Water transfer printing production line

A water transfer printing and production line technology, applied in transfer printing, rotary printing machines, printing, etc., can solve the problems of high labor intensity for operators, unstable product quality, cumbersome operating procedures, etc., to improve the quality of water transfer printing, Guarantee the quality of water transfer printing and ensure the effect of air-drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

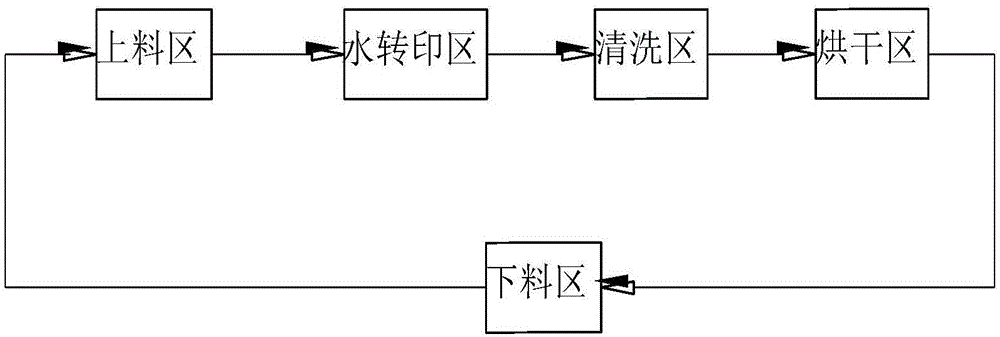

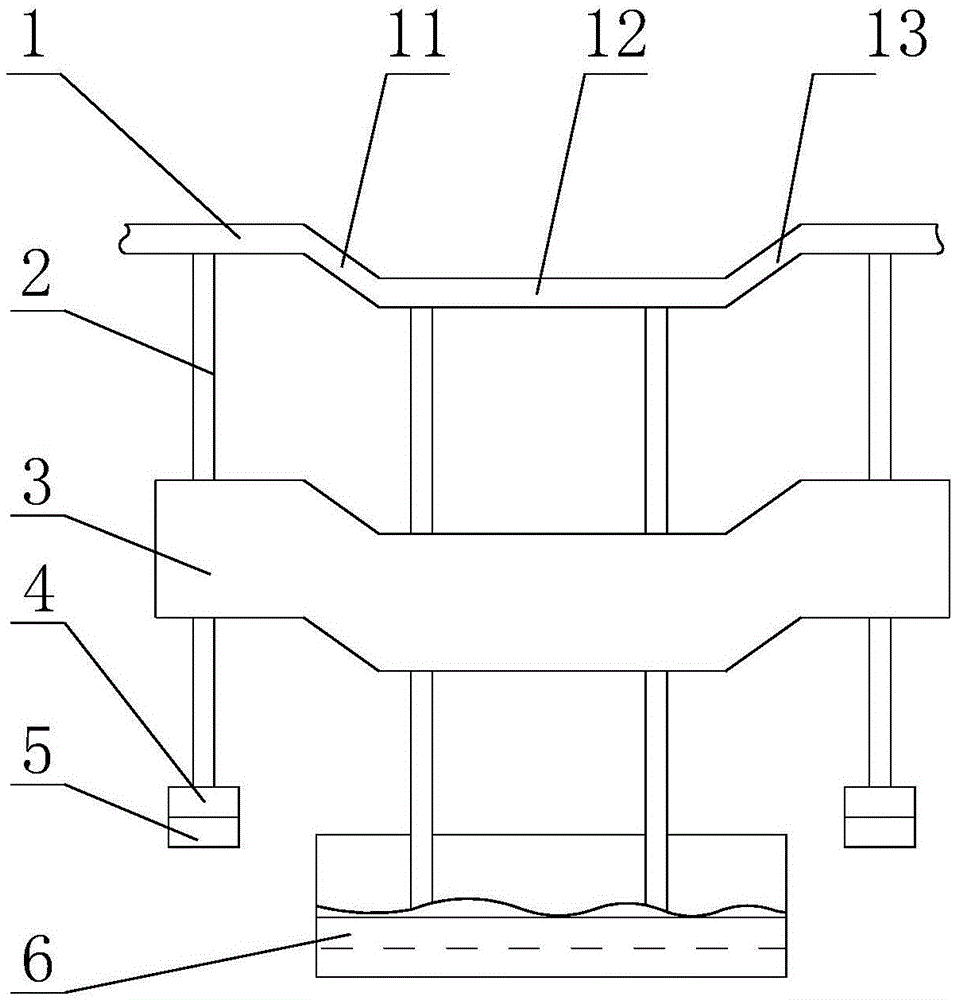

[0038] The water transfer printing production line of the present invention includes a hanging system for transporting the workpiece 5 and a feeding area, a water transfer printing area, a cleaning area, a drying area, and a feeding area arranged below the hanging system in sequence. The hanging system includes a guide rail 1 for automatically transporting the workpiece 5, a hanging rod 2 arranged on the guide rail 1 moving along the guide rail 1, and a clamp 4 arranged at the lower end of the hanging rod 2 for clamping the workpiece 5. The track of the guide rail 1 forms a closed curve.

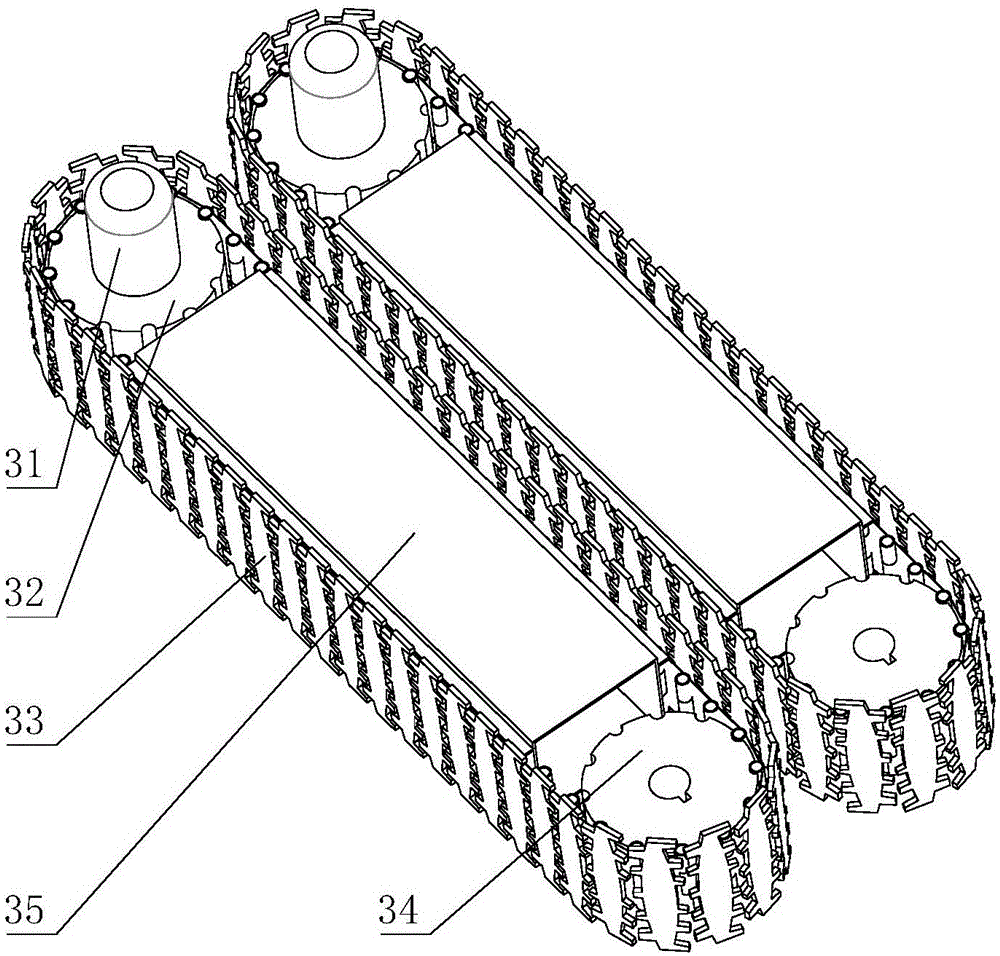

[0039] Specifically, the automatic transport function of the guide rail 1 adopts the existing chain drive structure, and a driven wheel is set at each reversing position, so that the track transport direction can be changed arbitrarily. Of course, it is no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com