Method and apparatus for foam mould inner color painting polymerization

A foaming mold and color painting technology, which is applied in the field of color painting polymerization in foam molds, can solve problems such as difficulties, cumbersome processing, difficulty in upgrading large areas, and curved surfaces, so as to achieve good transfer quality, facilitate mass production, and speed fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

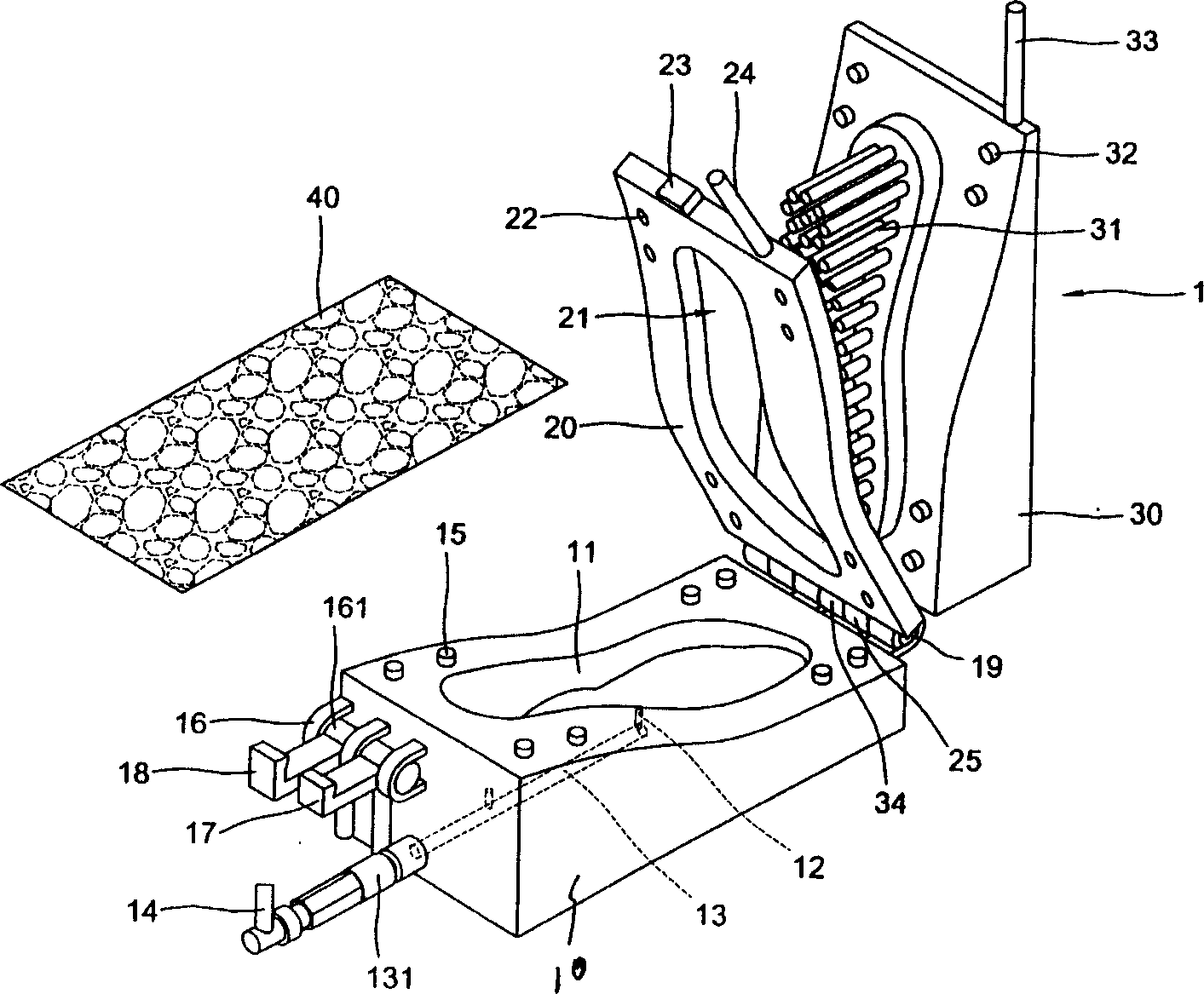

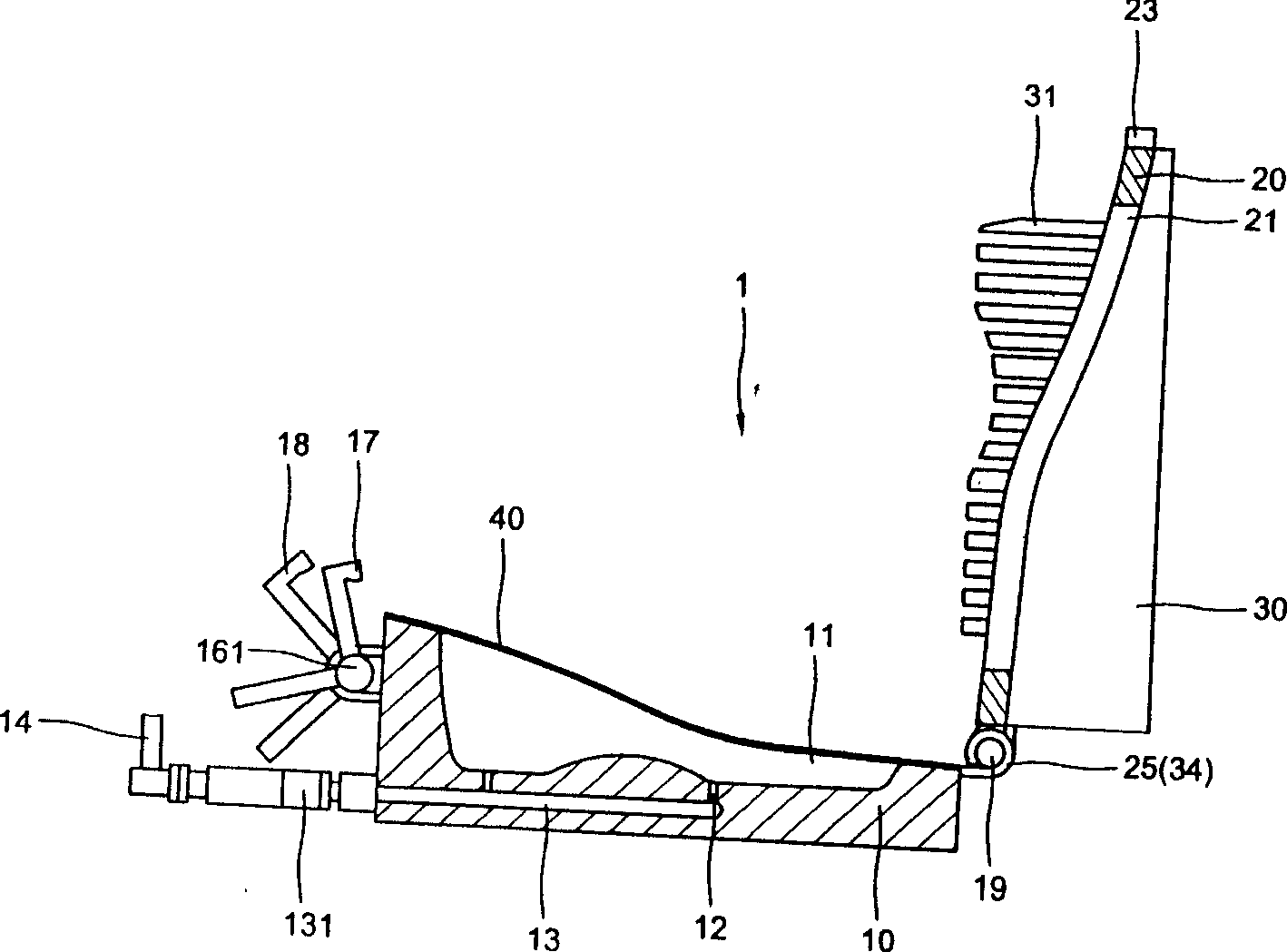

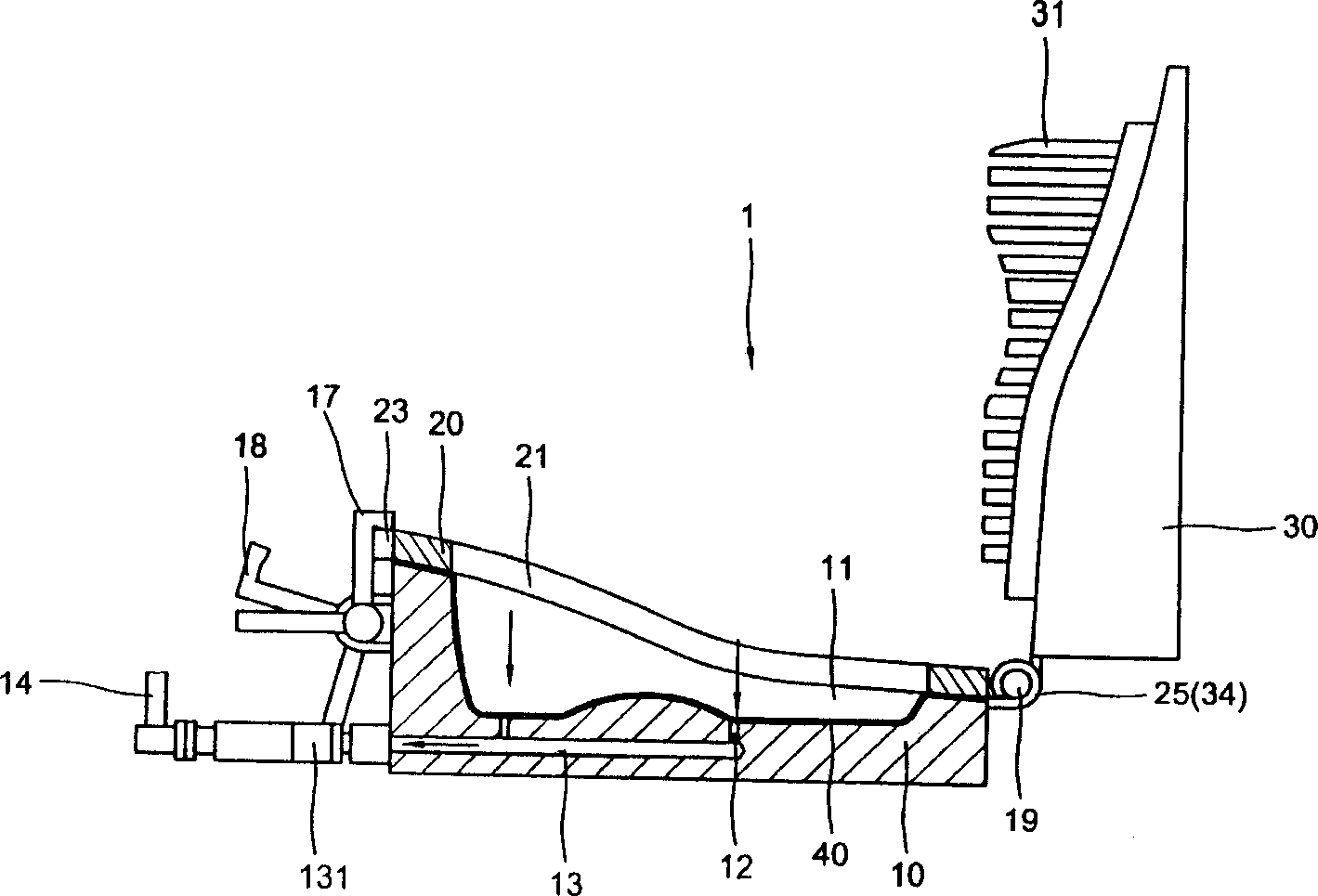

[0037] First of all, the present invention is a device for foaming in-mold painting polymerization, such as figure 1 As shown, the device is mainly a mold 1, which is divided into a lower mold 10, a middle mold 20 and an upper mold 30. The lower mold 10 has a cavity 11, and the cavity 11 is provided with lines. The air hole 12, the air hole 12 is connected with a gas pipe 13 embedded in the lower mold 10, the air pipe 13 is externally connected to a suction pipe 14 through the joint 131, and the suction pipe 14 is sucked by a powered air pressure mechanism. Several protrusions 15 are arranged on the surface, and several hook ears 16 are provided at the rear end of the lower mold 10 for a pivot connection of a rod body 161, and two fastening components 17, 18 are connected to the rod body 161, and a middle mold 20 has a vacant part 21. The position 21 is approximately opposite to the recess 11 of the lower mold 10, and the middle mold 20 is provided with several holes 22, the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com