Waste tyre fixed-bed gasification furnace and gasification method

A fixed-bed gasifier and waste tire technology, which is applied in fixed-bed gasification, combustible gas purification, combustible gas purification/renovation, etc. The effect of saving equipment investment and project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

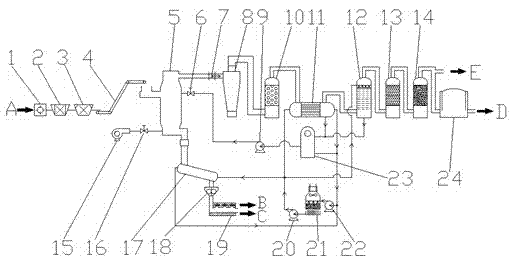

[0052] Taking a process system with a waste tire processing capacity of 140kg / hour as an example, the gasifier 5 has an inner diameter of 0.5m and a height of 3.8m (from the furnace top to the lower electric sealing valve 120).

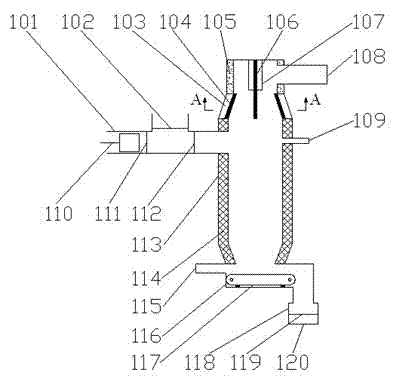

[0053] Waste truck tire A is cut into tire crown and side bead through ring cutting machine 1, and then the tire crown and side bead are sent to strip cutting machine 2, and the two are cut into long and narrow tire strips with a width of about 5cm. After the strips pass through the dicing machine 3, they are further cut into tire fragments with a size of about 5cm×5cm. Then the tire fragments are transported to the feeding system on the top of the gasifier 5 by the feeding belt conveyor 4 . At this time, the feed piston 110 is located at the initial position on the left end of the outer electric flapper valve 111, the outer electric flapper valve 111 and the inner electric flapper valve 112 are in the closed state, and the upper electric flapper valv...

Embodiment 2

[0065] Taking a process system with a waste tire processing capacity of 100kg / hour as an example, the size of the gasifier 5 is the same as that of Embodiment 1, with an inner diameter of 0.5m and a height of 3.8m (from the furnace top to the lower electric sealing valve 120). Adjust the opening of the gasification agent inlet regulating valve 16, and control the gasification agent (air) flow rate to 250Nm 3 / h, the cross-sectional flow velocity of the gasification agent at the bottom of the gasifier 5 is about 0.4m / s. The feeding and discharging process of the gasifier 5 is the same as that of Embodiment 1, and will not be repeated here. The high-temperature slag after the gasification reaction is cooled to about 45° C. in the slag cooler 17 .

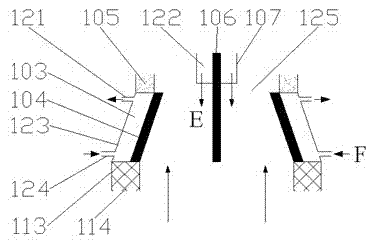

[0066] The angle between the electrode anode 104 of the top arc type tar breaker in the gasification furnace 5 and the horizontal plane is maintained at 50°, the cross-sectional size is 14cm×14cm, and the total area of the four ano...

Embodiment 3

[0069] Taking a process system with a waste tire processing capacity of 100 kg / hour as an example, the size of the gasifier 5 and the feeding and discharging process are the same as those in Embodiment 1. Control gasification agent (air) flow to 250Nm 3 / h, the gas pressure on the upper part of the gasifier 5 is maintained at about -150Pa.

[0070] The angle between the electrode anode 104 of the top arc type tar breaker in the gasification furnace 5 and the horizontal plane is maintained at 50°, the cross-sectional size is 6cm×14cm, and the total area of the four anode plates accounts for the area of the circumference of the inner wall of the furnace where they are located (the same height Below) 15%, electrode cathode length 20cm. The linear high-voltage DC power supply adopts a supply voltage of 800V and a supply current of 4.5A. The air flow velocity in the cooling channel 103 of the arc tar breaker is about 6m / s, the flow velocity of the combustible gas in the catho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com