Method for manufacturing polymeric membrane with photonic crystal structure

A manufacturing method and polymer film technology, applied in the field of polymer film manufacturing, can solve the problems of increased manufacturing cost and difficulty in practical application, and achieve the goals of increasing polymerization rate, reducing manufacturing cost, strong photonic crystal structure and Bragg reflection characteristics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] A method for manufacturing a polymer film with a photonic crystal structure according to a preferred embodiment of the present invention will be described below with reference to related drawings, wherein the same components will be described with the same component symbols.

[0047] Please refer to Figure 4 As shown, it is a flowchart of a method for manufacturing a polymer film with a photonic crystal structure according to a preferred embodiment of the present invention. The manufacturing method of this embodiment includes step S01 to step S04.

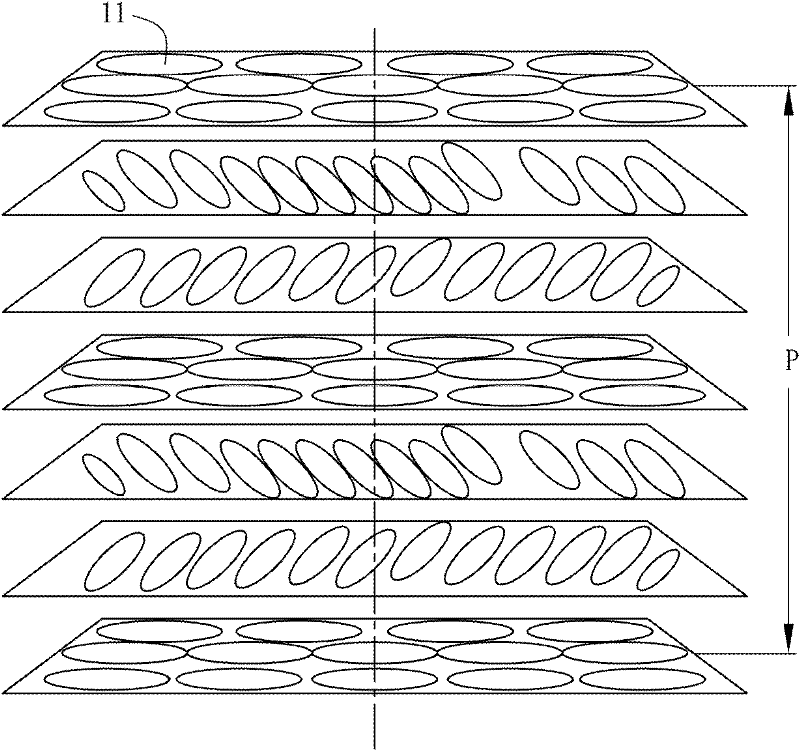

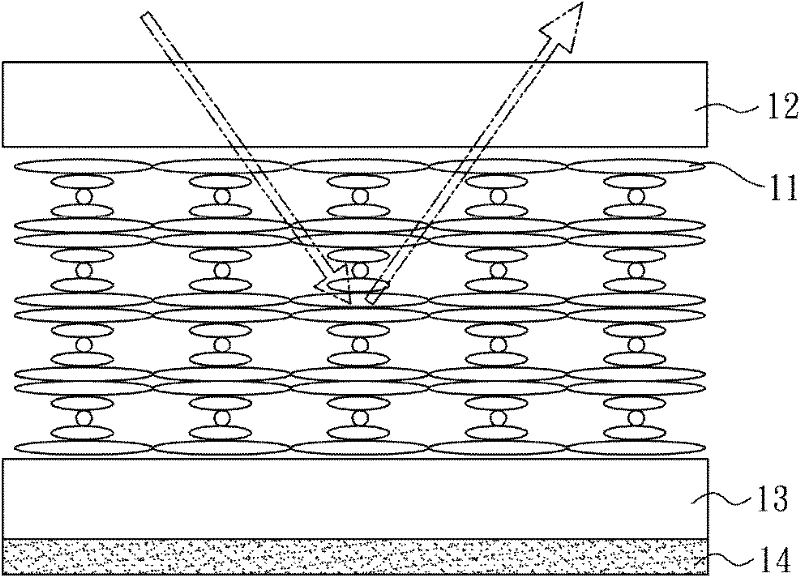

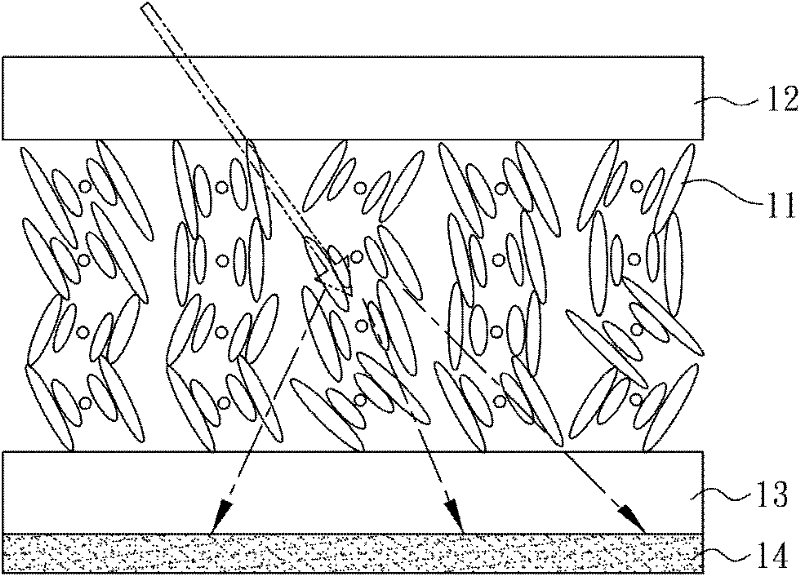

[0048] Step S01: a mixing step, mixing at least one achiral liquid crystal, one optically active additive (chiral dopant), one monomer (monomer) and one photo initiator (photo initiator) to form a Liquid-crystal-monomer mixture, the liquid-crystal-monomer mixture is filled in a light-transmitting container, and the light-transmitting container may, for example, have a light-transmitting portion to allow light to pass throu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com