Offset print water-borne UV (ultraviolet) photo-sensitive resist jetting plate-making method

A technology of photosensitive glue and water-based printing, which is applied in the field of offset printing water-based UV photosensitive glue jet plate-making, which can solve the problems of simplified plate-making process and inability to realize the quality of printing plates at the same time, so as to achieve good transfer quality, save process time and equipment space, reduce Effects of Environmental Pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The water-based UV photosensitive adhesive is prepared by the following method:

[0023] First, weigh the above-mentioned components by weight percentage. Next, prepare each component weighed in a container equipped with a stirring device and a heating device: the photoinitiator is slowly and Evenly add to the active monomer, after the photoinitiator is completely dissolved, slowly and evenly add the water-based oligomer, mix well, wherein, control the adding time of the photoinitiator and the water-based oligomer to 25-40 minutes; finally add Additives and diluents, stirred until fully mixed, and obtained after filtration.

[0024]During the spraying process, the contact angle of the water-based UV photosensitive adhesive on the surface of the hydrophilic metal plate base is 0-30 degrees. The inkjet precision of the inkjet printing equipment used is not less than 1440DPI, and if the inkjet precision can reach more than 2880DPI, the resolution of the printing plate ca...

Embodiment 1

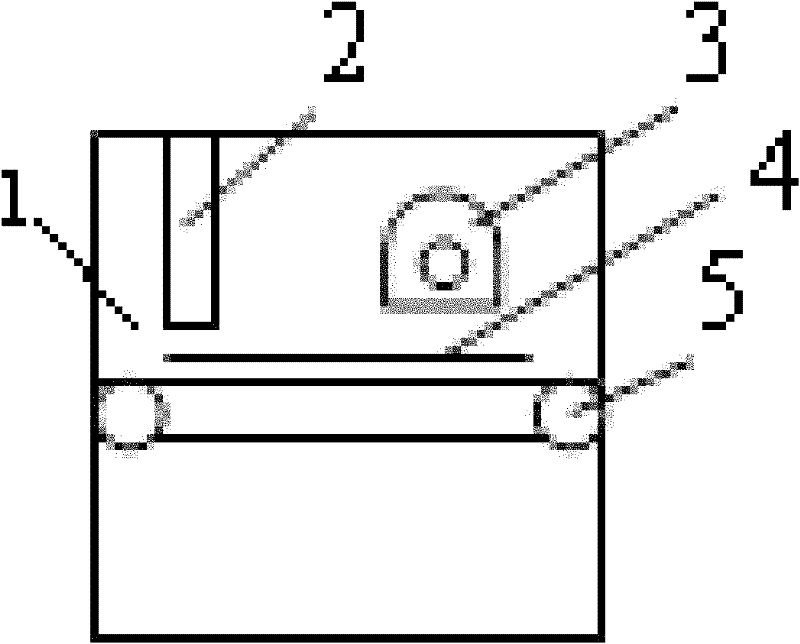

[0027] Step 1. Under the control of the computer, use an inkjet printer or an inkjet printer to spray the water-based UV photosensitive glue on the PS plate that is not coated with a photosensitive layer or the aluminum plate base that has been electrolytically anodized as the substrate, according to the layout information requirements, And an oily information recording area is formed on the surface of the metal plate base. The metal base has a thickness of 0.10-0.15 mm. The plate running servo system is optimized according to the thickness of the selected metal plate base. The format of the inkjet printer or inkjet printer should meet the actual printing needs, and the inkjet precision is 1440DPI.

[0028] The specific process is: generate general printing files, such as PS files or PDF files, on the computer with the graphic information to be printed, and then use the Founder RIP software to process the obtained printing files on the computer. It is divided into four color...

Embodiment 2

[0035] Step 1. Under the control of the computer, use an inkjet printer or an inkjet printer to spray the water-based UV photosensitive glue on the PS plate that is not coated with a photosensitive layer or the aluminum plate base that has been electrolytically anodized as the substrate, according to the layout information requirements, And an oily information recording area is formed on the surface of the metal plate base. The metal base has a thickness of 0.10-0.15 mm. The plate running servo system is optimized according to the thickness of the selected metal plate base. The format of the inkjet printer or inkjet printer should meet the actual printing needs, and the inkjet precision is 2880DPI.

[0036] The specific process is as follows: generate general-purpose printing files, such as PS files or PDF files, from the graphic information to be printed on the computer, and then process the obtained printing files on the computer using Founder RIP software to separate the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com