Quick collection and changing device for spinning frame cones

A technology of yarn bobbins and spinning frames, which is applied in the field of rapid collection and replacement devices, can solve the problems of wasting manpower, high error rate, time-consuming, etc., and achieves the effects of saving process and labor costs, avoiding manual errors, and having a simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

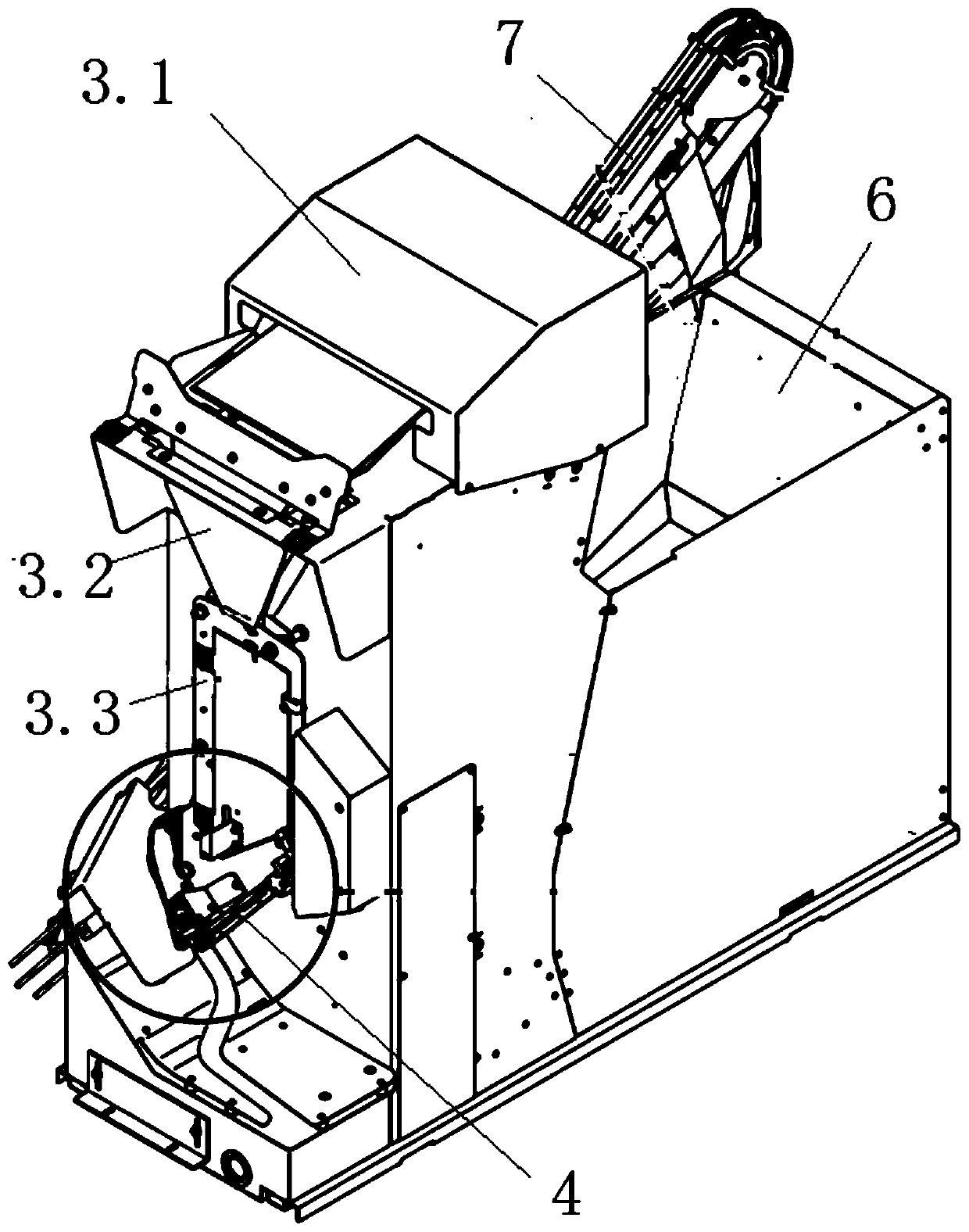

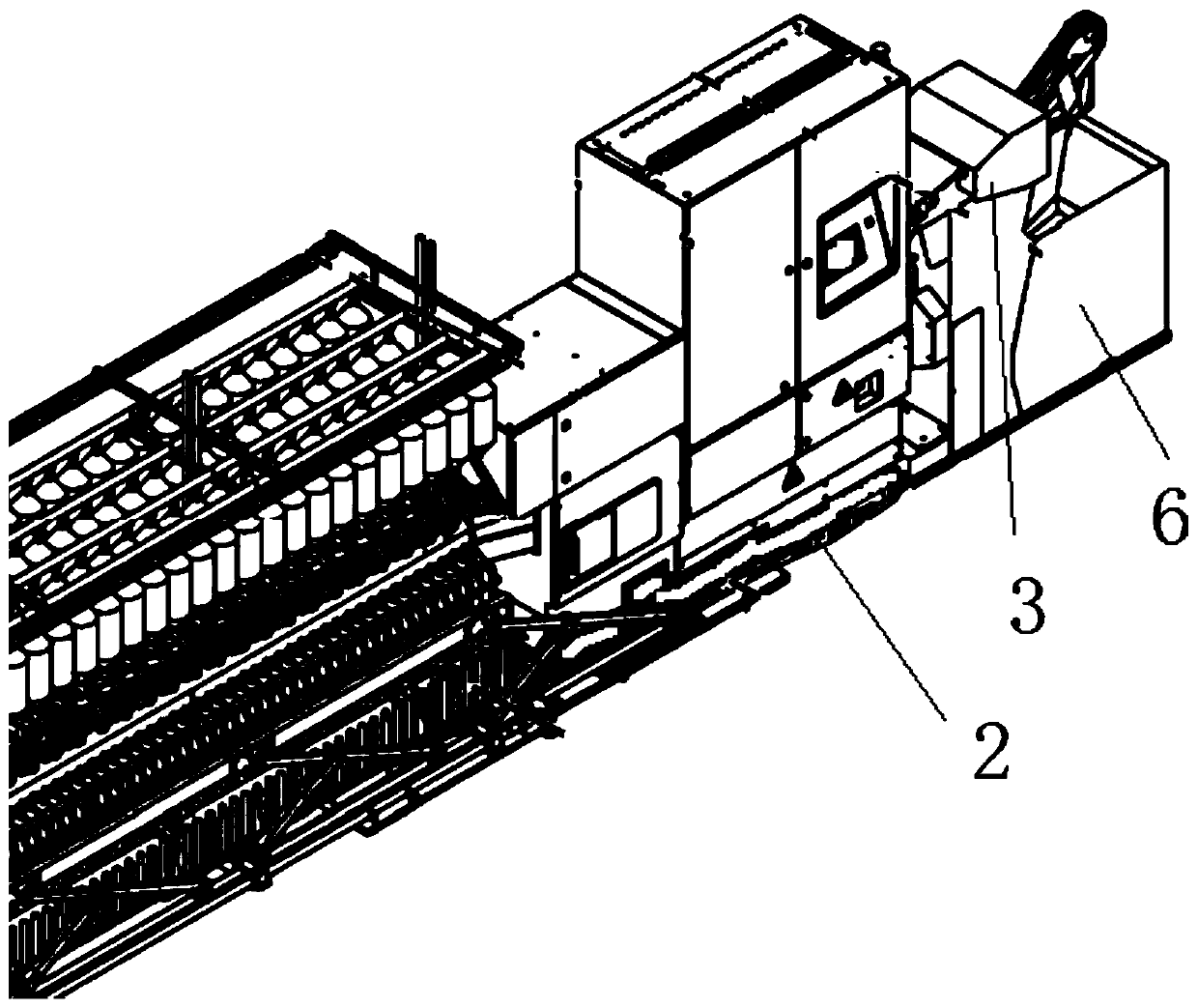

[0020] see Figure 1 to Figure 5 , The present invention relates to a fast collection and replacement device for spinning frame yarn bobbins, comprising a yarn reel 1, a track mechanism 2, a yarn bobbin delivery box 3, a blocking mechanism 4, a delivery device 5, and a yarn reel collection box 6.

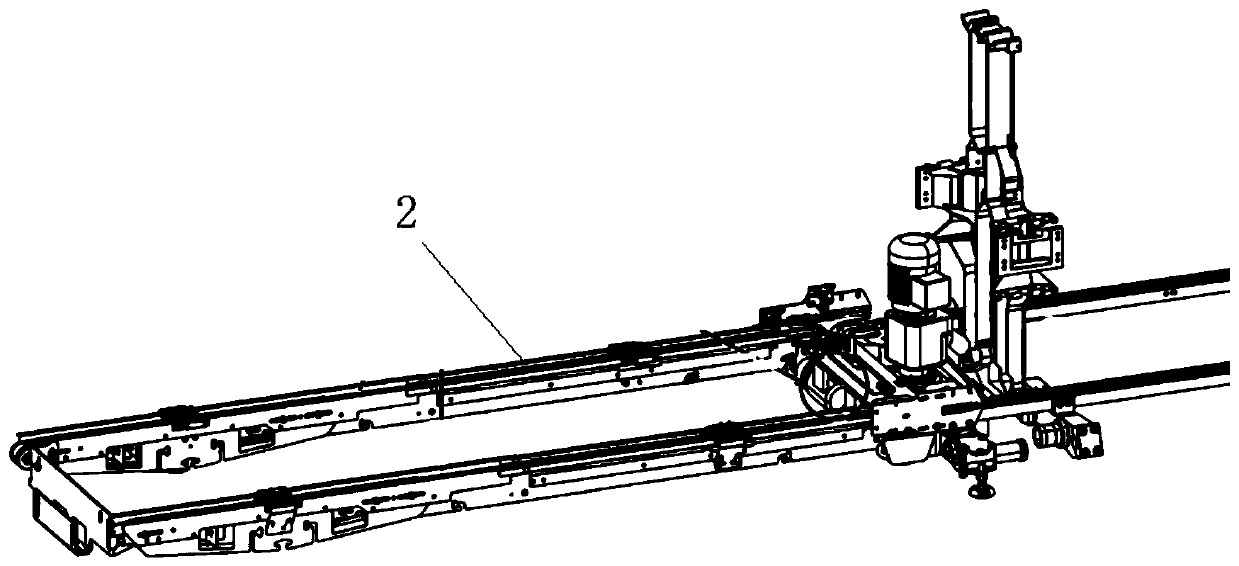

[0021] The yarn roll 1 is formed by winding the yarn 1.2 on the yarn barrel 1.1, the yarn roll 1 is set on the conveying device 5, and the conveying device 5 is placed on the track mechanism 2, and the track mechanism 2 includes A track 7, a conveyor belt 8 is arranged on the track 7, and is used to transport the conveying device 5 placed on its top. There are intervals, and the guardrail 9 is fixed on the track 4 through a fixing piece 10 .

[0022] The conveying device 5 is composed of a protruding part 5.1 and a cylindrical base 5.2. The protruding part 5.1 is rod-shaped and is arranged between the guard rails 9 on both sides. The diameter of the starting part 5.1 is smaller th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com