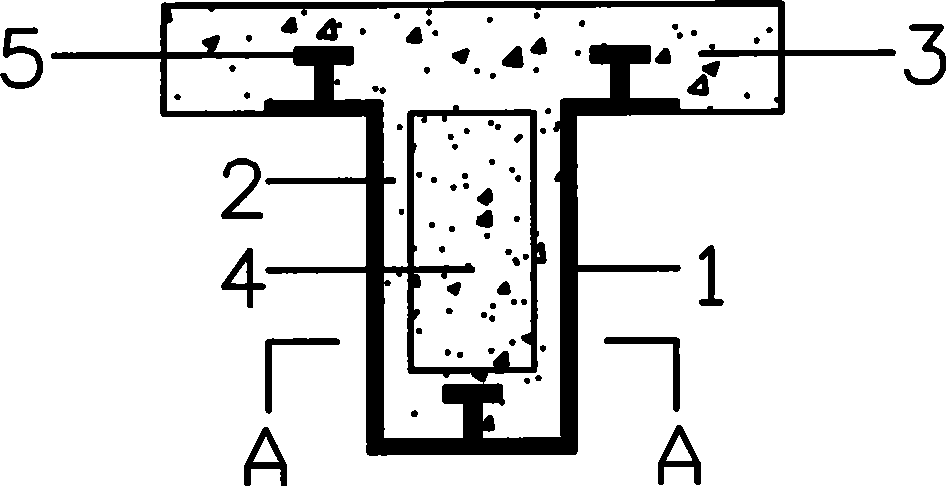

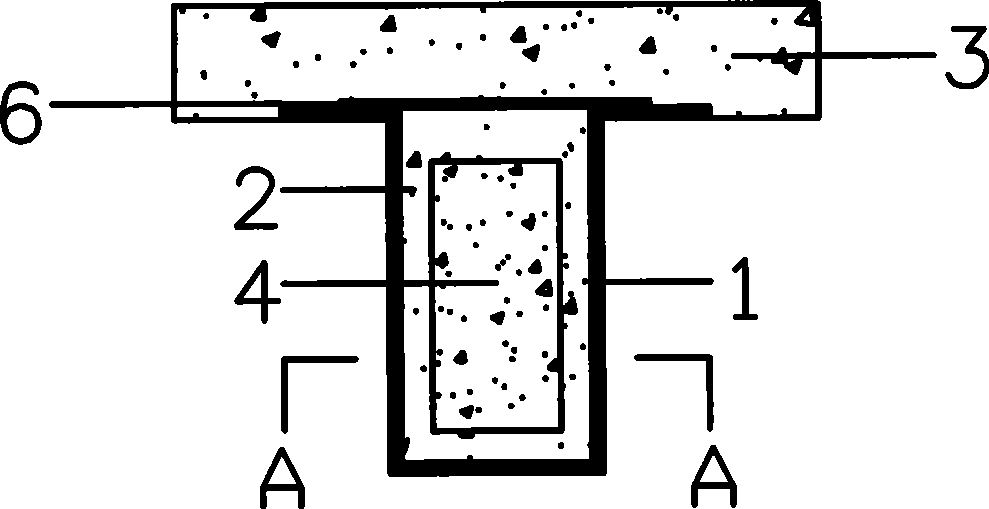

[0031] Such as Figure 1-12 As shown, a U-shaped outsourcing steel recycled composite beam includes U-shaped outsourcing steel 1, new concrete 2, floor slab or roof slab 3, waste concrete block 4, stud connector 5, steel sheet connector 6, Longitudinal reinforcing bar 7, outer folding part 8 on the top of the U-shaped outsourcing steel side plate.

[0032] See figure 1 , the top of the side plate of the U-shaped outsourcing steel is folded outward. At this time, if a number of stud connectors are arranged at intervals along the length direction of the beam on the bottom surface inside the U-shaped outer cladding steel and the upper surface of the upper folded part of the side plate, the cross-sectional schematic diagram is shown in figure 2 , if a number of steel sheet connectors are arranged at intervals along the length direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com