Transfer printing plate pretreatment device and transfer printing device

A technology of pretreatment device and transfer plate, which is applied in the direction of pretreatment surface, device for coating liquid on the surface, transportation and packaging, etc. It can solve the problems of long soaking time period and chemical reagent harm, and improve the transfer effect. , the effect of improving the utilization rate and improving the ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

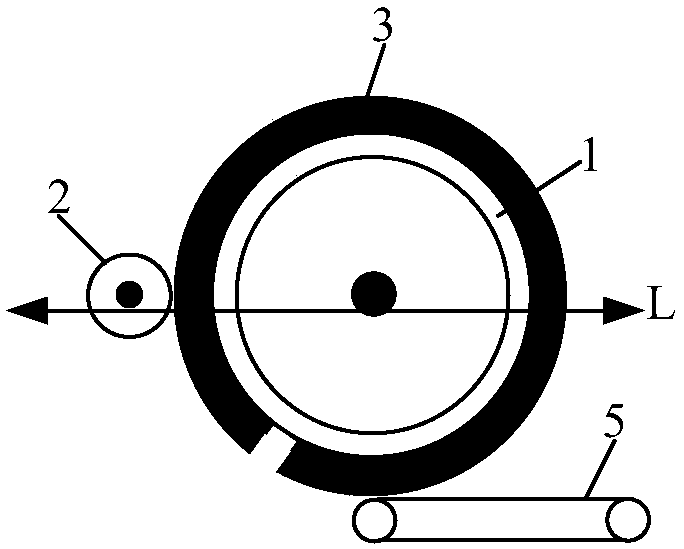

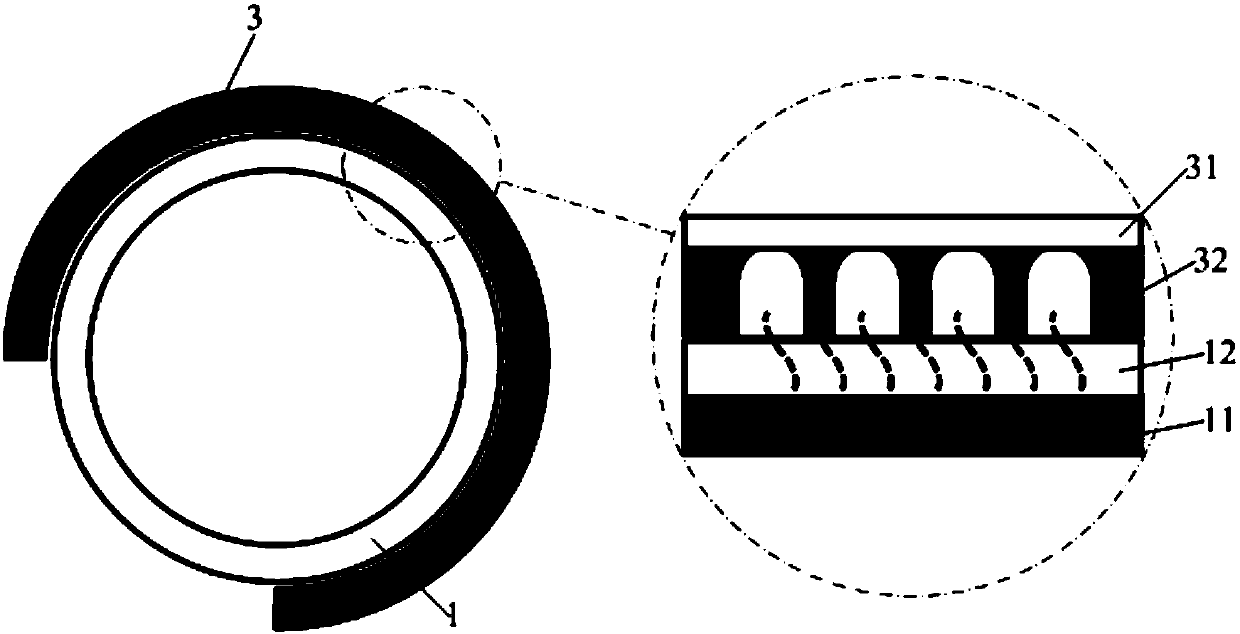

[0041] This embodiment provides a transfer plate pretreatment device, such as figure 1 As shown, it includes a corresponding driving roller 1 and a pressure roller 2. The driving roller 1 includes a heating layer for heating the transfer plate 3 spread on it, and the pressure roller 2 is used for heating the transfer plate 3 spread on it. The transfer plate 3 on the driving roller 1 is pressed to improve the wettability of the transfer plate 3 .

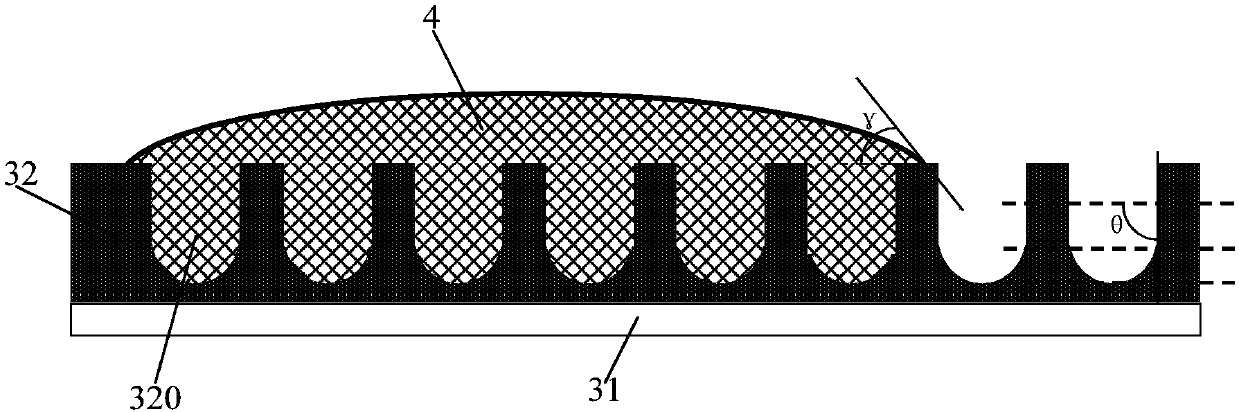

[0042] Among them, the driving roller 1 is a cylindrical roller, and the pressing roller 2 is also a cylindrical roller. By spreading the transfer plate 3 on the cylindrical surface of the driving roller 1, and heating and extruding it, the gradient angle of the meshes of the mesh layer of the transfer plate 3 can be increased microscopically, thereby reducing macroscopically. The contact angle between the small transfer liquid and the transfer plate 3 (for example, the contact angle between the transfer plate 3 and the transfer liq...

Embodiment 2

[0061] This embodiment provides a transfer device, such as Figure 5 As shown, it includes the transfer plate pretreatment device in Example 1; it also includes a hanging plate mechanism 6 and a plate ketone 7, and the plate hanging mechanism 6 is arranged between the transfer plate pretreatment device and the plate ketone 7, and is used to transfer the transfer plate. The transfer plate 3 processed by the printing plate pretreatment device is hung on the printing plate 7 .

[0062] By using the transfer plate pretreatment device in Example 1, the wettability of the transfer plate 3 can be improved automatically before the transfer plate 3 is hung on the plate ketone 7, and its wettability can be increased, so that the The transfer device can automatically improve the wettability of the transfer plate 3 before hanging the plate, thereby improving the hanging efficiency and the utilization rate of the transfer device.

[0063] Among them, the setting of the plate hanging mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com