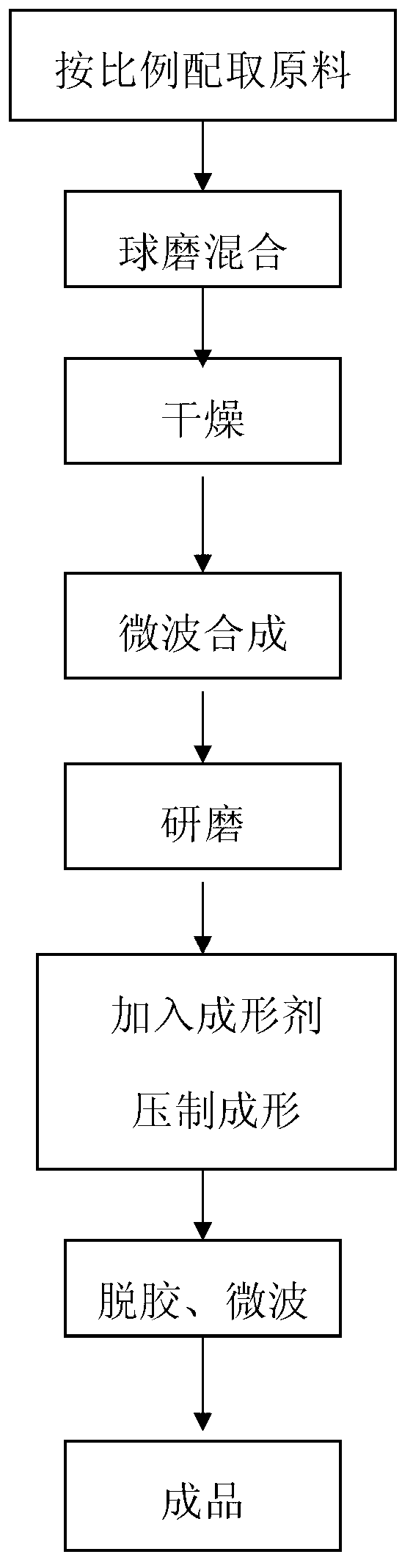

Method for preparing nickel-zinc ferrite by using microwave technology

A nickel-zinc ferrite technology, applied in the field of magnetic material preparation, can solve the problems of uneven grain growth inside the material, difficulty in batch production, and low synthesis rate, so as to save process time and cost and promote application , The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

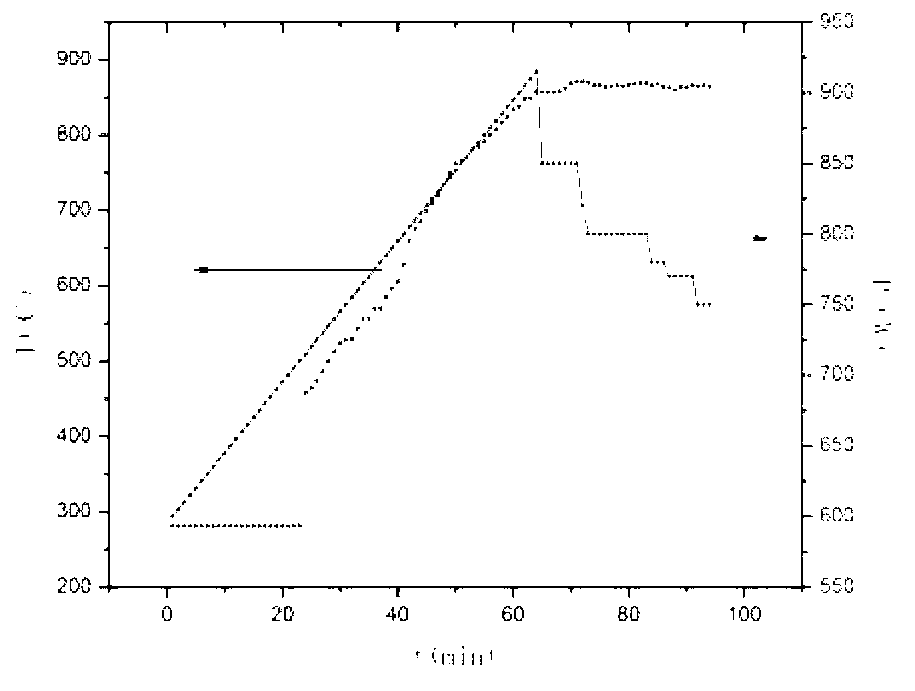

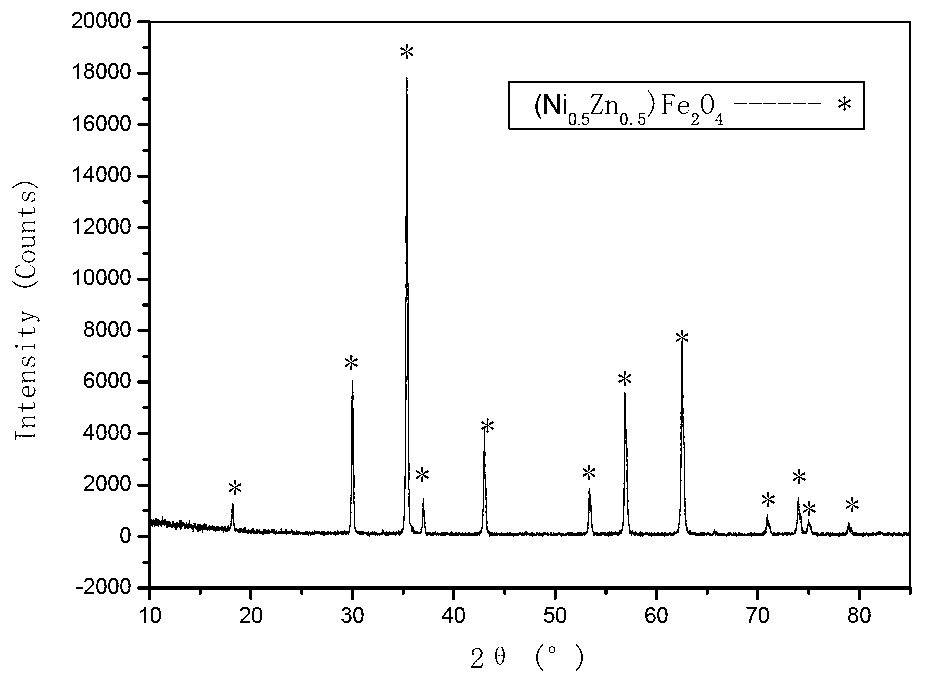

[0033] Use Fe with a particle size of 10-12μm 2 o 3 , Ni with a particle size of 35-38μm 2 o 3 , ZnO with a particle size of 5-8μm as the raw material, according to the chemical formula (Ni 0.5 Zn 0.5 ) Fe 2 o 4 The material is weighed at a molar ratio of Ni:Zn:Fe=0.5:0.5:2. The mass ratios of the three powders in the raw material are ZnO16.73%, Ni 2 o 3 17.15%, Fe 2 o 3 66.12%. The amount of steel balls, oxides and deionized water is mixed according to the ball: material: water = 3:1.5:1, the speed is 150r / min, the ball mill is 3h, and the size of the ball is Ф5mm. The wet mixture after ball milling was kept in a constant temperature drying oven at 120°C for 4h. The dried mixture is lumpy, which is taken out and put into a mortar for grinding, and passed through a 100-mesh sieve. Subsequently, the obtained powder mixture was subjected to microwave synthesis in a multi-cavity microwave oven (2.45GHz, 6kW). The temperature was adjusted by the output power of the equ...

Embodiment 2

[0036] Use Fe with a particle size of 25-27μm 2 o 3 , Ni with a particle size of 20-22μm 2 o 3 , ZnO with a particle size of 15-18μm as the raw material, according to the chemical formula (Ni 0.4 Zn 0.6 ) Fe 2 o 4 The material is weighed at a molar ratio of Ni:Zn:Fe=0.4:0.6:2, and the mass ratios of the three powders in the raw material are ZnO20.10%, Ni 2 o 3 13.73%, Fe 2 o 3 66.17%. The amount of steel balls, oxides and deionized water is mixed according to the ball: material: water = 4:1.5:1, the speed is 120r / min, the ball mill is 5h, and the size of the ball is Ф15mm. The wet mixture after ball milling was kept in a constant temperature drying oven at 150°C for 2h. The dried mixture is lumpy, which is taken out and put into a mortar for grinding, and passed through a 100-mesh sieve. Subsequently, the obtained powder mixture was subjected to microwave synthesis in a multi-cavity microwave oven (2.45GHz, 6kW). The temperature was adjusted by the output power of ...

Embodiment 3

[0038] Use Fe with a particle size of 42-45μm 2 o 3 , Ni with a particle size of 10-12μm 2 o 3 , ZnO with a particle size of 28-30μm as the raw material, according to the chemical formula (Ni 0.6 Zn 0.4 ) Fe 2 o 4 The material is weighed at a molar ratio of Ni:Zn:Fe=0.6:0.4:2. The mass ratios of the three powders in the raw material are ZnO13.38%, Ni 2 o 3 20.56%, Fe 2 o 3 66.06%. The amount of steel balls, oxides and deionized water is mixed according to the ball: material: water = 3:2:1, the speed is 180r / min, the ball mill is 2h, and the size of the ball is Ф20mm. The wet mixture after ball milling was kept in a constant temperature drying oven at 100°C for 6h. The dried mixture is lumpy, which is taken out and put into a mortar for grinding, and passed through a 100-mesh sieve. Subsequently, the obtained powder mixture was subjected to microwave synthesis in a multi-cavity microwave oven (2.45GHz, 6kW). The temperature was adjusted by the output power of the eq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com