MacPherson air suspension and assembly method thereof

A technology of air suspension and air spring, which is applied in the direction of suspension, elastic suspension, transportation and packaging, etc., to achieve the effects of reducing noise, saving costs and improving the life of shock absorbers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

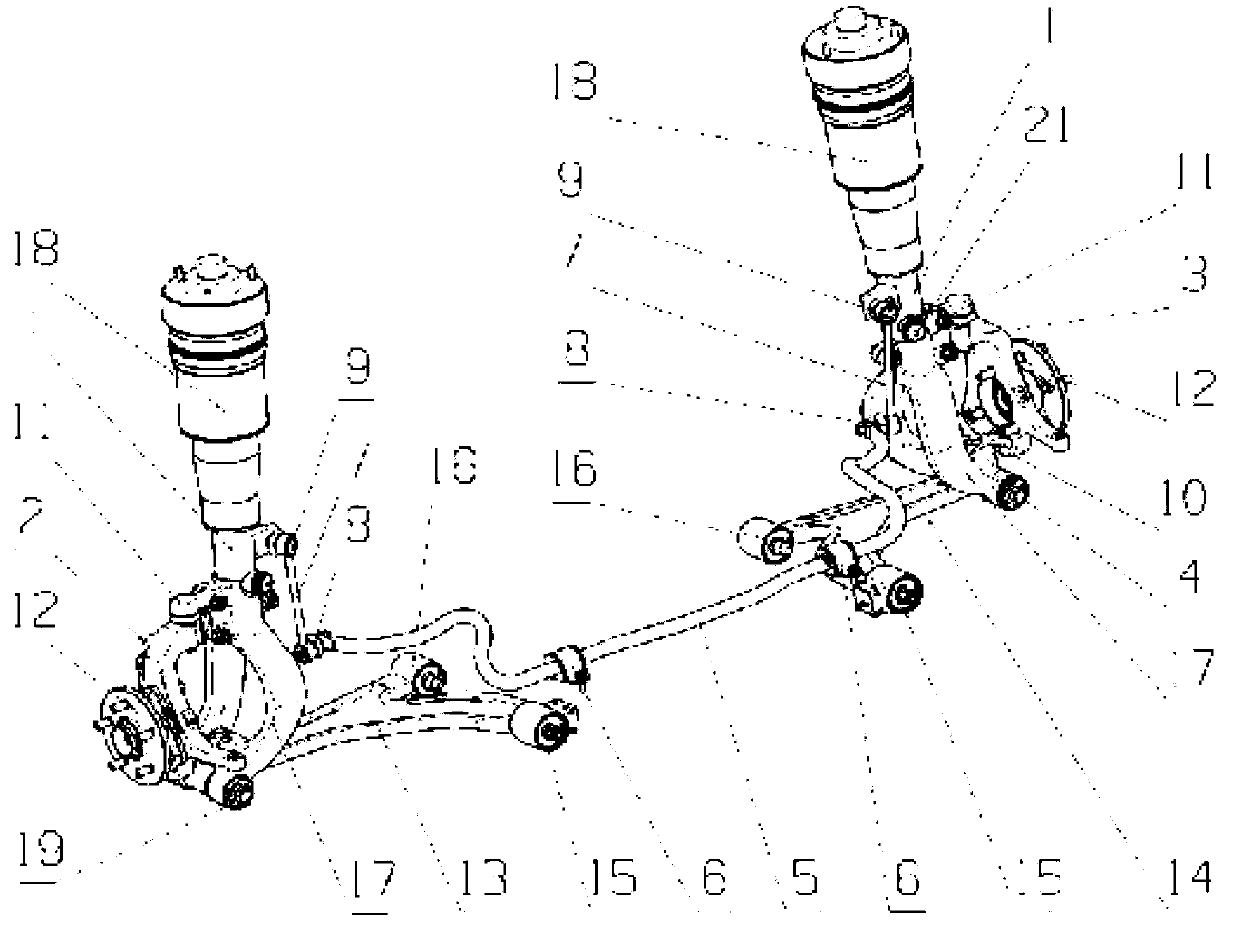

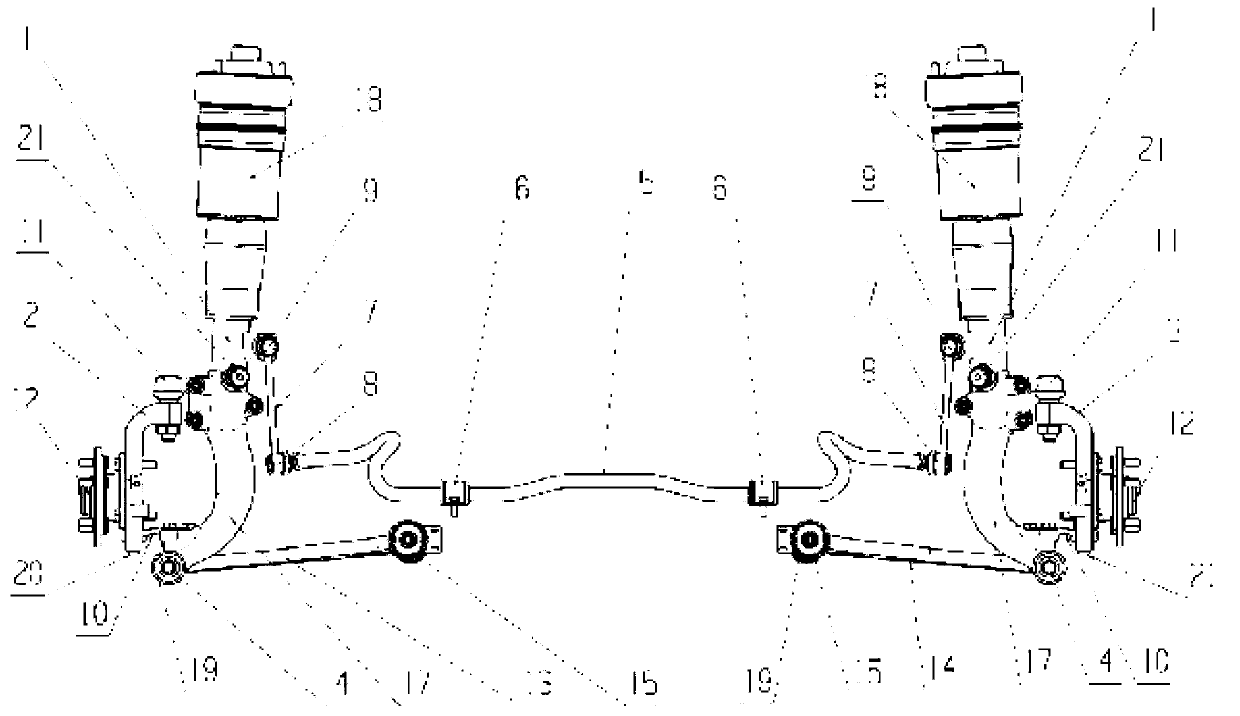

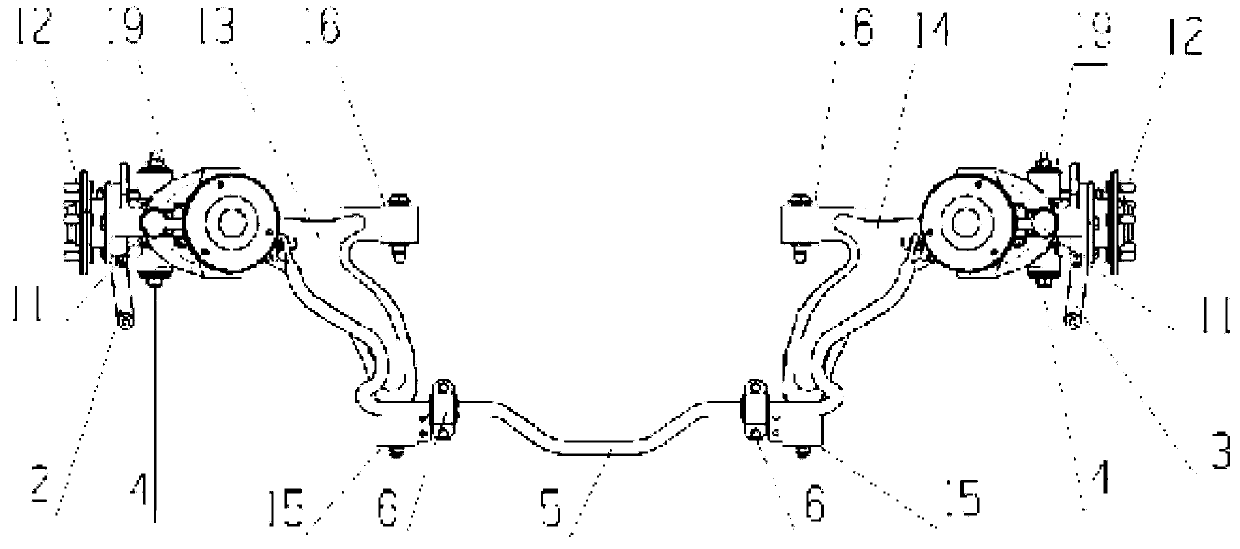

[0046] A MacPherson air suspension such as Figure 1 to Figure 5As shown, the MacPherson air suspension includes a stabilizer bar 5, two strut assemblies positioned at the left and right sides of the stabilizer bar 5, left and right steering knuckles 2,3, left and right lower swing arms 13,14 and The left and right stabilizer bar connecting push rods 7 that connect the stabilizer bar 5 to the pillar assembly; since the structure is left-right symmetrical, the following uses one side as an example to illustrate the specific structure and connection relationship, and generally no longer indicate left or right;

[0047] The strut assembly includes the front shock absorber 1 and the air spring assembly 18 integrated on the front shock absorber 1; the front shock absorber 1 and the front shock absorber lower bracket 17 are tightened by bolts;

[0048] The upper ends of the steering knuckles are respectively connected to the upper part of the lower bracket 17 of the front shock abso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com