Fluoroalkyl ether sulfonate surfactants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

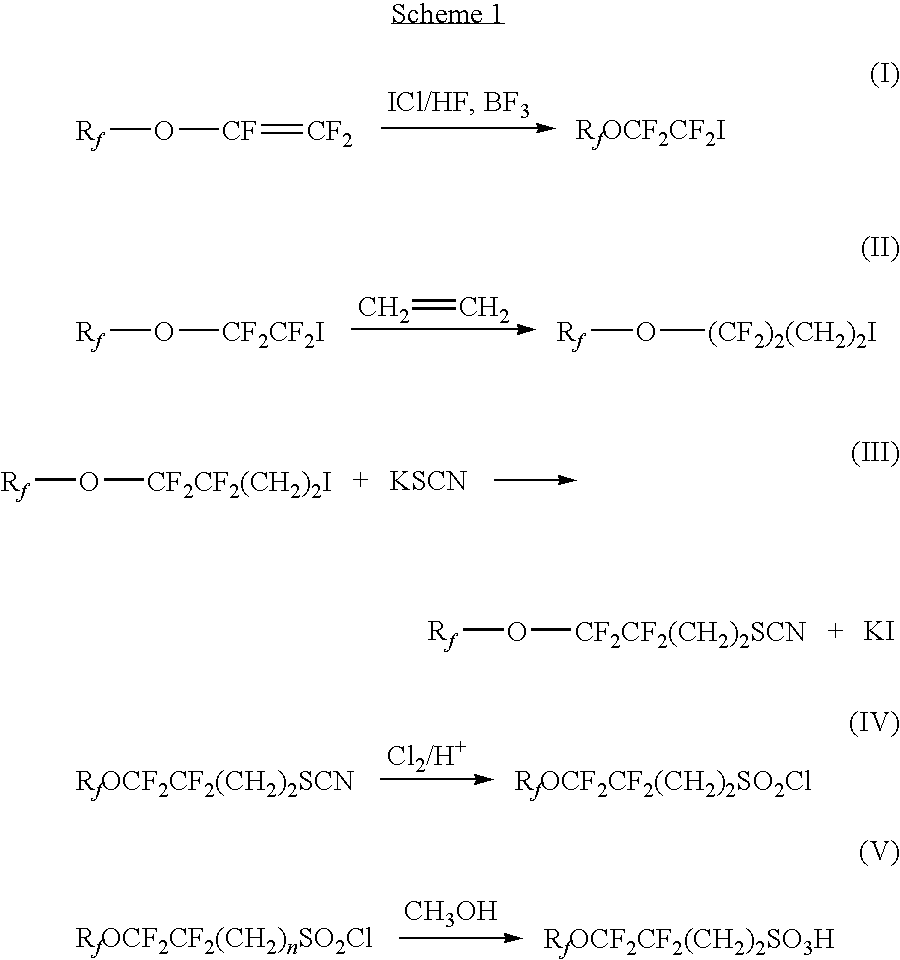

Method used

Image

Examples

example 1

[0103]C3F7OCF2CF2I (100 g, 0.24 mol) and benzoyl peroxide (3 g) were charged to a pressure vessel under nitrogen. A series of three vacuum / nitrogen gas sequences was then executed at −50° C. and ethylene (18 g, 0.64 mol) was introduced. The vessel was heated for 24 hour at 110° C. The autoclave was cooled to 0° C. and opened after degassing. Then the product was collected in a bottle. The product was distilled giving 80 g of C3F7OCF2CF2CH2CH2I in 80% yield. The boiling point was 56˜60° C. at 25 mm Hg (3333 Pa).

[0104]Potassium thiocynate (21.34 g, 0.22 mol) was added to the mixture of C3F7OCF2CF2CH2CH2I (50 g, 0.11 mol) and trioctylmethylammonium chloride (0.2222 g) in 50 g of water. The reaction was heated overnight at 90° C. After phase separation, the product C3F7OCF2CF2CH2CH2SCN was distilled as a colorless liquid (32 g, 78%). The compound can be characterized by: b.p. 83˜85 oC / 2.3 torr; 1H NMR (CDCl3, 400 MHz) δ 3.10˜3.07 (2H, m), 2.58˜2.46 (2H, m); 19F NMR (CDCl3, 373 Hz) δ−81....

example 2

[0109]C3F7OCF2CF2I (100 g, 0.24 mol) and benzoyl peroxide (3 g) were charged to a pressure vessel under nitrogen. A series of three vacuum / nitrogen gas sequences was then executed at −50° C. and ethylene (18 g, 0.64 mol) was introduced. The vessel was heated for 24 hour at 110° C. The autoclave was cooled to 0° C. and opened after degassing. Then the product was collected in a bottle. The product was distilled giving 80 g of C3F7OCF2CF2CH2CH2I in 80% yield. The boiling point was 56˜60° C. at 25 mm Hg (3333 Pa).

[0110]C3F7OCF2CF2CH2CH2I (220 g, 0.5 mol) was added to the mixture of ethanol (250 mL) and water (250 mL). Sodium sulfite (126 g, 1 mol) was added, followed by 15 g copper. The reaction mixture was stirred vigorously under reflux for a week. 500 mL water was added and filtered at 75° C. The filtrate was cooled and the product C3F7OCF2CF2CH2CH2SO3Na was collected by filtration as white solid (86 g, 41.35%). The compound was characterized by: 1H NMR (CDCl3, 400 MHz) δ 3.19˜3.15 ...

example 3

[0115]Following the general procedure of Comparative Example B, the Surfactant Solution used in Example 3 was made from 0.88 g of C3F7OCF2CF2CH2CH2SO3Na dissolved in 500 mL of deionized water. There was no additional water precharge. Results are reported in Table 5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com