Process for water transferring on the surface of large workpiece and equipment thereof

A technology of water transfer printing and large workpieces, applied in the process of producing decorative surface effects, printing of special varieties of printed matter, printing, etc., can solve problems such as blisters, patterns are easy to be stretched, and patterns are distorted and deformed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

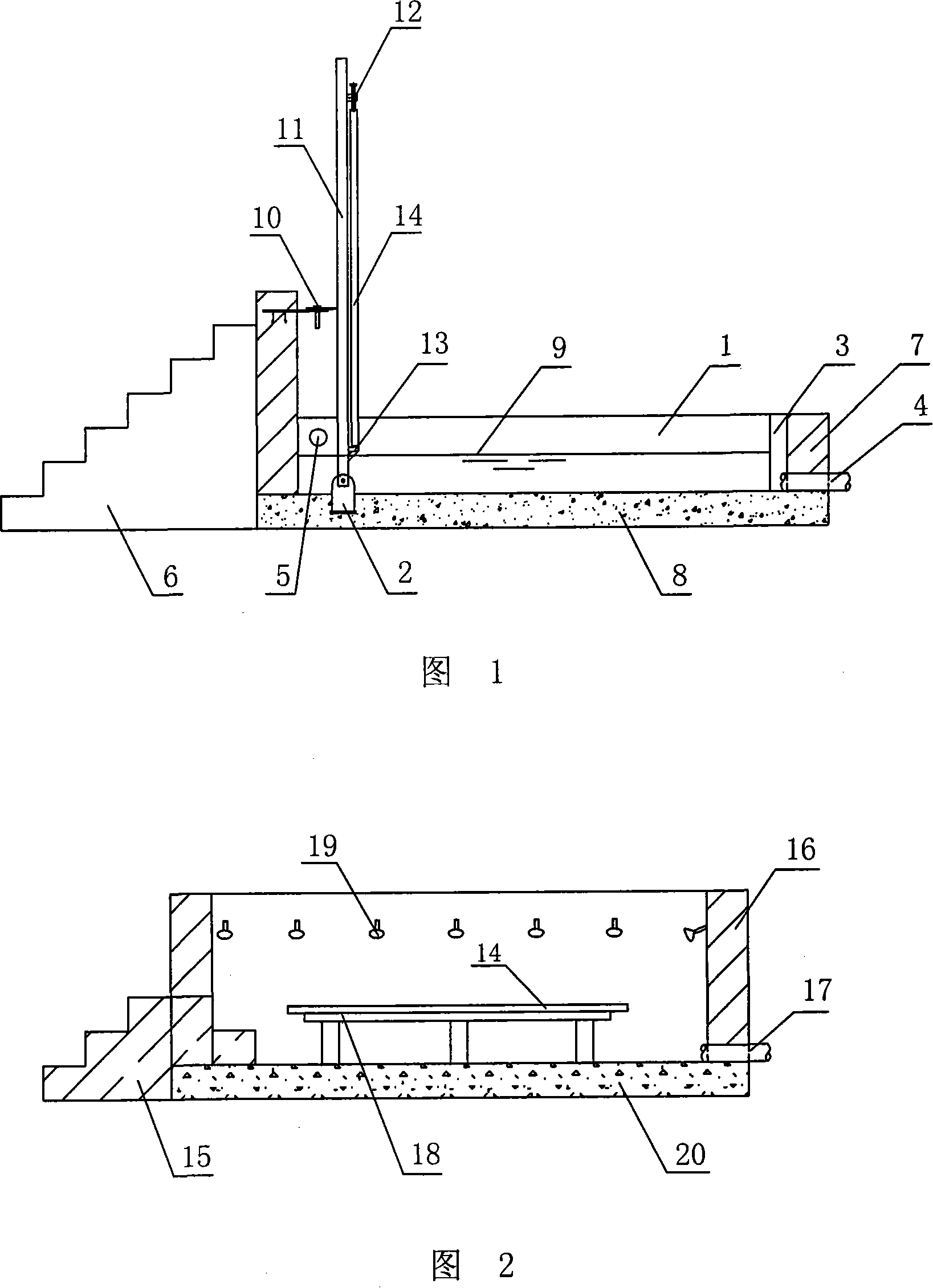

[0015] The present invention will be further described below in conjunction with drawings and embodiments.

[0016] Referring to Fig. 1, the embodiment of the water transfer printing equipment of the present invention includes a transfer printing pool 1, the bottom plate 8 of the transfer printing pool 1 is fixed with a fixed support 2 of a bracket 11, the bottom end of the bracket 11 is movably connected with the fixed support 2, and the bracket 11 The lower part of the tank is provided with a support member 13, and the upper part is provided with a fastener 12. One end of the transfer pool 1 has a higher wall, and a step 6 is provided on the outside of the high-end pool wall. The vertically fixed connecting device 10 and the support 11 are fixed by a loose buckle. The upper part of the pool wall 7 of the transfer pool 1 is provided with a water inlet 5, and the lower part is provided with a water outlet 4. The inside of the pool wall 7 is pasted with a glass plate 3.

[0017...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com