Patents

Literature

97results about How to "Improve transfer quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

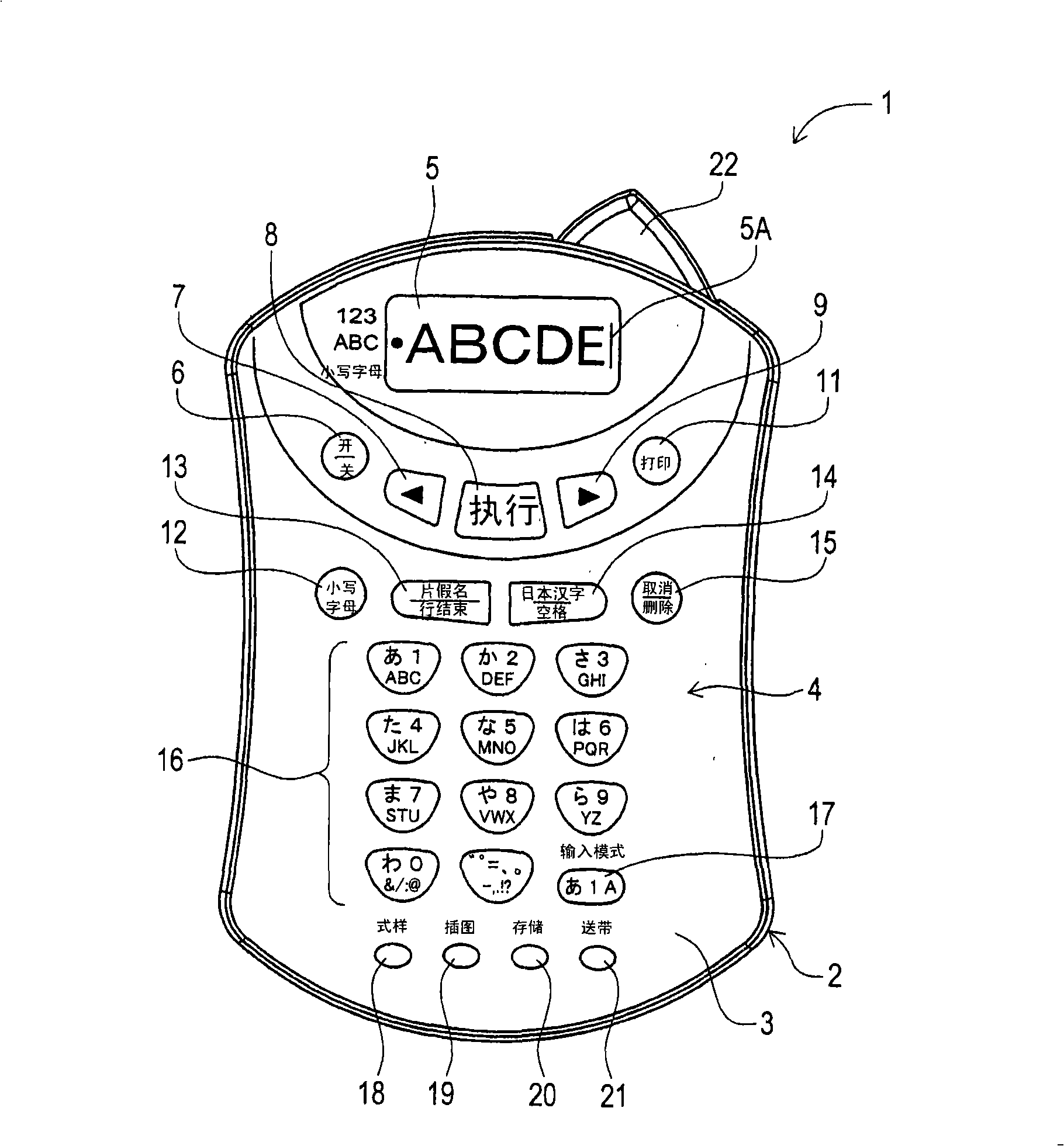

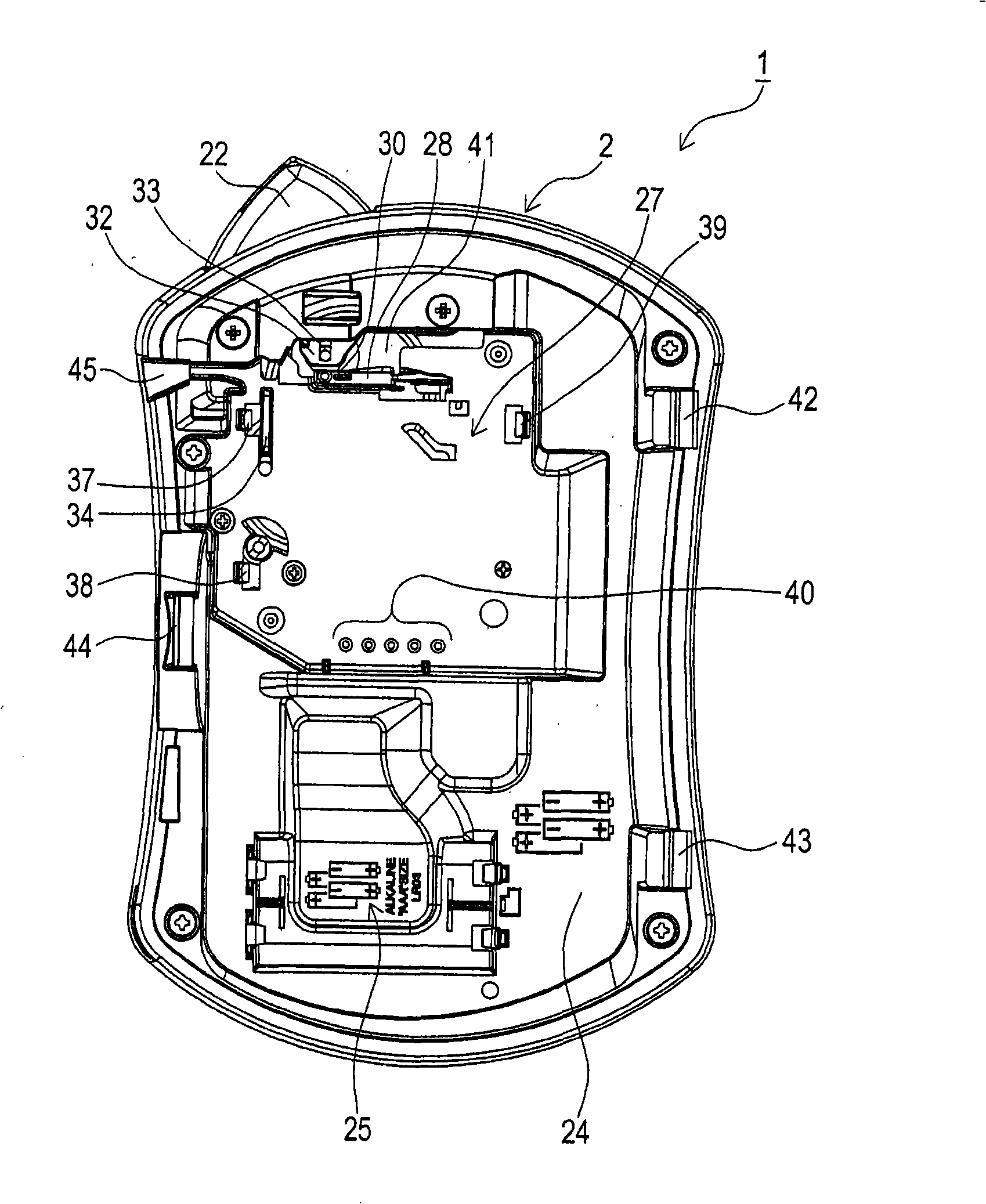

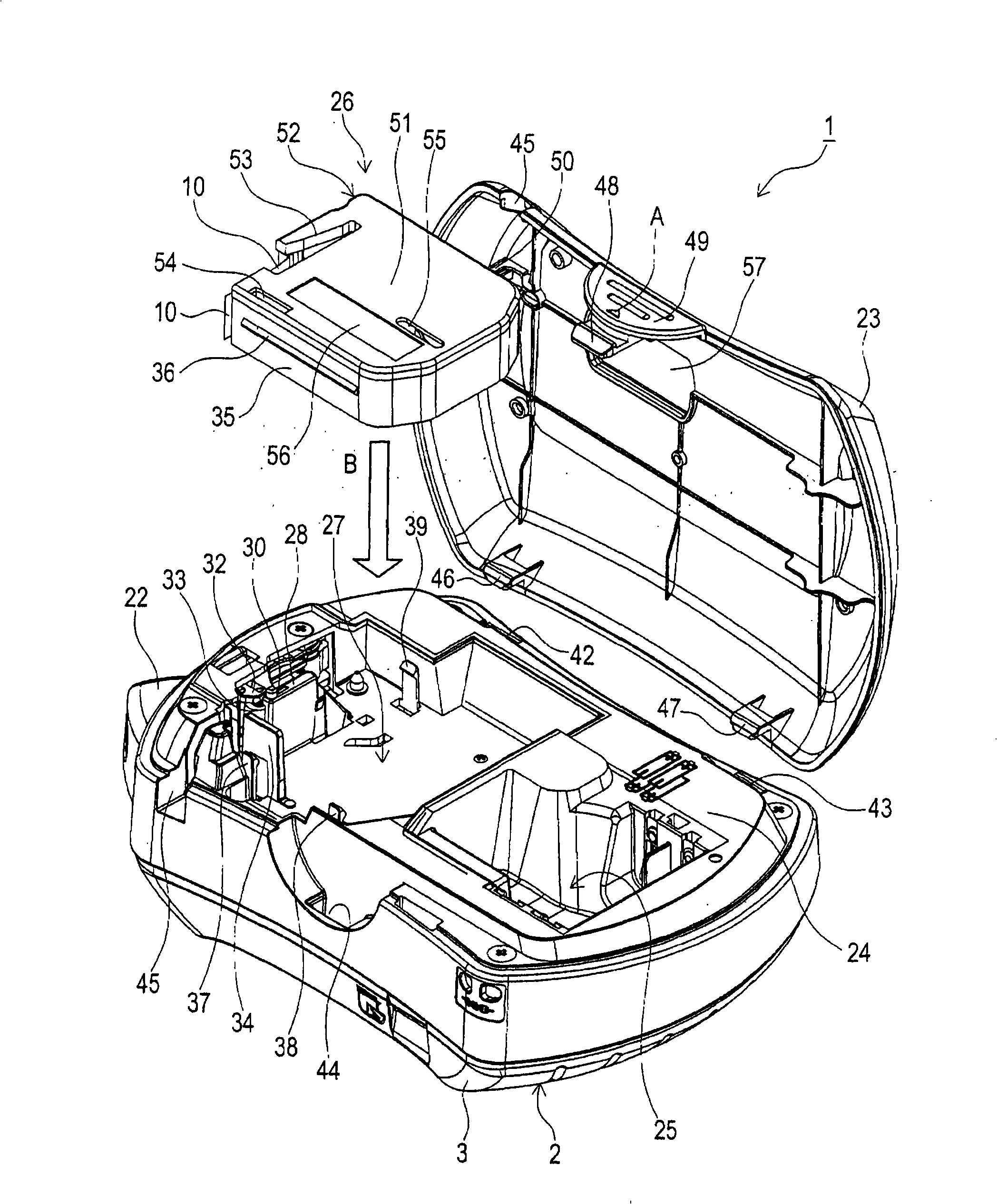

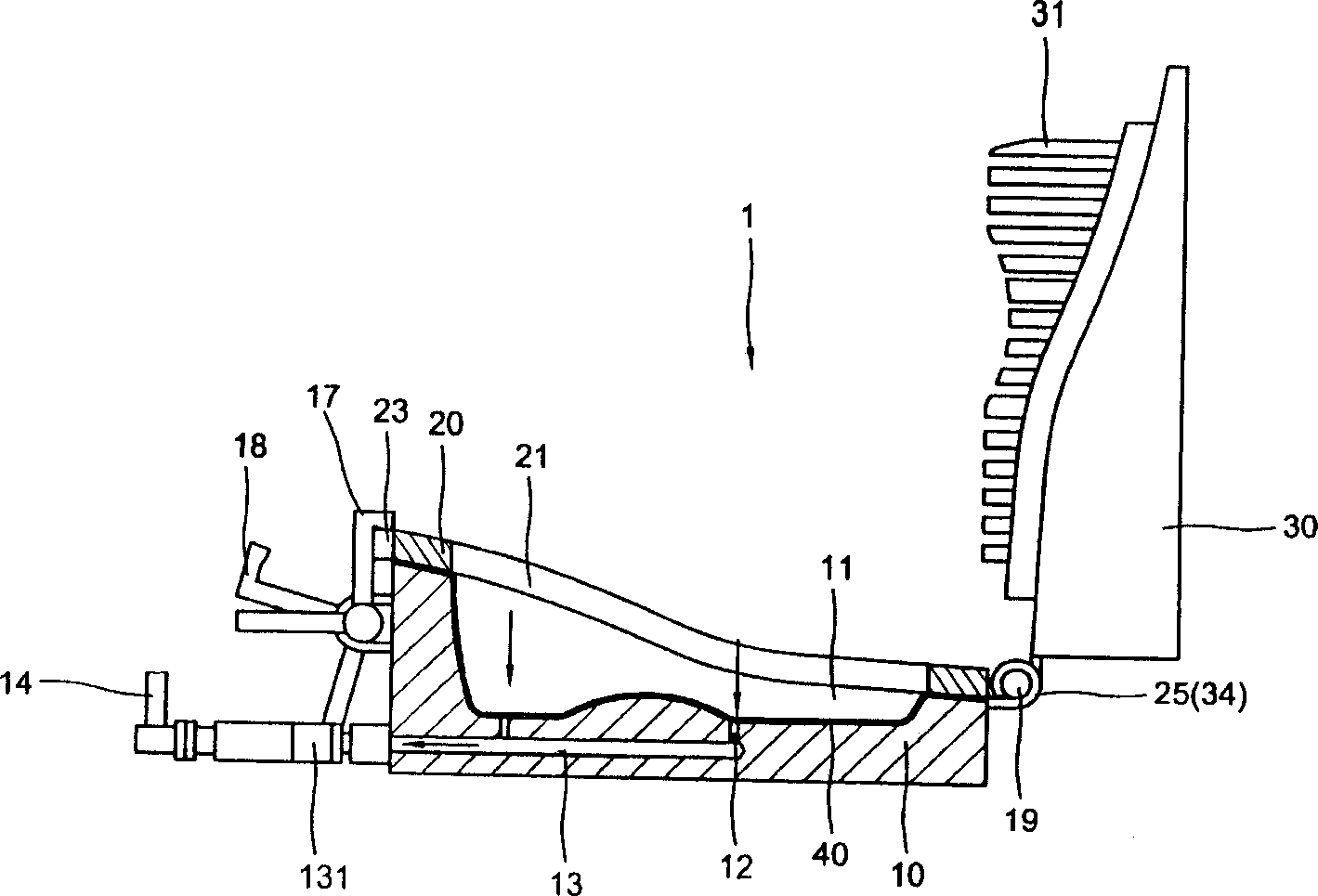

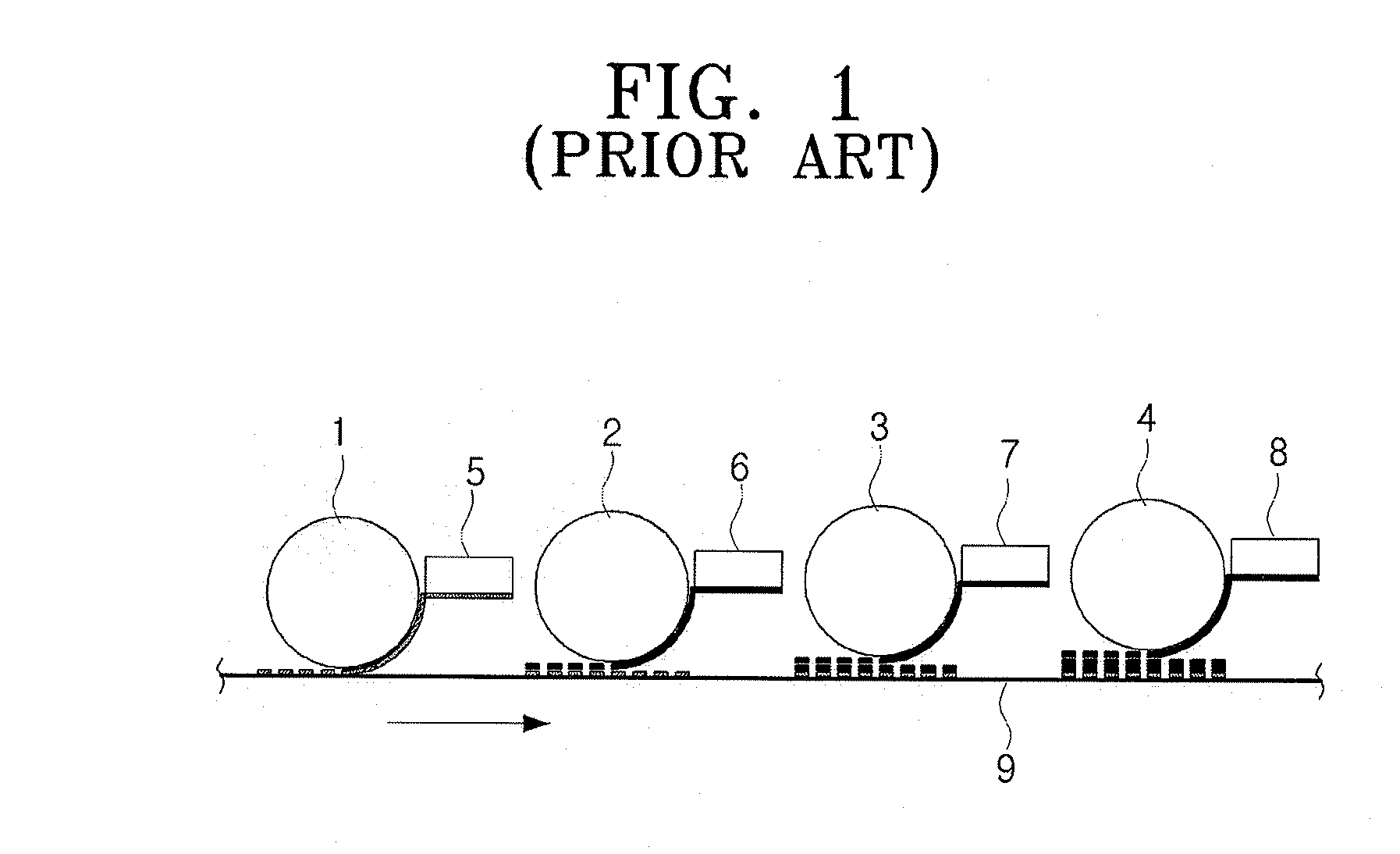

Lettering tape, tape cassette, tape printer

A lettering tape is formed having an integrated layered configuration in which a base layer, an ink layer, and an adhesive layer exhibiting adhesive properties when heated are sequentially stacked. When the lettering tape is selectively heated by a thermal head to form an image thereon, the heated portion of the ink layer onto which an image has been formed is adhered to the heated portion of the adhesive layer and simultaneously, the heated portion of the adhesive layer exhibits self-adhesive properties, thereby enabling transfer to the target transfer body.

Owner:BROTHER KOGYO KK

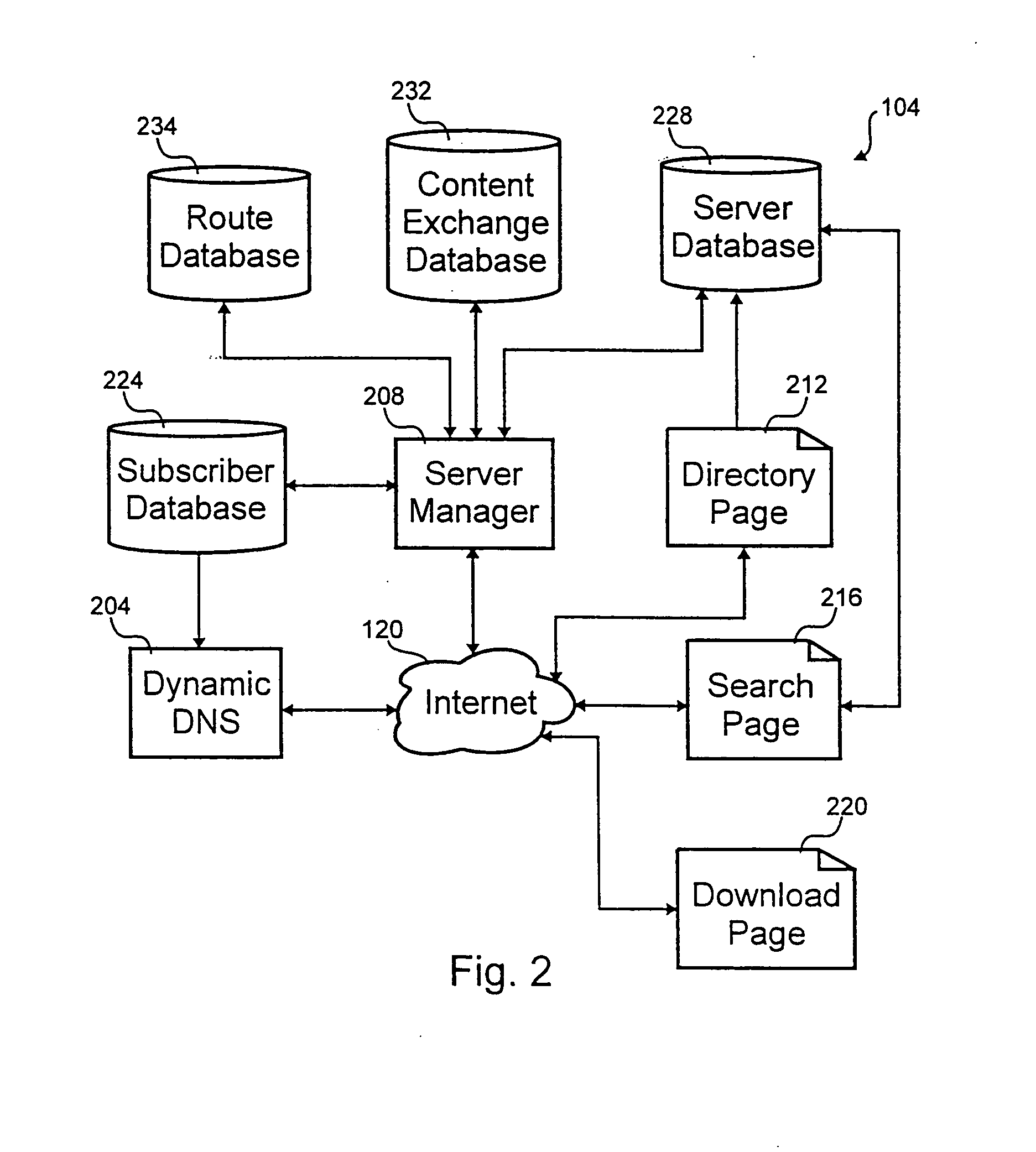

Viewer object proxy

InactiveUS6879998B1Improve transfer qualityEvaluating transfer qualityData processing applicationsError preventionContent distributionWorld Wide Web

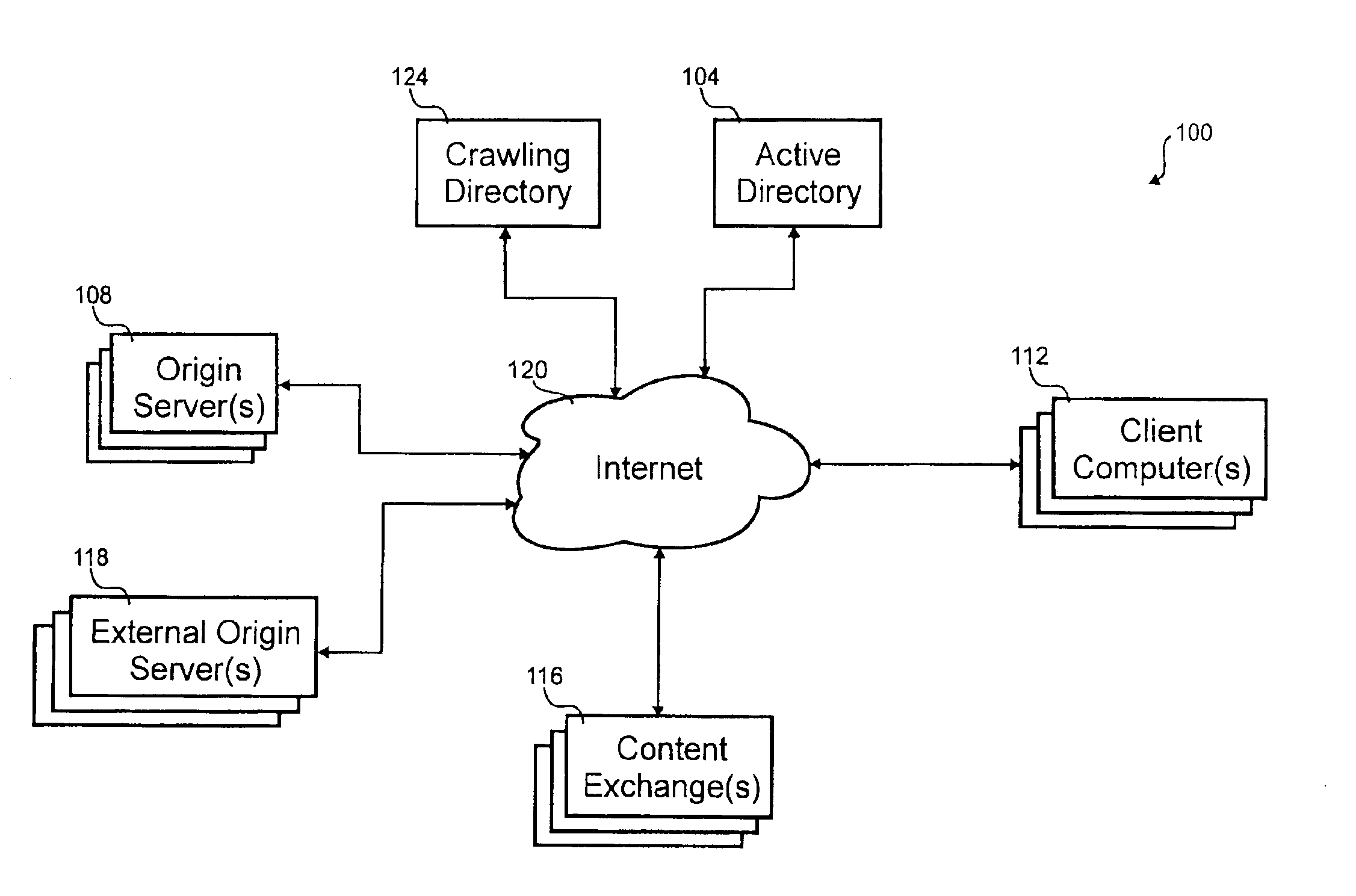

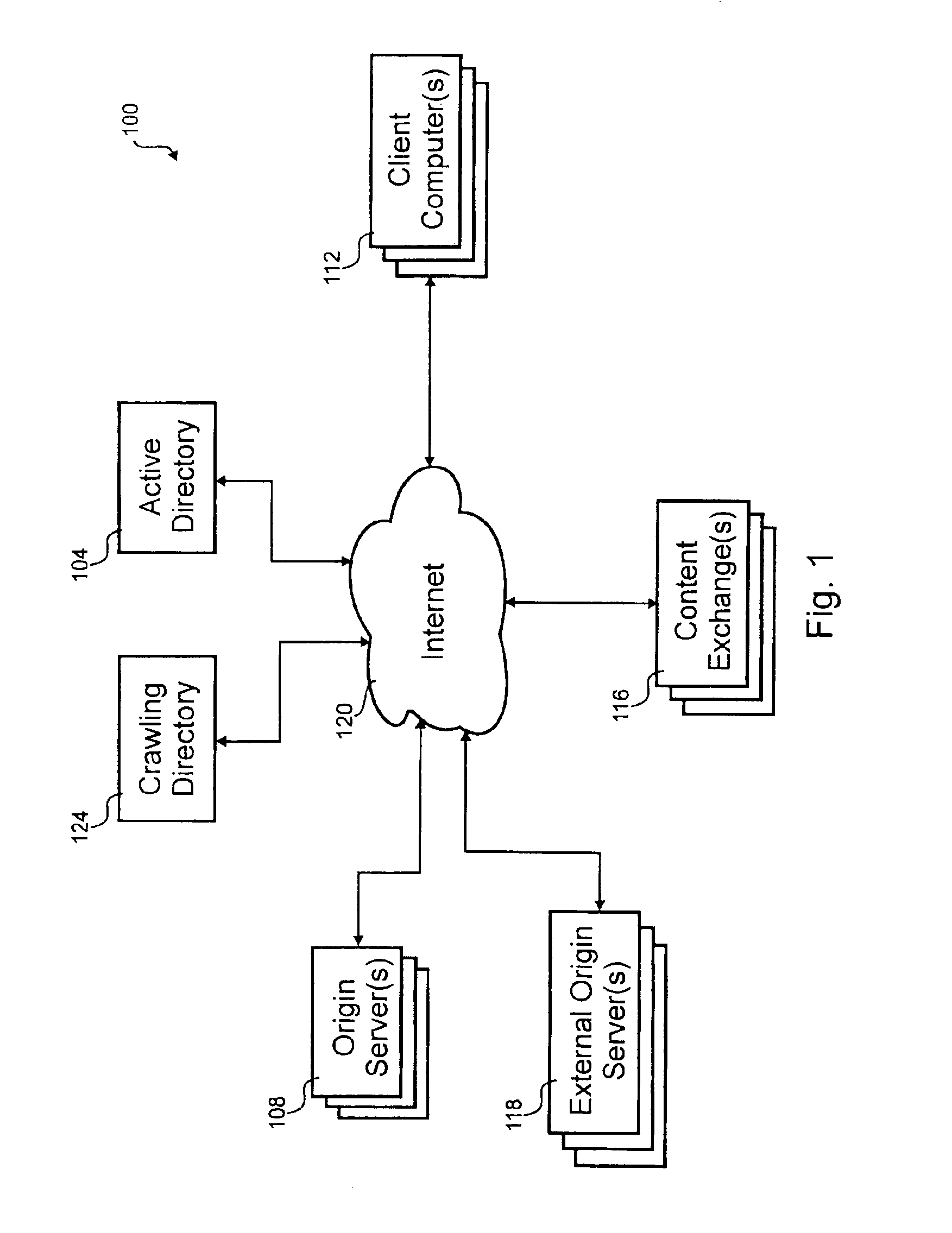

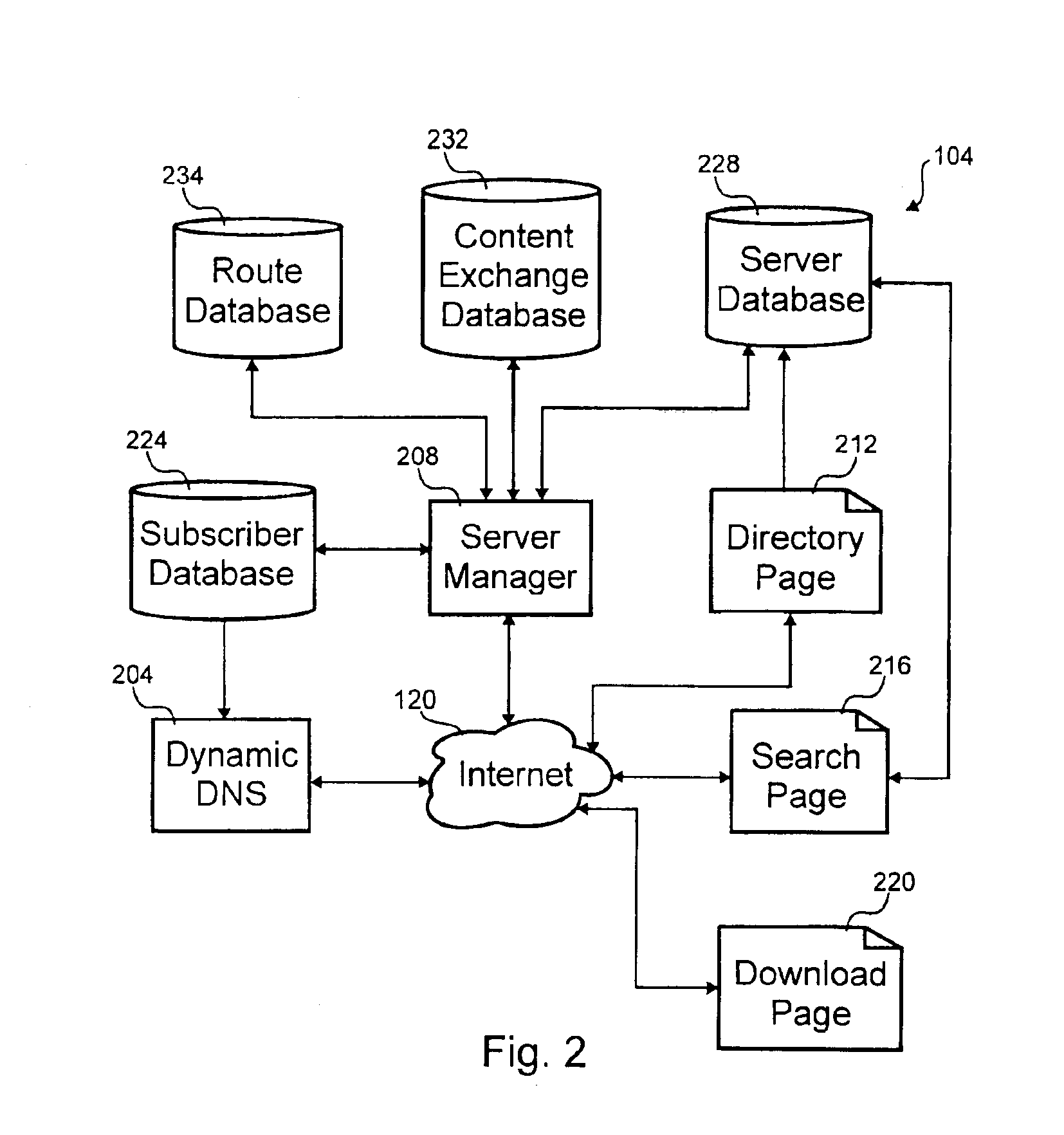

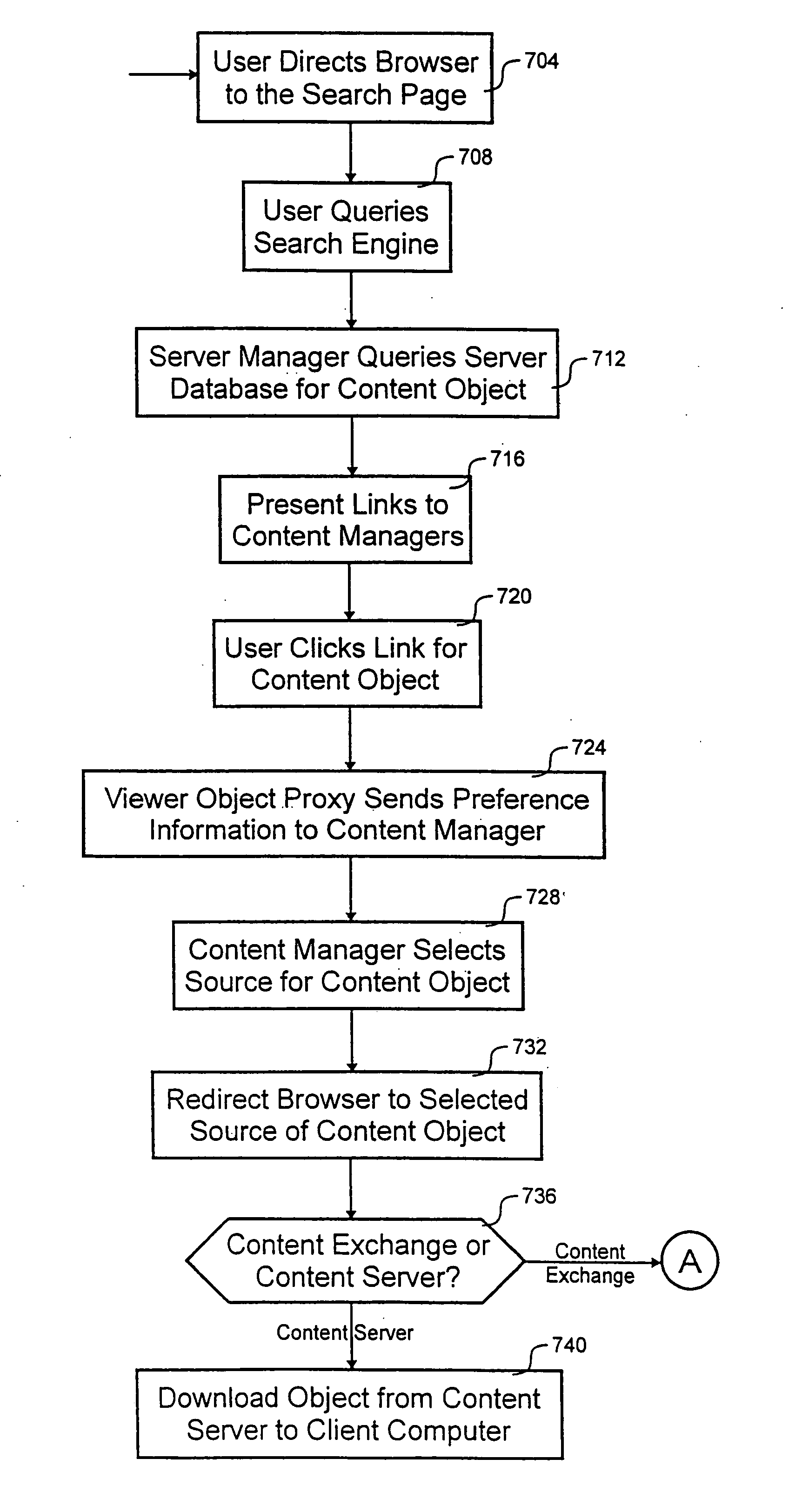

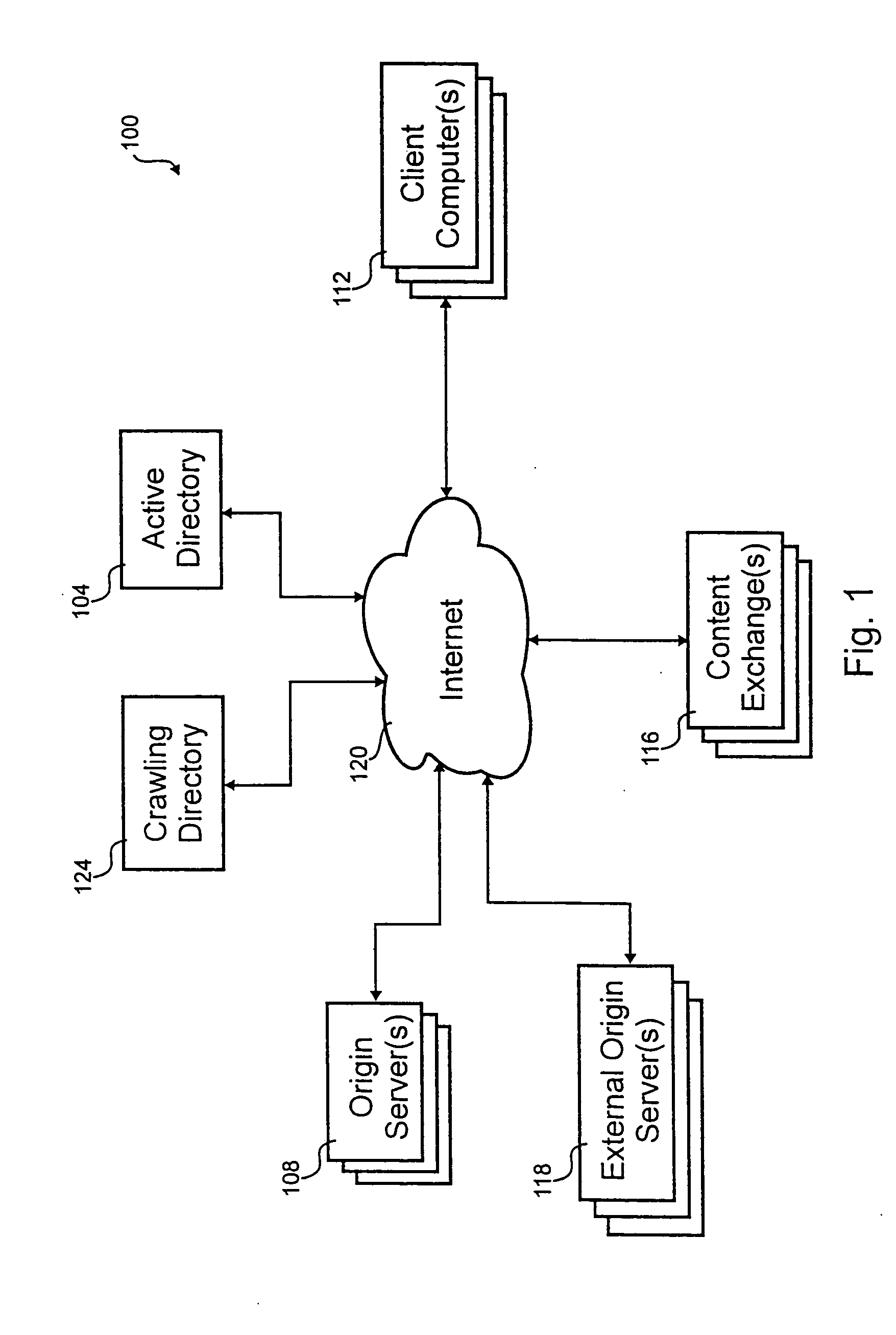

A method for increasing transfer quality between a content requestor and a content source on a content distribution system. The method involves determining transfer quality between the requestor and various content sources. The determination is made from the requestor's perspective. After determining transfer qualities for the various content sources, the requester provides the transfer qualities to a selector on the content distribution system. The selector uses the determined transfer qualities select a content source to supply the requestor.

Owner:GOOGLE TECH HLDG LLC

Viewer object proxy

InactiveUS20050160154A1Improve transfer qualityEvaluating transfer qualityData processing applicationsError preventionContent distributionDistributed computing

A method for increasing transfer quality between a content requestor and a content source on a content distribution system. The method involves determining transfer quality between the requestor and various content sources. The determination is made from the requestor's perspective. After determining transfer qualities for the various content sources, the requester provides the transfer qualities to a selector on the content distribution system. The selector uses the determined transfer qualities select a content source to supply the requestor.

Owner:GOOGLE TECH HLDG LLC

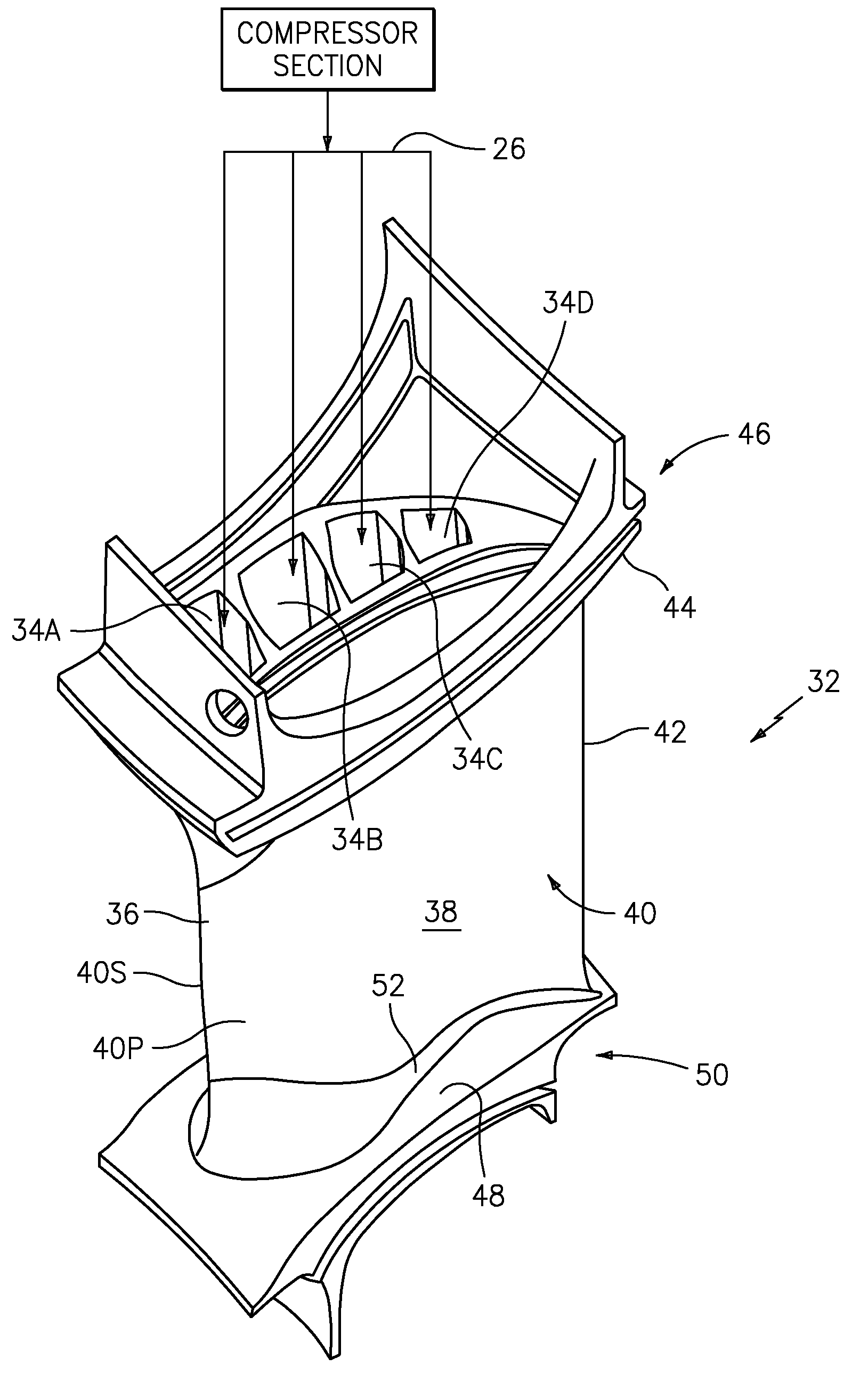

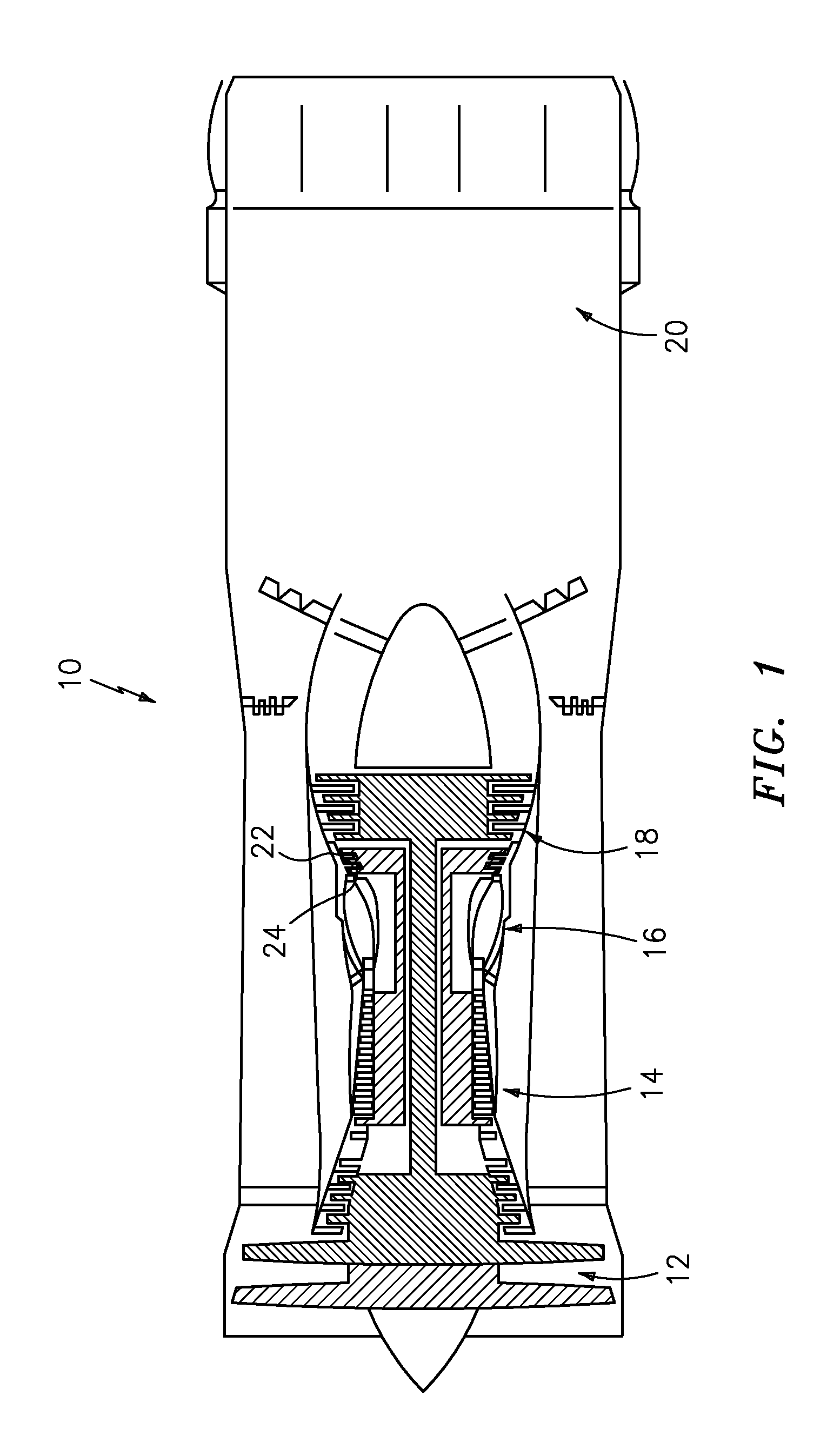

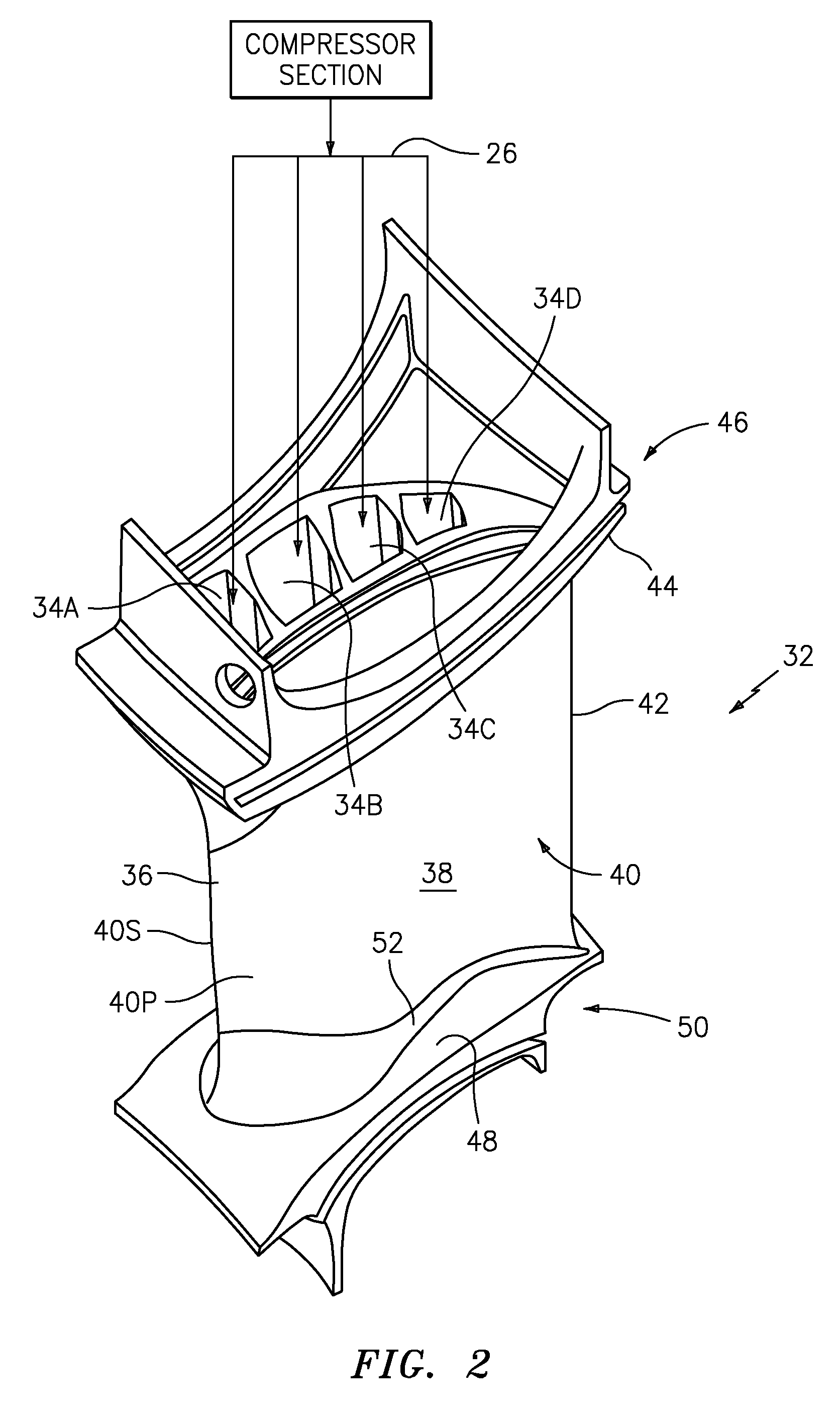

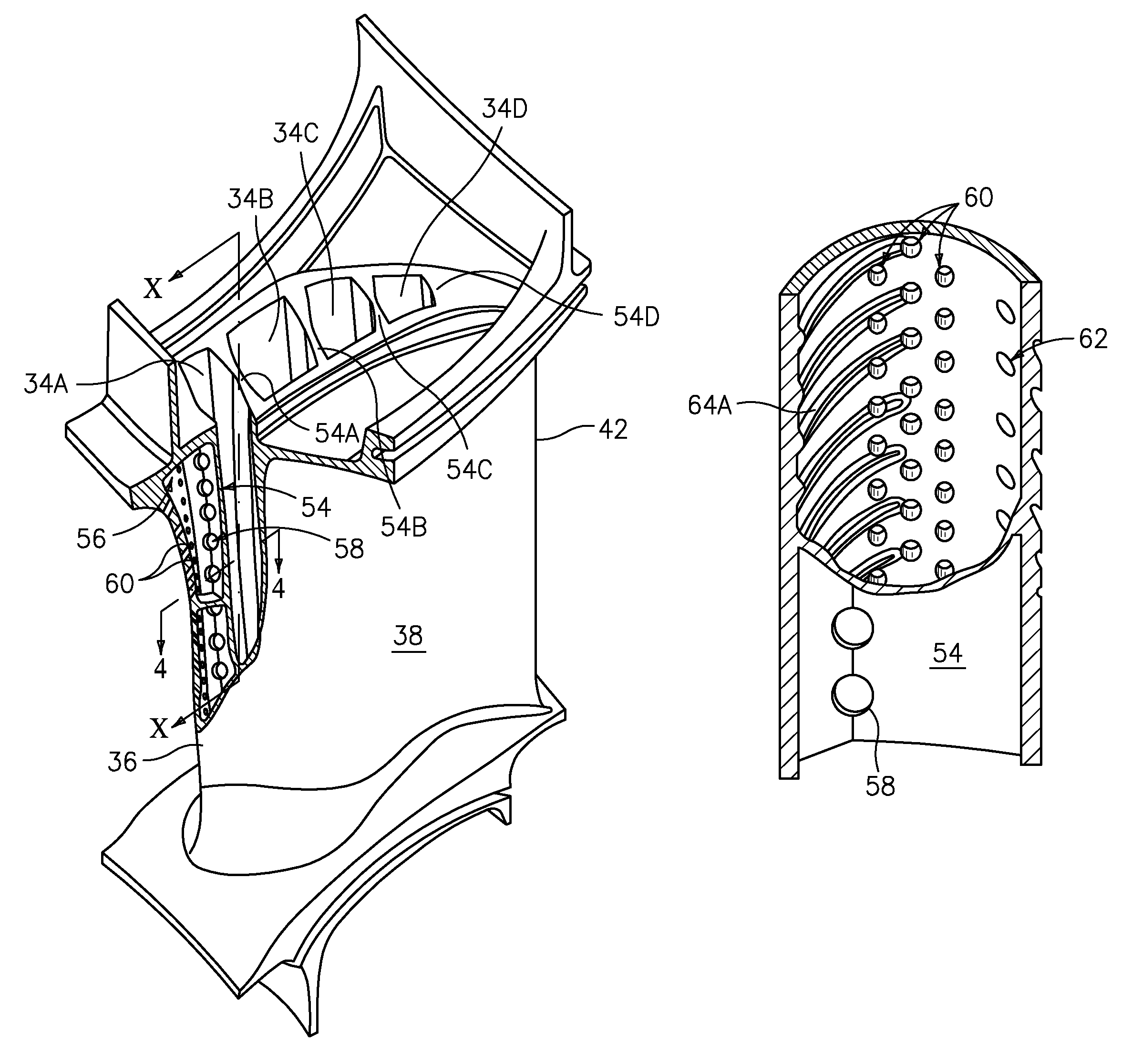

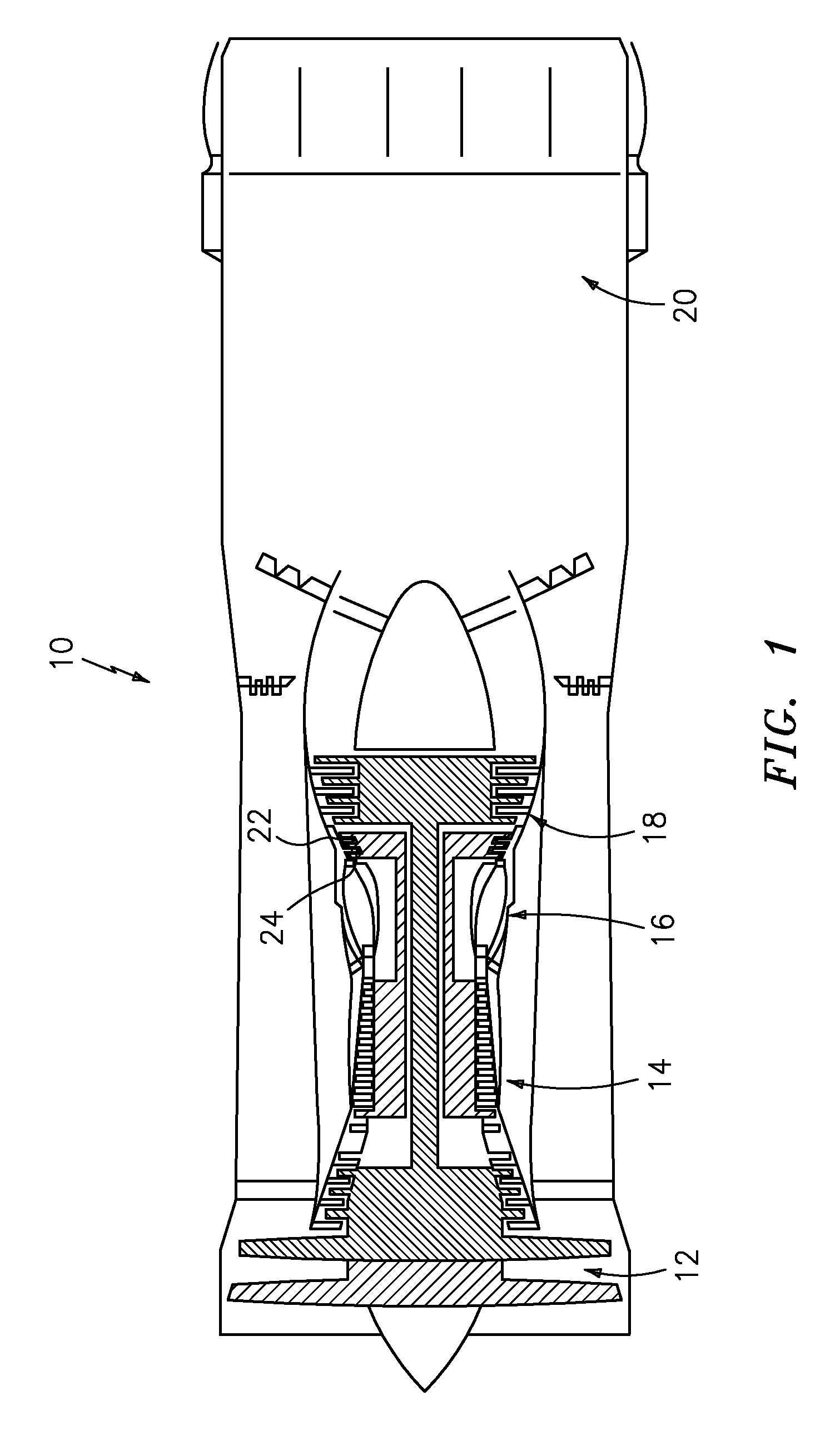

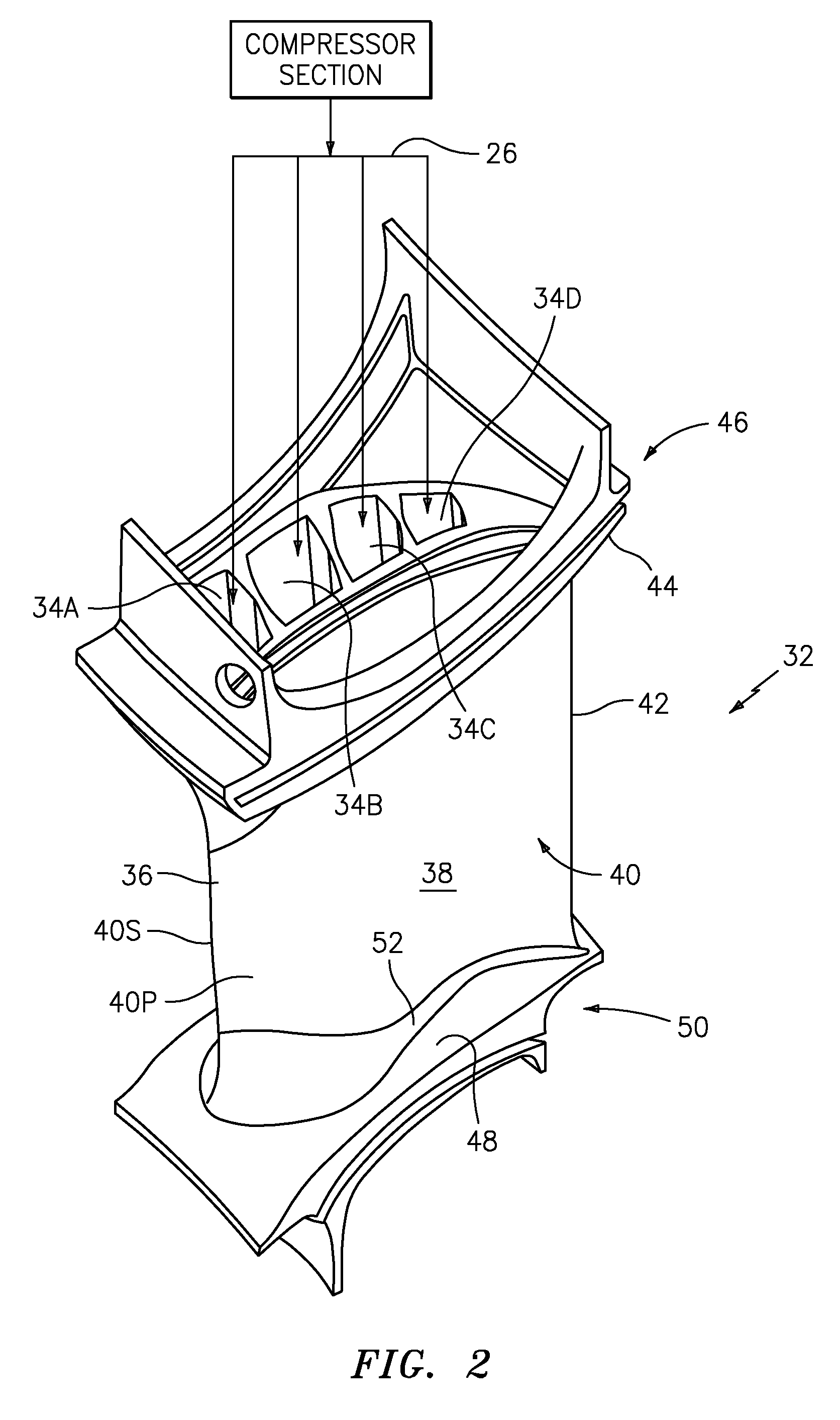

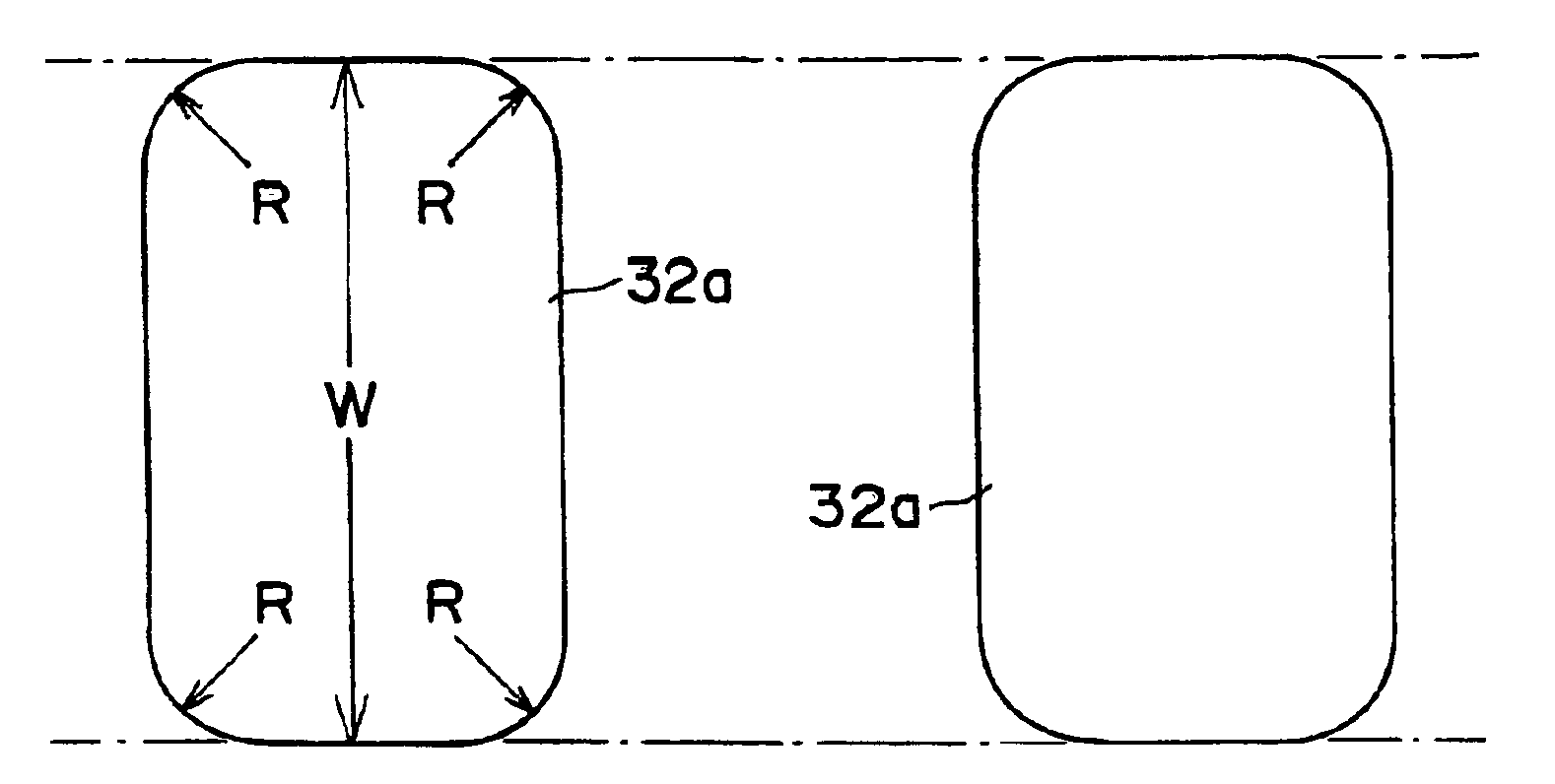

Cooling circuit flow path for a turbine section airfoil

ActiveUS20090074575A1Increase air velocityImprove transfer qualityPropellersPump componentsLeading edgeTurbine

A cooled airfoil includes an impingement rib having a multiple of openings which supply a cooling airflow from a cooling circuit flow path toward an airfoil leading edge. The multiple of openings are offset in the impingement rib opposite an outer airfoil wall which includes gill holes. Offsetting the multiple of openings opposite an outer airfoil wall which includes the gill holes focuses the cooling airflow across turbulators to increase the cooling airflow dwell time to increase the thermal transfer therefrom in higher temperature airfoil areas.

Owner:RTX CORP

Cooling circuit flow path for a turbine section airfoil

ActiveUS8757974B2Increase air velocityImprove transfer qualityEngine fuctionsBlade accessoriesLeading edgeTurbine

A cooled airfoil includes an impingement rib having a multiple of openings which supply a cooling airflow from a cooling circuit flow path toward an airfoil leading edge. The multiple of openings are offset in the impingement rib opposite an outer airfoil wall which includes gill holes. Offsetting the multiple of openings opposite an outer airfoil wall which includes the gill holes focuses the cooling airflow across turbulators to increase the cooling airflow dwell time to increase the thermal transfer therefrom in higher temperature airfoil areas.

Owner:RTX CORP

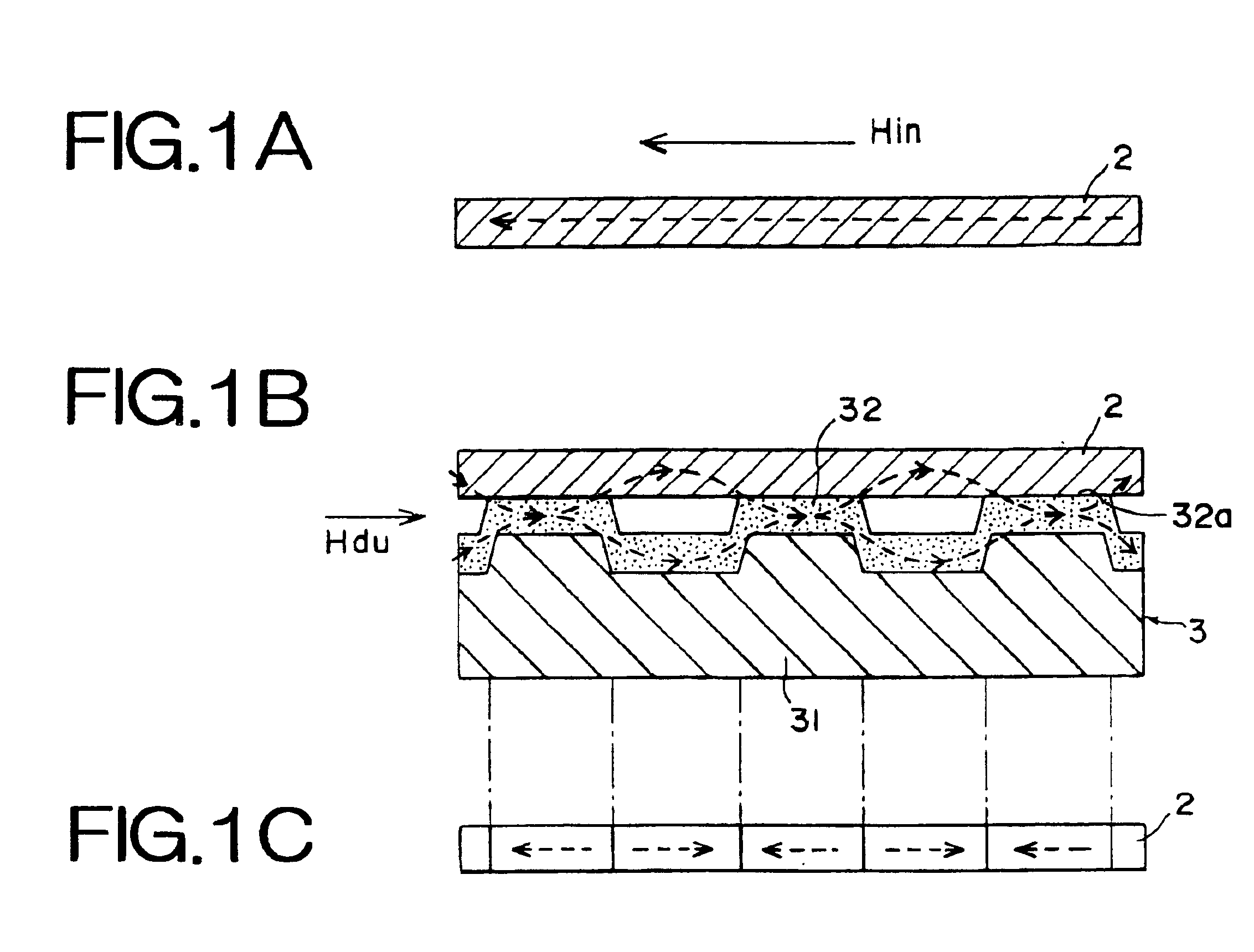

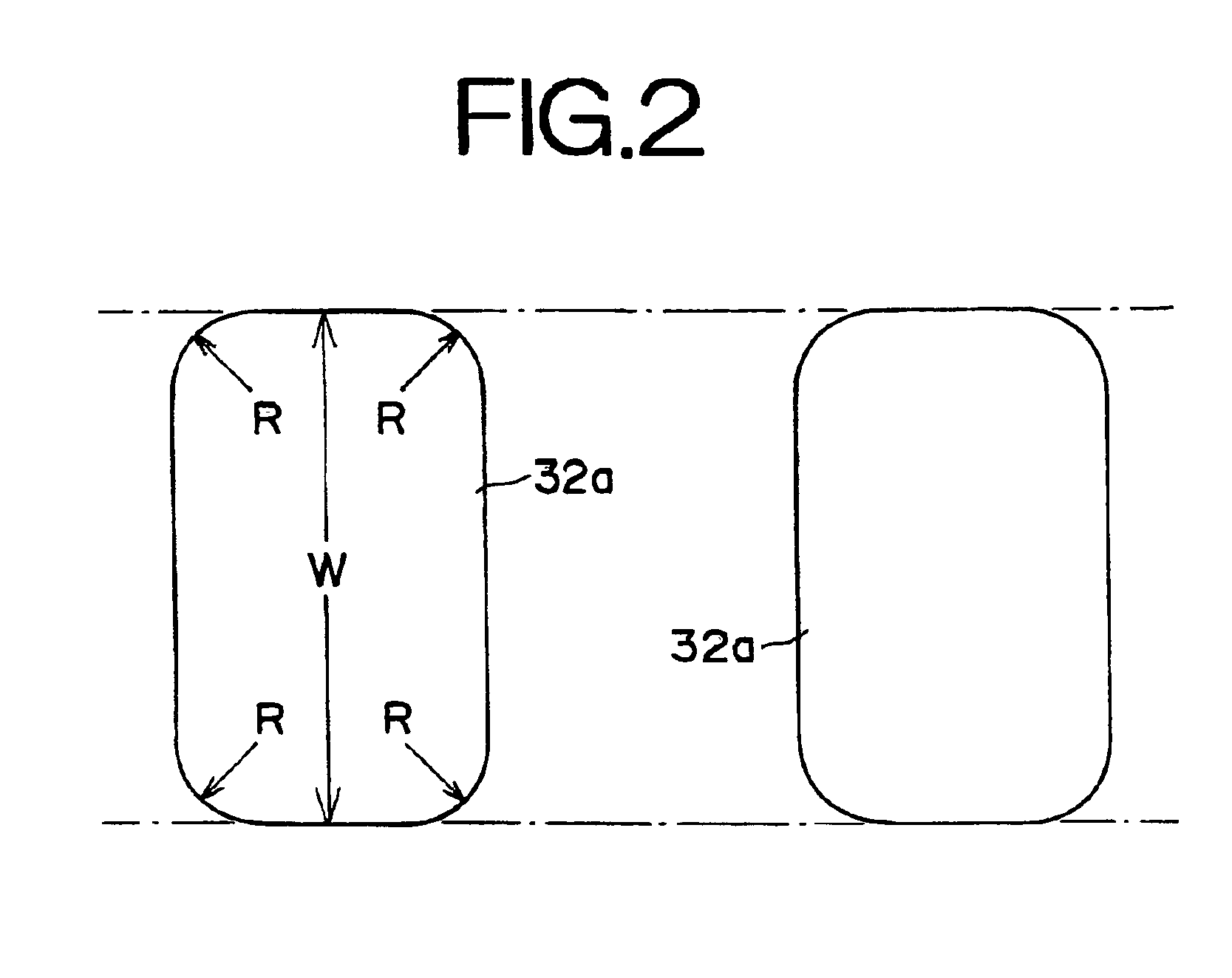

Master carrier for magnetic transfer

InactiveUS6909563B2Improve transfer qualityAvoid damageNanoinformaticsPatterned record carriersEngineeringElectrical and Electronics engineering

Owner:FUJIFILM HLDG CORP +1

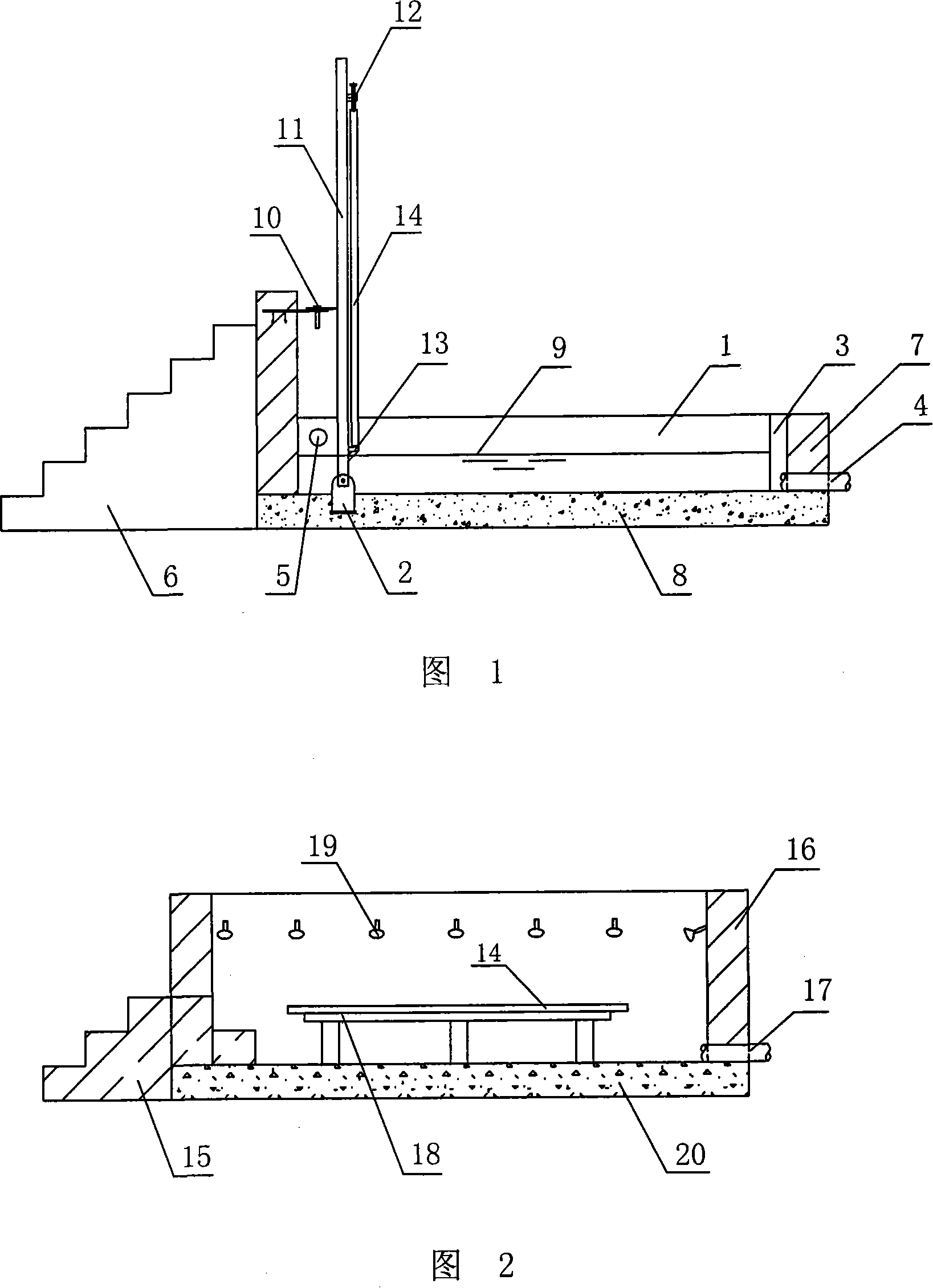

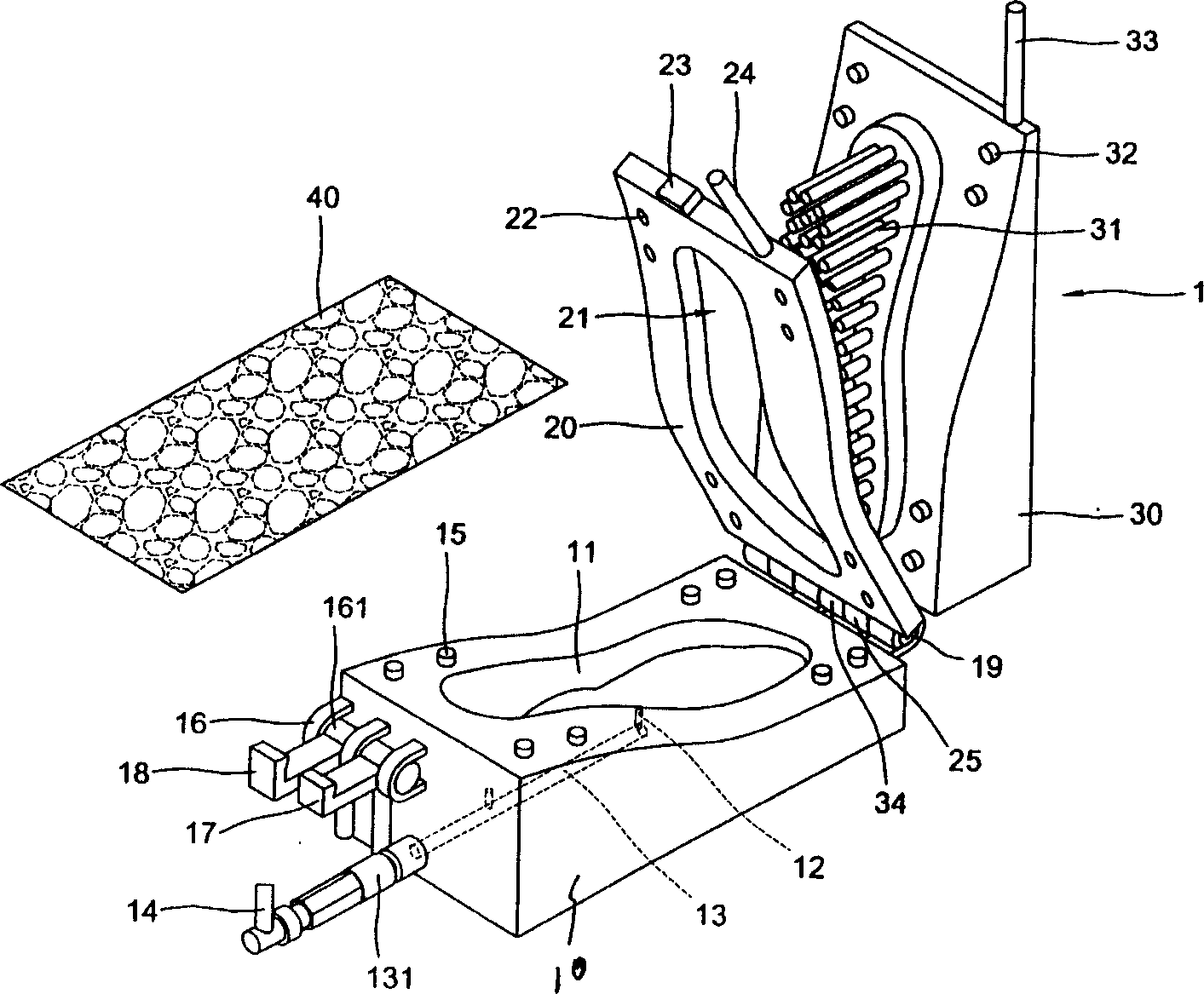

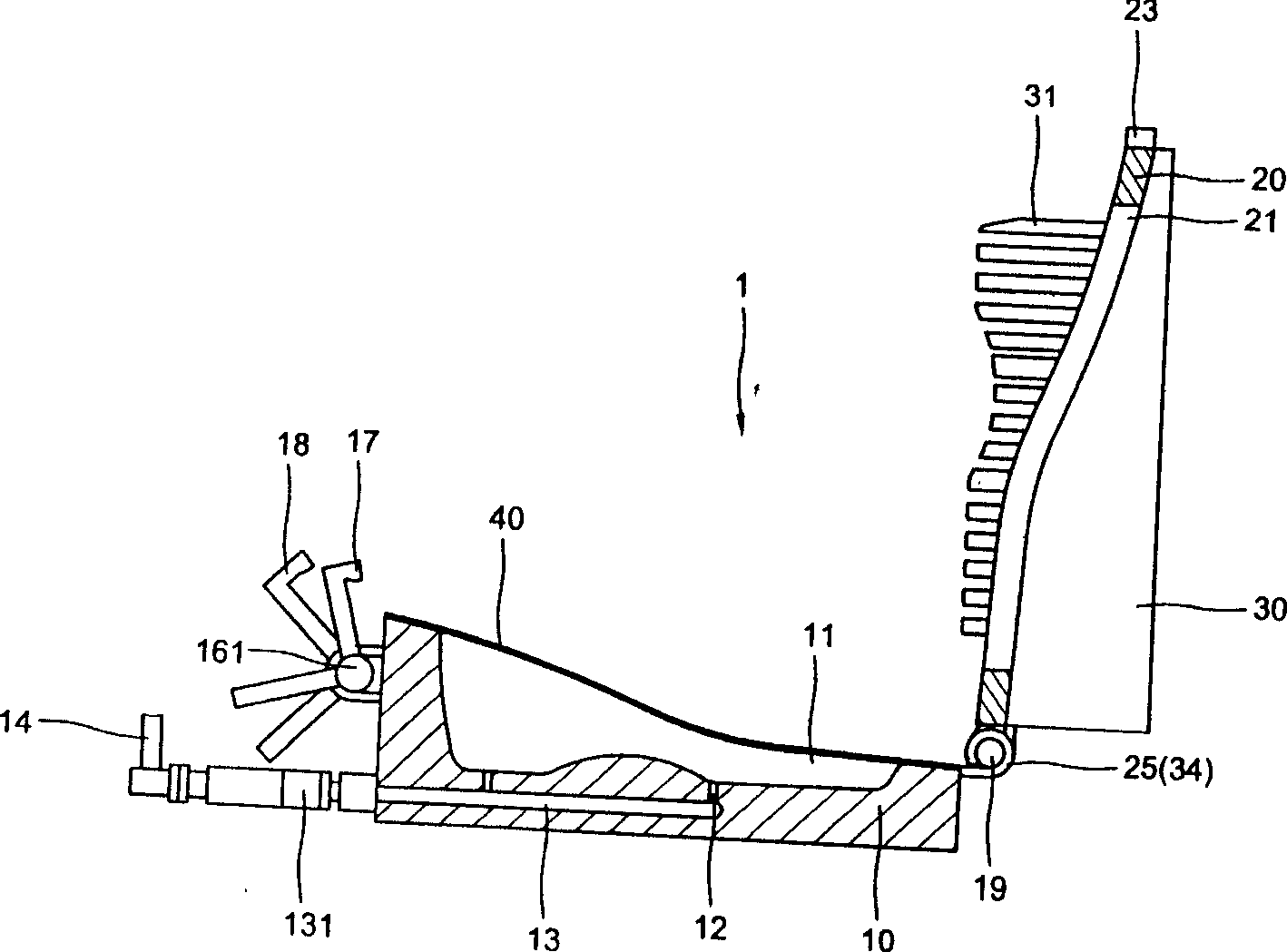

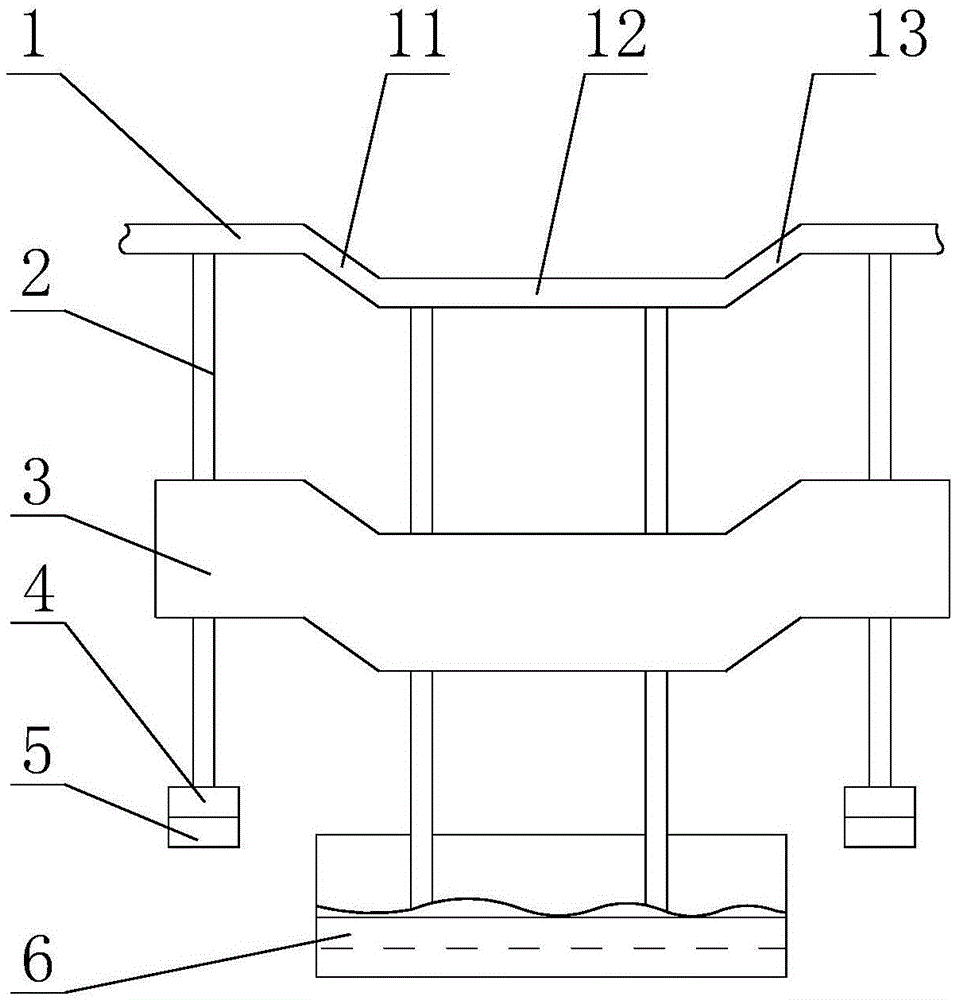

Process for water transferring on the surface of large workpiece and equipment thereof

InactiveCN101112837ANo distortionNo crackDecorative surface effectsPattern printingSewageEngineering

A method and the equipment carrying out the water transfer printing on the surface of the large workpiece are provided. The water transfer printing method comprises the steps that (1) the workpiece is fixed on a frame and the water is poured into a water pool; (2) the water transfer printing membrane is smoothly paved on the water surface and the bubble below the printing membrane is removed; (3) an oil ink activator is sprayed on the surface of the water transfer printing membrane; (4) the frame is downwards rotated, ensuring the workpiece to be dipped below the water surface; (5) after the water transfer printing membrane is completely coated on the surface of the workpiece, the frame is upwards rotated, ensuring the workpiece to be exposed out of the water in a vertical condition, and the workpiece is removed from the frame and is flatly arranged on a cleaning table; (6) the oil sewage on the surface of the workpiece is cleaned. The invention also comprises the large workpiece water transfer printing equipment and the cleaning pool. The invention is especially suitable for the graph-text water transfer printed on the surface of the large workpiece, the graph-text by transfer printed without distortion or deformation has no rupture crack and oblique crack, and has good quality and high efficiency.

Owner:吕海萍

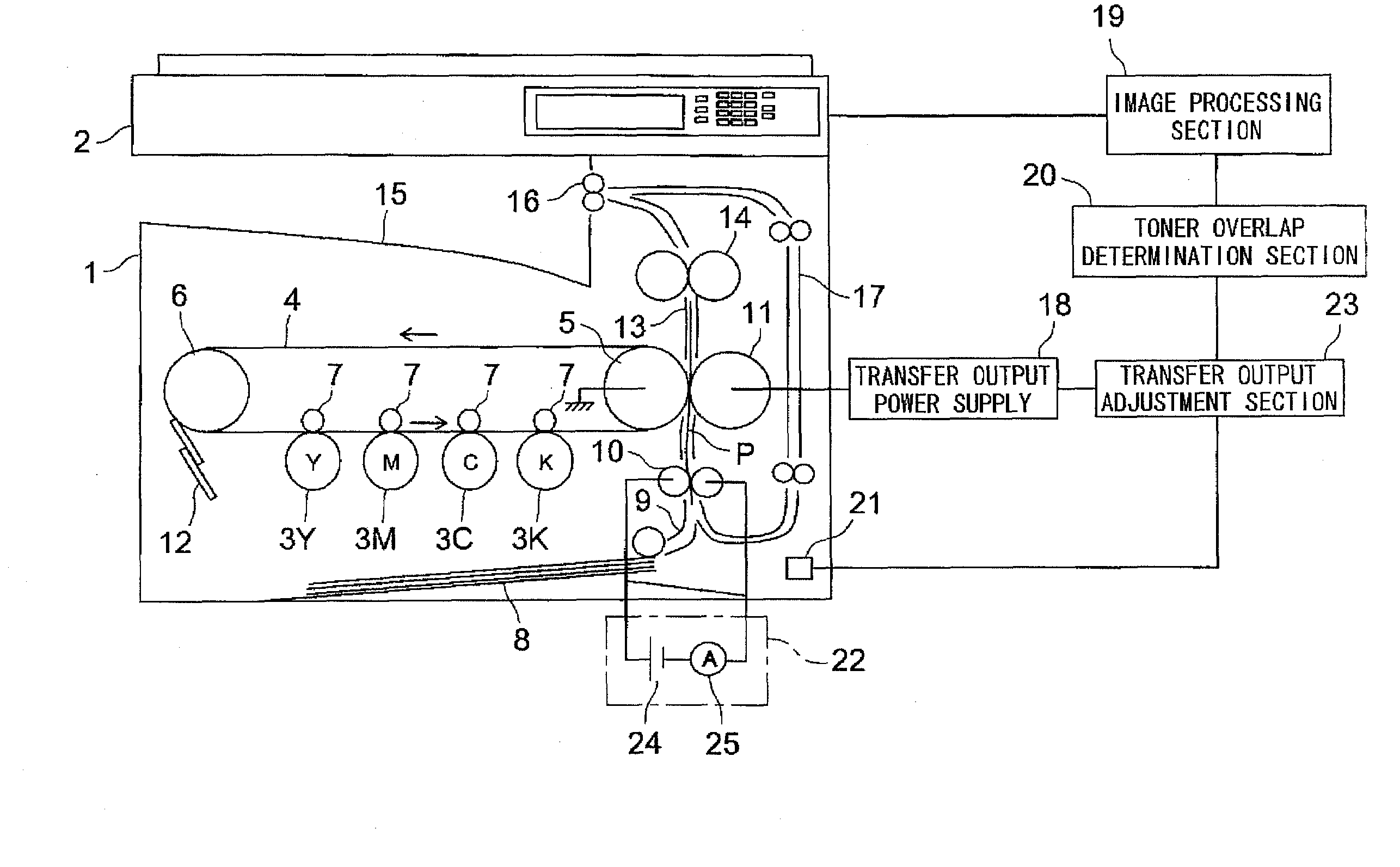

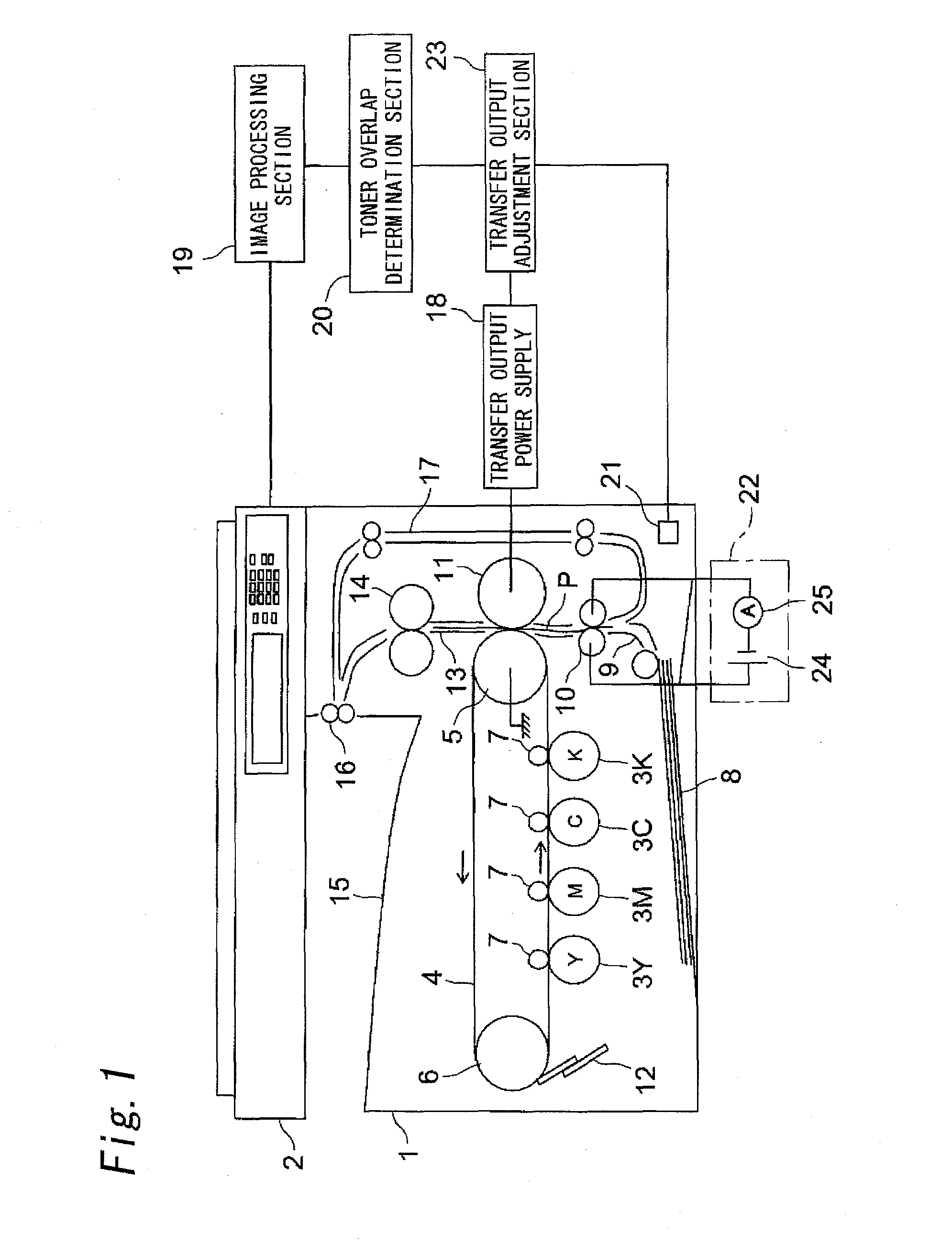

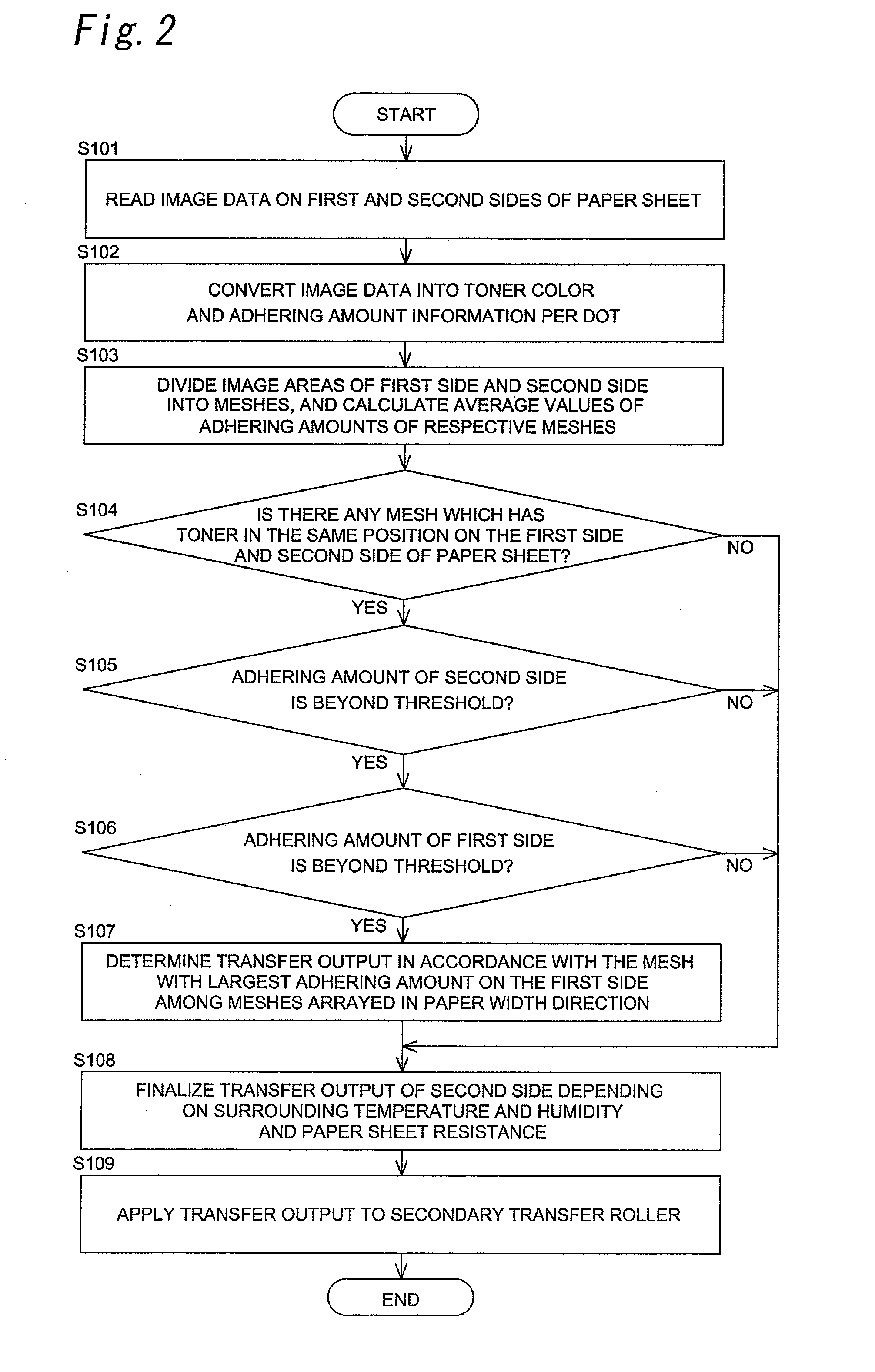

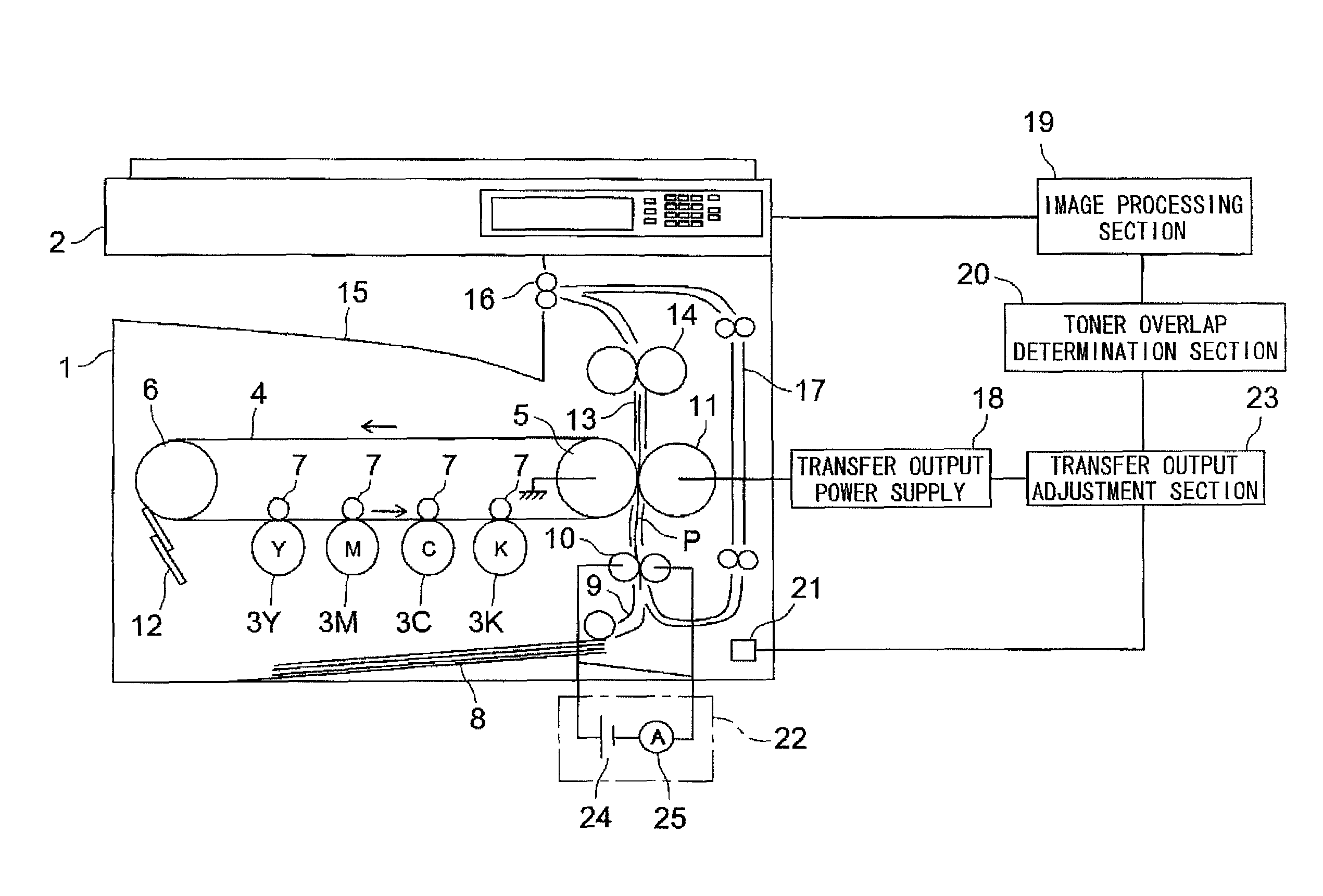

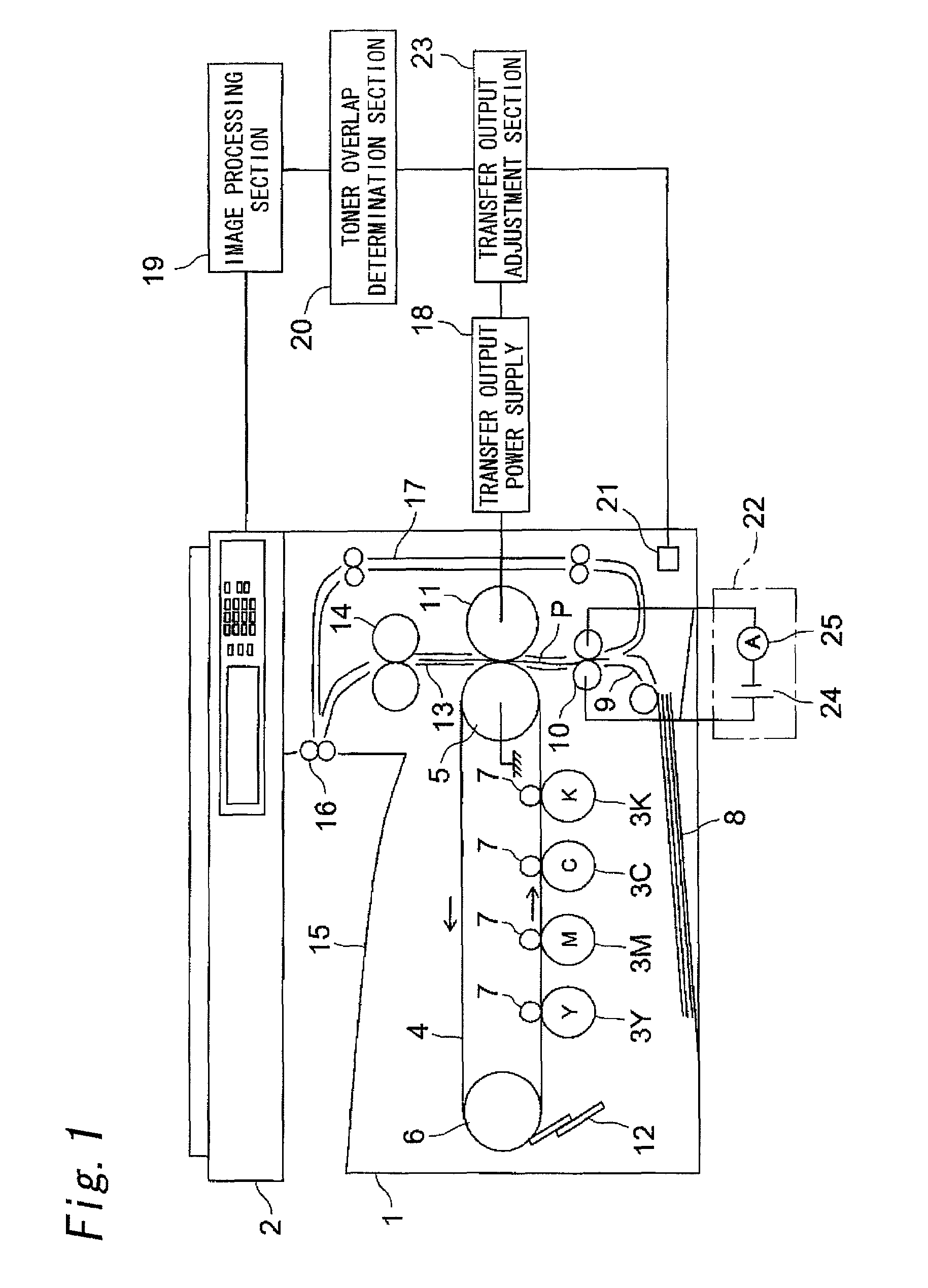

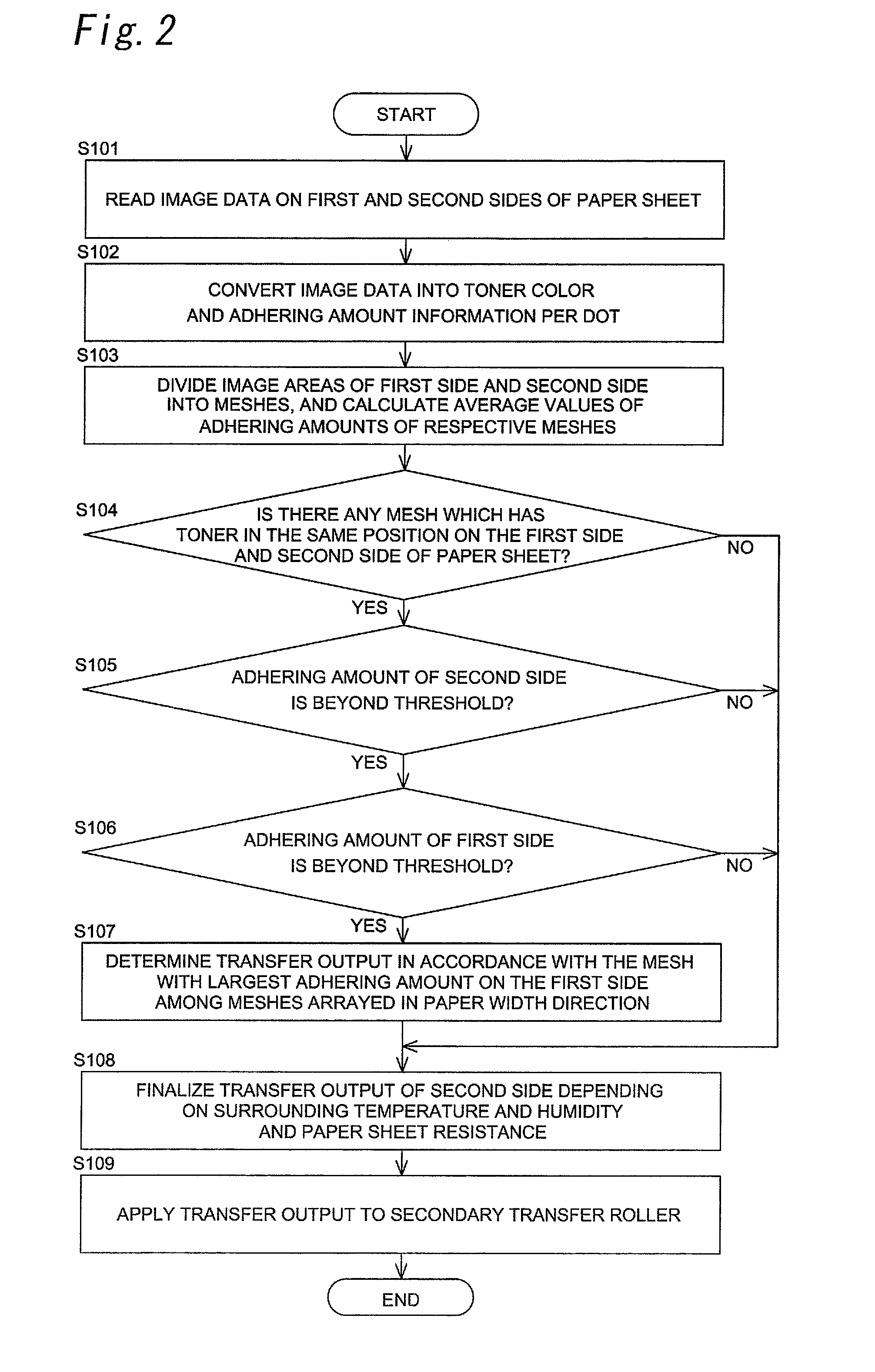

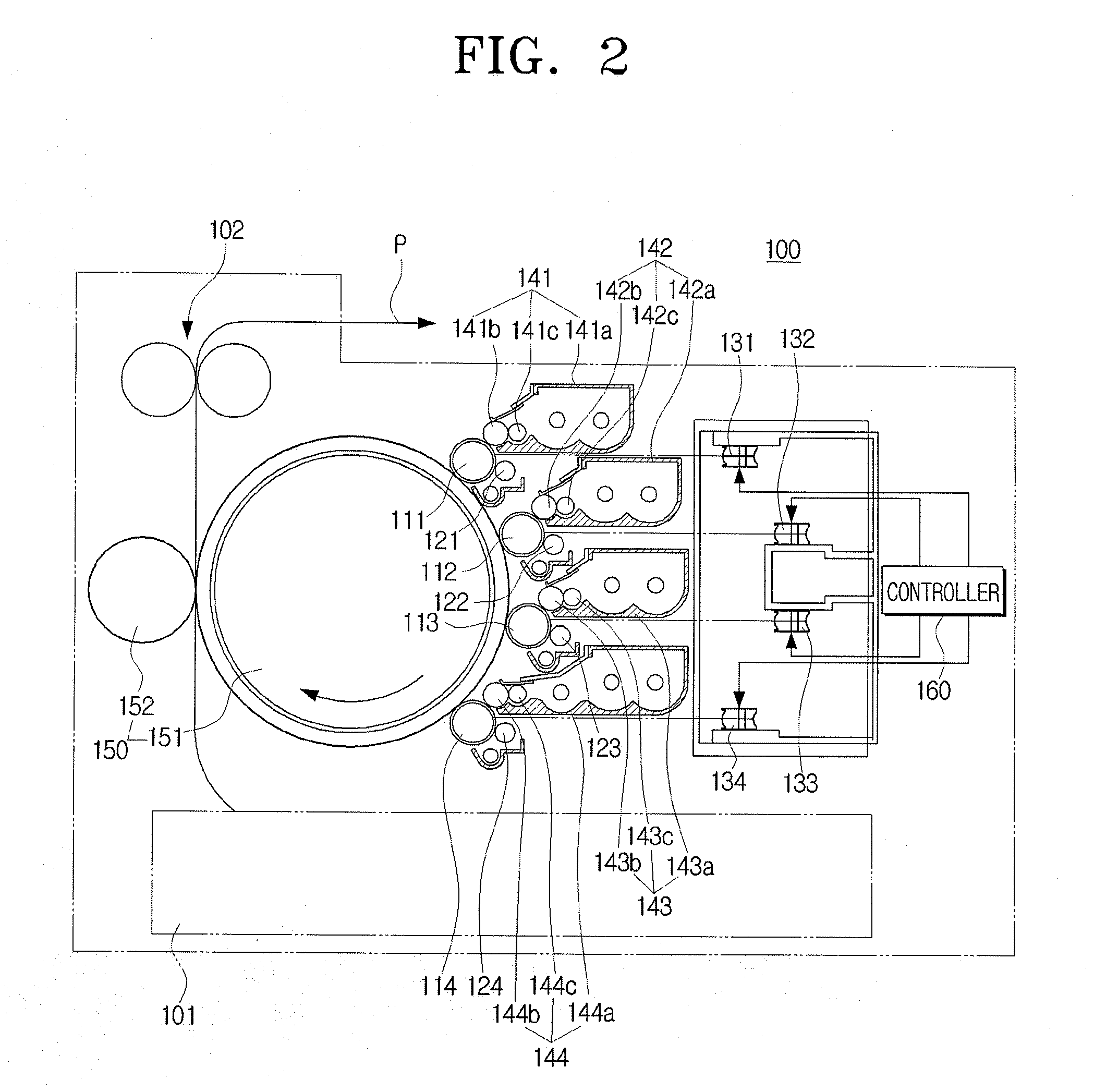

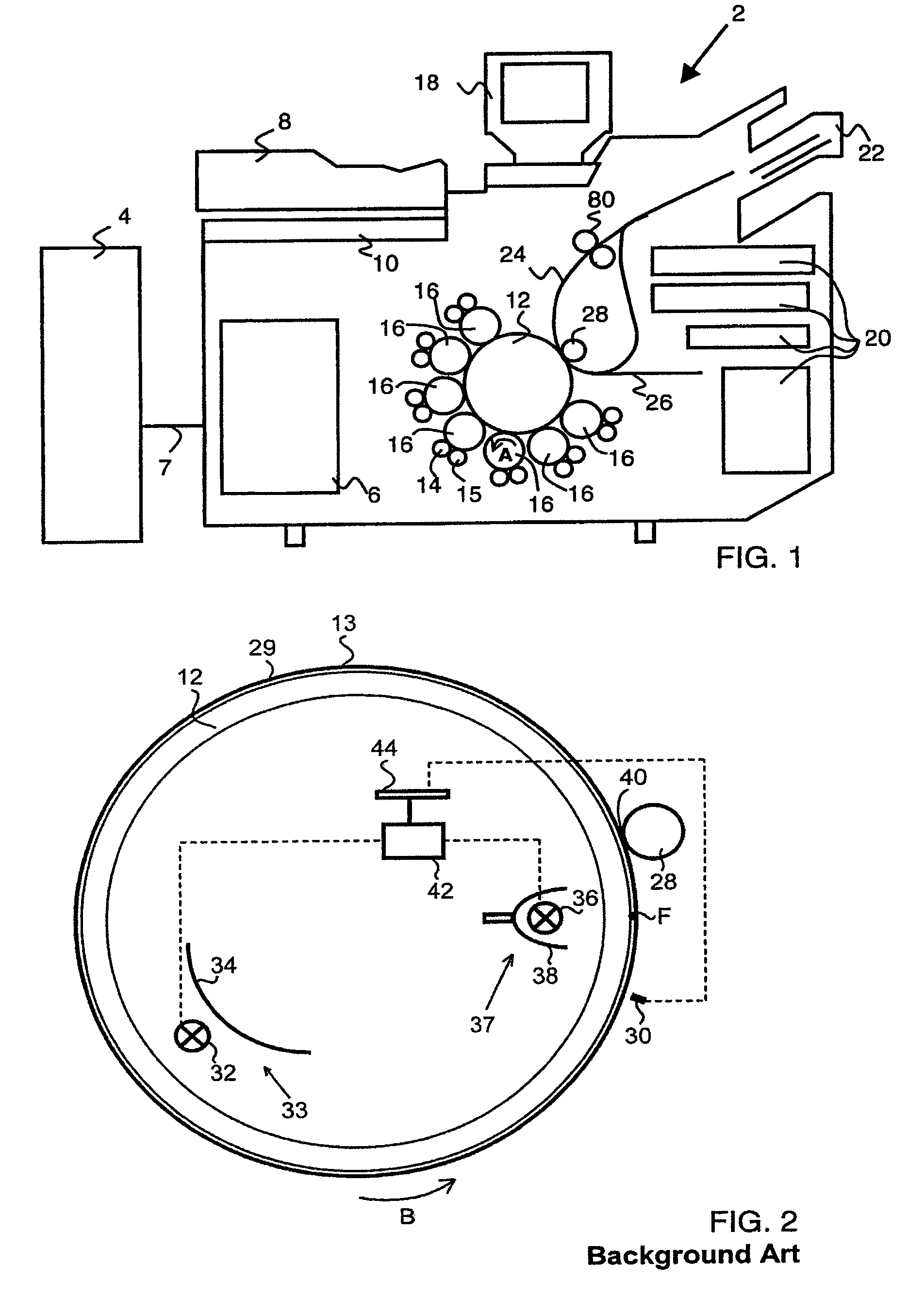

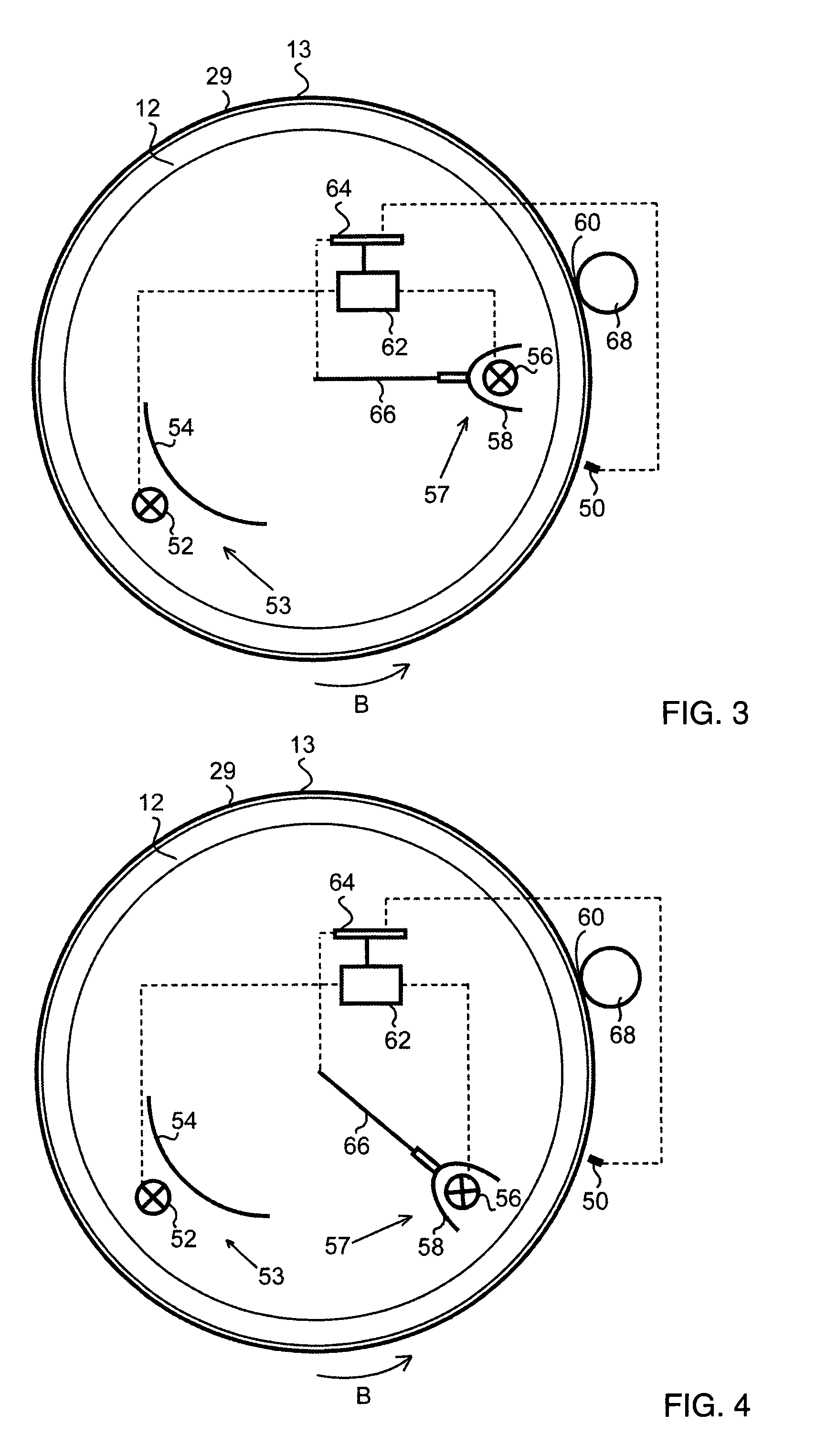

Image forming apparatus

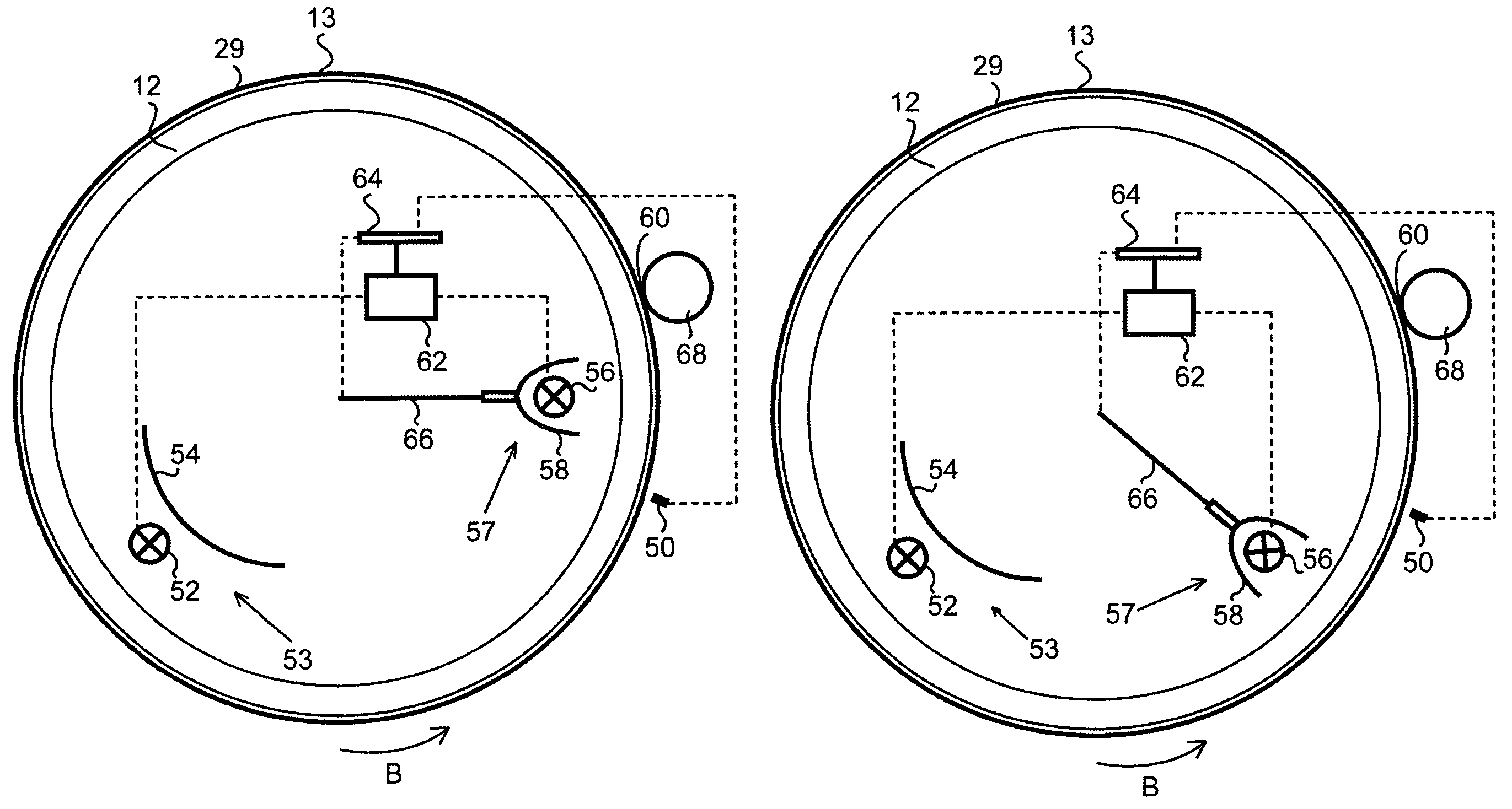

ActiveUS20100067925A1Accurate transferLow transfer rateElectrographic process apparatusImage formationEngineering

A toner image can properly be transferred onto the second side of a paper sheet without being influenced by the toner image on the first side. There are provided a detection unit 20 for detecting overlap of the toner images on the first side and the second side of the paper sheet based on image data, and a transfer output adjustment unit 22 which changes a transfer voltage output for the second side in an area with the overlap of the toner images depending on the toner adhering amount of the first side.

Owner:KONICA MINOLTA BUSINESS TECH INC

Image transferring sheet

InactiveUS6716493B1Improve the immunityImprove wettabilityCoatingsThermographyInk printerHot-melt adhesive

A transfer sheet for an ink jet printer comprises a support, and a transfer layer which is capable of separating from the support and contains a hot-melt adhesive particle, and the hot-melt adhesive particle comprises a first porous hot-melt adhesive fine particle having an oil absorption of not less than 50 ml / 100 g. The transfer layer may further comprise a second hot-melt adhesive fine particle having an oil absorption of less than 50 ml / 100 g, a film-forming resin component, and a dye fixing agent. The hot-melt adhesive fine particle may comprise a nylon fine particle, and the average particle size thereof may be 1 to 100 mm.

Owner:DAICEL CHEM IND LTD

Method and apparatus for foam mould inner color painting polymerization

An apparatus for attaching a color painting onto a foamed body is a mould consisting of a lower mould with a concave cavity, an air hole connected with a suction tube and a fastener module, a middle mould with an empty cavity and an upper mould with a projected part for inserting it in said middle and lower moulds. Its method includes such steps as putting a transfer film on lower mould, fastening three moulds together, sucking air to make the transfer film close to concave cavity of lower mould, filling substance in the mould, foaming, demoulding and trimming.

Owner:成昌兴企业股份有限公司

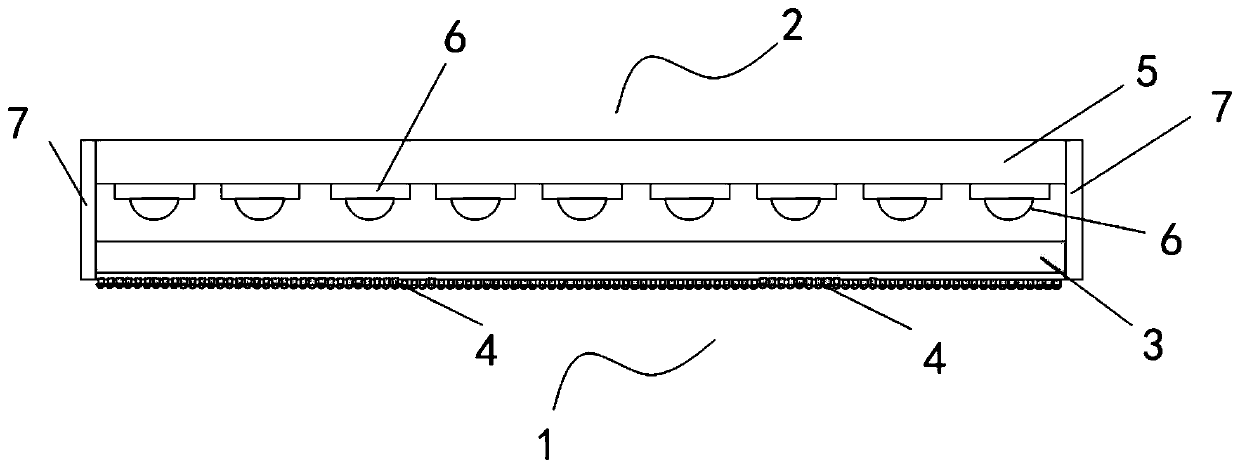

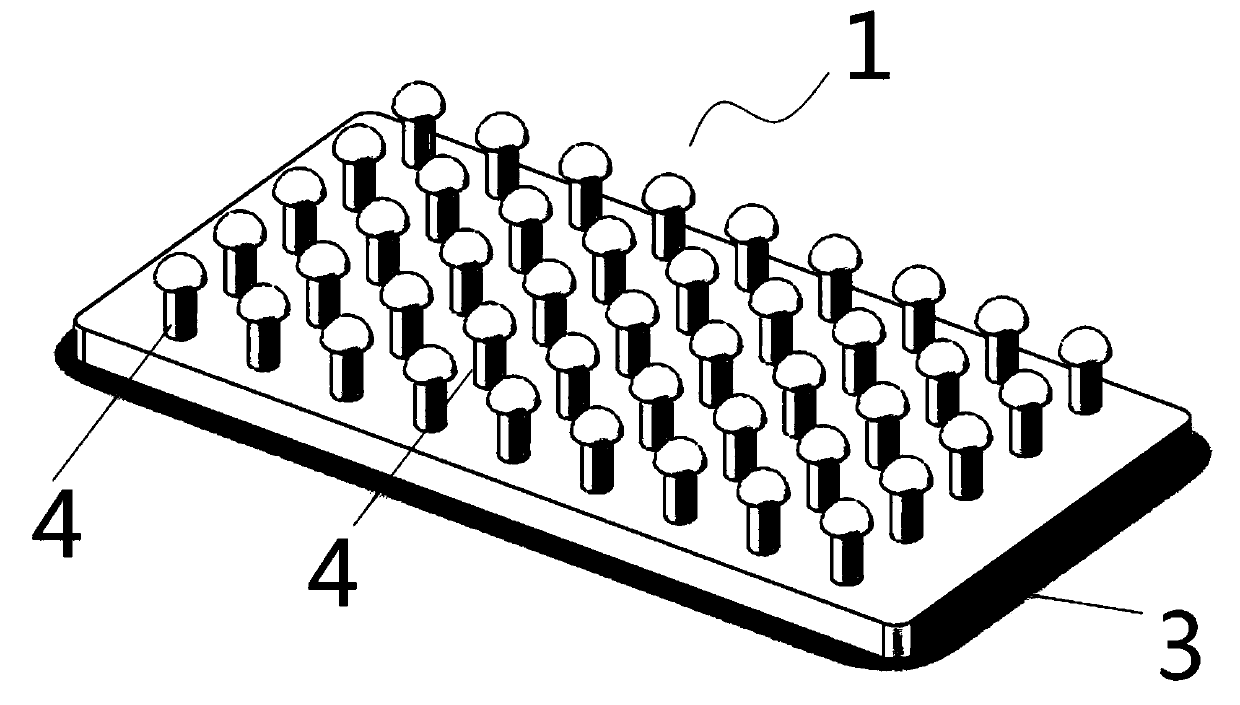

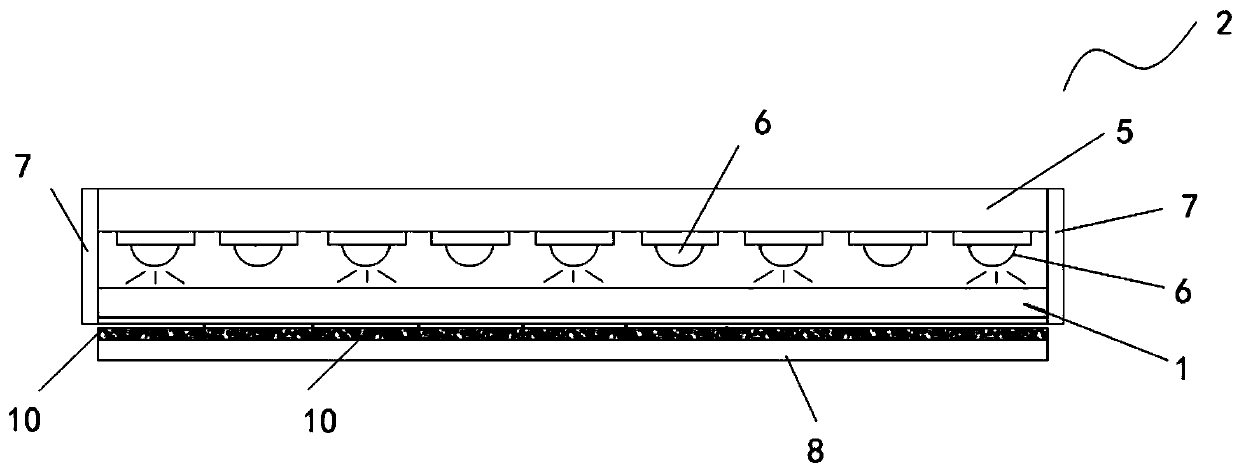

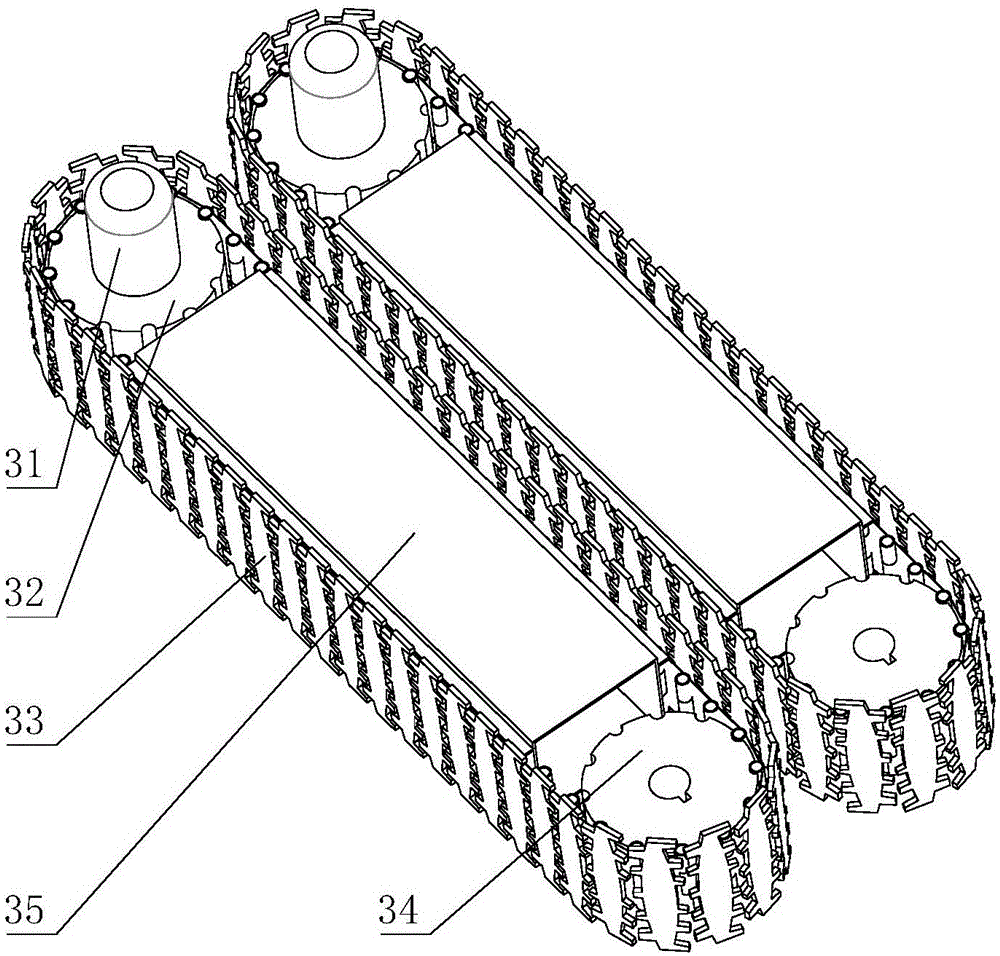

Bionic grabbing device for Micro-LED mass transfer and using and manufacturing method

ActiveCN111370349AMass transfer with high qualityImprove transfer qualitySolid-state devicesSemiconductor/solid-state device manufacturingPhysicsLight source

The invention discloses a bionic grabbing device for Micro-LED mass transfer and a using and manufacturing method of the bionic grabbing device. The device comprises a graphene-based shape memory polymer microstructure film and a Micro-LED transfer device, the graphene-based shape memory polymer microstructure film comprises a polyurethane film substrate and a plurality of graphene-based shape memory polymer micro-columns, the plurality of graphene-based shape memory polymer micro-columns are distributed in an array on the polyurethane film substrate; the Micro-LED transfer device comprises alight source fixing substrate, a laser emission unit and a fixing plate. When the laser emission unit emits a laser beam, the corresponding graphene-based shape memory polymer micro-column is converted from a glassy state to a viscoelastic state. The problems of high operation cost, high difficulty, low yield and the like of existing Micro-LED mass transfer are solved, and the requirements of lowcost, easiness in operation, high yield, high efficiency and the like are further met while the accuracy is ensured.

Owner:GUANGDONG UNIV OF TECH

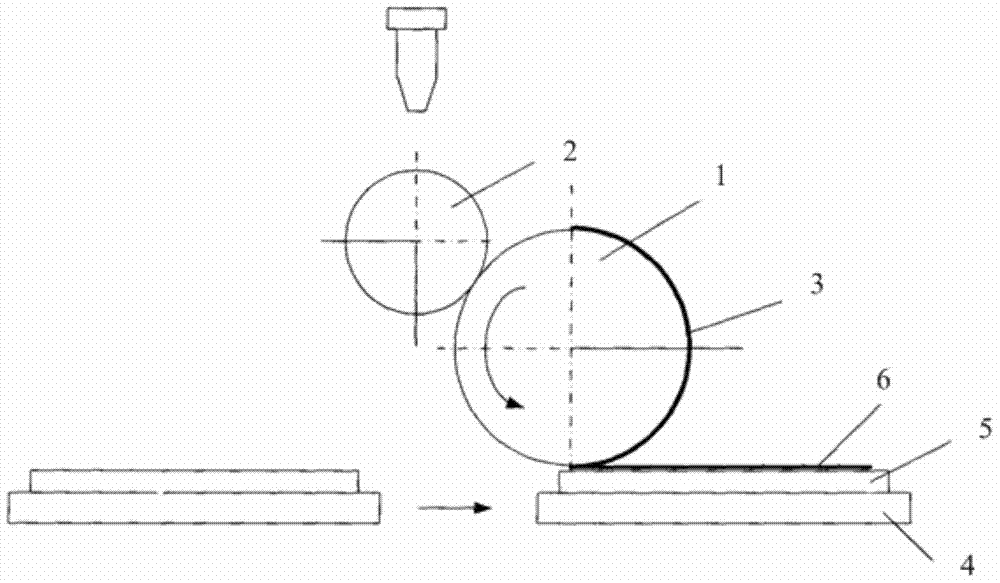

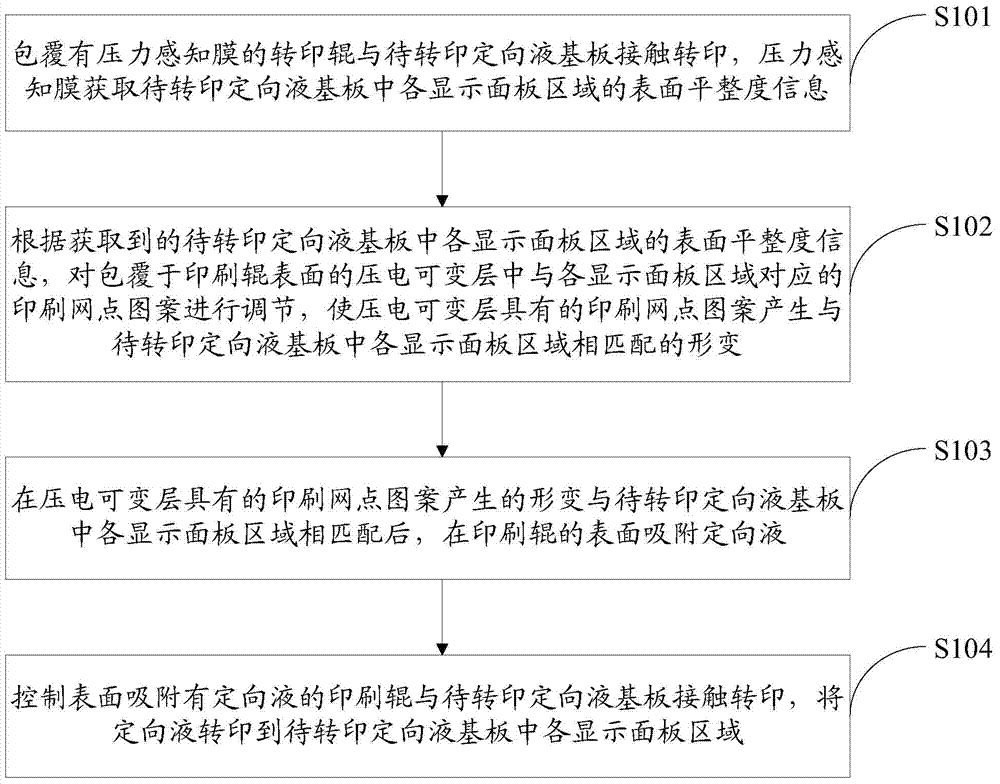

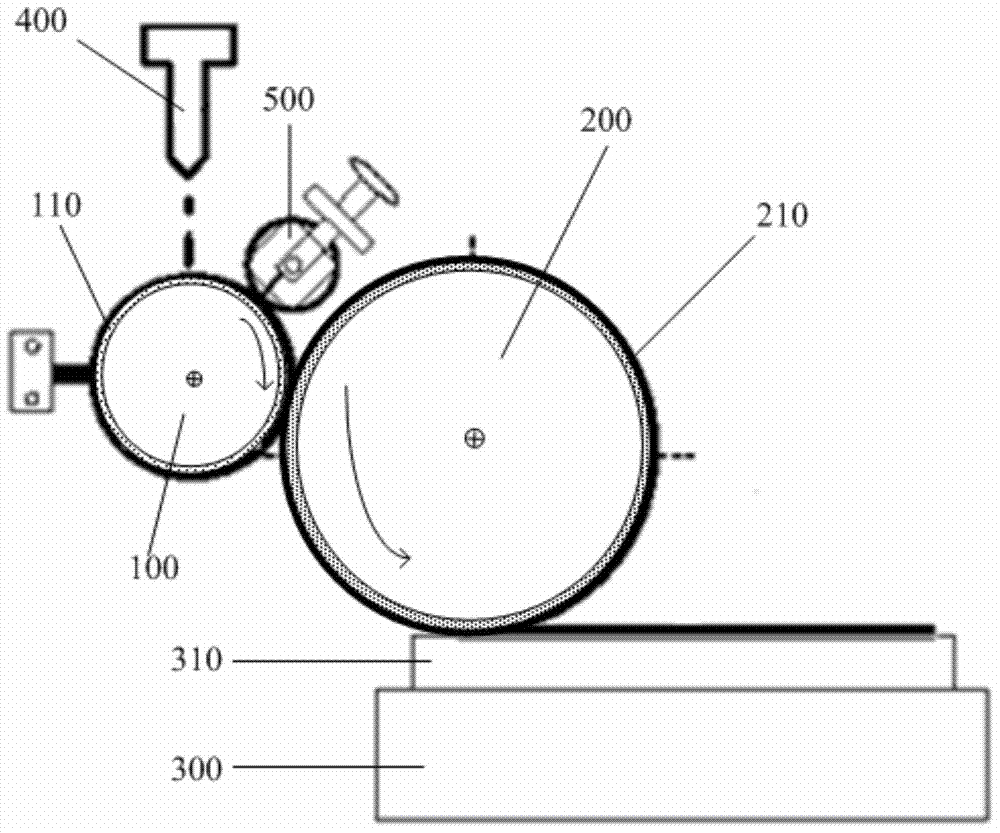

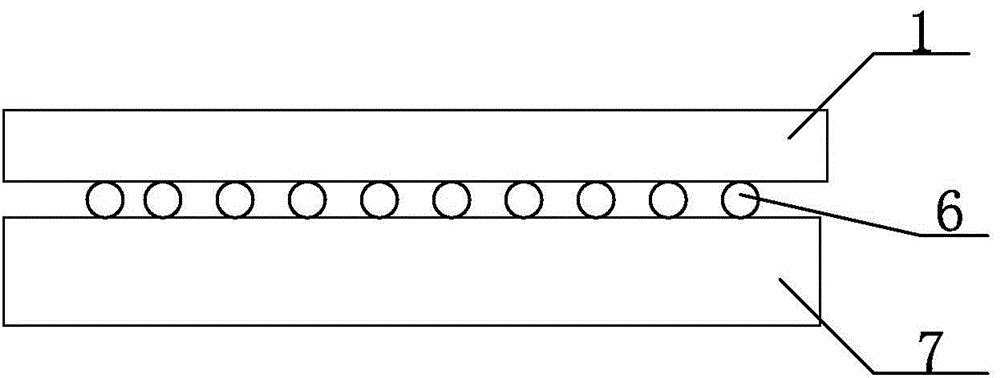

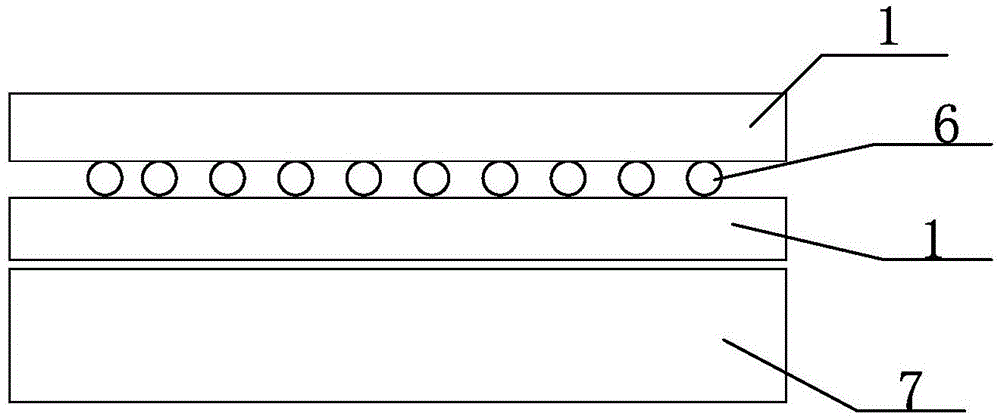

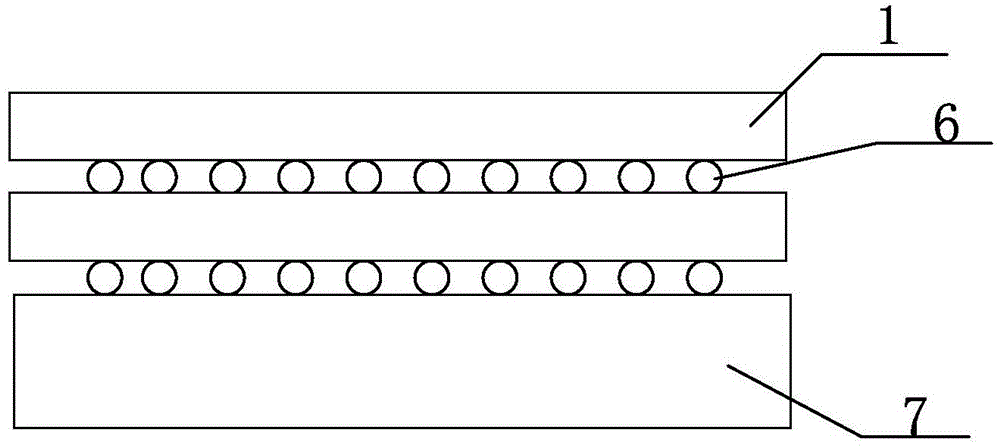

Directional liquid transfer method and device

InactiveCN103698941AUniform pressure per unit areaImprove transfer qualityNon-linear opticsEngineeringSurface flatness

The invention discloses a directional liquid transfer method and device. In the transfer method, a pressure perception film wrapping a transfer roll can obtain surface evenness information of display panel regions in a directional liquid substrate to be transferred and adjust printing dot patterns in a piezoelectric variable layer wrapping the surface of the printing roll and corresponding to the display panel regions according to the obtained surface evenness information to enable printing dot patterns of the piezoelectric variable layer to be deformed into the shape matched with the display panel regions in the directional liquid substrate to be transferred, so that unit area pressure borne by the display panel regions in the directional liquid substrate to be transferred is uniform when the printing roll conducts directional liquid transferring on the display panel regions in the directional liquid substrate to be transferred, and transfer quality is improved accordingly.

Owner:HEFEI BOE OPTOELECTRONICS TECH +1

Stable doping method for graphene

ActiveCN104528698AMaintain the original doped state for a long timeAvoid direct contactDopantCvd graphene

The invention relates to a stable doping method for graphene. The stable doping method for the graphene comprises the step of wrapping the doping agent between two pieces of graphene and / or wrapping a doping agent between a substrate and the graphene, wherein no clinical substrate is used in the step of wrapping the doping agent between the substrate and the graphene. The stable doping method for the graphene has the advantages that a stable doping effect is realized, a doping agent molecule is overlaid between a graphene layer and a substrate layer, the direct contact between the air and the doping agent molecule is avoided, and the original doping state of the doping agent molecule on the surface of the graphene is maintained for a long time, so that the long-term stable doping effect can be guaranteed.

Owner:CHONGQING GRAPHENE TECH +1

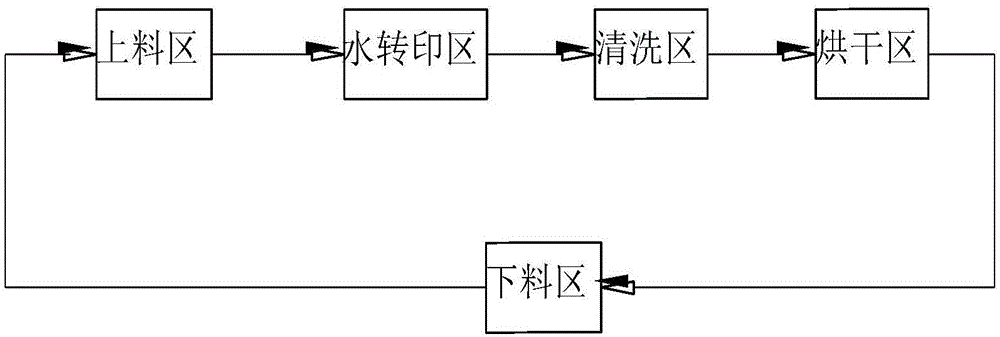

Water transfer printing production line

ActiveCN105129426AReduce labor intensityIncrease productivityTransfer printingCharge manipulationProduction lineEngineering

The invention discloses a water transfer printing production line. The water transfer printing production line comprises a hanging system, a feeding area, a water transfer printing area, a cleaning area, a drying area and a discharging area, wherein the hanging system is used for conveying workpieces, and the feeding area, the water transfer printing area, the cleaning area, the drying area and the discharging area are sequentially arranged below the hanging system. The hanging system comprises a guide rail which is used for conveying the workpieces automatically, hanging rods which are arranged on the guide rail and move along the guide rail, and clamps which are arranged at the lower ends of the hanging rods and used for clamping the workpieces. The trajectory of the guide rail constitutes a closed curve. According to the water transfer printing production line, the guide rail, the hanging rods and the clamps are used so that the workpieces can be conveyed automatically, the labor intensity of operators is relieved, and production efficiency is improved.

Owner:重庆市魏来雄鑫橡塑制品有限责任公司

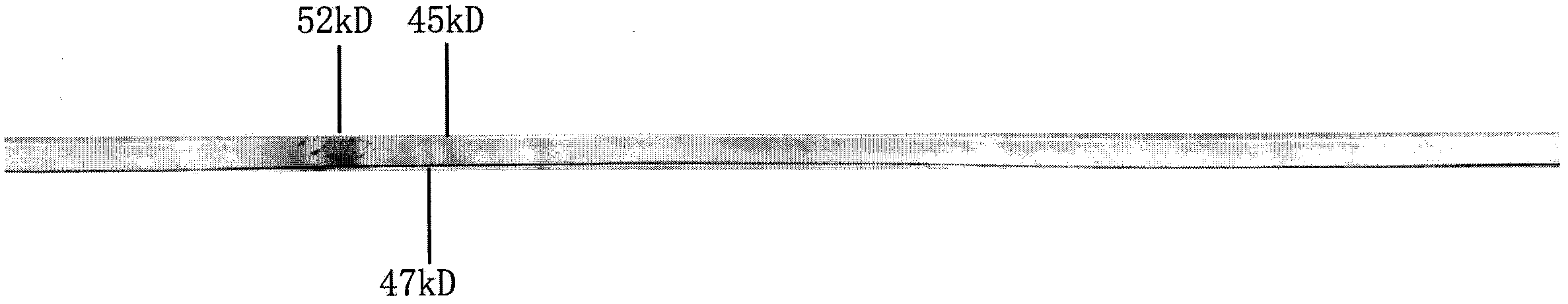

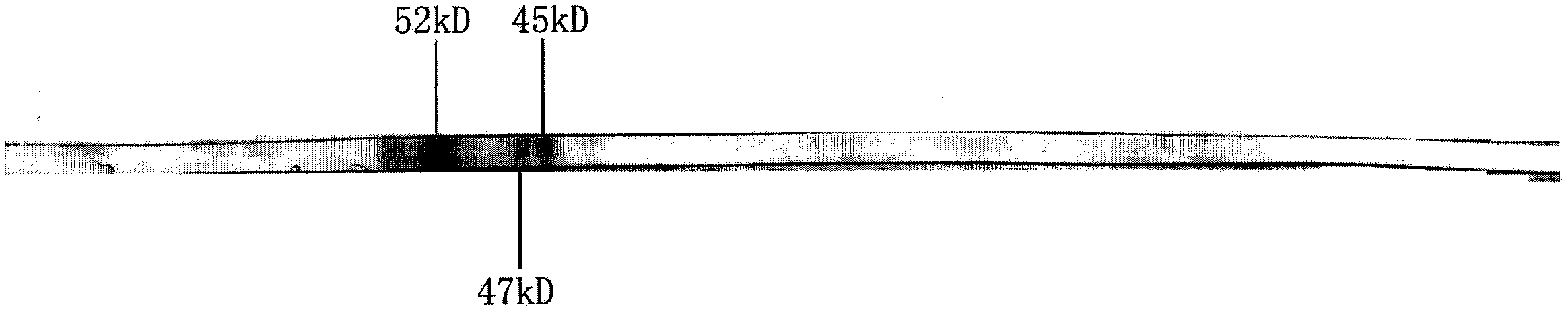

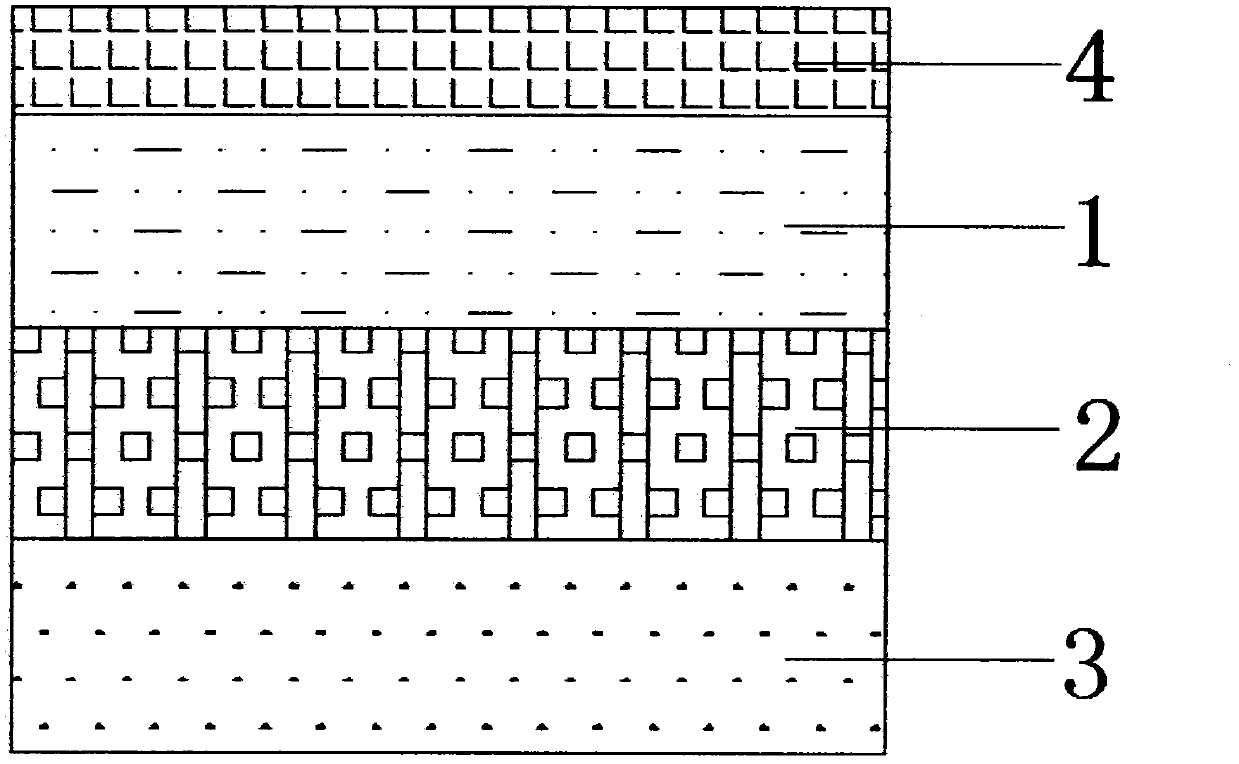

Gradient gel and preparation method thereof

InactiveCN103575792AHigh transfer rateImprove transfer qualityMaterial analysis by electric/magnetic meansElectrophoresisProtein transfer

The invention discloses a gradient gel and a preparation method thereof. The preparation method is characterized by comprising the following steps: respectively blending water, acrylamide separation gel stock solution, separation gel buffer solution, SDS (sodium dodecyl sulfate) and ammonium persulfate into two or more separation gels with concentration of 8-15% according to a certain proportion, quickly pouring the blended two or more separation gels in different concentrations into a glass plate crack in vertical slab electrophoresis from high to low concentration in order, adding water, adding spacer gel after the separation gel is solidified, and waiting the solidification of the spacer gel. According to the method, the electrophoresis speed is increased, the penetrability of protein molecules is enhanced, and the protein transfer rate and the protein transfer quality are improved.

Owner:GUANGZHOU WONDFO BIOTECH

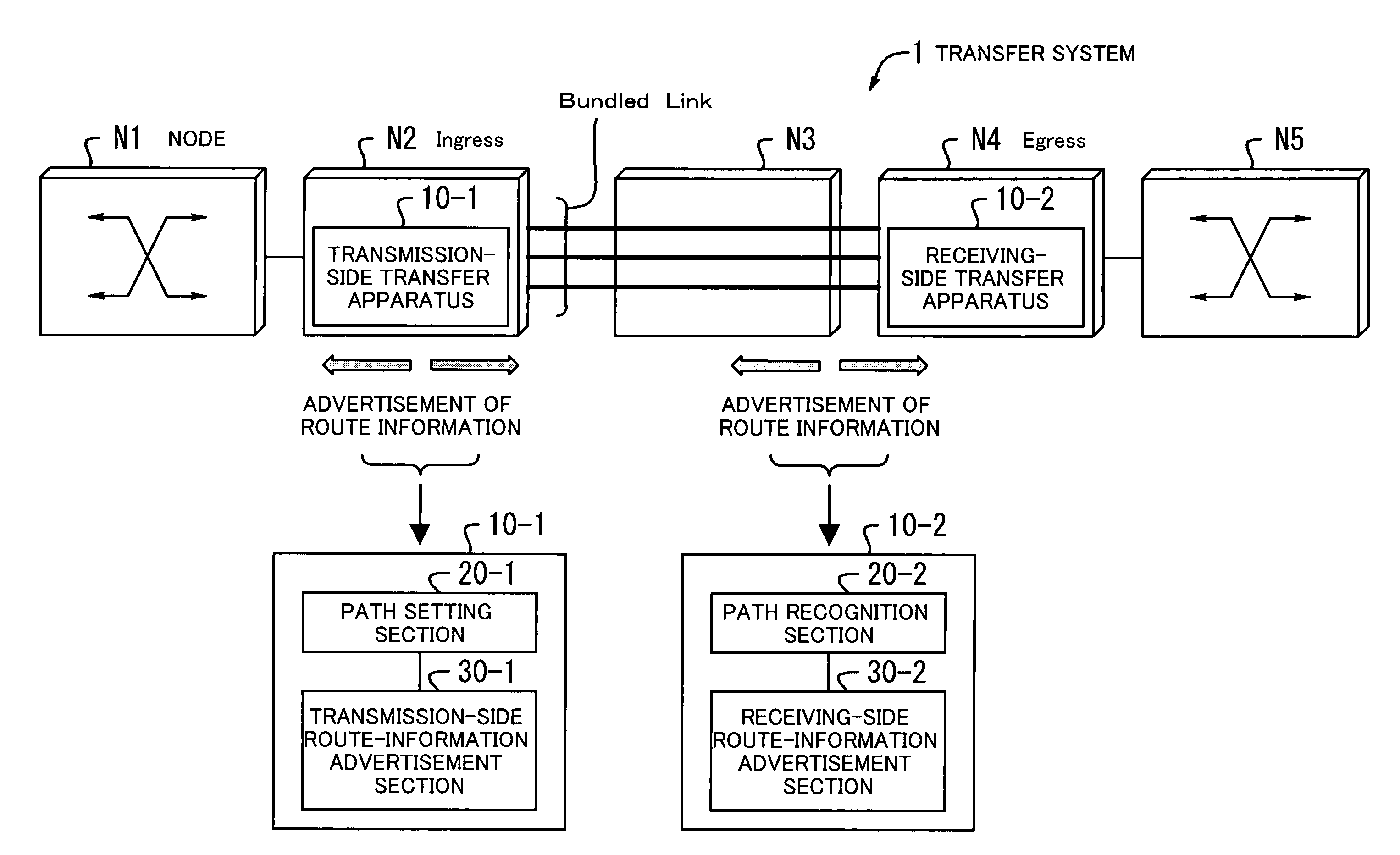

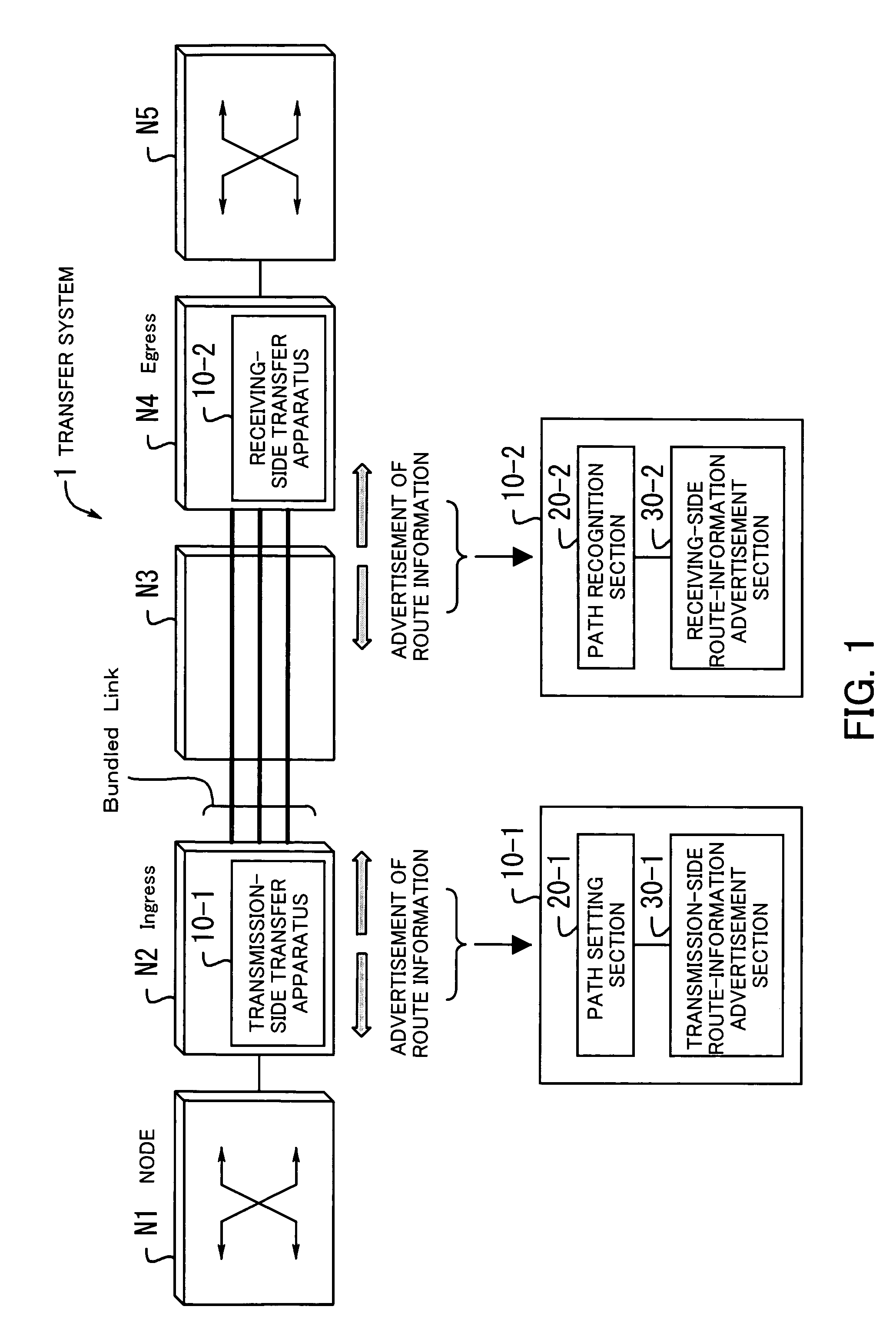

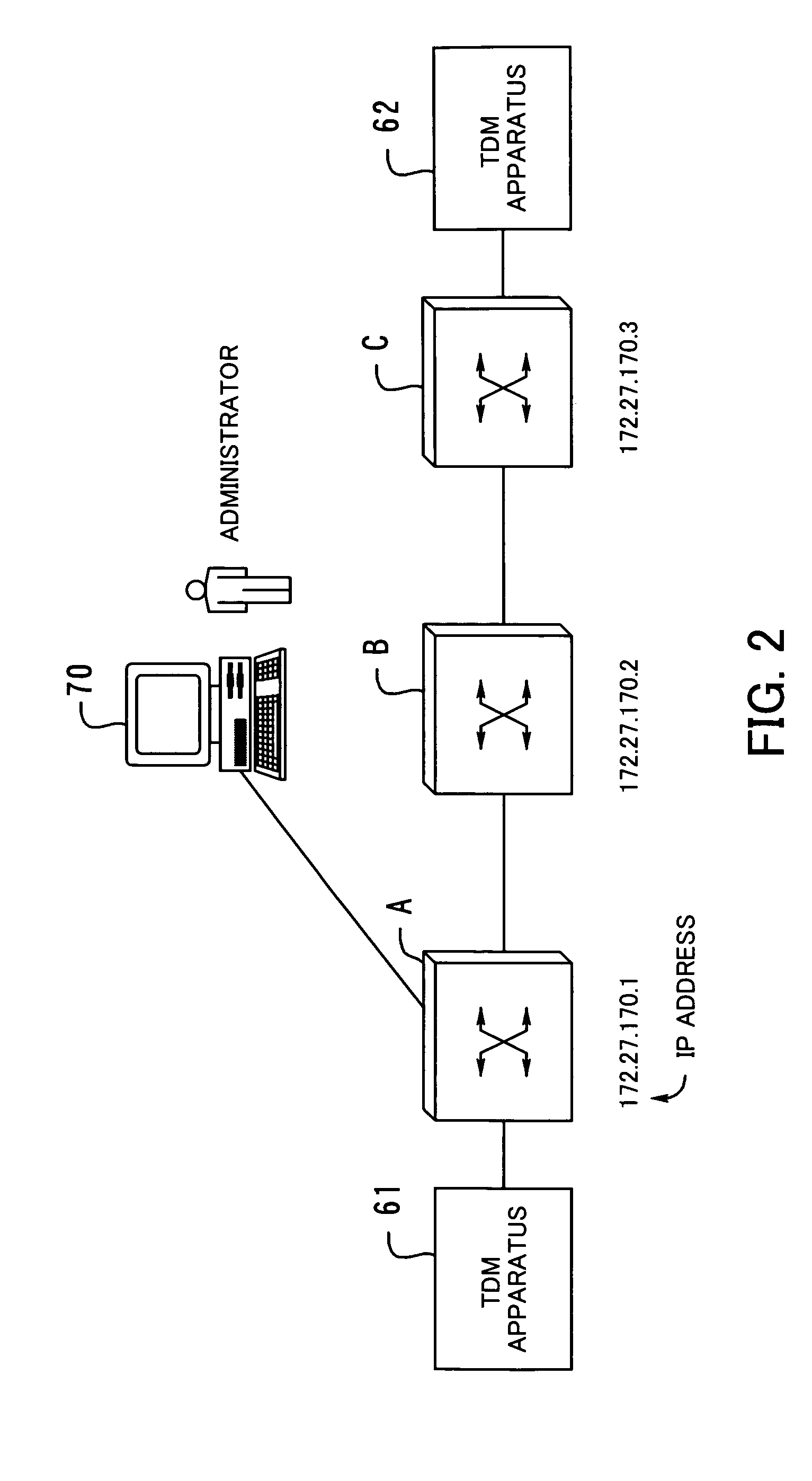

Transfer system

InactiveUS7633938B2Improve transfer qualityReduce the amount requiredMultiplex system selection arrangementsError preventionTransfer systemComputer science

A transfer system for bundle transfer, in which the amount of route information and the number of times advertisement is performed are reduced, and maintenance and management are made to be highly efficient to implement improved transfer quality. A path setting section specifies a path between nodes for a receiving side as a bundled link which can have a plurality of paths tied up. A transmission-side route-information advertisement section advertises route information in a network when recognizing that the path has been established. A path recognition section recognizes the path and sets the path as a bundled link. A receiving-side route-information advertisement section advertises the route information in the network when recognizing that the path has been established.

Owner:FUJITSU LTD

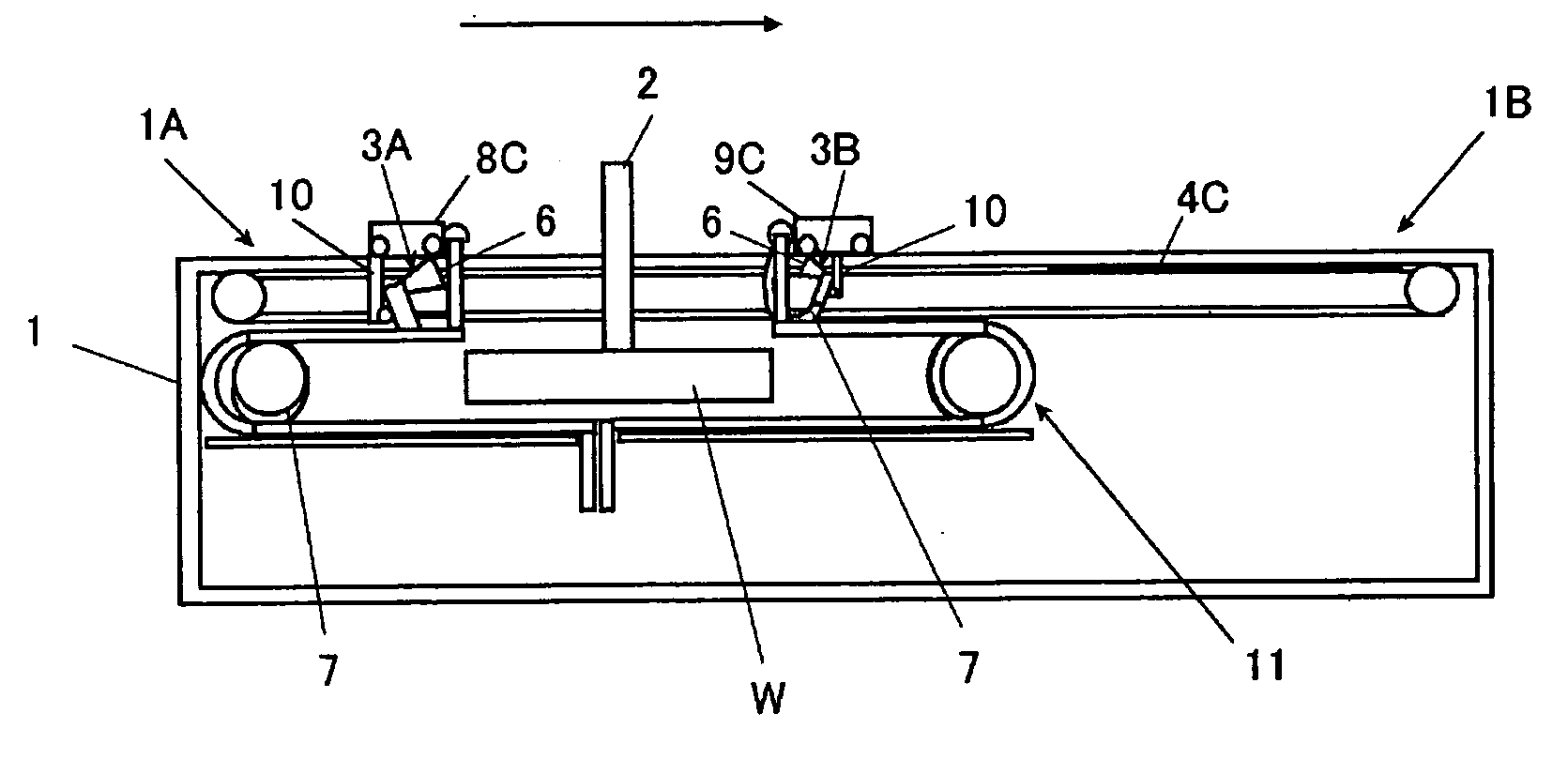

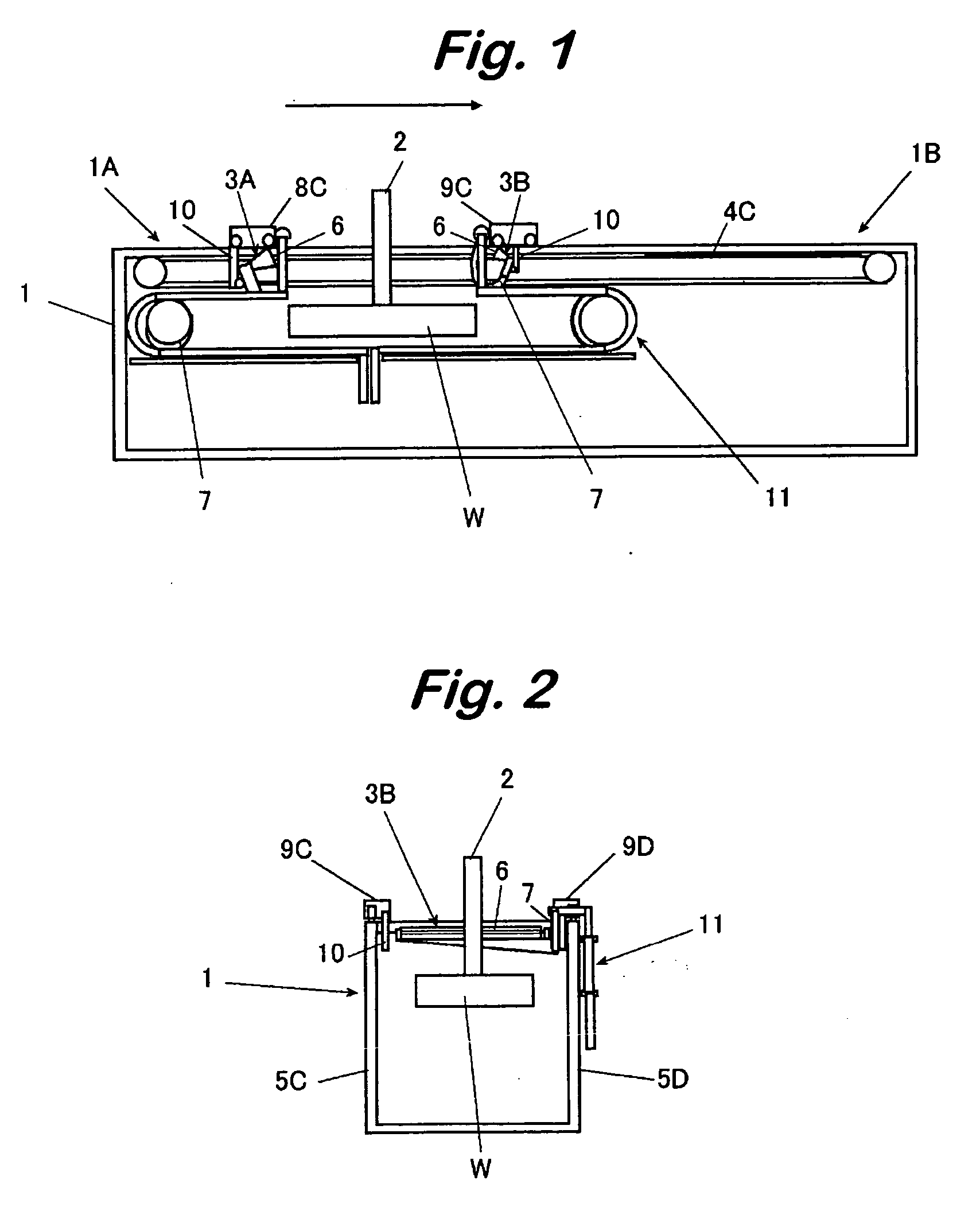

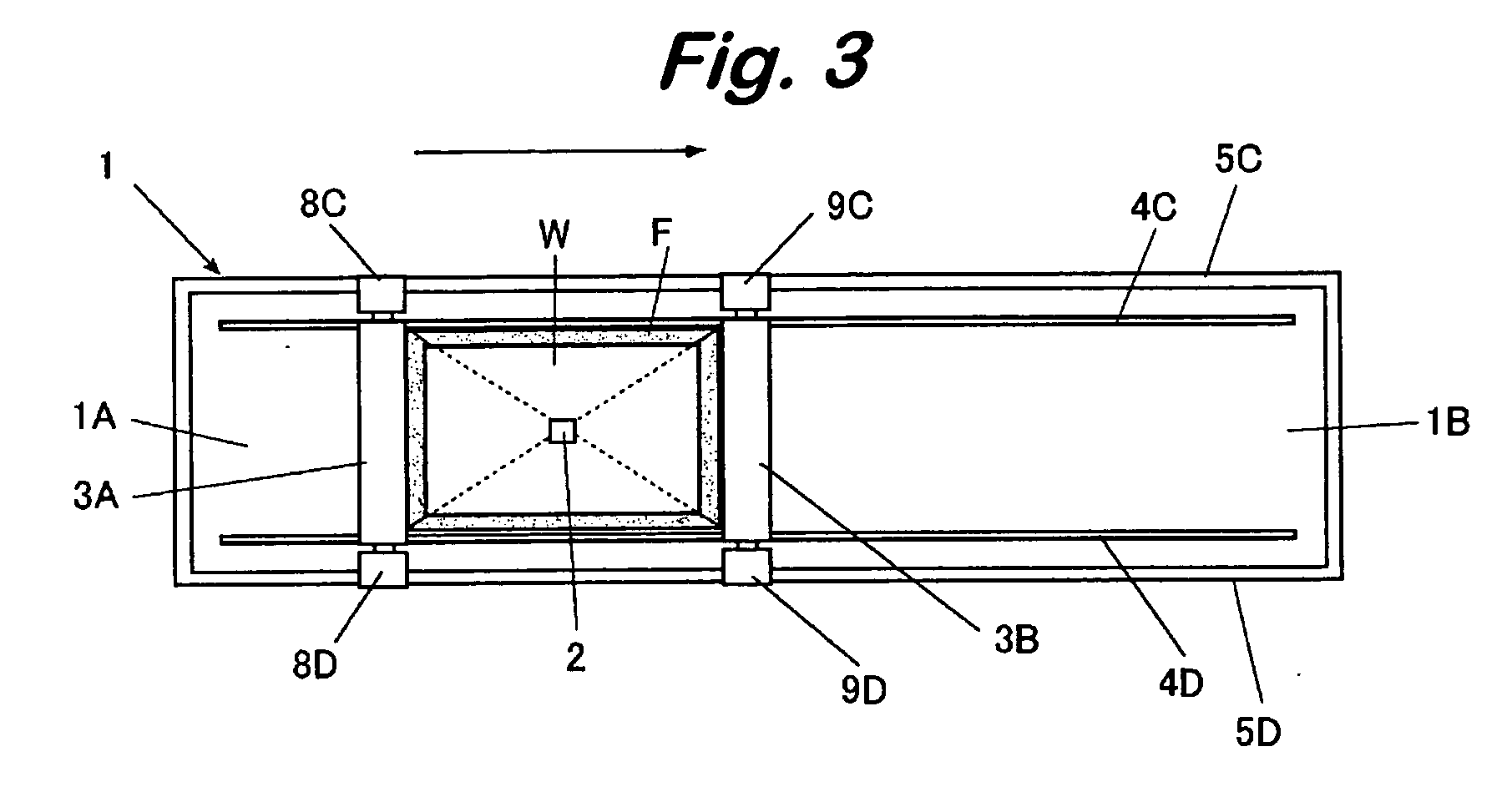

Liquid pressure transfer printing apparatus

InactiveUS20060162583A1Avoid depositionSimple compositionTransfer printingDecorative surface effectsAdemetionineExit side

A liquid pressure transfer printing apparatus in which a work to be applied with transfer printing is urged onto a film for applying liquid pressure transfer printing supplied to the surface of a liquid in a tank for liquid pressure transfer printing to submerge the film into the liquid comprises a pair of gates each having a suction mechanism for sucking residues not transferred to the submerged work but remained on the surface of the liquid in the tank from the inlet side and the exit side of the tank while the work W is submerged in the liquid, thereby capable of preventing the residues of the film remained on the surface of the liquid in the tank not transferred to the surface of the work from depositing to the surface of the work and forming seeds.

Owner:TRINITY IND CORP

Heat transfer printing solvent-proof label paper and processing method thereof

InactiveCN102888786AGood solvent resistanceWon't fadeCoatings with pigmentsSpecial paperTectorial membraneAlcohol

The invention relates to heat transfer printing solvent-proof label paper which comprises label base material, pressure-sensitive glue coated on the label base material, and release paper below the pressure-sensitive glue. The heat transfer printing solvent-proof label paper is characterized in that a solvent-proof coating is coated on one printed side of the label base material and formed by combining a mixture of alcohol-resistant resin, acrylic acid resin, titanium dioxide, talcum powder and the like; and the glue adopts acrylic acid series, rubber series or organic silicon series. The solvent-proof coating on the surface has an excellent solvent-proof property, can be wiped under the solvent and 1kg of pressure without color fading, the heat transfer printing and the printing quality can be prompted through the solvent-proof coating on the surface, another protective film is not required after the treatment is conducted, and the cost is effectively saved.

Owner:朱向忠

Image forming apparatus

ActiveUS8447217B2Accurate transferLow transfer rateElectrographic process apparatusImage formationEngineering

A toner image can properly be transferred onto the second side of a paper sheet without being influenced by the toner image on the first side. There are provided a detection unit 20 for detecting overlap of the toner images on the first side and the second side of the paper sheet based on image data, and a transfer output adjustment unit 22 which changes a transfer voltage output for the second side in an area with the overlap of the toner images depending on the toner adhering amount of the first side.

Owner:KONICA MINOLTA BUSINESS TECH INC

Thermal dye sublimation transfer film

InactiveCN106700731AImprove wear resistanceImprove antioxidant capacityInksThermographyDisperse dyePolyvinyl alcohol

The invention discloses a thermal dye sublimation transfer film which comprises a base film, wherein the surface of the base film is coated by a printed layer; the printed layer comprises 5-30 parts of dispersed dye slurry, 2-20 parts of resin, 2-15 parts of hydroxymethyl cellulose, 1-10 parts of a bactericide, 2-15 parts of xylene, 1-10 parts of paraffin, 2-15 parts of a surfactant, 1-10 parts of aluminum oxide, 1-15 parts of a thickening agent, 1-10 parts of a neutralizer, 1-15 parts of polyacrylamide, 1-10 parts of a polysaccharide derivative, 1-15 parts of polyvinyl alcohol, 1-10 parts of an ink medium adsorbent, 1-12 parts of starch, 2-10 parts of a preservative, 1-10 parts of a defoaming agent, 1-15 parts of cellulose, 1-15 parts of kaolin, 1-15 parts of calcium carbonate, 4-10 parts of nano titanium dioxide powder, 1-15 parts of superfine tin antimony oxide powder, 2-10 parts of sodium alginate, 1-20 parts of deionized water, 4-8 parts of bis-imidazoline quaternary ammonium corrosion inhibitor and 1-20 parts of thiophene aqueous dispersion. The thermal dye sublimation transfer film is simple in preparation process, and the prepared ink is good in corrosion resistance, wearing resistance, oxidation resistance, water resistance and adhesion property.

Owner:SUZHOU JIGU NEW MATERIAL CO LTD

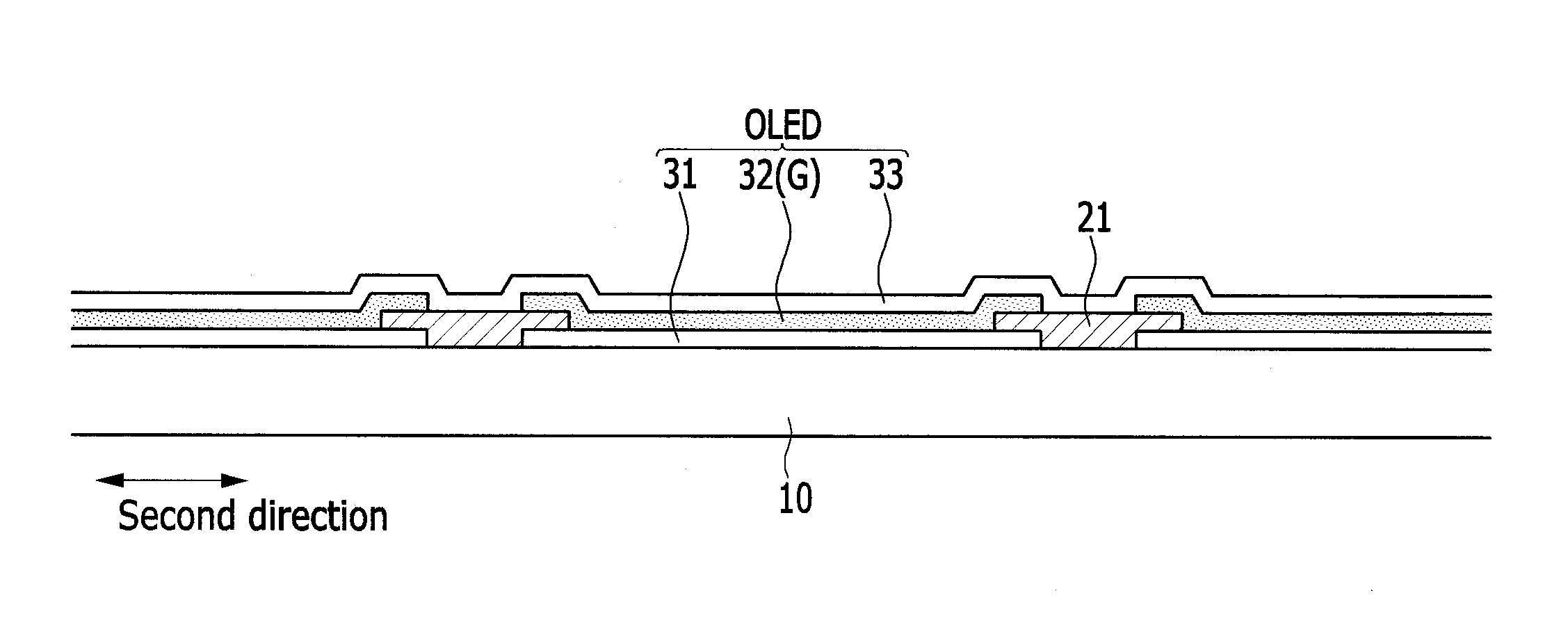

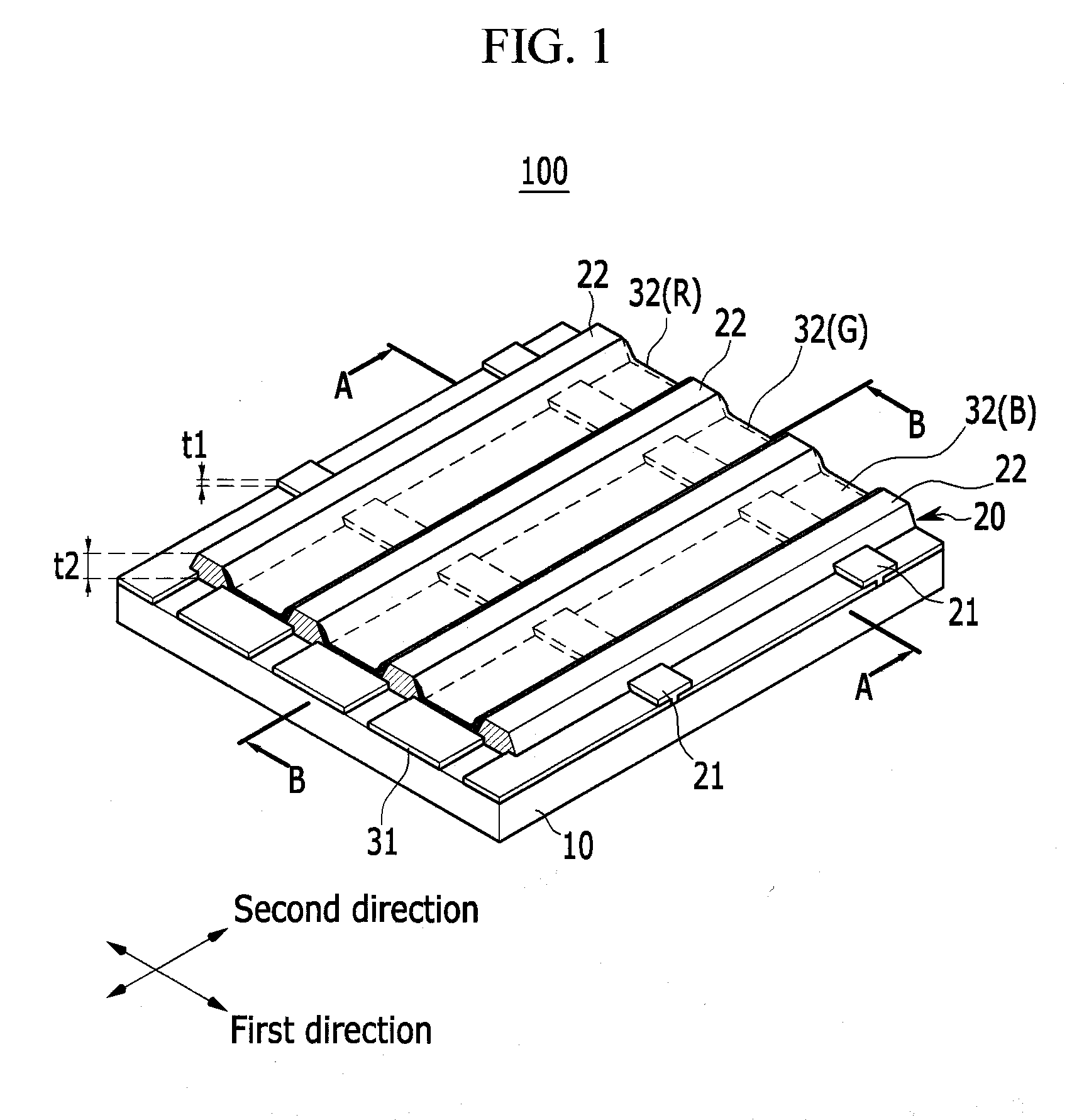

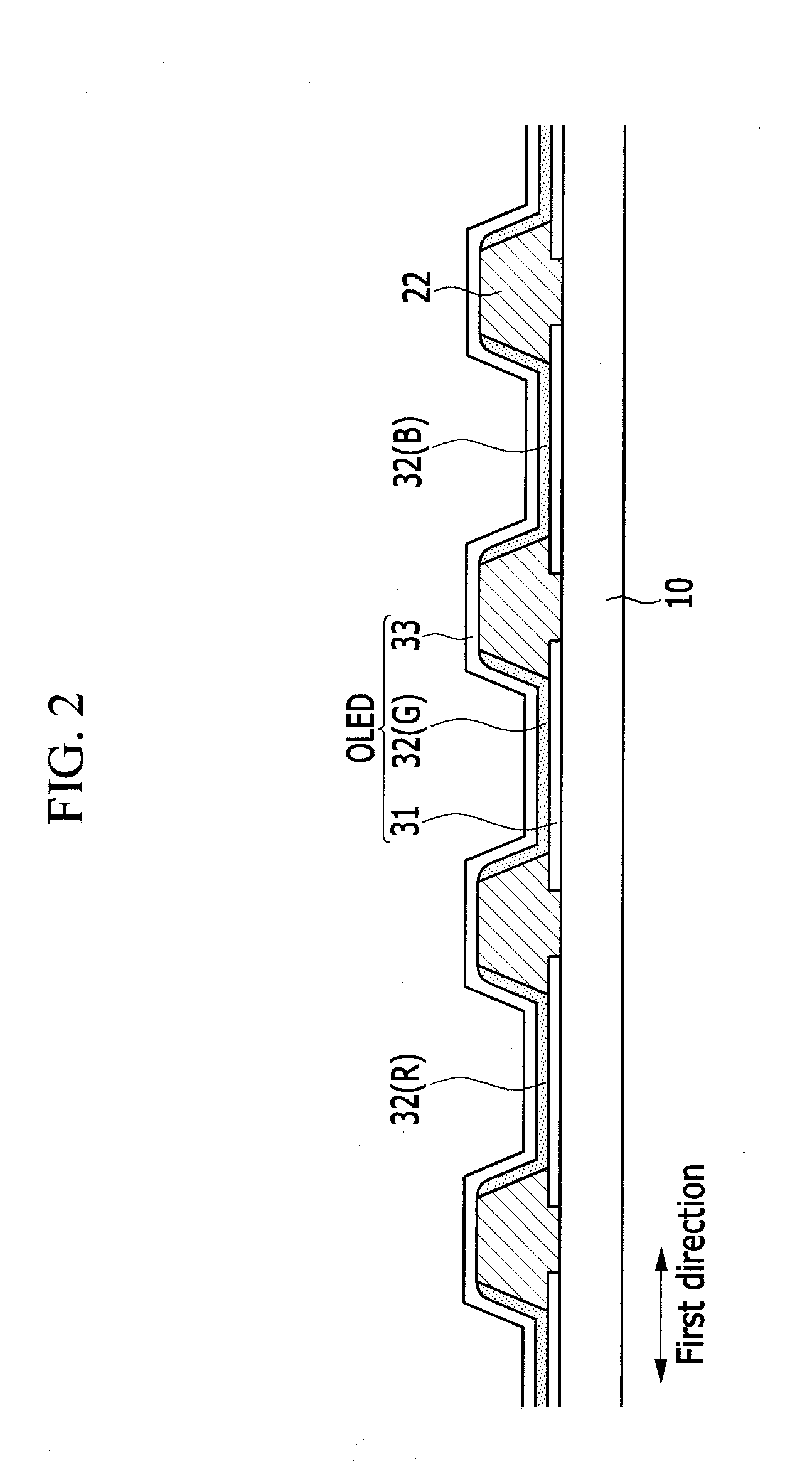

Organic light emitting diode display and manufacturing method thereof

ActiveUS20140191219A1Improve transfer qualitySolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceLight-emitting diode

An organic light emitting diode (OLED) display includes: pixel electrodes formed on a substrate; a pixel definition layer between the pixel electrodes and partitioning a pixel area; organic emission layers of a plurality of colors on the pixel electrodes; and a common electrode on the organic emission layers. The pixel definition layer includes a first pattern and a second pattern having different formation materials, thicknesses, and extension directions.

Owner:SAMSUNG DISPLAY CO LTD

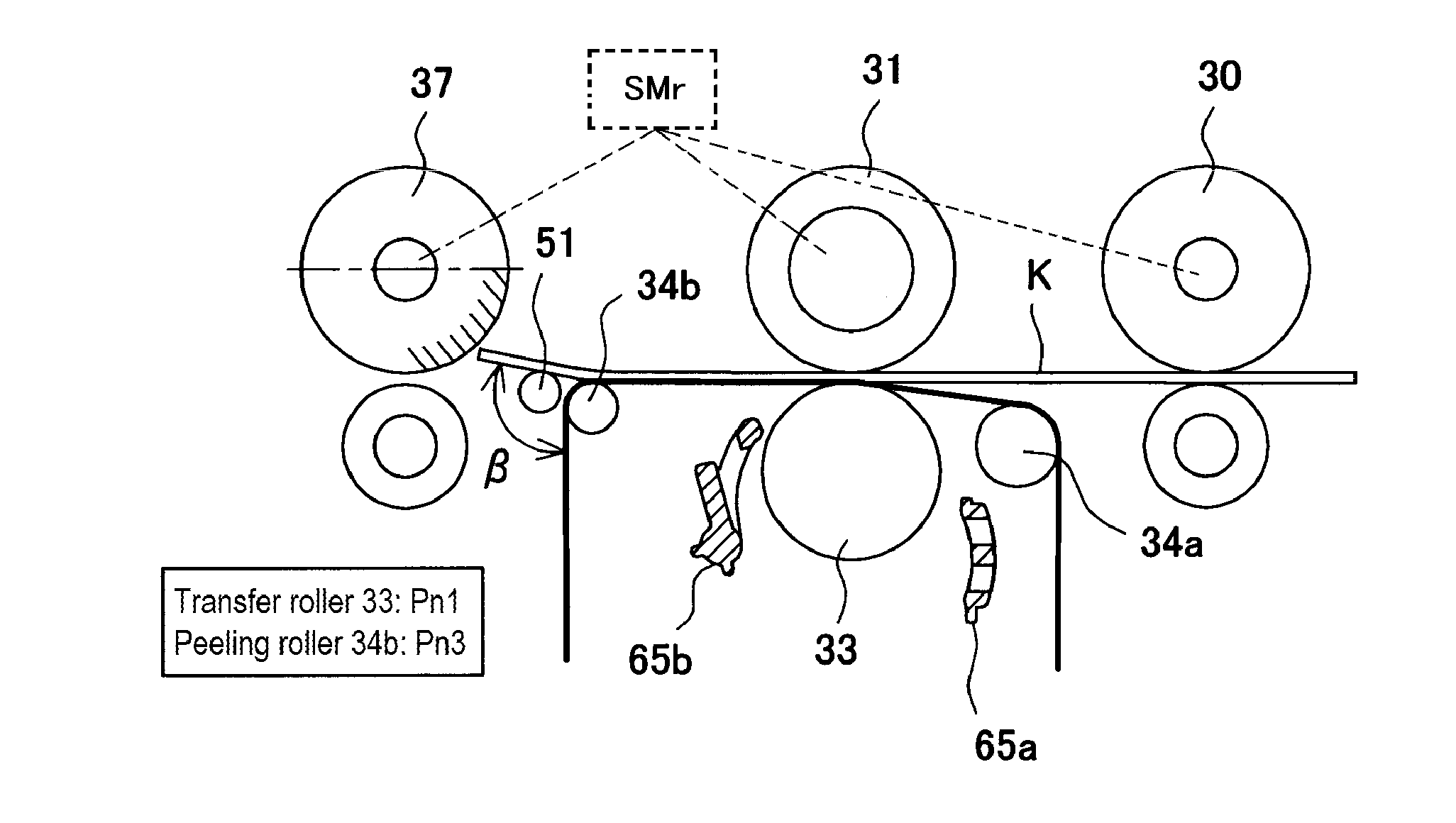

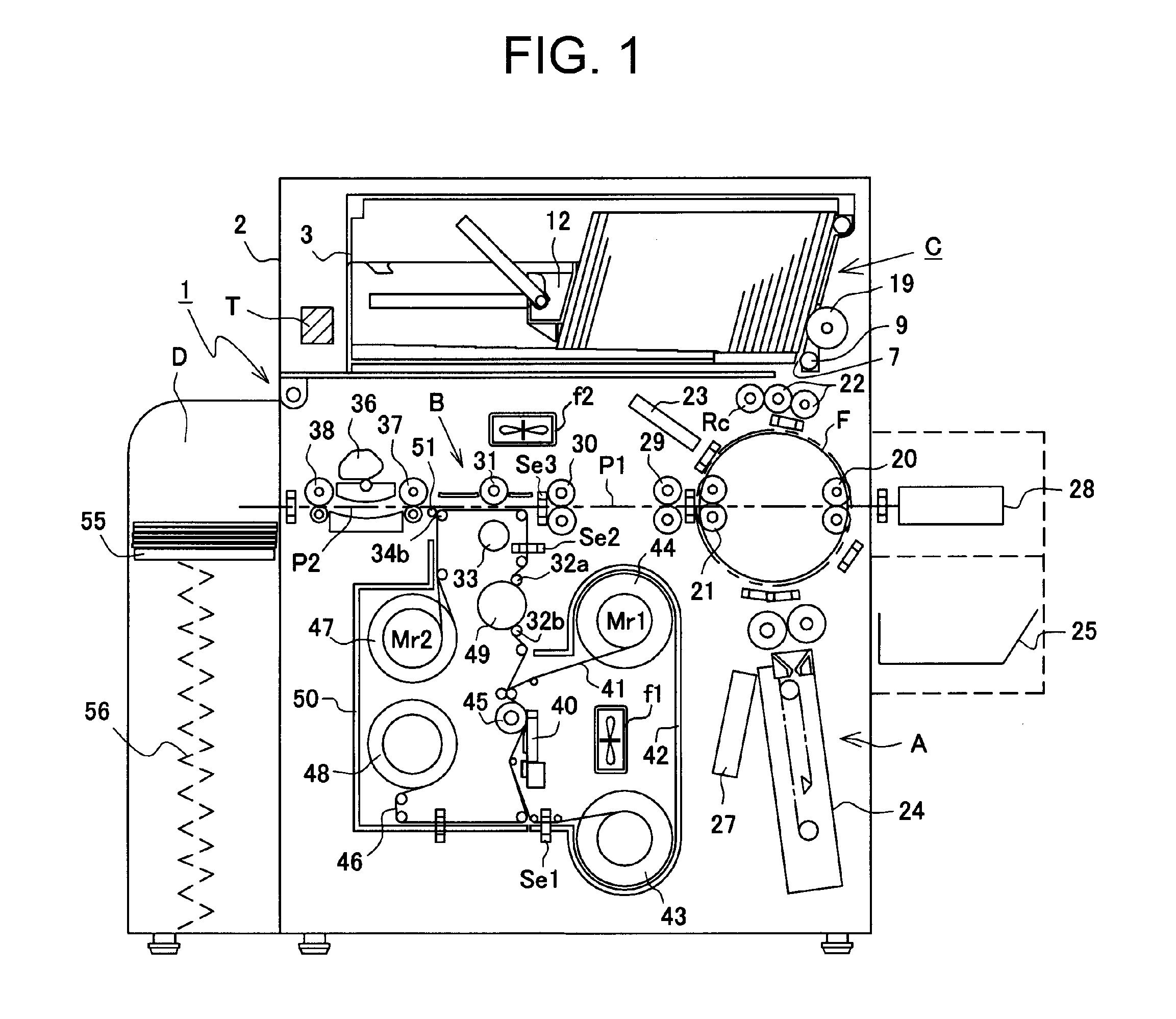

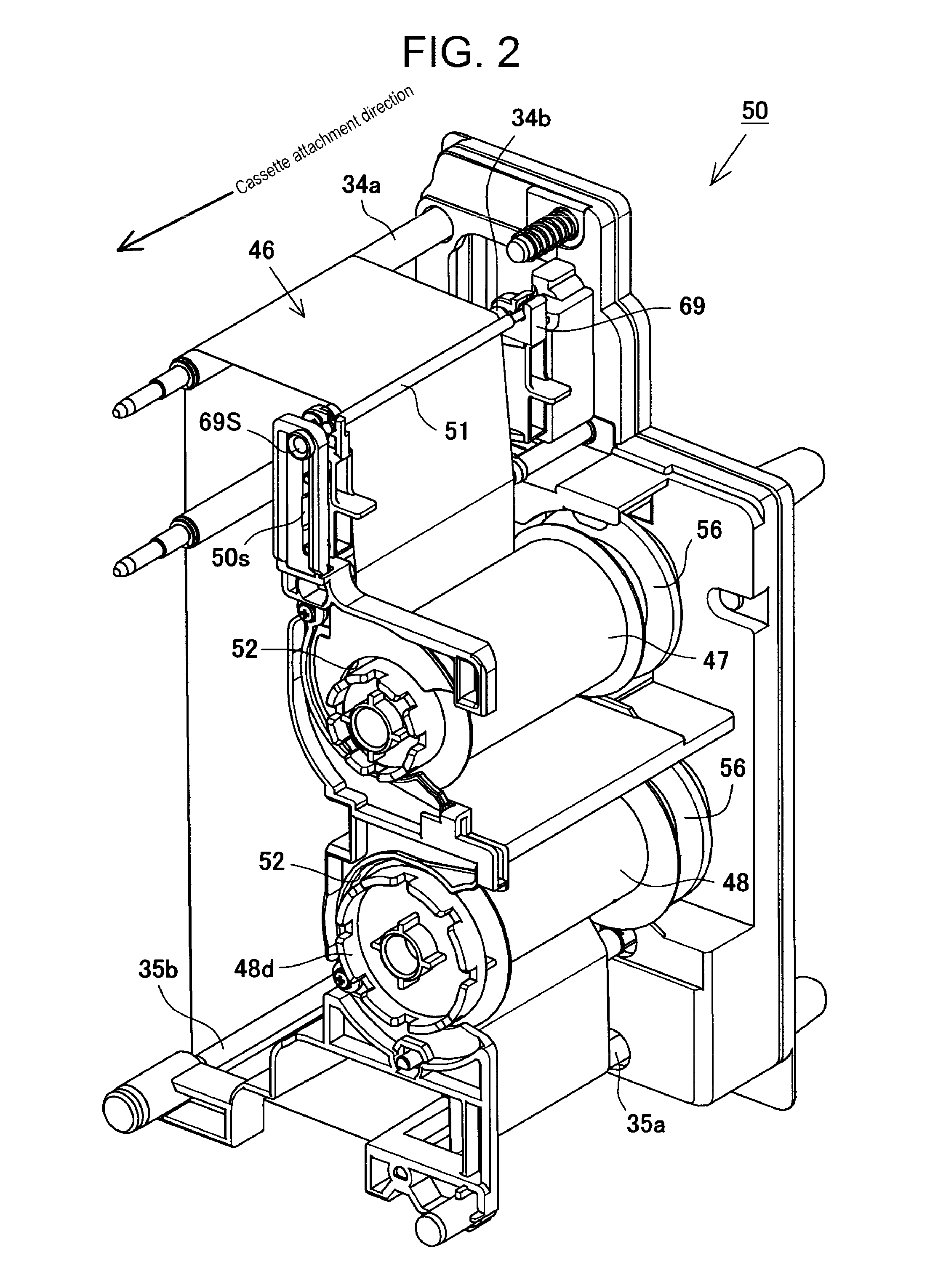

Transfer device

ActiveUS20160185125A1Quality improvementIncrease delivery speedPrinting mechanismsRecording apparatusEngineeringMechanical engineering

The present invention is to eliminate loosening of a transfer film on a rear end side of a card caused due to collision of a front end of the card against a conveying roller pair provided downstream of a transfer roller to prevent wrinkles from occurring in a transferred image. A rotation amount of a card conveying motor SMr and a wind amount of a transfer film 46 (conveying amount of the transfer film) are compared after a front end of a card K rushes into a conveying roller pair 37 during transfer processing for the card K to thereby detect a slip amount of the card K. A card conveying speed and a transfer film feed speed are controlled in accordance with the detected slip amount so as to eliminate loosening of the transfer film 46.

Owner:NISCA KK

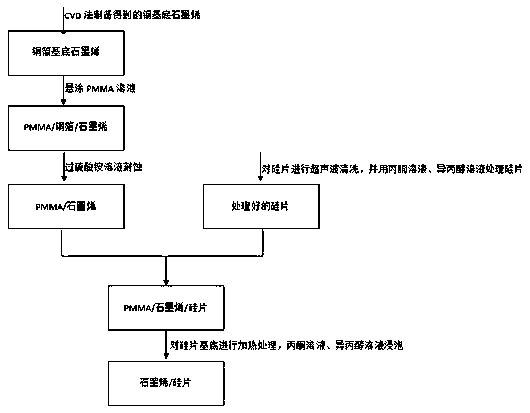

Graphene transfer method taking copper foil as substrate

The invention relates to a method for transferring graphene on a copper foil substrate. The method comprises the following steps of: firstly, airing the graphene on the copper foil substrate; suspending and coating a prepared PMMA solution on the graphene / copper foil to form a PMMA / graphene / copper foil composite layer; and etching by using an ammonium persulfate solution. In order to improve the transfer quality of graphene, acetone and isopropanol are used for treating a silicon wafer in advance, then the PMMA / graphene composite layer is placed on the silicon wafer, then the silicon wafer substrate is heated, then the composite layer is soaked in an acetone solution to remove the PMMA solution, and finally the silicon substrate graphene is successfully obtained. According to the method, the defects of wrinkles, cracks and the like of the transferred graphene are reduced, the metal particles on the target substrate are removed to the greatest extent, the hydrophilicity is enhanced, andthe transfer quality of the graphene is improved.

Owner:南通晶锐新型碳材料科技有限公司

Transfer printing plate pretreatment device and transfer printing device

ActiveCN107728386AImprove ductilityImprove wettabilityPretreated surfacesCoatingsExtensibilitySlope angle

The invention provides a transfer printing plate pretreatment device and a transfer printing device. The transfer printing plate pretreatment device comprises a driving roller and a pressure roller which are correspondingly arranged, the driving roller comprises a heating layer, the heating layer is used for heating a transfer printing plate laid on the driving roller, and the pressure roller is used for extruding the transfer printing plate laid on the driving roller, so that the wetting property of the transfer printing plate is improved. According to the transfer printing plate pretreatmentdevice, slope angles of mesh openings of a mesh opening layer of the transfer printing plate are microcosmically increased, so that contact angles between transfer printing liquid and the transfer printing plate are macroscopically decreased, the extensibility of the transfer printing plate and the elasticity of the mesh opening layer are improved, so that the mesh opening layer of the transfer printing plate is easily wetted by the transfer printing liquid, the wetting property of the transfer printing plate is improved, laying of the transfer printing liquid on the transfer printing plate is facilitated, transfer printing effects of the transfer printing liquid is improved, thickness uniformity of a coating formed after transfer printing of the transfer printing liquid is improved, wetting time of the transfer printing plate can be shortened, the operation ratio of the transfer printing plate pretreatment device is increased, and the wetting effects of the transfer printing plate can be kept for a longer time.

Owner:HEFEI BOE OPTOELECTRONICS TECH +1

Energy-saving type sublimation transfer paper

InactiveCN106676960AGood ink transfer abilityImprove wear resistanceCoatings with pigmentsPaper/cardboardAcrylic resinPolyethylene glycol

The invention discloses energy-saving type sublimation transfer paper which comprises a substrate, a binder and a coating layer coating the surface of the substrate, wherein the coating volume of the coating layer on the surface of the substrate is 4-15g per square meter; the coating layer comprises 1-10 parts of saccharose, 1-15 parts of pentaerythritol, 5-30 parts of carboxymethylcellulose, 2-15 parts of polyethylene glycol fatty acid ester, 2-10 parts of bactericide, 2-20 parts of inkjet medium adsorbent, 5-20 parts of starch, 5-20 parts of acrylic resin, 2-15 parts of tall oil fatty acid, 1-15 parts of polyacrylamide, 1-10 parts of polysaccharide derivative, 2-20 parts of poly-citric acid, 1-15 parts of silicon dioxide, 1-15 parts of aluminum oxide, 1-15 parts of titanium dioxide, 1-15 parts of kaolin, 1-15 parts of calcium carbonate, 4-10 parts of nanometer titanium dioxide powder and 8-15 parts of superfine tin antimony oxide powder. The preparation technology according to the invention is simple. The prepared printing ink has excellent ink loading capacity, corrosion resistance, abrasive resistance, oxidation resistance, water tolerance and adhesive ability.

Owner:SUZHOU JIGU NEW MATERIAL CO LTD

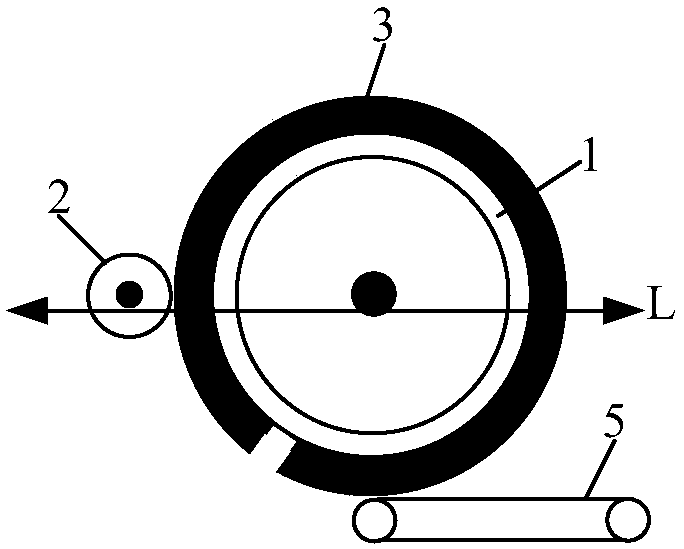

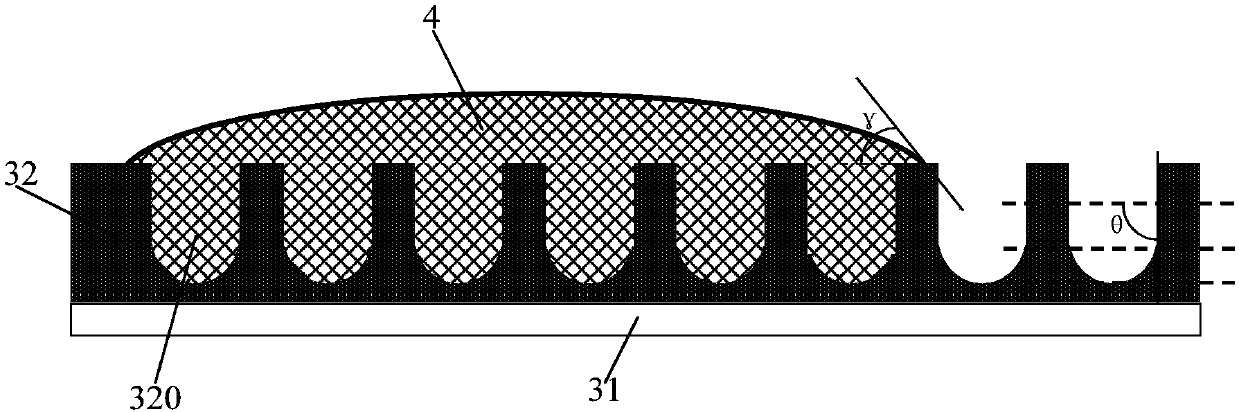

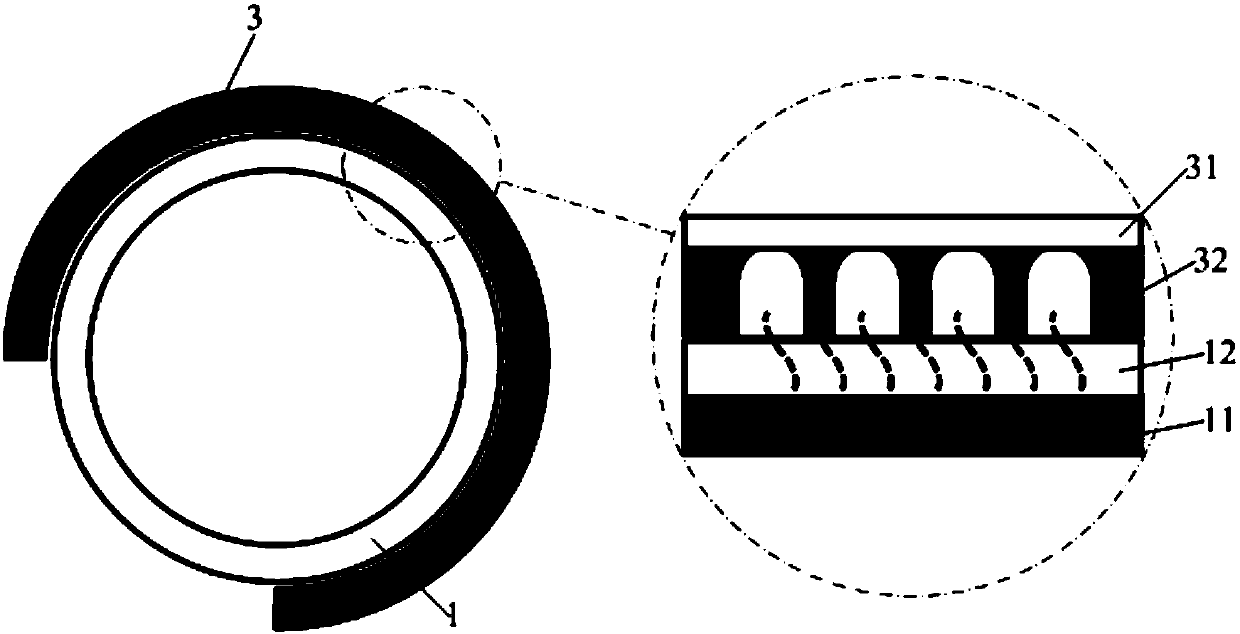

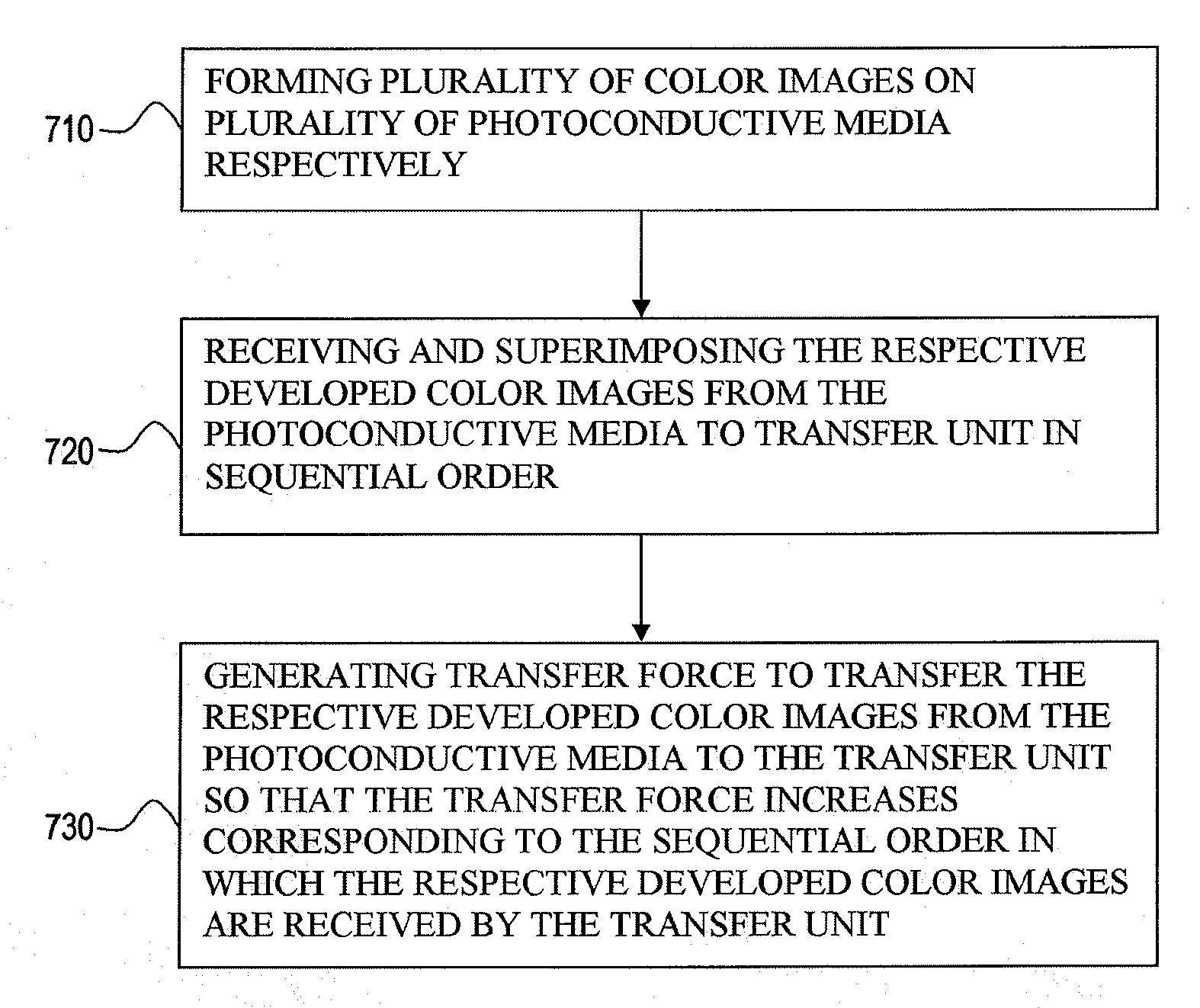

Image forming apparatus and control method thereof

InactiveUS20080298828A1Facilitate transmissionReduce the amount of solutionElectrographic process apparatusCorona dischargeLatent imageControl manner

An image forming apparatus capable of varying a transferring force according to an amount of developer, thereby improving transfer quality, and a control method thereof. The image forming apparatus includes a plurality of photoconductive media on which electrostatic latent images are formed, a transfer unit onto which color developer images respectively developed on the plurality of photoconductive media are transferred and superimposed in sequence, and a controller to control in a manner that electric potential differences between image areas and non-image areas of the electrostatic latent images vary in an order in which the color developer images are transferred.

Owner:HEWLETT PACKARD DEV CO LP

Offset print water-borne UV (ultraviolet) photo-sensitive resist jetting plate-making method

InactiveCN102176107AEliminate exposure washoutOmit retouchingPhotomechanical apparatusPrintingResistUltraviolet

The invention discloses an offset print water-borne UV (ultraviolet) photo-sensitive resist jetting plate-making method which comprises the following steps: firstly jetting a water-borne UV photo-sensitive resist on a hydrophilic metal base by using an ink-jet printing device, and forming an oiliness information recording region on the surface of the metal base; and in addition, curing a information recording region on the surface of the metal base by using an ultraviolet lamp, and then printing on the machine. The offset print water-borne UV photo-sensitive resist jetting plate-making method is simple in process, rapid in printing plate drying speed, less in energy consumption, good in printing plate quality, good in printing-resistance rate, and free from environment pollution.

Owner:XIAN UNIV OF TECH

Sublimation printing stainless steel and preparation method thereof

InactiveCN106564343AEasy to viewImprove clarityDecorative surface effectsInksDisperse dyeAcrylic resin

The invention discloses sublimation printing stainless steel and a preparation method thereof. The sublimation printing stainless steel comprises a stainless steel body. The front face and the back face of the stainless steel body are each coated with a dewatering resin coating layer, the outer surface of each dewatering resin coating layer is covered with a layer of printed transfer printing film, the surface of each transfer printing film is coated with a hydrophilic material layer, and the surface of each hydrophilic material layer is printed with a layer of heat transfer printing ink. The heat transfer printing ink comprises, by weight, 25-45 parts of disperse dyes, 8-17 parts of carboxymethylcellulose, 3-12 parts of viscosity modifier, 3-8 parts of a surface active agent, 4-12 parts of sodium lignin sulfonate, 3-7 parts of inorganic oxide, 2-6 parts of preservative, 5-15 parts of corrosion inhibitor, 3-13 parts of styrene acrylic resin and 3-12 parts of polyvinyl alcohol. The preparation method is simple, a printed pattern on the prepared stainless steel is high in definition and not prone to falling off and improves the ornamental value of the stainless steel, and the degree of adhesion is achieved.

Owner:SUZHOU JIGU NEW MATERIAL CO LTD

Transfer apparatus for transferring an image of a developer in a printer and method for calibrating the heating system thereof

InactiveUS7809316B2Constant qualityImprove transfer qualityOhmic-resistance heatingElectrographic process apparatusTemperature differenceHeating system

A transfer apparatus for transferring an image of a developer from an image-bearing medium onto an image receiving medium in a transfer zone includes a heating device that heats the image-bearing medium, an adjustable power supply device that supplies electrical power to the heating device, a first temperature sensor for sensing a basis temperature in the vicinity of the image-bearing medium away from the transfer zone and for transmitting to a controller a signal indicative of the basis temperature. The controller is adapted to adjust the power supplied by the power supply device to the heating device to obtain a target temperature in the transfer zone, in response to the signal indicative of the sensed basis temperature and based on a pre-established relationship between the power supplied to the heating device and a temperature difference between a temperature in the transfer zone and the basis temperature.

Owner:OCE TECH

Antistatic coating for heat sublimation transfer printing

InactiveCN106479275AImprove antistatic performanceImprove wear resistanceElectrically-conductive paintsElectrostatic coatingAntimony tin oxide

The invention discloses an antistatic coating for heat sublimation transfer printing, the antistatic coating comprises the following components by weight: 15-25 parts of carboxymethylcellulose, 4-10 parts of nano titanium dioxide powder, 8-15 parts of ultrafine antimony tin oxide powder, 10-18 parts of starch, 15-25 parts of polyacrylamide, 10-20 parts of sodium alginate, 4-10 parts of bentonite powder, 5-10 parts of diatomite powder, 4-8 parts of phenolic resin, 4-8 parts of quaternary ammonium bis-imidazoline corrosion inhibitor and 10-20 parts of thiophene water dispersion, the antistatic coating has the advantage of simple preparation process, the prepared antistatic coating has excellent antistatic capacity, also has good abrasion resistance, oxidation resistance, water resistance and adhesion ability.

Owner:SUZHOU JIGU NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com