Automatic marking, spacer feeding, stacking, magnetic flux measuring system for magnetic steel

A magnetic flux measurement and automatic identification technology, applied in the field of machinery, can solve problems such as affecting production efficiency, reducing production efficiency, laborious and time-consuming detection, etc., to save process flow time, improve labor efficiency, and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings.

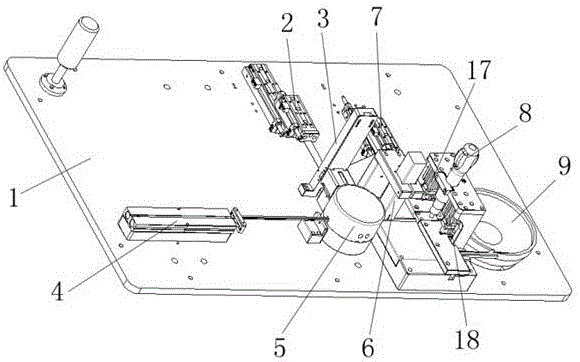

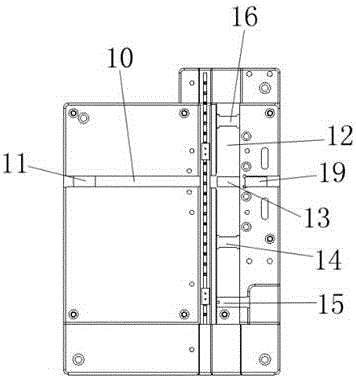

[0019] The present invention includes a working table 1, a material pushing cylinder 2, a material feeding cylinder 4, a material guide pipe 3, a magnetic flux detector 5, a coding device 6, a sorting cylinder 7, a vibrating plate 9, a first material jacking cylinder 17, a second jacking cylinder Material cylinder 18, the first track, the second track 10 and the third track 12, the inkjet device 6 includes an inkjet pen and an inkjet stand, and the material guide pipe 3 is arranged above the first track, and the pushing cylinder The pushing punch on the 2 can push the magnetic steel falling on the first track from the material guide tube 3 to the detection platform of the magnetic flux detector 5 under the drive of the pushing cylinder 2, and the second track 10 The first position 11 is set on the third guide rail, the second position 13, the third position 15, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com