Directional liquid transfer method and device

A technology of orientation liquid and transfer roller, which is applied in nonlinear optics, instruments, optics, etc., can solve the problems of uneven pressure, inability to sense the substrate, and affect the quality of the alignment film, so as to improve the transfer quality and uniform pressure per unit area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

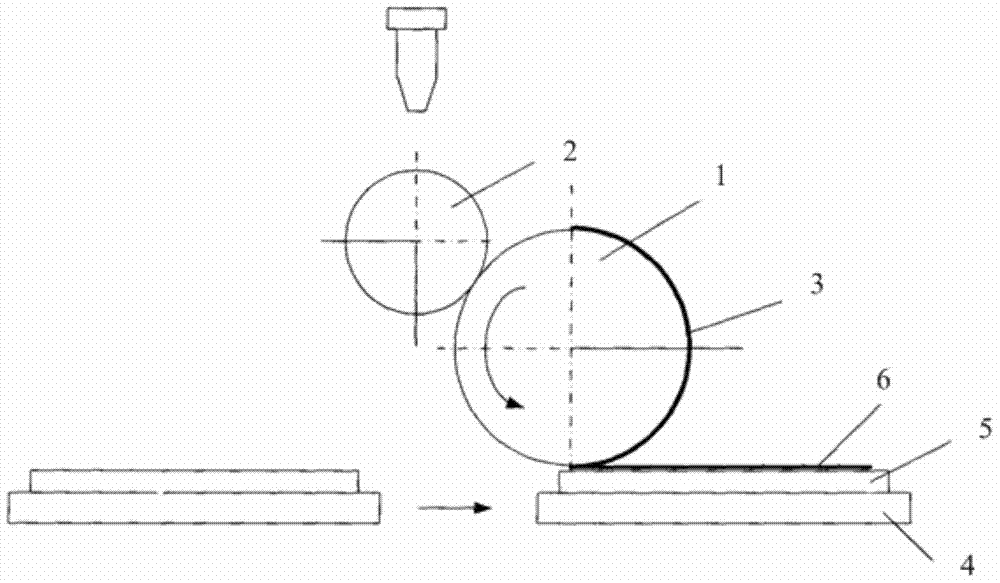

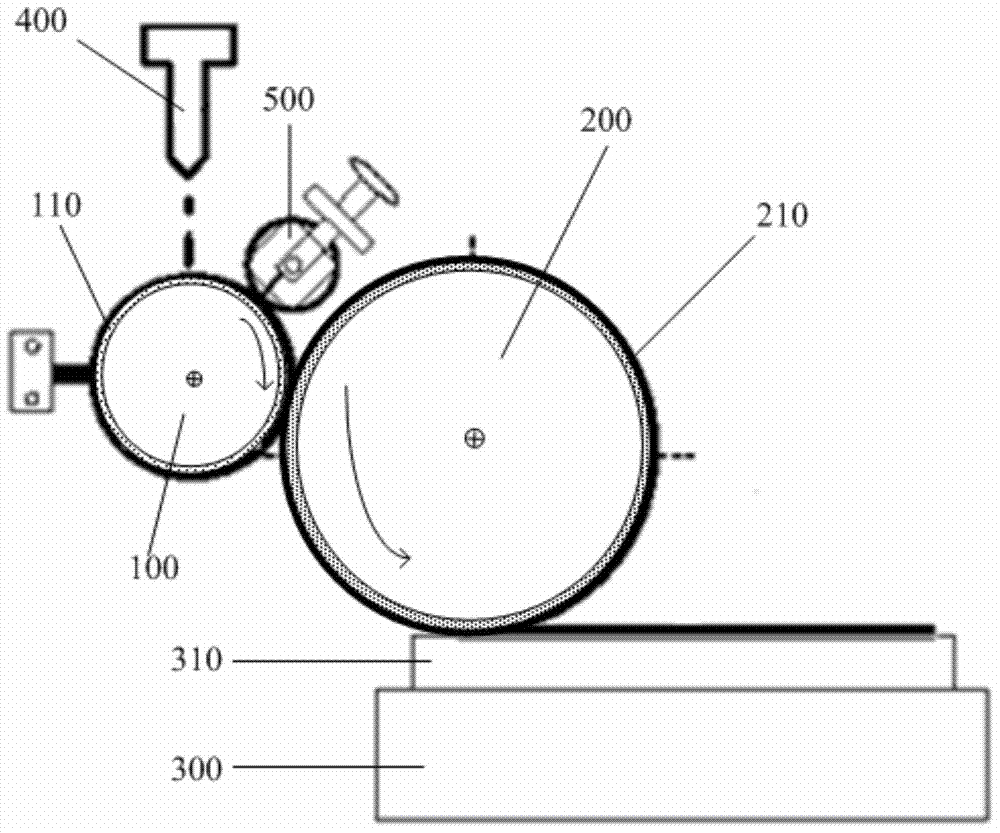

[0039] The specific implementation manners of the alignment liquid transfer method and the transfer device provided in the embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

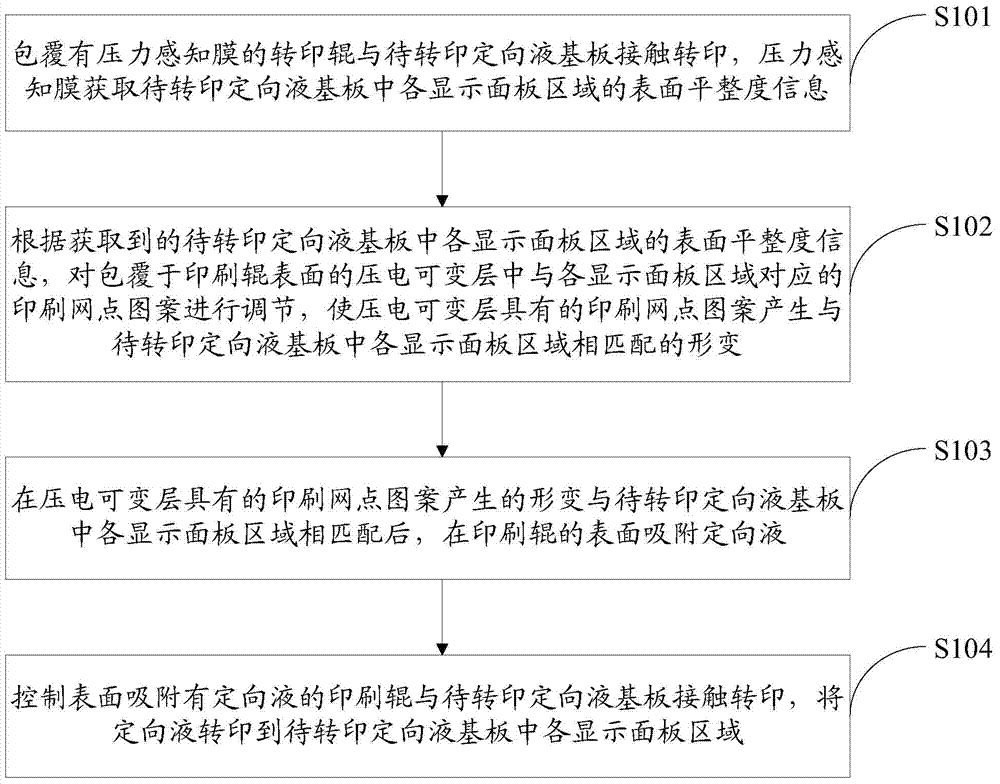

[0040] A method for aligning liquid transfer printing provided by an embodiment of the present invention, such as figure 2 As shown, it specifically includes the following steps:

[0041] S101. The transfer roller coated with the pressure-sensing film contacts and transfers the alignment liquid substrate to be transferred, and the pressure-sensing film acquires surface roughness information of each display panel area in the alignment liquid substrate to be transferred;

[0042] S102. According to the obtained surface flatness information of each display panel area in the alignment liquid substrate to be transferred, adjust the printing dot pattern corresponding to each display panel area in the piezoelectric variable layer covering the sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com