Bionic grabbing device for Micro-LED mass transfer and using and manufacturing method

A technology of grabbing device and transfer device, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., and can solve problems such as high operating cost, high difficulty, and low yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

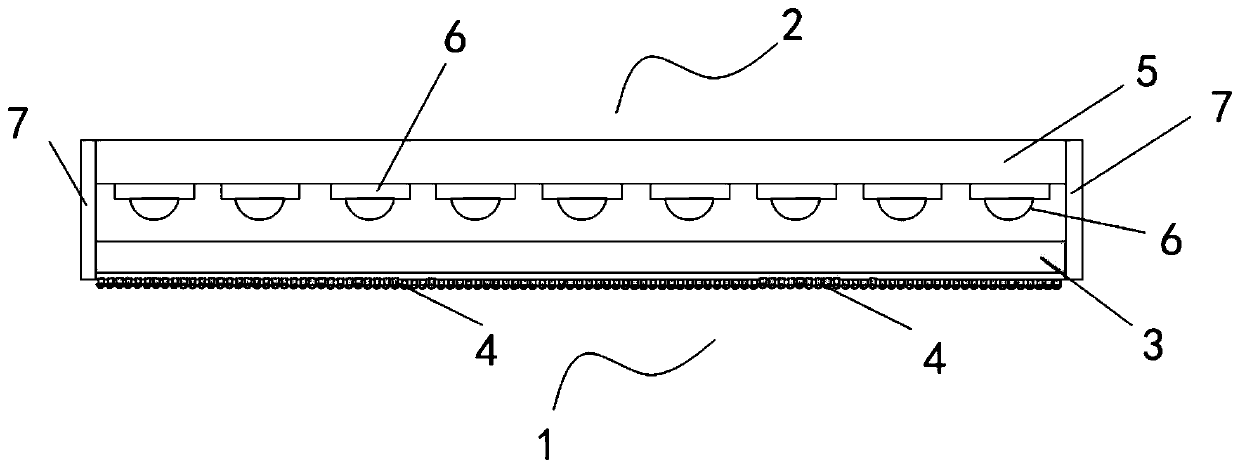

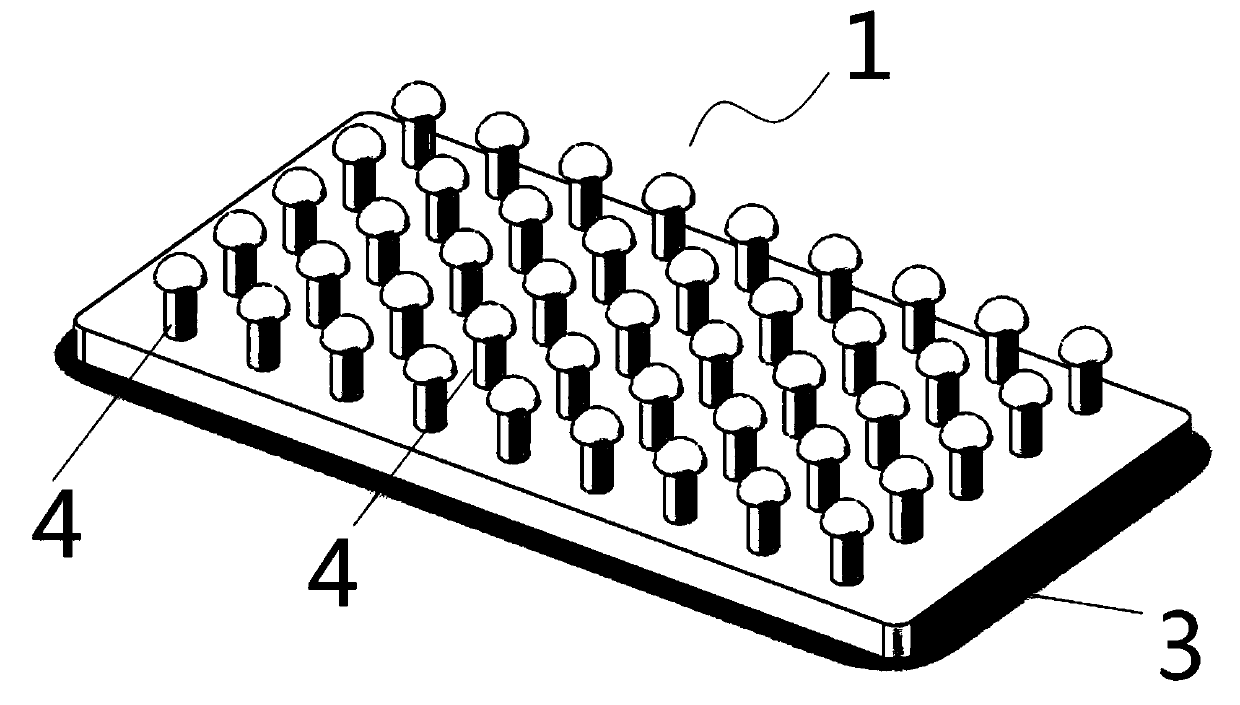

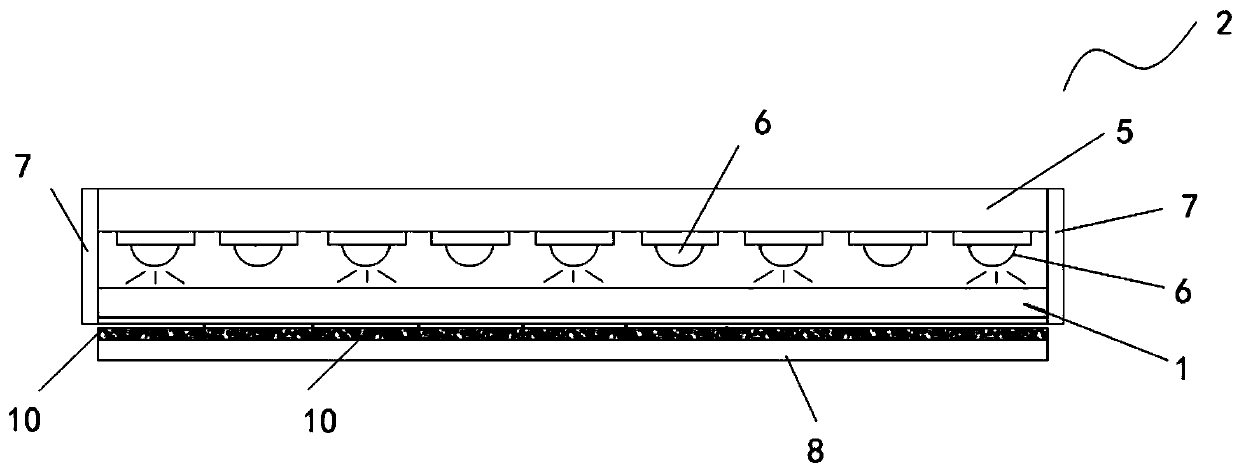

[0036] The bionic grasping device used for Micro-LED mass transfer in this embodiment, such as figure 1 As shown, including graphene-based shape memory polymer microstructure film 1 and Micro-LED transfer device 2, such as figure 2 As shown, the graphene-based shape-memory polymer microstructure film 1 includes a polyurethane film substrate 3 and a plurality of graphene-based shape-memory polymer micropillars 4, and a plurality of graphene-based shape-memory polymer micropillars The columns 4 are distributed in an array on the polyurethane film substrate 3;

[0037] The Micro-LED transfer device 2 includes a light source fixing substrate 5, a laser emitting unit 6 and a fixing plate 7, the fixing plates 7 are installed at both ends of the light source fixing substrate 5, the bottom surface of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com