Graphene transfer method taking copper foil as substrate

A transfer method and graphene technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of residual metal solution, prone to cracks in graphene, low quality of graphene transfer, etc., achieving less damage, Improves overall transfer quality and reduces wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

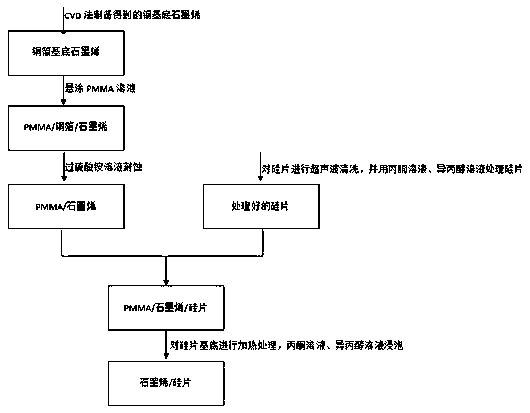

[0022] The scheme of the present invention will be described in more detail below in conjunction with the flow chart.

[0023] Such as figure 1 As shown, the specific steps of a copper foil substrate graphene transfer method provided in this embodiment are as follows.

[0024] (1) Adhere the copper foil graphene sample prepared by the chemical vapor deposition method on the cover glass with adhesive tape, and stick it on all four sides. If the copper sheet is not flat, flatten it with two coverslips.

[0025] (2) Place the above sample on the suspension coating apparatus, drop two drops of PMMA solution, and carry out suspension coating.

[0026] (3) After the application, gently tear off the tape, let it dry naturally, and do not bend the copper sheet.

[0027] (4) Put the copper sheet into the ammonium persulfate solution (concentration not exceeding 0.5ml / L) and let it stand for 3 minutes. Then take out the copper sheet, place the copper sheet in turn on the dust-free pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com