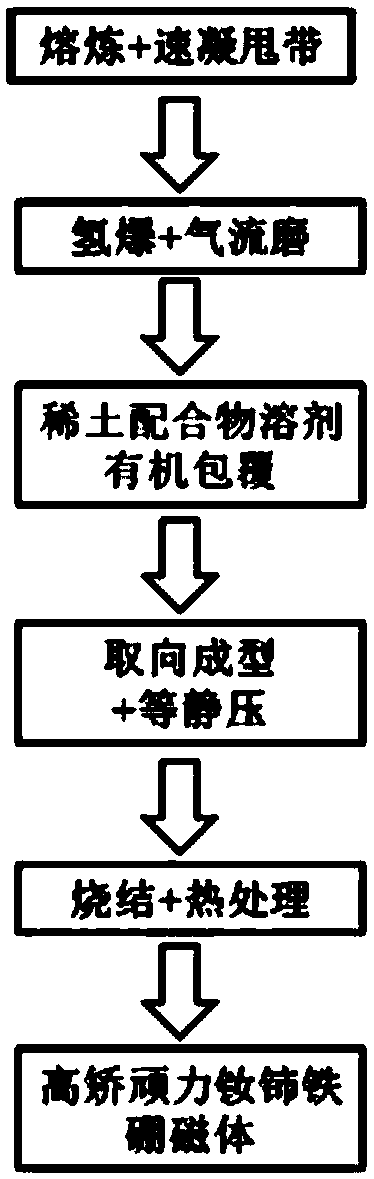

Fabrication method of high-coercivity Nd-Ce-Fe-B sintered magnet

A technology of Nd-Cerium-Fe-Bron and sintered magnets, which is applied in the fields of magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., can solve the problems of low coercive force and easy oxidation of magnetic powder, so as to improve coercive force and save energy Consumption, the effect of preventing powder oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

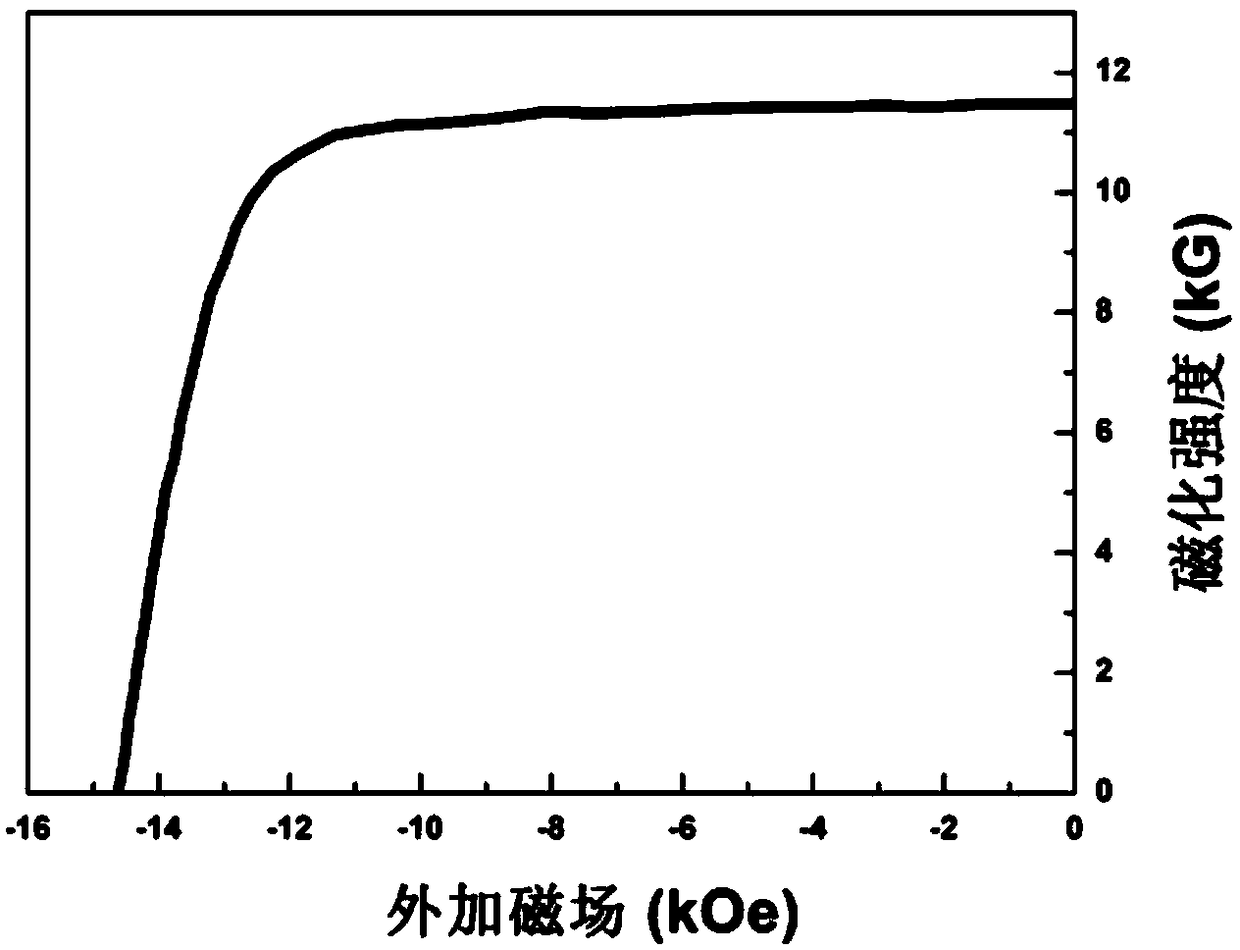

Embodiment 1

[0037] (1) The Ce principal element alloy is prepared by induction smelting and quick-setting strip technology to prepare alloy flakes, wherein the alloy is expressed in mass percentage, and its composition is (Pr 0.12 Nd 0.48 Ce 0.4 ) 33 Fe 65 m 1.0 B 1.0 , wherein M is Co=0.5, Cu=0.35, Zr=0.05, Ga=0.1.

[0038] (2) The alloy flakes are subjected to hydrogen explosion and jet milling, and the average particle size is about 3.5 μm.

[0039] (3) Add the Dy organic complex solution to the mixed alloy powder, under nitrogen (N 2 ) under a protective atmosphere in a three-dimensional drum mixer for 0.5h, wherein dysprosium tricyclopentadiene Dy(C 5 h 5 ) 3 The volume of the 95# aviation gasoline solution is compared to the mixed alloy powder mass ratio to add 5mL in every kilogram of alloy powder; Described Dy organic complex solution is preferably tricyclopentadiene dysprosium Dy(C 5 h 5 ) 3 95# aviation gasoline solution. The three-dimensional drum mixer is preferab...

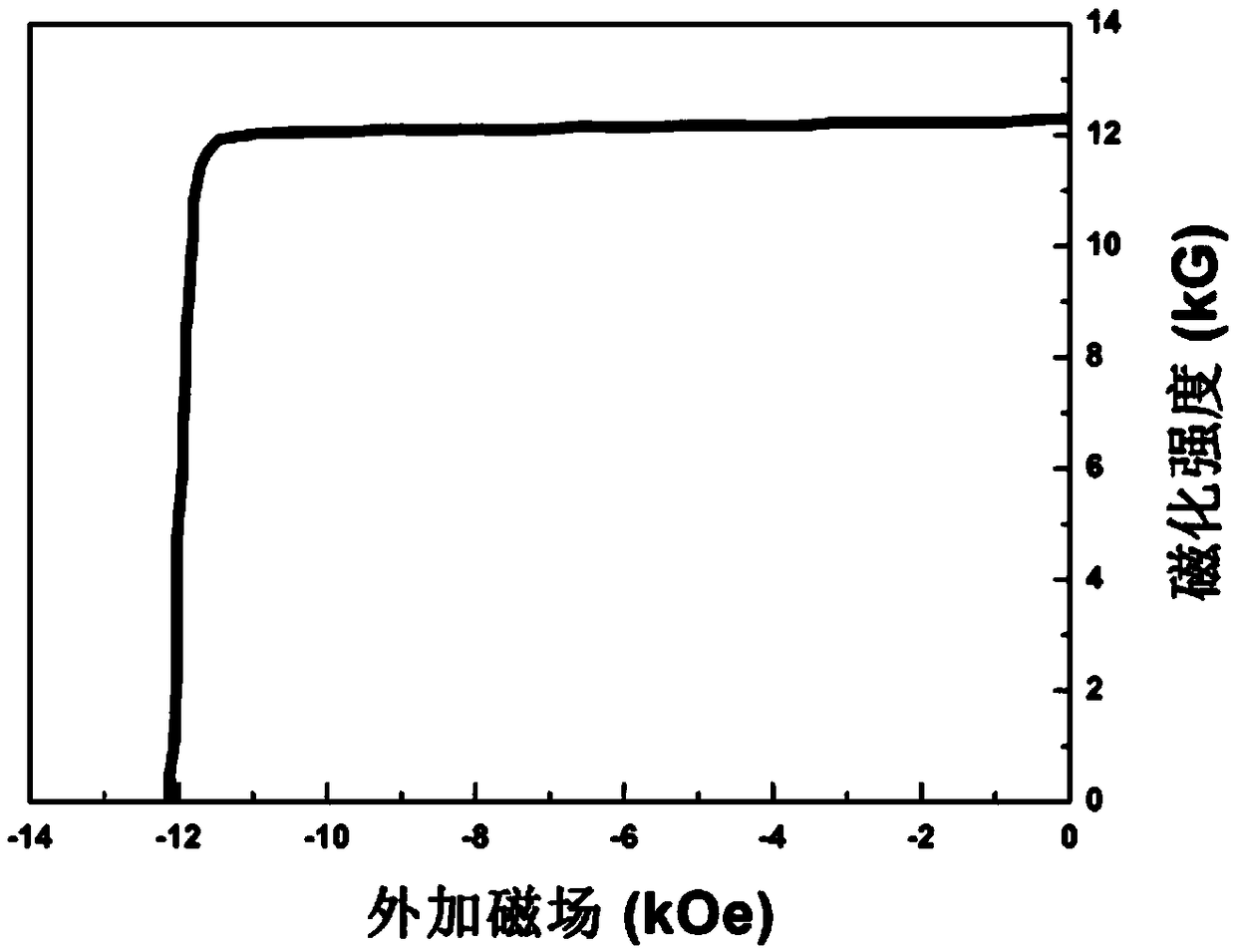

Embodiment 2

[0045] (1) The Ce-rich principal element alloy and the Ce-free principal element alloy are respectively prepared into alloy powders by induction melting, rapid solidification casting, hydrogen explosion and jet milling. The average particle size of the powder is about 3.5 μm. Elemental alloys are expressed in mass percentages, and their composition is (Pr 0.1 Nd 0.4 Ce 0.5 ) 30.5 Fe 67 m 1.5 B 1.0 , wherein M is Al=0.5, Co=0.5, Cu=0.35, Zr=0.05, Ga=0.1; the Ce-free principal element alloy is expressed in mass percentage, and its composition is (Pr 0.2 Nd 0.8 ) 30.5 Fe 67 m 1.5 B 1.0 , wherein M is Al=0.5, Co=0.5, Cu=0.35, Zr=0.05, Ga=0.1.

[0046] (2) Take the Ce-rich principal element alloy powder and the Ce-free principal element alloy powder according to the ratio of mass fraction of 6:4, and then add the Pr complex organic solution to the mixed alloy powder, under nitrogen protection atmosphere Mix evenly in a three-dimensional drum mixer for 0.5h, in which tri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com