Gradient gel and preparation method thereof

A gel and gradient technology, applied in measuring devices, material analysis through electromagnetic means, instruments, etc., can solve the problems of insufficient transfer, slow electrophoresis speed, hindering the speed of protein molecules, etc., to speed up electrophoresis speed and strengthen wear Permeability, improve protein transfer rate and protein transfer quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

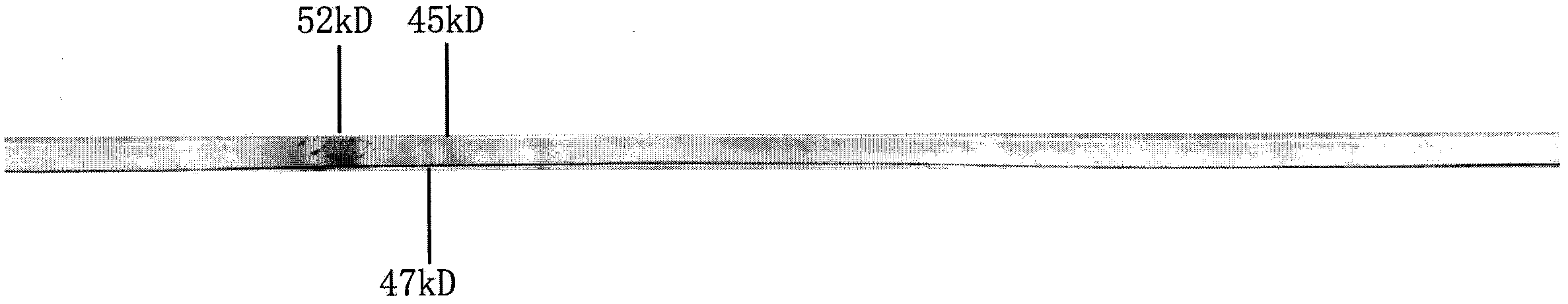

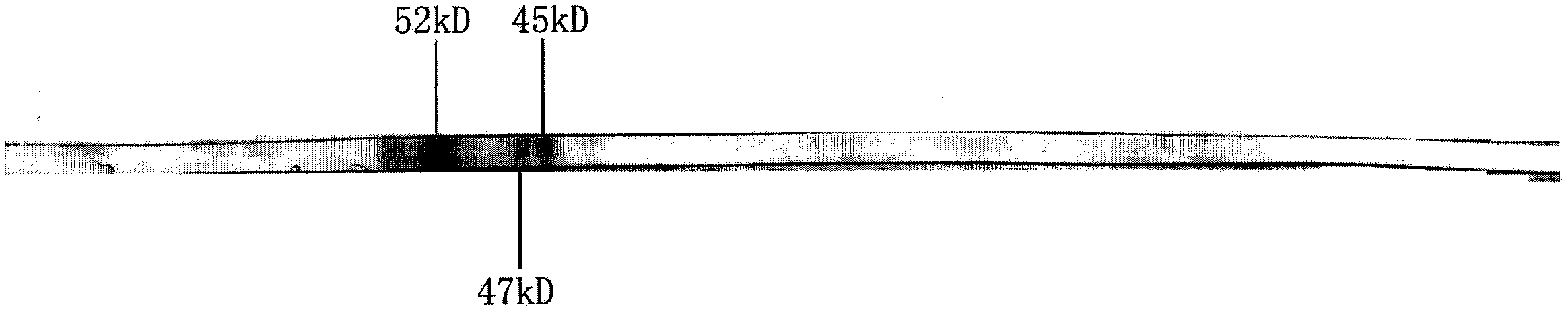

Image

Examples

Embodiment 1

[0015] 1. Prepare separation gel: mix H 2 O, acrylamide stock solution, separating gel buffer, 10% SDS, and ammonium persulfate are adjusted to 8%, 10%, 13%, and 15% concentration of separating gel in a certain proportion. The formulations of these two different concentrations of separating gels are as follows:

[0016] (1) The separation gel with a concentration of 8%: 7.8mL H 2 O, 3.3mL acrylamide separation gel stock solution, 7.01mL separation gel buffer, 0.19mL10% SDS, 0.42mL16mL / mL ammonium persulfate;

[0017] (2) The concentration is 15% separating gel: 0.78mL H 2 O, 9.5mL acrylamide separation gel stock solution, 7.01mL separation gel buffer, 0.19mL 10% SDS, 0.42mL 16mL / mL ammonium persulfate.

[0018] 2. Prepare concentrated gel: mix 13.3mL H 2 O, 1.8 mL of acrylamide stacking gel stock solution, 2.3 mL of stacking gel buffer, 0.19 mL of 10% SDS, and 0.42 mL of 16 mL / mL ammonium persulfate were prepared to form a stacking gel.

[0019] 3. Take two test tubes, na...

Embodiment 2

[0021] 1. Prepare separation gel: mix H 2 O, acrylamide stock solution, separating gel buffer, 10% SDS, and ammonium persulfate are adjusted to 8%, 11%, and 15% concentration of separating gel in a certain proportion. The formulations of these three different concentrations of separating gels are as follows:

[0022] (1) The separation gel with a concentration of 8%: 7.8mL H 2 O, 3.3mL acrylamide separation gel stock solution, 7.01mL separation gel buffer, 0.19mL10% SDS, 0.42mL16mL / mL ammonium persulfate;

[0023] (2) The concentration is 11% separating gel: 3.2mL H 2 O, 7.68mL acrylamide separation gel stock solution, 7.01mL separation gel buffer, 0.19mL10% SDS, 0.42mL16mL / mL ammonium persulfate;

[0024] (3) The concentration is 15% separating gel: 0.78mL H 2 O, 9.5mL acrylamide separation gel stock solution, 7.01mL separation gel buffer, 0.19mL 10% SDS, 0.42mL 16mL / mL ammonium persulfate.

[0025] 2. Prepare concentrated gel: mix 13.3mL H 2 O, 1.8 mL of acrylamide sta...

Embodiment 3

[0028] 1. Prepare separation gel: mix H 2 O, acrylamide stock solution, separating gel buffer, 10% SDS, and ammonium persulfate are adjusted to 8%, 10%, 13%, and 15% concentration of separating gel in a certain proportion. The formulations of these four different concentrations of separating gels are as follows:

[0029] (1) The separation gel with a concentration of 8%: 7.8mL H 2 O, 3.3mL acrylamide separation gel stock solution, 7.01mL separation gel buffer, 0.19mL10% SDS, 0.42mL16mL / mL ammonium persulfate;

[0030] (2) The concentration is 10% separating gel: 3.8mL H 2 O, 6.65mL acrylamide separation gel stock solution, 7.01mL separation gel buffer, 0.19mL10% SDS, 0.42mL16mL / mL ammonium persulfate;

[0031] (3) The separation gel with a concentration of 13%: 1.2mL H 2 O, 9.5mL acrylamide separation gel stock solution, 7.01mL separation gel buffer, 0.19mL 10% SDS, 0.42mL 16mL / mL ammonium persulfate.

[0032] (4) The concentration is 15% separating gel: 0.78mL H 2 O, 9....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com