Adhesive resin of color matching agent and color matching agent

A binder resin and toner technology, which is applied in the field of low-temperature fixability and durability of toners, can solve problems such as deterioration of chargeability, and achieve improved printing quality, reduced waste toner, and excellent low-temperature fixability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The present invention also provides a method for preparing the above-mentioned binder resin. The binder resin is prepared by a melt-kneading method. The melt-kneading method ensures that by applying shear stress (or shearing force) to each component in a low viscosity state Reasons for sufficient dispersion. However, if the temperature is too high or excessive shear stress is applied, problems such as scission of molecular chains in the resin may occur. Therefore, the kneading method must be carefully used in consideration of the change in molecular weight (especially the decrease in molecular weight). Therefore, it is preferable that the temperature range of melt-kneading is preferably 110°C to 125°C.

[0048] Specifically, the preparation method of the binder resin provided by the present invention specifically includes mixing crystalline polyester, polyethylene oxide, and ethanolamine-modified graphene, and sending it into a twin-screw extrusion-kneader at 110°C to 125...

Embodiment 1

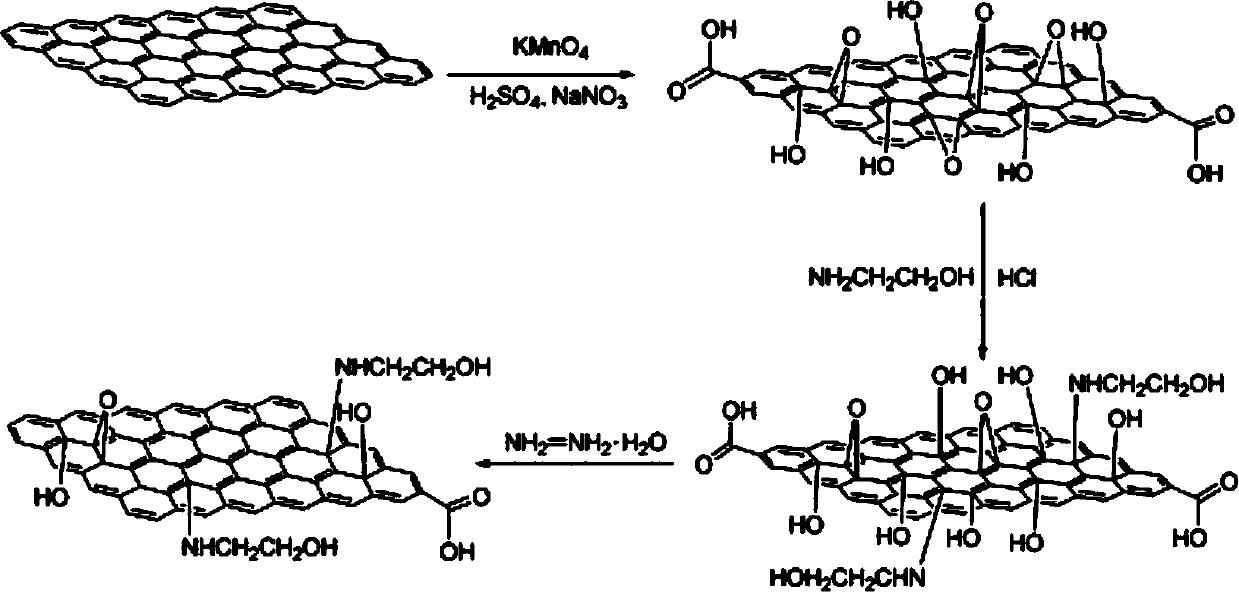

[0112] Example 1 Preparation of ethanolamine modified graphene

[0113] Treat the natural flake graphite with 5% hydrochloric acid solution for 24h, wash the paint thoroughly with water, and dry it in an oven at 110℃ for 24h, then slowly add 2g of 500 mesh processed natural flake graphite to 50ml concentrated sulfuric acid under stirring In a 500ml large beaker, the temperature is maintained at (0±1)℃, then slowly add 1g sodium nitrate and 6g potassium permanganate, and stir for 2h while maintaining (0±1)℃, at (35±3) In a constant temperature water bath at ℃, keep stirring for 30min, slowly add 90ml of water to increase the temperature to 98℃, maintain at this temperature for 15min; dilute to 200ml with warm water, pour 10ml of H with a concentration of 5% 2 O 2 , Filter while hot, and wash the filter cake with 5% HCl until there is no 80% in the filtrate 4 2- (Use BaCl 2 Solution detection), at 50℃ at P 2 O 5 In the presence of vacuum drying for 24 hours or drying in room tempera...

Embodiment 2

[0114] Example 2 Preparation of crystalline polyester

[0115] Add 1,170 parts of 1,6-hexanediol, 23.7 parts of sodium dimethyl 5-sulfoisophthalate, and 22.8 parts of dimethyl fumarate to a reaction vessel equipped with a condenser, agitator, and nitrogen inlet pipe , 857 parts of dimethyl sebacate, and 0.4 parts of dibutyl tin oxide. In order to create an inert atmosphere in the reaction vessel, the air was replaced with nitrogen by reducing the pressure. After that, the mixture was mechanically stirred at 180 rpm for 5 hours. The mixture was gradually heated to 220°C under reduced pressure and stirred for 2 hours until the mixture became viscous. The mixture was then air cooled to terminate the reaction. Thus, crystalline polyester 1 was prepared, the weight average molecular weight of crystalline polyester 1 was 6,800, and the melting point was 90°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com