Spindle motor

A technology of lead screw motor and lead screw, which is applied in the direction of electromechanical devices, electrical components, mechanical equipment, etc., can solve the problems of short service life and achieve the effect of saving costs and parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The present invention is now described in detail with the aid of the accompanying drawings:

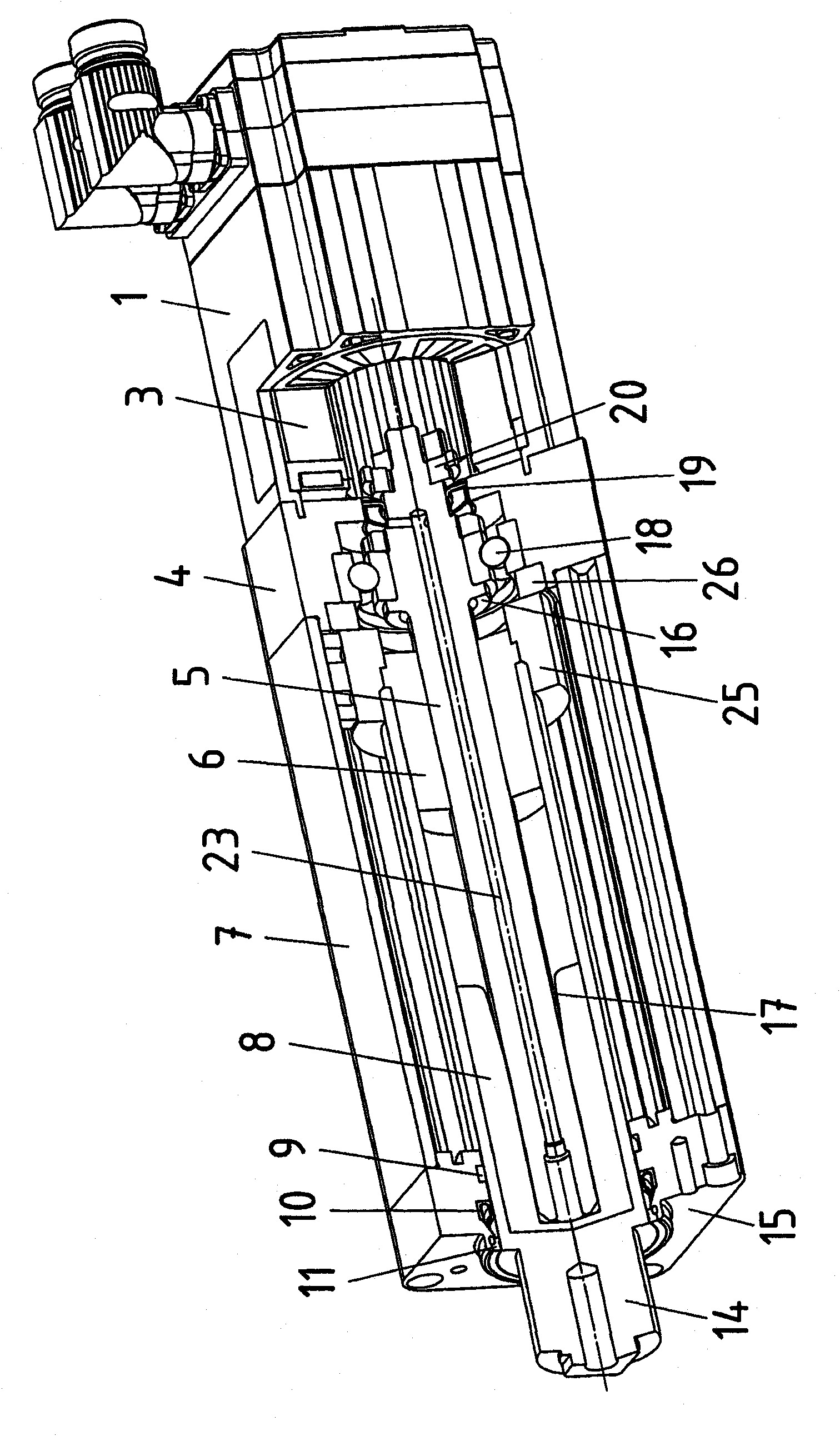

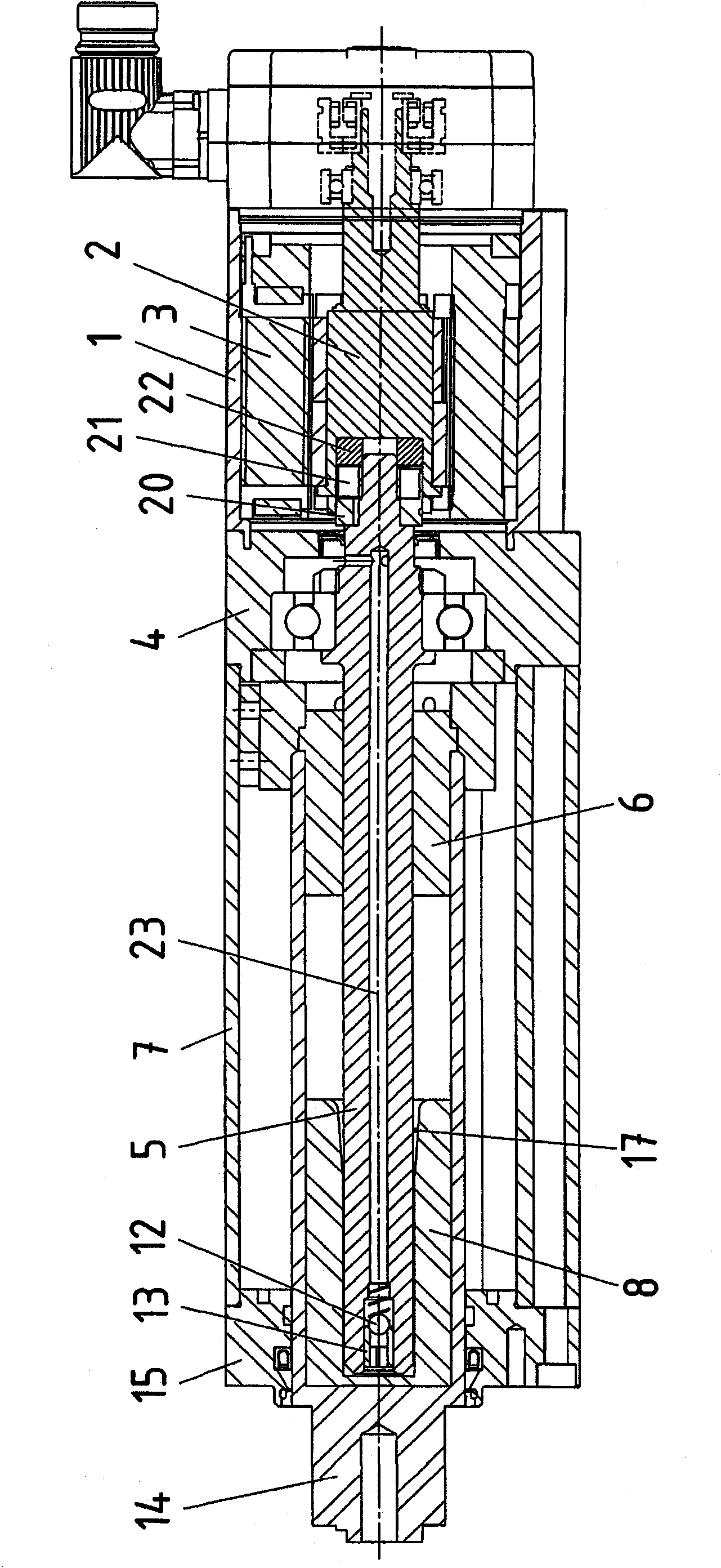

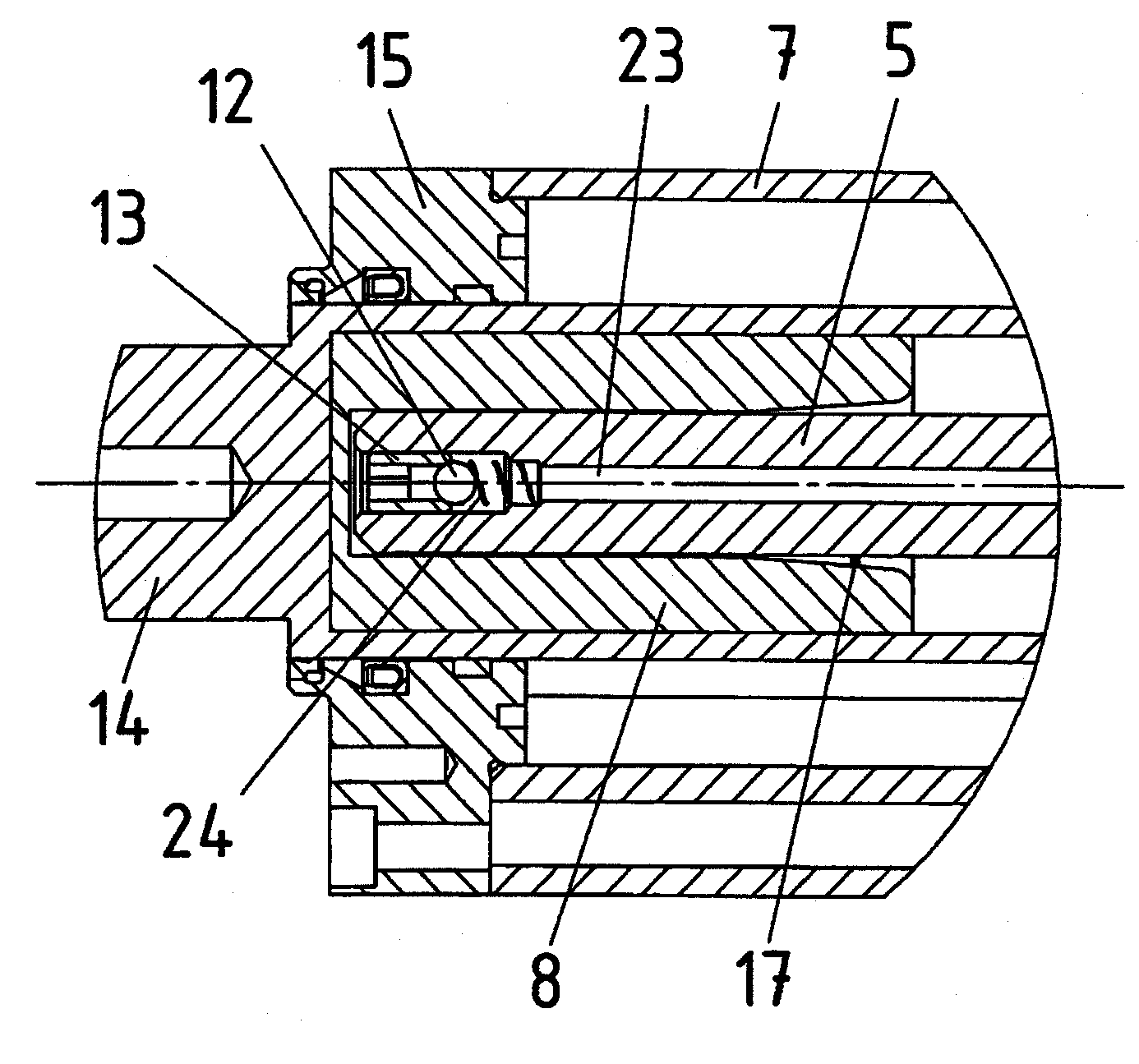

[0075] exist figure 1 The lead screw motor of the present invention is shown in a cut oblique view, in Figure 1a The lead screw motor of the present invention is shown in cross-sectional view. exist figure 2 with image 3 are enlarged and shown in Figure 1a Partial view of the lead screw motor in .

[0076] The housing parts 4 , 7 and 15 of the spindle motor are connected sealingly to the motor housing 1 of the motor comprising the rotor 2 and the stator 3 . An O-ring is preferably inserted at each connection point of the housing parts in order to ensure tightness even at overpressures of greater than, for example, 2 bar.

[0077] Housing part 4 accommodates a bearing 18 via which spindle 5 is supported. The lead screw is connected to the rotor shaft 2 via an axially pluggable coupling. The coupling has a claw 20 and a claw 22 between which a plastic star 21 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com