Stable doping method for graphene

A graphene and graphene surface technology, which is applied in the field of stably improving the electrical properties of graphene films, can solve problems affecting the stability of square resistance, reduction of doping effects, disappearance, etc., to achieve improved time stability, quality, and stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

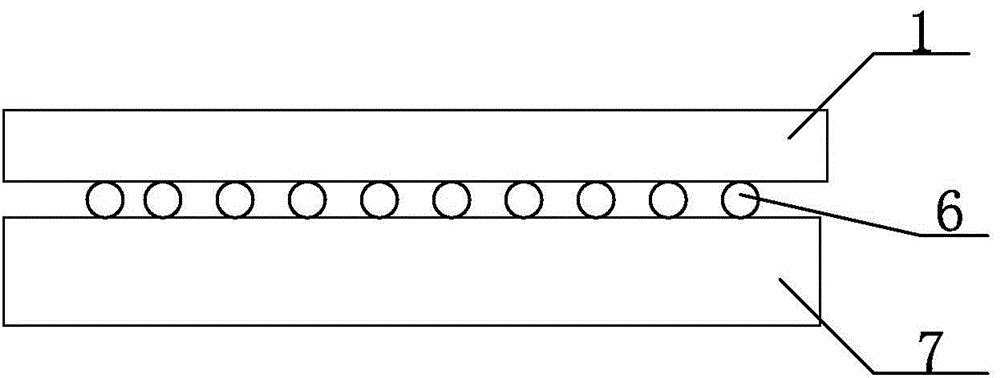

[0043] Such as figure 1 The graphene stable doping structure of the shown dopant between the substrate and graphene, the process is as follows Figure 8 As shown, the specific steps are as follows:

[0044] 1.1) Graphene is grown on the copper foil by CVD, and then the temporary substrate is pasted on the graphene;

[0045] 1.2) Put the copper foil into the etching solution, etch the copper foil to obtain a temporary substrate / graphene sample, and then put the graphene surface of the sample into the doping solution for doping, Then bond one side of the doped graphene to the substrate, then remove the temporary substrate to obtain a sample sheet with a dopant on the graphene surface, and finally obtain the substrate, dopant and graphene from bottom to top. sequential dailies; or,

[0046] Put the copper foil / graphene into the mixed solution composed of etching solution and doping solution, etch and dope at the same time, then attach the doped graphene side to the substrate, ...

Embodiment 2

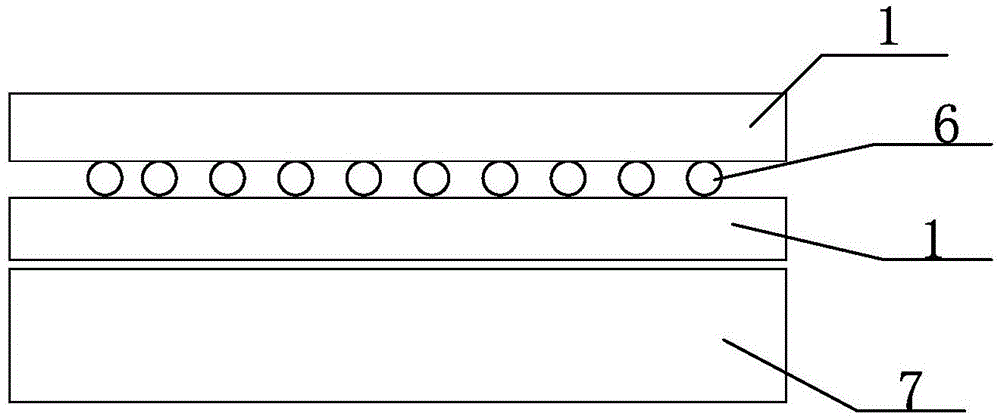

[0048] Such as figure 2 The stable doping structure of the shown dopant between the graphene and the graphene layer, the process is as follows Figure 9 As shown, the specific steps are as follows:

[0049] Step 1) Graphene is grown on the copper foil by CVD, and then the temporary substrate is pasted on the graphene;

[0050] Step 2) Put the copper foil into an etching solution, etch, wash and dry the copper foil to obtain a temporary substrate / graphene layer sample, and connect the graphene side of the sample to the substrate Bonding, and then remove the temporary substrate, then put the graphene surface into the doping solution for doping, after washing and drying, a sample with dopant on the graphene surface is obtained;

[0051] Step 3) the sample sheet that is provided with dopant on the graphene surface is pasted on the sample sheet of another temporary substrate / graphene layer, and then removes described temporary substrate, obtains successively from bottom to top as ...

Embodiment 3

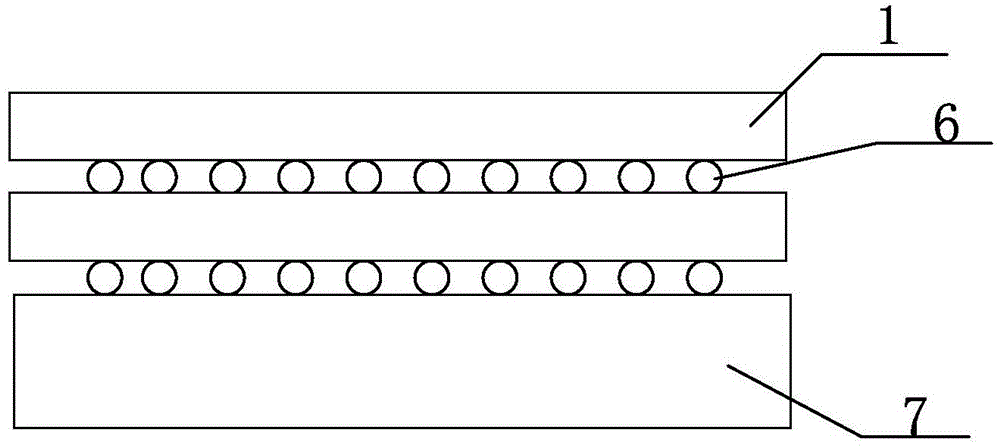

[0053] Such as image 3 The double-layer stable doping structure of the shown dopant between the substrate and graphene, graphene and graphene, the process is as follows Figure 8 , Figure 9 As shown, the specific steps are as follows:

[0054] The step of wrapping dopant reagent molecules between graphene and graphene is specifically as follows:

[0055] Step 1) Graphene is grown on the copper foil by CVD, and then the temporary substrate is pasted on the graphene;

[0056] Step 2) Put the copper foil into an etching solution, etch, wash and dry the copper foil to obtain a temporary substrate / graphene layer sample, and connect the graphene side of the sample to the substrate Bonding, and then remove the temporary substrate, then put the graphene surface into the doping solution for doping, after washing and drying, a sample with dopant on the graphene surface is obtained;

[0057] Step 3) the sample sheet that is provided with dopant on the graphene surface is pasted on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com